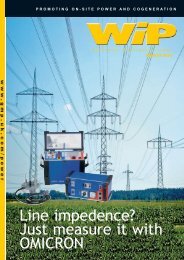

DIRANA technology from OMICRON - Global Media Publishing Ltd ...

DIRANA technology from OMICRON - Global Media Publishing Ltd ...

DIRANA technology from OMICRON - Global Media Publishing Ltd ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

14<br />

GAS ENGINES<br />

Jenbacher biogas engines waste<br />

Increasingly, Jenbacher biogas engines<br />

are using the biogas <strong>from</strong> anaerobic<br />

fermentation of organic waste <strong>from</strong><br />

agriculture, foodstuff or feed industries.<br />

This fuel can substitute for fossil fuels.<br />

The global installed base of almost 1,300<br />

GE Jenbacher gas engines running on<br />

biogas has the capacity to generate more<br />

than 6.8 million MWh of electricity per<br />

year without burning fossil fuel. This is<br />

equivalent to the annual electricity<br />

demands of over 617,000 US households,<br />

over 1.6m European households or over<br />

1.5m urban Chinese households.<br />

A GE Jenbacher JGS 620 gas engine<br />

running at full capacity for 8,000 hours<br />

per year on associated petroleum gas,<br />

when used instead of a comparable diesel<br />

generator, is designed to avoid the<br />

combustion of more than 4.8m litres of<br />

diesel fuel per year while generating<br />

electricity. This could yield an annual<br />

savings of more than US$ 2.5m based on a<br />

diesel price of US$ 0.53 per litre.<br />

Along with natural gas operation,<br />

Jenbacher <strong>technology</strong> makes it possible to<br />

dispose of environmentally offensive gases<br />

(e.g., <strong>from</strong> landfills, agriculture, coal<br />

mining, chemical plants, and other<br />

industries). To date, Jenbacher gas engine<br />

cogeneration systems are also used for<br />

CO2 fertilisation in greenhouses and<br />

absolutely nothing<br />

Renewable resources such as grass, corn, and chicken dung can be fermented to produce biogas to<br />

fuel a Jenbacher gas engine, along with waste gases. The generated electricity is then fed into the<br />

public grid and the heat produced is primarily used for heating purposes, WIP reports.<br />

trigeneration<br />

systems. When it<br />

comes to use with<br />

biogas, the<br />

Jenbacher Type 2<br />

engine offers<br />

extremely high<br />

efficiency in the<br />

250 to 350 kW<br />

power range. Its<br />

robust design &<br />

stationary engine<br />

concept results in<br />

excellent<br />

component<br />

durability and a<br />

service life of<br />

60,000 operating<br />

hours before the<br />

first major overhaul.<br />

Optimised<br />

components and a<br />

proven control and<br />

monitoring concept give this engine<br />

outstanding reliability.<br />

In addition to two existing Jenbacher<br />

systems, a J208 GS engine has already<br />

been installed in at least one sewage<br />

treatment plant.<br />

Due to the high efficiency of this new<br />

engine, the annual electricity output<br />

could be increased by more than 20%<br />

while maintaining the<br />

fuel gas consumption<br />

at the same level.<br />

Three cogeneration<br />

systems cover 85% of<br />

the total electricity<br />

requirement and 100%<br />

of the heat requirement<br />

of the sewage<br />

treatment plant.<br />

Renewable resources<br />

such as grass, corn,<br />

JULY 2010 • WORLDWIDE I NDEPENDENT P OWER<br />

Type 2 Jenbacher engine.<br />

GE Jenbacher JGS 620 gas engine.<br />

and chicken dung can also be fermented<br />

to produce biogas to fuel a Jenbacher gas<br />

engine. The generated electricity is<br />

normally fed into the public grid; the heat<br />

produced is used for heating purposes<br />

During summer, the exhaust gas <strong>from</strong> the<br />

engine can be used to dry grain and wood<br />

chips. The substrate <strong>from</strong> the biomass<br />

fermentation can even serve as fertiliser.<br />

Gas engines can also run on biogas<br />

produced <strong>from</strong> materials such as liquid<br />

manure and corn.<br />

Features and benefits for the Jenbacher<br />

biogas engines include: optimised<br />

combustion for maximum efficiency and a<br />

turbocharger bypass which evens out<br />

extreme operating conditions.<br />

Internet link<br />

www.ge.ecomagination.com<br />

WIP