Furnace refractory erosion - Mintek

Furnace refractory erosion - Mintek

Furnace refractory erosion - Mintek

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

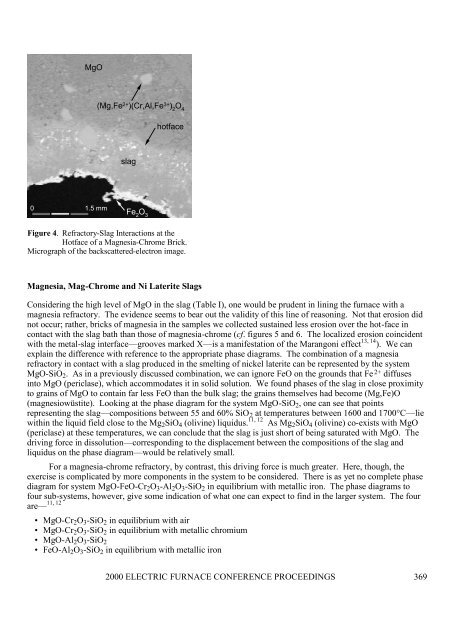

MgO(Mg,Fe 2+ )(Cr,Al,Fe 3+ ) 2O 4hotfaceslag0 1.5 mmFe 2O 3Figure 4. Refractory-Slag Interactions at theHotface of a Magnesia-Chrome Brick.Micrograph of the backscattered-electron image.Magnesia, Mag-Chrome and Ni Laterite SlagsConsidering the high level of MgO in the slag (Table I), one would be prudent in lining the furnace with amagnesia <strong>refractory</strong>. The evidence seems to bear out the validity of this line of reasoning. Not that <strong>erosion</strong> didnot occur; rather, bricks of magnesia in the samples we collected sustained less <strong>erosion</strong> over the hot-face incontact with the slag bath than those of magnesia-chrome (cf. figures 5 and 6. The localized <strong>erosion</strong> coincidentwith the metal-slag interface—grooves marked X—is a manifestation of the Marangoni effect 13, 14 ). We canexplain the difference with reference to the appropriate phase diagrams. The combination of a magnesia<strong>refractory</strong> in contact with a slag produced in the smelting of nickel laterite can be represented by the systemMgO-SiO 2 . As in a previously discussed combination, we can ignore FeO on the grounds that Fe 2+ diffusesinto MgO (periclase), which accommodates it in solid solution. We found phases of the slag in close proximityto grains of MgO to contain far less FeO than the bulk slag; the grains themselves had become (Mg,Fe)O(magnesiowüstite). Looking at the phase diagram for the system MgO-SiO 2 , one can see that pointsrepresenting the slag—compositions between 55 and 60% SiO 2 at temperatures between 1600 and 1700°C—lie11, 12within the liquid field close to the Mg 2 SiO 4 (olivine) liquidus. As Mg 2 SiO 4 (olivine) co-exists with MgO(periclase) at these temperatures, we can conclude that the slag is just short of being saturated with MgO. Thedriving force in dissolution—corresponding to the displacement between the compositions of the slag andliquidus on the phase diagram—would be relatively small.For a magnesia-chrome <strong>refractory</strong>, by contrast, this driving force is much greater. Here, though, theexercise is complicated by more components in the system to be considered. There is as yet no complete phasediagram for system MgO-FeO-Cr 2 O 3 -Al 2 O 3 -SiO 2 in equilibrium with metallic iron. The phase diagrams tofour sub-systems, however, give some indication of what one can expect to find in the larger system. The four11, 12are—• MgO-Cr 2 O 3 -SiO 2 in equilibrium with air• MgO-Cr 2 O 3 -SiO 2 in equilibrium with metallic chromium• MgO-Al 2 O 3 -SiO 2• FeO-Al 2 O 3 -SiO 2 in equilibrium with metallic iron2000 ELECTRIC FURNACE CONFERENCE PROCEEDINGS 369