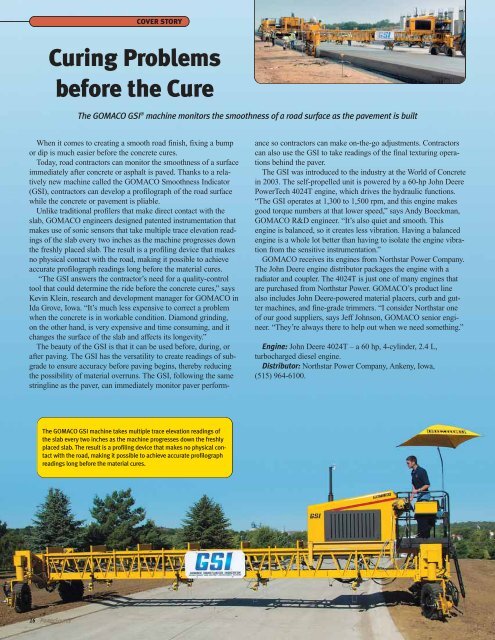

COVER STORYCuring Problemsbefore the CureThe GOMACO GSI ® machine monitors the smoothness of a road surface as the pavement is builtWhen it comes to creating a smooth road finish, fixing a bumpor dip is much easier before the concrete cures.Today, road contractors can monitor the smoothness of a surfaceimmediately after concrete or asphalt is paved. Thanks to a relativelynew machine called the GOMACO Smoothness Indicator(GSI), contractors can develop a profilograph of the road surfacewhile the concrete or pavement is pliable.Unlike traditional profilers that make direct contact with theslab, GOMACO engineers designed patented instrumentation thatmakes use of sonic sensors that take multiple trace elevation readingsof the slab every two inches as the machine progresses downthe freshly placed slab. The result is a profiling device that makesno physical contact with the road, making it possible to achieveaccurate profilograph readings long before the material cures.“The GSI answers the contractor’s need for a quality-controltool that could determine the ride before the concrete cures,” saysKevin Klein, research and development manager for GOMACO inIda Grove, Iowa. “It’s much less expensive to correct a problemwhen the concrete is in workable condition. Diamond grinding,on the other hand, is very expensive and time consuming, and itchanges the surface of the slab and affects its longevity.”The beauty of the GSI is that it can be used before, during, orafter paving. The GSI has the versatility to create readings of subgradeto ensure accuracy before paving begins, thereby reducingthe possibility of material overruns. The GSI, following the samestringline as the paver, can immediately monitor paver perform-ance so contractors can make on-the-go adjustments. Contractorscan also use the GSI to take readings of the final texturing operationsbehind the paver.The GSI was introduced to the industry at the World of Concretein 2003. The self-propelled unit is powered by a 60-hp <strong>John</strong> <strong>Deere</strong>PowerTech 4024T engine, which drives the hydraulic functions.“The GSI operates at 1,300 to 1,500 rpm, and this engine makesgood torque numbers at that lower speed,” says Andy Boeckman,GOMACO R&D engineer. “It’s also quiet and smooth. Thisengine is balanced, so it creates less vibration. Having a balancedengine is a whole lot better than having to isolate the engine vibrationfrom the sensitive instrumentation.”GOMACO receives its engines from Northstar Power Company.The <strong>John</strong> <strong>Deere</strong> engine distributor packages the engine with aradiator and coupler. The 4024T is just one of many engines thatare purchased from Northstar Power. GOMACO’s product linealso includes <strong>John</strong> <strong>Deere</strong>-powered material placers, curb and guttermachines, and fine-grade trimmers. “I consider Northstar oneof our good suppliers, says Jeff <strong>John</strong>son, GOMACO senior engineer.“They’re always there to help out when we need something.”Engine: <strong>John</strong> <strong>Deere</strong> 4024T – a 60 hp, 4-cylinder, 2.4 L,turbocharged diesel engine.Distributor: Northstar Power Company, Ankeny, Iowa,(515) 964-6100.The GOMACO GSI machine takes multiple trace elevation readings ofthe slab every two inches as the machine progresses down the freshlyplaced slab. The result is a profiling device that makes no physical contactwith the road, making it possible to achieve accurate profilographreadings long before the material cures.16 PowerSource

The Perfect MixBremat finds that <strong>John</strong> <strong>Deere</strong> power is just the rightingredient for its automated sand/cement screed carrierRELIABILITY“While the sand/ cement screed carriers are a fixed design,”Alexander continues, “we develop fluid/foam mortar carriers accordingto each individual customer’s requirements. Self-levelling screed isused for foundation floors in various types of buildings, and as ‘shopfloors’ to carry a steel chassis in high-rise structures. Foam mortar alsohas many applications, but is particularly valuable where weight is aconsideration. If the weight calculations for an apartment block areincorrect, it may provide the only option! And it also provides insulation.So you’ll often find it in houses, in crawl spaces, sports floors,and so on. It can even be used as a foundation for asphalt in roadconstruction.”Consistent screed quality and high productivity are just two of thebenefits the sand cement screed carrier offers.When it comes to screed, Bremat Holland BV is an expert. Sinceit was founded in 1963, this Dutch company has built up extensiveknow-how in screed mixing and conveying. In 2000, it applied thisexperience to design one of the first fully automated sand/cementscreed carriers and self-levelling screed carriers. By the end of2005, the company had sold 85 units in its initial target market ofBelgium and The Netherlands and is now set to expand into the restof Europe.Initially, the machines designed in 2000 used two different enginebrands, but problems with both led Bremat to look further for theright power source. Because they had positive experience with<strong>John</strong> <strong>Deere</strong> engines in the generator sets of their foam mortar carriers,they tried out the 5030T <strong>John</strong> <strong>Deere</strong> engine and realized theyhad made the right choice.Floored by Bremat. Bremat’s automated sand/cement screed carrieris designed to take the strain out of mortar mixing, which is a processthat is still largely done manually. Tailored to this application, it makeswork easier and offers advantages such as productivity gains and costreductions.Alexander Tinus, sales engineer, explains: “The sand/ cement screedcarrier is basically a large trailer with compartments for sand andcement, a water tank, fiber and fluid dosing. The operator simply collectsthe cement and sand directly from the depot. Mixing then takesplace at the construction site using the automated process. This cutscosts further because fewer people are required to operate the machinery.No more shovelling sand and cement into a mixer. Backache is athing of the past!”Powered by <strong>John</strong> <strong>Deere</strong>. In 2004, <strong>John</strong> <strong>Deere</strong> introduced the5030T – the only type Bremat now installs. Alexander explainsthat this engine, which is suited to construction industry, is thecompany’s preferred choice.“The size/power ratio of the engine is amazing – in my opiniononly a <strong>John</strong> <strong>Deere</strong> can generate so much power in such a smallengine. The indicated lifetime is considerably higher than the competitionand the quality/price ratio made this an obvious choice.”Besides <strong>John</strong> <strong>Deere</strong>’s reliability and range of products, Brematbenefits from the extensive international service network. “As weexpand from our base in The Netherlands, it’s good to know therewill always be <strong>John</strong> <strong>Deere</strong> service providers nearby,” Alexanderpoints out.A bright future. In the summer of 2005 Bremat started thedevelopment of a model dedicated to the European market – theScreedBlower ZCM4, which meets allEU regulations. The first of these verysmall carriers will go to Bulgaria, with a<strong>John</strong> <strong>Deere</strong> engine, naturally. With fewcompetitors, Bremat hopes to build onits 100 percent market share in TheNetherlands as it moves into the UK,France, Germany and Spain – the biggestareas of growth in house construction inEurope.“We’re also working on a fully automatedcarrier for producing self-levelling screedwith a <strong>John</strong> <strong>Deere</strong> engine in a generator set,”Tinus says. “Our <strong>John</strong> <strong>Deere</strong> engineer colleaguescontributed to the specs for these newmachines. There’s a lot to an engine, so workingclosely together is a great benefit.”A simple push of a buttonis all it takes to startpumping with the fullyautomated sand cementscreed carrierEngine: <strong>John</strong> <strong>Deere</strong> PowerTech 5030T – a 57 kW (76 hp),5-cylinder, 3.0 L turbocharged diesel engine.Distributor: Louis Nagel B.V., Nijmegen, The NetherlandsTel. +31 24 371 6640; Fax +31 24 378 2270;email: edhes@nagel.nlPowerSource 17