Smoother Roads Ahead - John Deere Industrial Engines

Smoother Roads Ahead - John Deere Industrial Engines

Smoother Roads Ahead - John Deere Industrial Engines

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

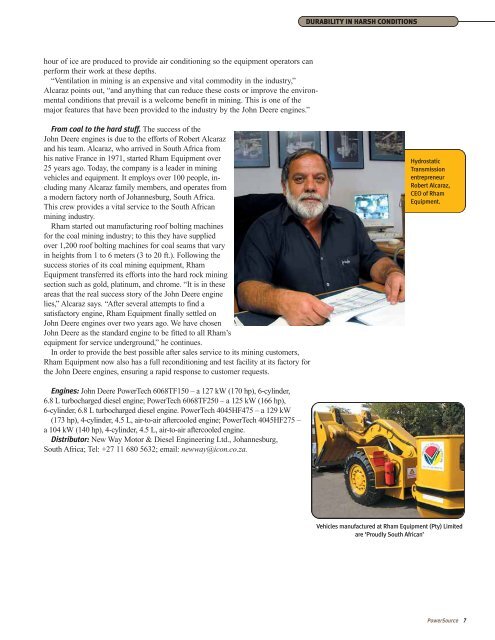

DURABILITY IN HARSH CONDITIONShour of ice are produced to provide air conditioning so the equipment operators canperform their work at these depths.“Ventilation in mining is an expensive and vital commodity in the industry,”Alcaraz points out, “and anything that can reduce these costs or improve the environmentalconditions that prevail is a welcome benefit in mining. This is one of themajor features that have been provided to the industry by the <strong>John</strong> <strong>Deere</strong> engines.”From coal to the hard stuff. The success of the<strong>John</strong> <strong>Deere</strong> engines is due to the efforts of Robert Alcarazand his team. Alcaraz, who arrived in South Africa fromhis native France in 1971, started Rham Equipment over25 years ago. Today, the company is a leader in miningvehicles and equipment. It employs over 100 people, includingmany Alcaraz family members, and operates froma modern factory north of Johannesburg, South Africa.This crew provides a vital service to the South Africanmining industry.Rham started out manufacturing roof bolting machinesfor the coal mining industry; to this they have suppliedover 1,200 roof bolting machines for coal seams that varyin heights from 1 to 6 meters (3 to 20 ft.). Following thesuccess stories of its coal mining equipment, RhamEquipment transferred its efforts into the hard rock miningsection such as gold, platinum, and chrome. “It is in theseareas that the real success story of the <strong>John</strong> <strong>Deere</strong> enginelies,” Alcaraz says. “After several attempts to find asatisfactory engine, Rham Equipment finally settled on<strong>John</strong> <strong>Deere</strong> engines over two years ago. We have chosen<strong>John</strong> <strong>Deere</strong> as the standard engine to be fitted to all Rham’sequipment for service underground,” he continues.In order to provide the best possible after sales service to its mining customers,Rham Equipment now also has a full reconditioning and test facility at its factory forthe <strong>John</strong> <strong>Deere</strong> engines, ensuring a rapid response to customer requests.HydrostaticTransmissionentrepreneurRobert Alcaraz,CEO of RhamEquipment.<strong>Engines</strong>: <strong>John</strong> <strong>Deere</strong> PowerTech 6068TF150 – a 127 kW (170 hp), 6-cylinder,6.8 L turbocharged diesel engine; PowerTech 6068TF250 – a 125 kW (166 hp),6-cylinder, 6.8 L turbocharged diesel engine. PowerTech 4045HF475 – a 129 kW(173 hp), 4-cylinder, 4.5 L, air-to-air aftercooled engine; PowerTech 4045HF275 –a 104 kW (140 hp), 4-cylinder, 4.5 L, air-to-air aftercooled engine.Distributor: New Way Motor & Diesel Engineering Ltd., Johannesburg,South Africa; Tel: +27 11 680 5632; email: newway@icon.co.za.Vehicles manufactured at Rham Equipment (Pty) Limitedare ‘Proudly South African’PowerSource 7