Great Products - Balmar

Great Products - Balmar

Great Products - Balmar

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

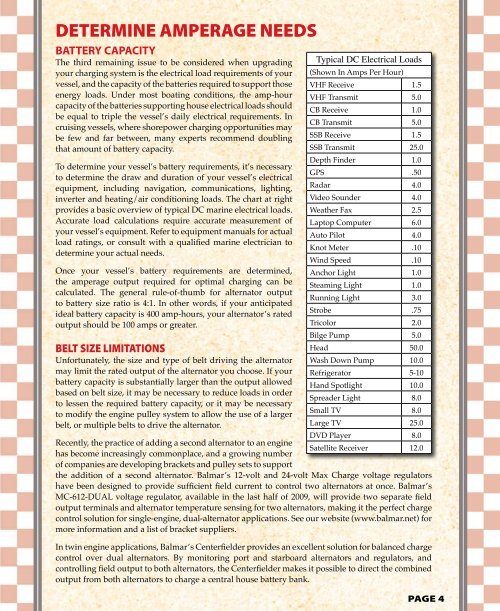

DETERMINE AMPERAGE NEEDSBATTERY CAPACITYThe third remaining issue to be considered when upgradingyour charging system is the electrical load requirements of yourvessel, and the capacity of the batteries required to support thoseenergy loads. Under most boating conditions, the amp-hourcapacity of the batteries supporting house electrical loads shouldbe equal to triple the vessel’s daily electrical requirements. Incruising vessels, where shorepower charging opportunities maybe few and far between, many experts recommend doublingthat amount of battery capacity.To determine your vessel’s battery requirements, it’s necessaryto determine the draw and duration of your vessel’s electricalequipment, including navigation, communications, lighting,inverter and heating/air conditioning loads. The chart at rightprovides a basic overview of typical DC marine electrical loads.Accurate load calculations require accurate measurement ofyour vessel’s equipment. Refer to equipment manuals for actualload ratings, or consult with a qualified marine electrician todetermine your actual needs.Once your vessel’s battery requirements are determined,the amperage output required for optimal charging can becalculated. The general rule-of-thumb for alternator outputto battery size ratio is 4:1. In other words, if your anticipatedideal battery capacity is 400 amp-hours, your alternator’s ratedoutput should be 100 amps or greater.BELT SIZE LIMITATIONSUnfortunately, the size and type of belt driving the alternatormay limit the rated output of the alternator you choose. If yourbattery capacity is substantially larger than the output allowedbased on belt size, it may be necessary to reduce loads in orderto lessen the required battery capacity, or it may be necessaryto modify the engine pulley system to allow the use of a largerbelt, or multiple belts to drive the alternator.Typical DC Electrical Loads(Shown In Amps Per Hour)VHF Receive 1.5VHF Transmit 5.0CB Receive 1.0CB Transmit 5.0SSB Receive 1.5SSB Transmit 25.0Depth Finder 1.0GPS .50Radar 4.0Video Sounder 4.0Weather Fax 2.5Laptop Computer 6.0Auto Pilot 4.0Knot Meter .10Wind Speed .10Anchor Light 1.0Steaming Light 1.0Running Light 3.0Strobe .75Tricolor 2.0Bilge Pump 5.0Head 50.0Wash Down Pump 10.0Refrigerator 5-10Hand Spotlight 10.0Spreader Light 8.0Small TV 8.0Large TV 25.0DVD Player 8.0Recently, the practice of adding a second alternator to an engineSatellite Receiver 12.0has become increasingly commonplace, and a growing numberof companies are developing brackets and pulley sets to supportthe addition of a second alternator. <strong>Balmar</strong>’s 12-volt and 24-volt Max Charge voltage regulatorshave been designed to provide sufficient field current to control two alternators at once. <strong>Balmar</strong>’sMC-612-DUAL voltage regulator, available in the last half of 2009, will provide two separate fieldoutput terminals and alternator temperature sensing for two alternators, making it the perfect chargecontrol solution for single-engine, dual-alternator applications. See our website (www.balmar.net) formore information and a list of bracket suppliers.In twin engine applications, <strong>Balmar</strong>’s Centerfielder provides an excellent solution for balanced chargecontrol over dual alternators. By monitoring port and starboard alternators and regulators, andcontrolling field output to both alternators, the Centerfielder makes it possible to direct the combinedoutput from both alternators to charge a central house battery bank.Page 4