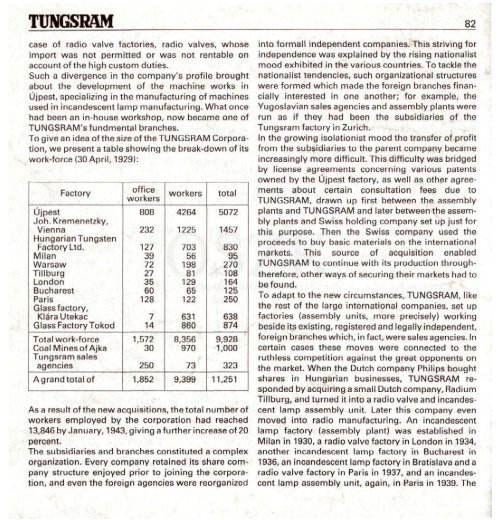

<strong>TUNGSRAM</strong> 82case of radio valve factories, radio valves, whoseimport was not permitted or was not rentable onaccount of the high custom duties.Such a divergence in the company's profile broughtabout the development of the machine works inUjpest, specializing in the manufacturing of machinesused in incandescent lamp manufacturing. What oncehad been an in-house workshop, now became one of<strong>TUNGSRAM</strong>'S fundmental branches.To give an idea of the size of the <strong>TUNGSRAM</strong> Corporation,we present a table showing the break-down of itswork-force (30 April, 1929):FactoryUjpestJoh. Kremenetzky,ViennaHungarian TungstenFactory Ltd.MilanWarsawTillburgLondonBucharestParisGlass factory,KlaraUtekacGlass Factory TokodTotal work-forceCoal Mines of AjkaTungsram salesagenciesA grand total ofofficeworkers80823212739722735601287141,572302501,852workers426412257035619881129651226318608,356970739,399total50721457830952701081641252506388749,9281,00032311,251Asa result of the new acquisitions, the total number ofworkers employed by the corporation had reached13,846 by January, 1943, giving a further increase of 20percent.The subsidiaries and branches constituted a complexorganization. Every company retained its share companystructure enjoyed prior to joining the corporation,and even the foreign agencies were reorganizedinto formall independent companies. This striving forindependence was explained by the rising nationalistmood exhibited in the various countries. To tackle thenationalist tendencies, such organizational structureswere formed which made the foreign branches financiallyinterested in one another; for example, theYugoslavian sales agencies and assembly plants wererun as if they had been the subsidiaries of theTungsram factory in Zurich. j wIn the growing isolationist mood the transfer of profitfrom the subsidiaries to the parent company becameincreasingly more difficult. This difficulty was bridgedby license agreements concerning various patentsowned by the Ujpest factory, as well as other agreementsabout certain consultation fees due to<strong>TUNGSRAM</strong>, drawn up first between the assemblyplants and <strong>TUNGSRAM</strong> and later between the assemblyplants and Swiss holding company set up just forthis purpose. Then the Swiss company used theproceeds to buy basic materials on the internationalmarkets. This source of acquisition enabled<strong>TUNGSRAM</strong> to continue with its production throughtherefore,other ways of securing their markets had tobe found.To adapt to the new circumstances, <strong>TUNGSRAM</strong>, likethe rest of the large international companies, set upfactories (assembly units, more precisely) workingbeside its existing, registered and legally independent,foreign branches which, in fact, were sales agencies, incertain cases these moves were connected to theruthless competition against the great opponents onthe market. When the Dutch company Philips boughtshares in Hungarian businesses, <strong>TUNGSRAM</strong> respondedby acquiring a small Dutch company. RadiumTillburg, and turned it into a radio valve and incandescentlamp assembly unit. Later this company evenmoved into radio manufacturing. An incandescentlamp factory (assembly plant) was established inMilan in 1930, a radio valve factory in London in 1934,another incandescent lamp factory in Bucharest in1936, an incandescent lamp factory in Bratislava and aradio valve factory in Paris in 1937, and an incandescentlamp assembly unit, again, in Paris in 1939. The

83 <strong>TUNGSRAM</strong>Warsaw branch added the assembling of radio valvesto its list of products in 1938; two factories went intothe possession of <strong>TUNGSRAM</strong> in Yugoslavia, in Zagreband Panchova, specializing in the assembly ofincandescent lamps, and then came the setting up ofthe factory in Belgrade. The establishing of assemblyunits were on the cards in Argentina, Switzerland,Sweden, Egypt and Turkey. A large part of the machineryfor the Argentine factory had already beencompleted, when the war came and ruined the plans.The listed factories all had production capacities in theneighbourhood of 2 million incandescent lamps or, inthe case of the radio valve factories, between 300,000and 700,000 tubes.All the foreign branches were fitted with machinerybuilt in Ojpest and — wherever the law of that countrypermitted — were provided with parts and technologyimported from Ojpest, working under the guidance ofthe technical staff, again, delegated from Ojpest. Theirproduction, both in volume and structure, entirelyfollowed the directions issued in Ojpest. Most of thetimes these factories produced normal lamps or, in theout the war. In 1941 <strong>TUNGSRAM</strong>'S Ojpest plant hadenough copper to last three years, its tungsten supplywas enough for five years, nickel and molybdenumenough for two years, tin for four years, etc.The Production and Trade Figures ofthe Company from the First Year of theDepression until the End of World WarTwoThe famous Wall Street Crash broke out in New Yorkon 24 October, 1929. It marked the beginning of aworldwide economic depression. The crisis did notacknowledge geographical barriers or national borders:it soon spread to Europe. As a result of theDepression, masses of goods became unmarketable,prices rapidly fell, industrial production took a nosedive and mass-unemployment followed. The Depressionwas very acutely felt in Hungary, too. The situationwas especially bad in the agriculture and theindustry, first of all in the heavy industry, whereproduction fell by more than half. Atthesametime,thefood industry and some other companies, mostlyproducing consumer's goods, were slightly less hurtby the Depression.<strong>TUNGSRAM</strong> also belonged to those companies whichproduced consumer's goods and, therefore, were lesssusceptible to the effects of the Depression of 1929—1933. The opening phrases of the report prepared foraboard meeting assessing the company's performancein the fiscal year of 1930—1931 described the company'sgrave situation throughout these difficultyears: "The economic crisis has been felt in almostevery country, where we are present on the marketwith our products, unfavourably affecting our trade.We have been only able to achieve sales figuresapproaching last year's performance, because wecould further develop some of our recently introducedbusiness projects."The second sentence in this report refers to the factthat, while the volume of production significantly fellin the incandescent lamps business, the production ofradio valves rose.Year192919301931193219331934incandescent lampsproduction in pieces22,157,00023,429,00012,970,00010,194,00011,084,00015,670,000radio valves642,0001,123,0001,936,0001,834,0001,611,0002,345,000It is evident from the table that the two charts showquite a different story. While incandescent lamp productionfell by 60 percent in 1932, as compared to therecord figures of 1930, the volume of radio valveproduction grew year after year until 1931 — it trebledin two years! — and, following a two-year long slightsetback, rose to a new record in 1934, crossing thetwo-million valve barrier. . .,

- Page 3:

X'H-^v•c•-,-x.>W.,r•»••.

- Page 6 and 7:

. * • . • • * - "BASED ON THE

- Page 8 and 9:

• . ; . ^ •>(•'' % •^ i-^J-

- Page 10 and 11:

TUNGSRAMin Budapest, producing elec

- Page 12 and 13:

TUNGSRAM•.V8reduction in the prod

- Page 14 and 15:

TUNGSRAM 10Erno Egger, David Egger

- Page 16 and 17:

TUNGSRAM•>,^12marketing staff mal

- Page 18 and 19:

TUNGSRAM 14the board of directors d

- Page 20 and 21:

TUNGSRAM:k-^16director from 1 July,

- Page 22 and 23:

TUNGSRAM 18competitive. The patents

- Page 24 and 25:

TUNGSRAM.4-. »fe-"201905. The tech

- Page 26 and 27:

TUNGSRAM•>-^:.V22-the production

- Page 28 and 29:

TUNGSRAM.^.•:-i-'24TUNGSRAM throu

- Page 30 and 31:

TUNGSRAM• > . ^26The incandescent

- Page 32 and 33:

TUNGSRAM..^.'i^28investments, the c

- Page 34 and 35:

TUNGSRAM 30"^X\ * l .-«l*^" VDesk

- Page 36 and 37: TUNGSRAM 32marketing of light bulbs

- Page 38 and 39: TUNGSRAM 34signed high priority to

- Page 40 and 41: TUNGSRAM 36>'riTUNGSRAM tool shop i

- Page 42 and 43: TUNGSRAM 38Balazs, the head of the

- Page 44 and 45: TUNGSRAM 40merits guaranteed that o

- Page 46 and 47: TUNGSRAM*..V42The staff of TUNGSRAM

- Page 48 and 49: TUNGSRAM• \ ^ .44The acquisition

- Page 50 and 51: TUNGSRAM^•rV46The necessary, quit

- Page 52 and 53: TUNGSRAM• > . ^48cartel made a bi

- Page 54 and 55: TUNGSRAM 50was aimed at two major o

- Page 56 and 57: TUNGSRAM-.i-'.V'52Radio valve produ

- Page 58 and 59: TUNGSRAM 54major areas. One was imp

- Page 60 and 61: TUNGSRAM->.'.V56the volume of produ

- Page 62 and 63: TUNGSRAM 58(i)(ii)(iii)(iv)the plan

- Page 64 and 65: TUNGSRAM 60pressure mercury vapour

- Page 66 and 67: TUNGSRAM.-•:-V62caused important

- Page 68 and 69: TUNGSRAM 64Next Brody went back to

- Page 70 and 71: TUNGSRAM 66prospects of krypton pro

- Page 72 and 73: TUNGSRAM- . * • • ' ^ - ^68cons

- Page 74 and 75: TUNGSRAM•>.>-;70chner's invitatio

- Page 76 and 77: TUNGSRAM\*-'!\?'72It had already be

- Page 78 and 79: TUNGSRAM•.*-VV'74patents in the e

- Page 80 and 81: TUNGSRAM 76new designs developed by

- Page 82 and 83: TUNGSRAM-.^.•.v=78more than one o

- Page 84 and 85: TUNGSRAM 80Ujantalvolgy (Utekac), a

- Page 88 and 89: TUNGSRAM 84Behind the drastic drop

- Page 90 and 91: TUNGSRAM• > . ^86In 1937, for the

- Page 92 and 93: TUNGSRAM-.^••V88export which ch

- Page 94 and 95: TUNGSRAM 90prominent place among th

- Page 96 and 97: TUNGSRAM 92looking after the affair

- Page 98 and 99: TUNGSRAM 94Ojpest plant, and, there

- Page 100 and 101: TUNGSRAM 96FemaleworkersTheworker's

- Page 102 and 103: TUNGSRAM 98The surveyance and the d

- Page 104 and 105: TUNGSRAM 100The management of TUNGS

- Page 106 and 107: TUNGSRAM 10232) OL Z 40-462: report

- Page 108 and 109: - ^ • . . .TUNGSRAM 104meeting on

- Page 110 and 111: TUNGSRAM 106173) OL Z 600-1: contra

- Page 112 and 113: •..V

- Page 114 and 115: , % • • • • *5>^•>c'y>"^-

- Page 116 and 117: TUNGSRAM 112V,>•>Carbon filaments

- Page 118 and 119: TUNGSRAM 114r « 9 t * r V n g a r

- Page 120 and 121: TUNGSRAM 116OrimAmm

- Page 122 and 123: TUNGSRAM 118'^uraaOit vtllanjroaMkc

- Page 124 and 125: TUNGSRAM 120W^ - g ^^ ^ 4 ^ .^^^^^^

- Page 126 and 127: TUNGSIVIM 122This group photography

- Page 128 and 129: TUNGSRAM 124%*. ^ . ''^yv^w^ ^y^

- Page 130 and 131: TUNGSRAM 126This old Russian TUNGSR

- Page 132 and 133: TUNGSRAM 128ti.-'J-VC.-url t-l*Xr :

- Page 134 and 135: TUNGSRAM 130IZZOLAMPAOSZTALV.a^oL*^

- Page 136 and 137:

TUNGSRAM 132to V L r. I. MG LU H LA

- Page 138 and 139:

TUNGSRAM 1349V,T^Jil Vl*. SB Knrni<

- Page 140 and 141:

TUNGSRAM 136(irMWimtAilKr KM MDurii

- Page 142 and 143:

TUNGSRAM 138• > ., ^ - y •Jlr.

- Page 144 and 145:

TUNGSRAM 140M«nU«*>«*>>t ilHKft.

- Page 146 and 147:

TUNGSRAM 142> •-•, i^ J- -'\.'

- Page 148 and 149:

TUNGSRAM 144The clothing of these w

- Page 150 and 151:

TUNGSRAM 146The bases of the lamps

- Page 152 and 153:

TUNGSRAM 148ARJEGYZEK"mwxvoriMTll.h

- Page 154 and 155:

TUNGSRAM 150TUNGSRAM SPIRAL DRAHTLA

- Page 156 and 157:

TUNGSRAM 152TUNGSRAMTASCHENLAMPEN>

- Page 158 and 159:

TUNGSRAM 154NORMAL LAMPAK HIBA»yzW

- Page 160 and 161:

TUNGSRAM 156KGYKSOLT YILLAMOSSAGI R

- Page 162 and 163:

TUNGSRAM 158iHTf: JTletailumMEttaui

- Page 164 and 165:

TUNGSRAM 160X. MolyaM. BucUpnl, 191

- Page 166 and 167:

s;'TUNGSRAM 162MTonpsrar Wolframlii

- Page 168 and 169:

TUNGSRAM 164• \This photograph sh

- Page 170 and 171:

TUNGSRAM 166XIn the 1920s, when thi

- Page 172 and 173:

TUNGSRAM 168villamvila^iiasi t,•^

- Page 174 and 175:

TUNGSRAM 170The lathe workshop of t

- Page 176 and 177:

TUNGSRAM 172'^The Jozsef Telephone

- Page 178 and 179:

TUNGSRAM 174A f) I ii (1 \ •ilfru

- Page 180 and 181:

TUNGSRAM 1767 » rA."..'!*!* ' In l

- Page 182 and 183:

TUNGSRAM 178The assembling of stems

- Page 184 and 185:

TUNGSRAM 180"N-^Lamp production usi

- Page 186 and 187:

TUNGSRAM 182•\..The workshop prod

- Page 188 and 189:

TUNGSRAM 184: ^ ^Iv•V .' V': •K

- Page 190 and 191:

TUNGSRAM 186TUNGSRAM TiDUnASPIKAtli

- Page 192 and 193:

TIINGSRAM 188Figure 8: Gas-filled G

- Page 194 and 195:

TUNGSRAM 19032. ibniniWSRAM3X Abn 3

- Page 196 and 197:

TUNGSRAM 192A21& «z.30 IMB. ilmird

- Page 198 and 199:

iTUNGSRAM 194This is what was left

- Page 200 and 201:

TUNGSRAM 196This compound steam eng

- Page 202 and 203:

TUNGSRAM 198^-2?s.-J rslanlcn-B." t

- Page 204 and 205:

TUNGSRAM 200Two eminents persons fr

- Page 206 and 207:

TUNGSRAM 202• ^llpesl/no^yolVDUPO

- Page 208 and 209:

TUNGSRAM 204Trained labourers work

- Page 210 and 211:

TUNGSRAM 206TUNG 5^^^RAD/o.^^^ RENT

- Page 212 and 213:

TUNGSRAM 208The first design of the

- Page 214 and 215:

TUNGSRAM 210The title page of TUNGS

- Page 216 and 217:

TUNGSRAM 212The basing of incandesc

- Page 218 and 219:

TUNGSRAM 214'VThe TUNGSRAM sales of

- Page 220 and 221:

TUNGSRAM 216¥»>•—isa»SZCIV^N

- Page 222 and 223:

TUNGSRAM 218The central executive a

- Page 224 and 225:

TUNGSRAM 220In cold winters the ten

- Page 226 and 227:

TUNGSRAM 222Originally, this buildi

- Page 228 and 229:

TUNGSRAM 224A vullalatra voiialUo/.

- Page 230 and 231:

TUNGSRAM 226.mm--aV1) f^^^^^^^^^^^^

- Page 232 and 233:

TUNGSRAM 228•\"V\These were the p

- Page 234 and 235:

TUNGSRAM 230The tools used in drawi

- Page 236 and 237:

TUNGSRAMV232"••"•'•••'

- Page 238 and 239:

TUNGSRAM 234m-am«•i?iiiU-« l»t

- Page 240 and 241:

TUNGSRAM 236TUNGSRAM launched an in

- Page 242 and 243:

TUNGSRAM 238V'x""^.^'V -^egy a sok-

- Page 244 and 245:

TUNGSRAM~^-.240k Krypton rvndkiviil

- Page 246 and 247:

TUNGSRAM 242n==r^ /Ay^d^^"*• v.-^

- Page 248 and 249:

TUNGSRAM 244I«JI:«M:7J::.l'lBd.'l

- Page 250 and 251:

TUNGSRAM 246*' " ^ • * \The techn

- Page 252 and 253:

TUNGSRAM 248^^^GSR^>^^^''^^-Cs6vt^t

- Page 254 and 255:

TUNGSRAM 250The combined valve prod

- Page 256 and 257:

TUNGSRAM 252brtfi¥ 6 t (, ».likba

- Page 258 and 259:

TUNGSRAM 254mt6'3 Vollos univerzali

- Page 260 and 261:

TUNGSRAM 256This picture shows the

- Page 262 and 263:

TUNGSRAM 258:«l.XQb. 194o. dAoanbe

- Page 264 and 265:

TUNGSRAM 260-VA disciplined work-fo

- Page 266 and 267:

TUNGSRAM 262The furnaces and the gl

- Page 268 and 269:

TUNGSRAM 264• \When the block was

- Page 270 and 271:

TUNGSRAM 266And finally, another ty

- Page 272 and 273:

./ .TUNGSRAM 268••\.The develop

- Page 274 and 275:

TUNGSRAM-

- Page 276 and 277:

TUNGSRAM 272M E G H I V 6A Tungirom

- Page 278 and 279:

TUNGSRAM 274Ai UjpestI Toms Egylet

- Page 280 and 281:

TUNGSRAM 276•V.•>5This was the

- Page 282 and 283:

TUNGSRAM 278'•v--''?»^^:>:s,.»>

- Page 284 and 285:

TUNGSRAM^r^280?!The working class m

- Page 286 and 287:

TUNGSRAM 282IN MKMORIAM.A hiibon'i

- Page 289 and 290:

- ^ • • * ^ ^ ^

- Page 291 and 292:

\-.,'>•-'Vf

![Letöltés egy fájlban [4.3 MB - PDF]](https://img.yumpu.com/50159926/1/180x260/letaltacs-egy-fajlban-43-mb-pdf.jpg?quality=85)