DURABILITY IN HARSH CONDITIONSBeing on the doorstep of thesmelters enables HenconRSA to custom design theHammer Crustbreaker to perfectlyfit a smelters’ needs.The Hencon Hammer CrustbreakerBreaks into the South African marketA Dutch company custom builds a <strong>John</strong> <strong>Deere</strong>-poweredimpact hammer for an aluminum smelterCompanies in heavy industry all over the world are finding justthe highly specialized custom-tailored mobile equipment they needfrom the Hencon Group. This long-established Dutch company hasoperations worldwide, with facilities in South Africa and Mozambique,as well as Russia and The Netherlands. Serving the lightmetal, aluminum, concrete, steel and timber industries, it worksclosely with its customers to meet their specifications. In SouthAfrica, Hencon Handling manufactures vehicles used in primaryaluminum production.Founded five years ago, Hencon’s South African subsidiary inRichard’s Bay manufactures vehicles mostly for the local market.With a staff of around 50, Hencon Handling performs production,maintenance, testing, and after-sales service.South Africa offers a rapidly changing business climate, JuanMüller, managing director at Hencon, points out. “Until some fiveyears ago, sanctions blocked access to international products, socompetition was primarily local. Now everything is opening up.We are getting more competition from internationalcompanies.”Müller sums up Hencon’s competitivestrengths: “We have an advantage becausewe’re basically on the doorstep of the smelters,whose sites are within a 5-km (3-mile)radius of our facility. Our close contact withthem gives us a heads-up on challenges andrequirements in the industry. We also distinguishourselves through excellent after sales,maintenance, and spare parts service. To giveyou an example, we recently flew out to acustomer’s site up to five times to help themset up the machines for maximumproductivity and solve start-up problems.”The Hencon Hammer Crustbreakers.Manufacturing to customer requirementsmeans installing the engine they prefer. “Unless we believe it’s technicallyunsound, we’re happy to go with what the customer wants.”A company in the United States recently ordered 10 crustbreakersand specifically requested <strong>John</strong> <strong>Deere</strong> engines to be installed. Thiswas Hencon South Africa’s first ‘encounter’ with <strong>John</strong> <strong>Deere</strong>, butwith a new range of machines in the offing for the same customer, itis unlikely to be the last.The Hammer Crustbreaker is designed to break the crust onSöderberg cells, a type of smelter widely used in the industry.Breaking this crust is an essential step in the primary production ofaluminum and requires an exceptionally rugged machine. It must beable to withstand the extremely hot and dusty environment insidethe plant, and operate 24 hours a day to support the continuous productionprocess.“The Crustbreaker can be adjusted to our customers’ requirements,including different smelter layouts,” explains Juan. “As forthe engine, this customer specified <strong>John</strong> <strong>Deere</strong> because of its outstandingreputation in the United States, and we were happy toinstall it because of its excellent horsepower-to-weight and -sizeratio.”South Africa is a relatively new market for <strong>John</strong> <strong>Deere</strong> industrialengines, but with the sanctions now lifted, Juan sees real potentialhere. “<strong>John</strong> <strong>Deere</strong> is set to prove itself in this market, backed by itsexcellent service, wide distributor network, easy access, and quickdelivery of spare parts,” Juan confirms. “Itreflects the same values as Hencon.”Turnkey solutions are the future. Anestablished name in the aluminum industry,Hencon now wants to move to turnkey solutions.“Manufacturing equipment for aluminumproduction has given us good insightinto the challenges this industry is facing.Our turnkey solution would consist of analyzinga plant and then optimizing it, or if necessary,creating a new plan, Juan says. “We cango from designing the appropriate machinesright through to maintenance, training theoperators, and helping them obtain the highestpossible productivity.”Engine: <strong>John</strong> <strong>Deere</strong> PowerTech 4045D –a 60 kW (80 hp), 4-cylinder, 4.5 L, naturally aspirated diesel engine.Axle: <strong>John</strong> <strong>Deere</strong> Funk Series 1200 Teammate II inboard planetarydrive axle.Distributor: New Way Motor & Diesel Engineering Ltd.,Johannesburg, South Africa; Tel: +27 11 680 5632; email:newway@icon.co.za.8 PowerSource

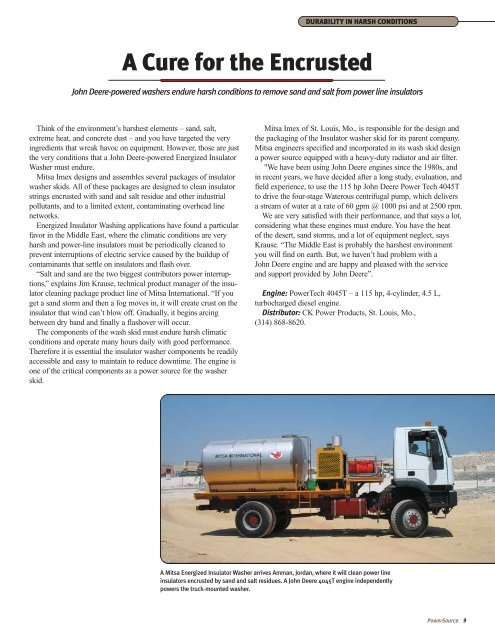

DURABILITY IN HARSH CONDITIONSA Cure for the Encrusted<strong>John</strong> <strong>Deere</strong>-powered washers endure harsh conditions to remove sand and salt from power line insulatorsThink of the environment’s harshest elements – sand, salt,extreme heat, and concrete dust – and you have targeted the veryingredients that wreak havoc on equipment. However, those are justthe very conditions that a <strong>John</strong> <strong>Deere</strong>-powered Energized InsulatorWasher must endure.Mitsa Imex designs and assembles several packages of insulatorwasher skids. All of these packages are designed to clean insulatorstrings encrusted with sand and salt residue and other industrialpollutants, and to a limited extent, contaminating overhead linenetworks.Energized Insulator Washing applications have found a particularfavor in the Middle East, where the climatic conditions are veryharsh and power-line insulators must be periodically cleaned toprevent interruptions of electric service caused by the buildup ofcontaminants that settle on insulators and flash over.“Salt and sand are the two biggest contributors power interruptions,”explains Jim Krause, technical product manager of the insulatorcleaning package product line of Mitsa International. “If youget a sand storm and then a fog moves in, it will create crust on theinsulator that wind can’t blow off. Gradually, it begins arcingbetween dry band and finally a flashover will occur.The components of the wash skid must endure harsh climaticconditions and operate many hours daily with good performance.Therefore it is essential the insulator washer components be readilyaccessible and easy to maintain to reduce downtime. The engine isone of the critical components as a power source for the washerskid.Mitsa Imex of St. Louis, Mo., is responsible for the design andthe packaging of the Insulator washer skid for its parent company.Mitsa engineers specified and incorporated in its wash skid designa power source equipped with a heavy-duty radiator and air filter."We have been using <strong>John</strong> <strong>Deere</strong> engines since the 1980s, andin recent years, we have decided after a long study, evaluation, andfield experience, to use the 115 hp <strong>John</strong> <strong>Deere</strong> Power Tech 4045Tto drive the four-stage Waterous centrifugal pump, which deliversa stream of water at a rate of 60 gpm @ 1000 psi and at 2500 rpm.We are very satisfied with their performance, and that says a lot,considering what these engines must endure. You have the heatof the desert, sand storms, and a lot of equipment neglect, saysKrause. “The Middle East is probably the harshest environmentyou will find on earth. But, we haven’t had problem with a<strong>John</strong> <strong>Deere</strong> engine and are happy and pleased with the serviceand support provided by <strong>John</strong> <strong>Deere</strong>”.Engine: PowerTech 4045T – a 115 hp, 4-cylinder, 4.5 L,turbocharged diesel engine.Distributor: CK Power Products, St. Louis, Mo.,(314) 868-8620.A Mitsa Energized Insulator Washer arrives Amman, Jordan, where it will clean power lineinsulators encrusted by sand and salt residues. A <strong>John</strong> <strong>Deere</strong> 4045T engine independentlypowers the truck-mounted washer.PowerSource 9