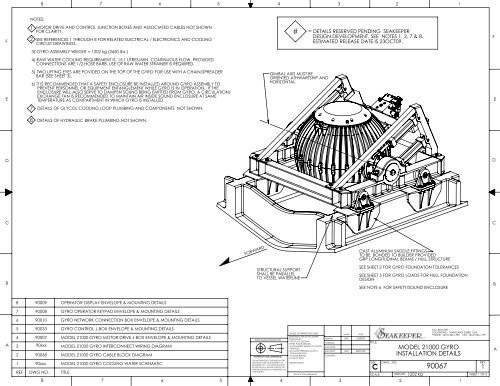

90067-1 Seakeeper Model 21000 Gyro Installation Details

90067-1 Seakeeper Model 21000 Gyro Installation Details

90067-1 Seakeeper Model 21000 Gyro Installation Details

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

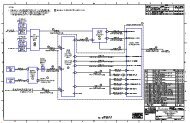

8 7 6 5 4 3 2 1NOTES:F12MOTOR DRIVE AND CONTROL JUNCTION BOXES AND ASSOCIATED CABLES NOT SHOWNFOR CLARITY.SEE REFERENCES 1 THROUGH 8 FOR RELATED ELECTRICAL / ELECTRONICS AND COOLINGCIRCUIT DRAWINGS.# = DETAILS RESERVED PENDING SEAKEEPERDESIGN DEVELOPMENT. SEE NOTES 1, 2, 7 & 8.ESTIMATED RELEASE DATE IS 23OCT09.F3) GYRO ASSEMBLY WEIGHT = 1202 kg (2650 lbs.)4) RAW WATER COOLING REQUIREMENT IS 15.1 LITRES/MIN. CONTINUOUS FLOW. PROVIDEDCONNECTIONS ARE 1/2 HOSE BARB. USE OF RAW WATER STRAINER IS REQUIRED.E5) TWO LIFTING EYES ARE POVIDED ON THE TOP OF THE GYRO FOR USE WITH A CHAIN/SPREADERBAR (SEE SHEET 3).6) IT IS RECOMMENDED THAT A SAFETY ENCLOSURE BE INSTALLED AROUND GYRO ASSEMBLY TOPREVENT PERSONNEL OR EQUIPMENT ENTANGLEMENT WHILE GYRO IS IN OPERATION. IF THEENCLOSURE WILL ALSO SERVE TO DAMPEN SOUND BEING EMITTED FROM GYRO, A CIRCULATION/EXCHANGE FAN IS RECOMMENDED TO MAINTAIN AIR INSIDE SOUND ENCLOSURE AT SAMETEMPERATURE AS COMPARTMENT IN WHICH GYRO IS INSTALLED.GIMBAL AXIS MUST BEORIENTED ATHWARTSHIP ANDHORIZONTALE7DETAILS OF GLYCOL COOLING LOOP PLUMBING AND COMPONENTS NOT SHOWN.8DETAILS OF HYDRAULIC BRAKE PLUMBING NOT SHOWN.DDCCFORWARDCAST ALUMINUM SADDLE FITTINGSTO BE BONDED TO BUILDER PROVIDEDGRP LONGITUDINAL BEAMS / HULL STRUCTUREBSTRUCTURAL SUPPORTSHALL BE PARALLELTO VESSEL WATERLINESEE SHEET 2 FOR GYRO FOUNDATON TOLERANCESSEE SHEET 5 FOR GYRO LOADS FOR HULL FOUNDATIONDESIGNSEE NOTE 6 FOR SAFETY/SOUND ENCLOSUREB87690009 OPERATOR DISPLAY ENVELOPE & MOUNTING DETAILS90008 GYRO OPERATOR KEYPAD ENVELOPE & MOUNTING DETAILS90010 GYRO NETWORK CONNECTION BOX ENVELOPE & MOUNTING DETAILSA5 90033 GYRO CONTROL J-BOX ENVELOPE & MOUNTING DETAILS4 90007 MODEL <strong>21000</strong> GYRO MOTOR DRIVE J-BOX ENVELOPE & MOUNTING DETAILS3 90xxx MODEL <strong>21000</strong> GYRO INTERCONNECT WIRING DIAGRAM2 90068 MODEL <strong>21000</strong> GYRO CABLE BLOCK DIAGRAM1 90xxx MODEL <strong>21000</strong> GYRO COOLING WATER SCHEMATICREF DWG NO. TITLE8765THIRD ANGLE PROJECTIONPROPRIETARY AND CONFIDENTIALTHE INFORMATION CONTAINED IN THISDRAWING IS THE SOLE PROPERTY OFSEAKEEPER, INC. ANY REPRODUCTIONIN PART OR AS A WHOLE WITHOUT THEWRITTEN PERMISSION OF SEAKEEPER, INC.IS PROHIBITED.4UNLESS OTHERWISE SPECIFIED:DIMENSIONS ARE IN MILLIMETERSTOLERANCES:-TWO PLACE DECIMAL-THREE PLACE DECIMAL-ALL DIAMETERS RUNOUT TO DATUMSURFACES-ALL FACES PERPENDICULAR TODATUM SURFACES-ALL EDGE BREAKS-ALL FILLET RADII-SURFACE FINISHDO NOT SCALE DRAWINGDRAWNCHECKEDQLTY APPR.ENG APPR.COMMENTS:3NAMEBHSJDADATE25SEP0902OCT09TITLE:SIZECSCALE:DWG. NO.MODEL <strong>21000</strong> GYROINSTALLATION DETAILSWEIGHT:21202 kgP.O. BOX 999SOLOMONS, MARYLAND 20688, USAPHONE: (410) 326-1590 FAX: (410) 326-1199<strong>90067</strong>1REV1SHEET 1 OF 5A

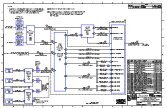

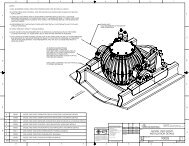

8 7 6 5 4 3 2 11.0025FFLIFTING POINTS(2)E22.50572EAPPROX.C.G.LOCATION7DRAW WATER COOLINGINLET/OUTLETCONNECTIONS1/2 INCH HOSE BARBDCHEAT EXCHANGER[22.5]572LIFT VERTICALLY USINGSPREADER BAR ORSIMILAR ARRANGEMENTCB1.0025.40BBOTTOM VIEWAAPPROX.C.G. LOCATION.7519ASIZECDWG. NO.<strong>90067</strong>REV1876543SCALE: 1:10WEIGHT:21SHEET 3

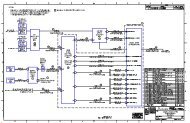

8 7 6 5 4 3 2 1FFEEDD60°60°CCFLYWHEELSPIN AXISFLWHEELSPIN AXISBBAGYRO SHOWN PRECESSEDTO NEGATIVE LIMIT (- 60 )GYRO SHOWN PRECESSEDTO POSITIVE LIMIT (+ 60 )ASIZECDWG. NO.<strong>90067</strong>REV1876543SCALE: 1:10WEIGHT:21SHEET 4

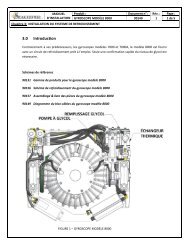

8 7 6 5 4 3 2 1FEGYRO LOADS FOR STRUCTURAL DESIGN:The <strong>Gyro</strong> is mounted in a foundation frame which is bolted to four aluminumsaddle fittings made of A356-T6 cast aluminum. The gyro frame incorporatessemi-elastic anti-vibration mounts whose intent is to damp vibrations from beingtransmitted into the hull structure. The saddles are designed to be permanentlyattached to longitudinal GRP hull beams with a structural adhesive. This mountingarrangement distributes the cyclic, fully reversing forces and moments generatedby the <strong>Gyro</strong> over a large surface area. The unit is not designed to be bolted to thehull structure and this method of attachment should never be attempted withoutconsultation with <strong>Seakeeper</strong>.The <strong>Gyro</strong> generates pitch moments, roll moments, yaw moments and verticaland horizontal forces - the magnitude of which is controlled by the <strong>Gyro</strong>’s activebrake system. These <strong>Gyro</strong> generated forces and moments result in loads beingapplied at the four points, 105mm (4.13 in.) above the saddle fittings as shownin the figure to the right.[30.00]762+Fz+Fx+Fy+Fz+Fx-Fz+FyTHIS PIN IS INSIDE THE GYROFOUNDATION FRAME ANDIS PART OF THE SEMI-ELASTICMOUNT[46.00]1168-FzFEThe reference point is the center of the pin in each of the anti-vibration mounts.The resultant forces at these points are illustrated on the adjacent figure andvalues to be used for foundation design are summarized below:-Fx+Fy+FyVertical Force (Fz) = 27.94 kN [6285 Lb]Longitudinal Force(Fx) = 9.81 kN [2205 Lb]Lateral Force (Fy) = 6.71 kN [1509 Lb]-FxDCThese forces should be considered to be:· Acting simultaneously· Fully reversing (i.e., acting in either direction)· Repeated an infinite number of timesThe boat builder or the gyro installer is responsible for designing the hull foundationto which the gyro is attached to accommodate the above forces and momentsplus a reasonable Factory of Safety. A Factor of Safety of 3.0 (Margin of Safety of 2) issuggested.The boat builder or gyro installer is also fully responsible for selecting the structuraladhesive to secure the aluminum saddle beams to the GRP hull beams. <strong>Seakeeper</strong>recommends that the builder or installer use a structural adhesive with a minimumshear strength of 13.8 MPa (2000 psi) . Additionally, it is strongly suggested that thebuilder or installer test the compatibility of the selected structural adhesive withcast A356 T6 aluminum and planned hull materials by performing mechanicalproperty tests.FWDBUILDER INSTALLS 4 SADDLES USING A FIXTURESUPPLIED BY SEAKEEPER TO MAINTAIN ALIGNMENTBETWEEN THE SADDLES DURING THE BONDING PROCEDURE.THE GYRO FOUNDATION FRAME IS THEN FASTENED TOSADDLES USING 8X M16 FASTERS PER SADDLE.SEE FIGURE BELOWFOR DIMENSIONS OF EACHMOUNTDC16.004069.752484.131054.88124BB8.00203.50R12.705.00127ASADDLE MOUNT DIMENSIONAL DETAILSASIZECDWG. NO.<strong>90067</strong>REV1876543SCALE: 1:10WEIGHT:21SHEET 5