Automatic Lubrication System - Andantex USA Inc.

Automatic Lubrication System - Andantex USA Inc.

Automatic Lubrication System - Andantex USA Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

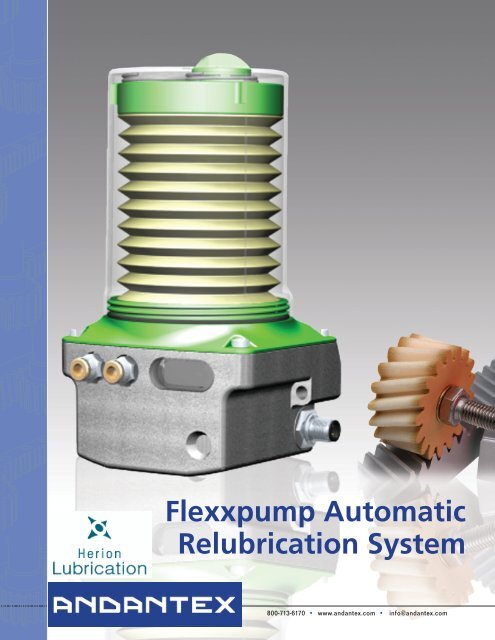

Flexxpump <strong>Automatic</strong>Relubrication <strong>System</strong>800-713-6170 • www.andantex.com • info@andantex.com

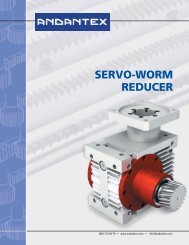

MODULAR RACK & PINION SYSTEMFLEXXPUMP AUTOMATIC LUBRICATION SYSTEMSA new high performance system to automatically lubricate racks and pinions, open gearing, linear guideways,ballscrews, and chain drives is available from <strong>Andantex</strong>, <strong>USA</strong>. A compact automatic relubrication unit,Flexxpump, that delivers grease (400 cc) or oil (500 cc) to the item being lubricated through a piston pump withprogrammable frequency and delivery rate is combined with tubing and open cellular polyurethane (P.U.) foamapplicators for chain and open gearing drives.Lubricate THESE COMPONENTS with the new FLEXXPUMP system from Herion <strong>Lubrication</strong> <strong>System</strong>sComplete system consists of:Flexxpump – <strong>Automatic</strong> relubrication unit with piston pump (pressure up to 70 Bars) and programmable frequency anddelivery rate settings!– <strong>Inc</strong>ludes up to 4 outlets for multi-point lubrication– Power by internal battery or 24V DC supply– Remote operation monitoring and setup available through 4 pin M12 connectorOptimized Grease or Oil – New lubricants specifically developed for components to be lubricated 400 cc replaceable greasebellows or 500 cc refillable oilPolyurethane (P.U.) Foam Applicators - New gear tooth or chain sprocket applicators insure correct film thickness. Lowdensity PU foam absorbs lubricant up to 90% of its volume allowing high viscositylubricants to be applied and absorbed to insure film thickness and avoid hardening.Tubing, Fittings and Tools – All interconnecting components available to provide complete <strong>Automatic</strong> Lube system800-713-6170 • www.andantex.com • info@andantex.com2

MODULAR RACK & PINION SYSTEMFLEXXPUMP LUBRICANT DELIVERY SYSTEM CONFIGURATIONSLUBRICANTGREASEOILFlexxPump 4xx400 cc Grease BellowsNumber of OutletsFlexxPump 5xx500 cc Oil Reservoir401 402 403 404501 502 503 504422522Operating PowerControl Metod24V DCDLSPulse Controlled by PLCBATTERYTime Controlled by on-BoardProgrammingON-BOARDPROGRAMMING4 = 400 CC Grease5 = 500 CC Oil3TYPEFlexxPump 4 0 2 DLSDLS = Pulse Control PLCB = Battery Power/Time Control= 24V DC/Time Control0 = 1 Pump Body/2 Outlets2 = 2 Pump Bodies/2 Outlets Number of Outlets800-713-6170 • www.andantex.com • info@andantex.com

MODULAR RACK & PINION SYSTEMFLEXXPUMP 400/500 DLS RELUBRICATION UNITDIRECT LUBRICATION SYSTEMDIMENSIONS FlexxPump 400/500 DLSTECHNICAL DATA FlexxPump 400/500 DLSDimensions, Max:width x height x depth: 112mm x 196mm x 94mmWeight, without lubricant:1120gStorage/volume: 400cm 3 grease in a cartridge (types: 400); 500ml oil (types: 500)Lubricant:oil or grease up to NLGI. 3 (also containing solid lubricants)Function/principle:piston pumpDelivery rate per pulse: 0, 15cm 3Number of outlets:up to 4; right-angled and pivotableOperating voltage:24V DCOperating current:Imax: 350mA; typical: 200mAFuse:500mA (characteristic: delay)Lube-connection:high pressure tube 6x4 (flexible tube with diameter 6mm outside; 4mm inside)Operating pressure:max. 70bar (1000 psi)Operating temperature:-25˚C... +70˚C (-13F ... +160F)Combination:possible with progressive systemsPressure monitoring:intergrated, electronic (monitoring backpressure)Level monitoring:intergrated, reed-contactelectrical connection:M12x1; 4-poleProtection class: IP 65 (= suitable for underwater operation up to 1m)*Relubrication unit delivered without grease bellows.Bellows are available as accessories.800-713-6170 • www.andantex.com • info@andantex.com4

MODULAR RACK & PINION SYSTEMFLEXXPUMP 400/500 DLS RELUBRICATION UNITDIRECT LUBRICATION SYSTEMPart Number Outlets Pump Bodies Grease (g) TypeOil (o)135-140-210 1 1 g FlexxPump 401 DLS135-240-210 2 1 g FlexxPump 402 DLS135-340-210 3 2 g FlexxPump 403 DLS135-440-210 4 2 g FlexxPump 404 DLS135-240-212 2 2 g FlexxPump 422 DLS135-150-210 1 1 o FlexxPump 501 DLS135-250-210 2 1 o FlexxPump 502 DLS135-350-210 3 2 o FlexxPump 503 DLS135-450-210 4 2 o FlexxPump 504 DLS135-250-212 2 2 o FlexxPump 522 DLSConnector PIN assignment M12x1The FlexxPump uses a four-pin socket to connect a M12x1 plug allowing communication with themachine controller. An external 24VDC power supply is used to switch ON and OFF (voltage of+20 ...up to +30 VDC, supplied to PIN1). When voltage is supplied the lubrication pump is inoperating condition. If there are no errors (Pump OK) the input voltage will be transferred to theoutput signal (PIN 4) indicating all is OK. Once the voltage supply to PIN 1 is stopped (switchedOFF), the pump rests and saves the current operating conditions in memory. When the pump isturned back on the saved operating conditions will be continued PIN 4 relays the operatingcondition.Connector PIN assignment M 12x1PIN 1: Input voltage +20...30 VDC, color brownPIN 2: Activation of the individual pump outlets (page 3), color whitePIN 3: Ground (GND), color bluePIN 4: Output Signal, color blackDetailsPeak current Imax (during pump operation) approx. 350 mA, typically < 200 mAStandby current (standby mode) < 20 mAOutlet signal PIN 4: High (+20...30 VDC) = OKLow = Error (empty signal, over-current)5800-713-6170 • www.andantex.com • info@andantex.com

MODULAR RACK & PINION SYSTEMFLEXXPUMP 400/500 DLS RELUBRICATION UNITDIRECT LUBRICATION SYSTEMIdentification of the pump outletsDeliver Rate per pulse signal = 0.15 cc/outletPulse signal to activate the outlets (Indication in seconds, accuracy +/- 10%)Time between two pulse signals: minimum 15 s- activate 1.1- activate 1.1 + 1.2(outlets will be servedalternatly and dispensedequal quanities from bothoutlets)- activate 2.1- activate 2.1 + 2.2(outlets will be servedalternatly and dispensedequal quanities from bothoutlets)- activate 1.1 + 1.2 + 2.1 + 2.2(outlets will be servedalternatly and dispensedequal quanities from bothoutlets)800-713-6170 • www.andantex.com • info@andantex.com6

MODULAR RACK & PINION SYSTEMFLEXXPUMP 400/500 B RELUBRICATION UNITDIMENSIONS FlexxPump 400/500 BTECHNICAL DATA FlexxPump 400/500 B (Battery)Dimensions, Max:width x height x depth: 112mm x 196mm x 94mmWeight, without lubricant:1120g (2.5 lbs.)Storage/volume:400cm grease in bellows* (types: 4xx); 500ml oil (types: 5xx)Lubricant:oil or grease up to NLGI 3 (also containing solid lubricants)Function/principle:piston pumpNumber of outlets: 1 or 2Delivery rate/stroke:1 outlet 0.30 cc, 2 outlet 0.15 ccOperating voltage:3.6 V. Battery PackOn-Board Programming:Via LCD displayLube-connection:high pressure tube 6x4Operating pressure:max. 70bar (1000 psi)Operating temperature:-25˚C... +70˚C (-13˚F ... +160˚F)Pressure monitoring:intergrated, electronic (monitoring backpressure)Level monitoring:intergrated, reed-contactOptional PLC connection:M12x1; 4-pole - for monitoring and on-off onlyProtection class: IP 65 (= suitable for underwater operation up to 1m)*Relubrication unit delivered without grease bellows. Bellows are available as accessories.Part Number Outlets Pump Bodies Grease (g) TypeOil (o)135-140-000 1 1 g FlexxPump 401 B135-240-000 2 1 g FlexxPump 402 B135-150-000 1 1 o FlexxPump 501 B135-250-000 2 1 o FlexxPump 502 B7800-713-6170 • www.andantex.com • info@andantex.com

MODULAR RACK & PINION SYSTEMFLEXXPUMP 400/500 RELUBRICATION UNITDIMENSIONS FlexxPump 400/500Connection tube6 x 4TECHNICAL DATA FlexxPump 400/500Dimensions, Max:width x height x depth: 112mm x 196mm x 94mmWeight, without lubricant:1120g (2.5 lbs.)Storage/volume:400cm grease in bellows* (types: 4xx); 500ml oil (types: 5xx)Lubricant:oil or grease up to NLGI 3 (also containing solid lubricants)Function/principle:piston pumpNumber of outlets: 1 or 2Delivery rate/stroke:1 outlet 0.30 cc, 2 outlet 0.15 ccOperating voltage:24 V DCOn-Board Programming:Via LCD displayLube-connection:high pressure tube 6x4Operating pressure:max. 70bar (1000 psi)Operating temperature:-25˚C... +70˚C (-13˚F ... +160˚F)Pressure monitoring:intergrated, electronic (monitoring backpressure)Level monitoring:intergrated, reed-contactOptional PLC connection:M12x1; 4-pole - for monitoring and on-off onlyProtection class: IP 65 (= suitable for underwater operation up to 1m)*Relubrication unit delivered without grease bellows. Bellows are available as accessories.Part Number Outlets Pump Bodies Grease (g) TypeOil (o)135-140-100 1 1 g FlexxPump 401135-240-100 2 1 g FlexxPump 402135-150-100 1 1 o FlexxPump 501135-250-100 2 1 o FlexxPump 502800-713-6170 • www.andantex.com • info@andantex.com8

MODULAR RACK & PINION SYSTEMLUBRICATION OF PINIONS AND RACKSFlexxPumppolyurethane pinionstraight and helical teeth module 2 … 10mounting axis - right-angledmounting axis - straight9800-713-6170 • www.andantex.com • info@andantex.com

MODULAR RACK & PINION SYSTEMLUBRICATION OF PINIONS AND RACKS<strong>Lubrication</strong> of open spur gear drives and racksFor tooth systems in open drives, an automatic lubrication supply is prefered. Exceptions are possible, in the case of verysmall modules, slow speed

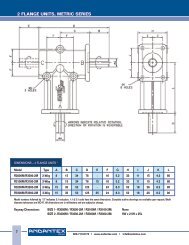

MODULAR RACK & PINION SYSTEMLUBRICATION PINIONTechnical specification lubrication pinionThe Herion lubrication pinions are made of an open cellular polyurethane foam (temperature range -30° C…+150° C).Pinionswith module 3 and bigger are put together with segments. To choose the correct lubrication pinion it has to be decided bydesign, if the lubrication pinion should be mounted on the rack or drive pinion. Mounting on the drive pinion is prefered,because the distribution of lubrication is better than a lubrication of the rack.Using lubrication pinions of an open-cellular polyurethane foam material ensures an optimal supply of the tooth system overlong distances. The material stores the lubricant and delivers it in smallest quantities. This lubrication avoids over-lubricationas well as wear (as a consequence of insufficient lubrication).LUBRICATION PINION - STRAIGHT TEETHmaterialopen cellularpolyurethane foamPart no. Module z* d a d d b b130-015-024 1.5 24 39.0 36.0 15.0 15.0130-020-017 2.0 17 38.0 34.0 12.0 20.0130-030-017 3.0 17 57.0 51.0 12.0 30.0130-040-017 4.0 17 76.0 68.0 12.0 40.0130-050-017 5.0 17 95.0 85.0 20.0 50.0130-060-017 6.0 17 114.0 102.0 20.0 60.0130-080-017 8.0 17 152.0 136.0 20.0 80.0130-100-017 10.0 17 190.0 170.0 20.0 100.0*number of teethSpecial design (all parameter disposable): on demand!Dimensions are in mm and are subject to change - consult factory.11800-713-6170 • www.andantex.com • info@andantex.com

MODULAR RACK & PINION SYSTEMLUBRICATION OF PINIONS AND RACKShelical, right handhelix angle 19° 31´42´´materialopen cellularpolyurethane foamArrangement with drive pinionPart no. Module z* d a d d b b131-015-024 1.5 24 41.2 38.2 15.0 15.0131-020-017 2.0 17 40.1 36.1 12.0 20.0131-030-017 3.0 17 60.1 54.1 12.0 30.0131-040-017 4.0 17 80.2 72.2 12.0 40.0131-050-017 5.0 17 100.2 90.2 20.0 50.0131-060-017 6.0 17 120.2 108.2 20.0 60.0131-080-017 8.0 17 160.3 144.2 20.0 80.0131-100-017 10.0 17 200.4 180.4 20.0 100.0Special design (all parameter disposable): on demand!helical, left handhelix angle 19° 31´42´´materialopen cellularpolyurethane foamPart no. Module z* d a d d b b132-015-024 1.5 24 41.2 38.2 15.0 15.0132-020-017 2.0 17 40.1 36.1 12.0 20.0132-030-017 3.0 17 60.1 54.1 12.0 30.0132-040-017 4.0 17 80.2 72.2 12.0 40.0132-050-017 5.0 17 100.2 90.2 20.0 50.0132-060-017 6.0 17 120.2 108.2 20.0 60.0132-080-017 8.0 17 160.3 144.3 20.0 80.0132-100-017 10.0 17 200.4 180.4 20.0 100.0*number of teethDimensions are in mm and are subject to change - consult factory.800-713-6170 • www.andantex.com • info@andantex.comArrangement with rackSpecial design (all parameter disposable): on demand!12

MODULAR RACK & PINION SYSTEMMOUNTING AXESPos. 1:right-angledmaterialsteelPart no. Module L l 1 l 2 d 1 connection b kg133-015-001 1.5 46.4 30.0 10.0 M 8 G 1/8" 15.0 0.13133-020-001 2.0 51.0 30.0 10.0 M 8 G 1/8" 20.0 0.14133-030-001 3.0 61.0 30.0 10.0 M 8 G 1/8" 30.0 0.17133-040-001 4.0 71.0 30.0 10.0 M 8 G 1/8" 40.0 0.20133-050-001 5.0 81.0 30.0 10.0 M 8 G 1/8" 50.0 0.25133-060-001 6.0 91.0 30.0 10.0 M 8 G 1/8" 60.0 0.45133-080-001 8.0 111.0 30.0 10.0 M 8 G 1/8" 80.0 0.64133-100-001 10.0 131.0 30.0 10.0 M 8 G 1/8" 100.0 0.90Special design (all parameter disposable): on demand!Pos. 2:straightmaterialsteelPart no. Module L l 1 d 1 SW connection d 2 b kg*133-015-002 1.5 60.2 34.0 M 10 17 M 6 15.0 0.07133-020-002 2.0 61.0 30.0 M 10 17 M 6 20.0 0.08133-030-002 3.0 71.0 30.0 M 10 17 M 6 30.0 0.11133-040-002 4.0 81.0 30.0 M 10 17 M 6 40.0 0.14133-050-002 5.0 116.0 30.0 M 16 24 G 1/8" 50.0 0.45133-060-002 6.0 126.0 30.0 M 16 24 G 1/8" 60.0 0.53133-080-002 8.0 146.0 30.0 M 16 24 G 1/8" 80.0 0.61133-100-002 10.0 166.0 30.0 M 16 24 G 1/8" 100.0 0.8713Special design (all parameter disposable): on demand!Dimensions are in mm and are subject to change - consult factory.800-713-6170 • www.andantex.com • info@andantex.com

MODULAR RACK & PINION SYSTEMASSEMBLY AND INITIATIONassembly - described by an ordering example:execution of the system in module 2- pinion with helical teeth (left hand for mounting with rack)- mounting axis: straight- tube connector: straight; thread 1/8´´- suitable hose, pre-filled with grease F01relubrication unit FlexxPumppart no.: 135-140-000straight tube-connectorlubrication pinion - helical teeth (left hand)part no.: 132-020-017part no.: 134-000-002hose pre-filledpart no.: 134-003-001mounting axe - straightpart no.: 133-020-002Initiation:When installation of all components is finished clean the rack until all particles and dirt is removed and wipe with a dry cloth.After this grease the rack and the lubrication pinion continuous with Herion Grease. Rotate the <strong>Lubrication</strong> piniondynamically on the rack until the pinion is enriched with grease (or use a already pre-greased pinion, on request).Now you can activate the system.For an H1/NSF application please use the grease Herion-F02.Reason:To avoid loss of lubrication grease because of insufficient adhesion of the lubrication grease, the rack surface must be cleanedfrom smut, oil, grease, wax, asphalt, resin and glue.In the case of insufficient cleaning, the grease „swims“ on a film and does not connect itself with the metallic material.The lubrication pinion is made up of a special foam and can absorb lubrication grease of appr. 90% of it´s own volume.Through this characteristic, grease is absorbed and dropped off again: storing effect.The foam is wear-resistant and resistant to oils and greases.800-713-6170 • www.andantex.com • info@andantex.com14

MODULAR RACK & PINION SYSTEMLUBRICANTSStandard grease for open gears and bearingsPart Number000-101-104Descriptionindividual bellow for FlexxPump, pre-filled with 400 cm³ grease Herion F01000-101-210grease Herion F01, 1 kg tinSpecial grease for linear guideways & ball screwsPart Number000-103-104000-103-210Descriptionindividual bellow for FlexxPump, pre-filled with 400 cm³ grease Herion F03grease Herion F03, 1 kg tinWith H1-approvalPart Number000-102-104000-102-210Descriptionindividual bellow for FlexxPump, pre-filled with 400 cm³ of grease Herion F02grease Herion F02, 1 kg tinTechnical InformationStandard grease for open gears, racks and pinions.grease Herion F01- based on lithium/calcium complex with extrem pressure additives, which are combined with the soap structure so that anoptimum adhesiveness to the metal surface is possible.- heat-resistant, good corrosion protection attributes, contains no solid lubricants.Applications:- developed as special grease for heavily loaded open gears.- due to the high temperature properties usable for a wide range of applications, where high temperatures and high loads exist.- can be recommended for open gearing, racks and pinions.temperature range -30°C to +150°C15800-713-6170 • www.andantex.com • info@andantex.com

MODULAR RACK & PINION SYSTEMTechnical InformationSpecial grease for linear guideways & ball screwsgrease Herion F03With H1 approvalgrease Herion F02LUBRICANTS- short-fibred and homogeneous lithium-saponified universalgrease with one mineral oil. It can be used for roller and slidebearing lubrication and is appropriate for medium and highload applications.- very adhesive; appropriate for short-stroke applications.- water resistant and protective against corrosion.Applications:- lubrication of linear bearings (recirculating ball bearing guides,roller guides and ballscrews)- in combination with a lubrication pinion and continuousrelubrication suitable for open gear lubrication- Easily pumped by relubrication unitstemperature range -20°C to +120°C- synthetic special grease for high temperatures based on synthetichydrocarbons with a partial special thickener of high metal affinity.- possesses the NSF/H1-registration, the continuation of the formerUSDA/H1-approval of lubricants which are allowed for foodcontact.quality attributes:- water (cold, hot) and steam resistant- high thermal and oxidation stability- for high load; very good wear-protection- high service life and wide temperature range- optimum lubricating effect at low friction valuestemperature range -40° C to +140° C800-713-6170 • www.andantex.com • info@andantex.com16

MODULAR RACK & PINION SYSTEMSPLITTERS FOR RELUBRICATION UNIT FlexxPumpPart No. Inlets Outlets Grease (g) Qty. of Lubricant TypeOil (o)per piston stroke134-005-002 1 2 g ~0.08 cc Splitter 1 inlet, 2 outlets, grease134-005-003 1 3 g 0.05 cc Splitter 1 inlet, 3 outlets, grease134-005-004 1 4 g ~0.04 cc Splitter 1 inlet, 4 outlets, grease134-005-006 1 2 o ~0.08 cc Splitter 1 inlet, 2 outlets, oil134-005-007 1 3 o 0.05 cc Splitter 1 inlet, 3 outlets, oil134-005-008 1 4 o ~0.04 cc Splitter 1 inlet, 4 outlets, oilEach outlet of the FlexxPump can be combined with only one splitter. The combination of 2 or more splitters at one pumpoutlet is not possible. Therefore, the maximum lubrication points that can be serviced by one FlexxPump 404DLS and4 splitters is 16.INSTALLATION RECOMMENDATIONS:The splitters are designed to connect to 6 mm outside diameter tubes. The splitters should be located as close as possible tothe FlexxPump outlets.The length of the tubes between the outlet side of the splitter and the lubrication points should be as close as possible toequal. Pressure differences between the outlets should not exceed 3 bars (43.5 PSI). The amount of lubricant supplied tolubrication points can vary slightly depending on the pressure differences at the outlets.17800-713-6170 • www.andantex.com • info@andantex.com

MODULAR RACK & PINION SYSTEMTUBE CONNECTORS134-000-001 134-000-002Straight male adaptorPart no. thread G tube outer ØT SW* E H L D134-000-001 M6 6 x 4 - 4 2.5 18.5 11134-000-002 G 1/8" 6 x 4 11 6 4 18 -Part no. thread G tube outer ØT SW* E D A L134-001-001 M6 6 x 4 9 5 11 21 16134-001-002 G 1/8" 6 x 4 13 6 11 21 20*width across flatshexagon socketApplication:connection between lubrication points and plastic tubes from relubrication systemsTechnical data:- working pressure max. 140 Bars (2000 PSI)- working temperature -30° C…+100° C- fluid oil, grease- material nickel-plated brass 58, NBR, stainless steelRotary elbow male adaptor - rotating under pressureFeatures:- full flow for the fluid- very simple seal function through integrated O-rings with own seat- can be inserted and extracted with one hand- all straight connectors with integrated hexagon socket- all rotary elbow male adaptors can be rotated by handOther tube connectors available on demandDimensions are in mm and are subject to change - consult factory.18800-713-6170 • www.andantex.com • info@andantex.com

MODULAR RACK & PINION SYSTEMTUBES FOR RELUBRICATION UNITSPart Number134-003-001134-003-002134-003-003134-004-001134-004-002Descriptiontube 6x4 - material PA 12, pre-filled with grease Herion F01tube 6x4 - material PA 12, pre-filled with grease Herion F02tube 6x4 - material PA 12, pre-filled with grease Herion F03tube 6x4 - of material PA 12tube 6x4 - of material PA 12 - transparent - for oilThe hoses are sold by meter; Maximum length 10 m.ACCESSORIEStube scissor 134-002-002 Replacement battery 134-002-004Part Number134-002-002134-002-003134-002-004134-002-005Descriptiontube scissor (metal, exchangable blades)cable M12x1; 5m long, PUR suitable for dragchain for mounting on PLCbattery for relubrication unit FlexxPump (high performance lithium battery)syringe - to fill the oil into the tubeTrademarked attributes of third parties are marked with ® and are property of the respective owner of that trademark.Dimensions are in mm and are subject to change - consult factory.800-713-6170 • www.andantex.com • info@andantex.com19

1705 Valley Road,Wanamassa, NJ 07712800/713-6170Fax 732/493-2949E-mail info@andantex.comwww.andantex.com