Smoother Roads Ahead - John Deere Industrial Engines

Smoother Roads Ahead - John Deere Industrial Engines

Smoother Roads Ahead - John Deere Industrial Engines

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

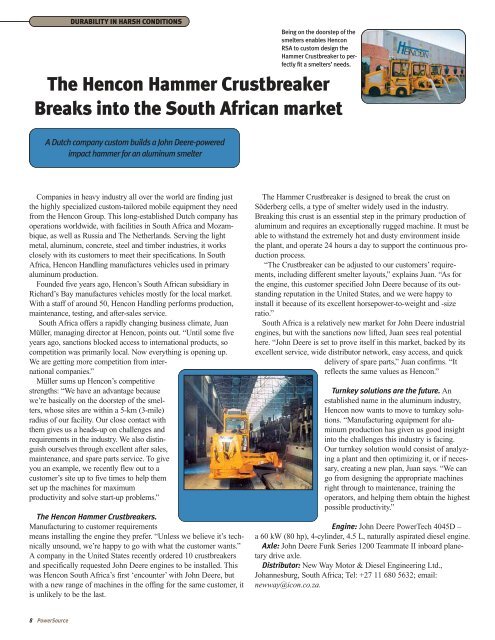

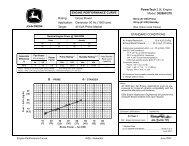

DURABILITY IN HARSH CONDITIONSBeing on the doorstep of thesmelters enables HenconRSA to custom design theHammer Crustbreaker to perfectlyfit a smelters’ needs.The Hencon Hammer CrustbreakerBreaks into the South African marketA Dutch company custom builds a <strong>John</strong> <strong>Deere</strong>-poweredimpact hammer for an aluminum smelterCompanies in heavy industry all over the world are finding justthe highly specialized custom-tailored mobile equipment they needfrom the Hencon Group. This long-established Dutch company hasoperations worldwide, with facilities in South Africa and Mozambique,as well as Russia and The Netherlands. Serving the lightmetal, aluminum, concrete, steel and timber industries, it worksclosely with its customers to meet their specifications. In SouthAfrica, Hencon Handling manufactures vehicles used in primaryaluminum production.Founded five years ago, Hencon’s South African subsidiary inRichard’s Bay manufactures vehicles mostly for the local market.With a staff of around 50, Hencon Handling performs production,maintenance, testing, and after-sales service.South Africa offers a rapidly changing business climate, JuanMüller, managing director at Hencon, points out. “Until some fiveyears ago, sanctions blocked access to international products, socompetition was primarily local. Now everything is opening up.We are getting more competition from internationalcompanies.”Müller sums up Hencon’s competitivestrengths: “We have an advantage becausewe’re basically on the doorstep of the smelters,whose sites are within a 5-km (3-mile)radius of our facility. Our close contact withthem gives us a heads-up on challenges andrequirements in the industry. We also distinguishourselves through excellent after sales,maintenance, and spare parts service. To giveyou an example, we recently flew out to acustomer’s site up to five times to help themset up the machines for maximumproductivity and solve start-up problems.”The Hencon Hammer Crustbreakers.Manufacturing to customer requirementsmeans installing the engine they prefer. “Unless we believe it’s technicallyunsound, we’re happy to go with what the customer wants.”A company in the United States recently ordered 10 crustbreakersand specifically requested <strong>John</strong> <strong>Deere</strong> engines to be installed. Thiswas Hencon South Africa’s first ‘encounter’ with <strong>John</strong> <strong>Deere</strong>, butwith a new range of machines in the offing for the same customer, itis unlikely to be the last.The Hammer Crustbreaker is designed to break the crust onSöderberg cells, a type of smelter widely used in the industry.Breaking this crust is an essential step in the primary production ofaluminum and requires an exceptionally rugged machine. It must beable to withstand the extremely hot and dusty environment insidethe plant, and operate 24 hours a day to support the continuous productionprocess.“The Crustbreaker can be adjusted to our customers’ requirements,including different smelter layouts,” explains Juan. “As forthe engine, this customer specified <strong>John</strong> <strong>Deere</strong> because of its outstandingreputation in the United States, and we were happy toinstall it because of its excellent horsepower-to-weight and -sizeratio.”South Africa is a relatively new market for <strong>John</strong> <strong>Deere</strong> industrialengines, but with the sanctions now lifted, Juan sees real potentialhere. “<strong>John</strong> <strong>Deere</strong> is set to prove itself in this market, backed by itsexcellent service, wide distributor network, easy access, and quickdelivery of spare parts,” Juan confirms. “Itreflects the same values as Hencon.”Turnkey solutions are the future. Anestablished name in the aluminum industry,Hencon now wants to move to turnkey solutions.“Manufacturing equipment for aluminumproduction has given us good insightinto the challenges this industry is facing.Our turnkey solution would consist of analyzinga plant and then optimizing it, or if necessary,creating a new plan, Juan says. “We cango from designing the appropriate machinesright through to maintenance, training theoperators, and helping them obtain the highestpossible productivity.”Engine: <strong>John</strong> <strong>Deere</strong> PowerTech 4045D –a 60 kW (80 hp), 4-cylinder, 4.5 L, naturally aspirated diesel engine.Axle: <strong>John</strong> <strong>Deere</strong> Funk Series 1200 Teammate II inboard planetarydrive axle.Distributor: New Way Motor & Diesel Engineering Ltd.,Johannesburg, South Africa; Tel: +27 11 680 5632; email:newway@icon.co.za.8 PowerSource