You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

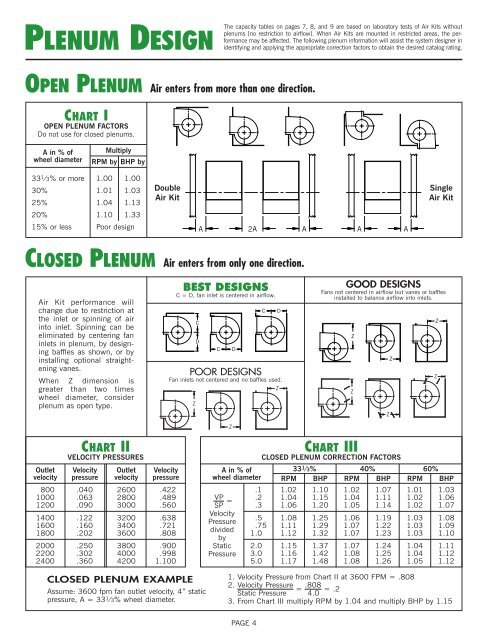

PLENUM DESIGNThe capacity tables on pages 7, 8, <strong>and</strong> 9 are based on laboratory tests of <strong>Air</strong> <strong>Kits</strong> withoutplenums [no restriction to airflow]. When <strong>Air</strong> <strong>Kits</strong> are mounted in restricted areas, the performancemay be affected. The following plenum information will assist the system designer inidentifying <strong>and</strong> applying the appropriate correction factors to obtain the desired catalog rating.OPEN PLENUM <strong>Air</strong> enters from more than one direction.CHART IOPEN PLENUM FACTORSDo not use for closed plenums.A in % ofwheel diameterMultiplyRPM by BHP by33 1 ⁄3% or more 1.00 1.0030% 1.01 1.0325% 1.04 1.1320% 1.10 1.3315% or less Poor design<strong>Double</strong><strong>Air</strong> KitA 2A AAA<strong>Single</strong><strong>Air</strong> KitCLOSED PLENUM <strong>Air</strong> enters from only one direction.<strong>Air</strong> Kit performance willchange due to restriction atthe inlet or spinning of airinto inlet. Spinning can beeliminated by centering faninlets in plenum, by designingbaffles as shown, or byinstalling optional straighteningvanes.When Z dimension isgreater than two timeswheel diameter, considerplenum as open type.BEST DESIGNSC = D, fan inlet is centered in airflow.ZCDCPOOR DESIGNSFan inlets not centered <strong>and</strong> no baffles used.DCDZGOOD DESIGNSFans not centered in airflow but vanes or bafflesinstalled to balance airflow into inlets.ZZZZZZZOutletvelocityCHART IIVELOCITY PRESSURESVelocitypressureOutletvelocityVelocitypressure800 .040 2600 .4221000 .063 2800 .4891200 .090 3000 .5601400 .122 3200 .6381600 .160 3400 .7211800 .202 3600 .8082000 .250 3800 .9002200 .302 4000 .9982400 .360 4200 1.100CLOSED PLENUM EXAMPLEAssume: 3600 fpm fan outlet velocity, 4” staticpressure, A = 33 1 ⁄3% wheel diameter.A in % ofwheel diameterVP =SPVelocityPressuredividedbyStaticPressureCHART IIICLOSED PLENUM CORRECTION FACTORS33 1 ⁄3%40% 60%RPM BHP RPM BHP RPM BHP.1 1.02 1.10 1.02 1.07 1.01 1.03.2 1.04 1.15 1.04 1.11 1.02 1.06.3 1.06 1.20 1.05 1.14 1.02 1.07.5 1.08 1.25 1.06 1.19 1.03 1.08.75 1.11 1.29 1.07 1.22 1.03 1.091.0 1.12 1.32 1.07 1.23 1.03 1.102.0 1.15 1.37 1.07 1.24 1.04 1.113.0 1.16 1.42 1.08 1.25 1.04 1.125.0 1.17 1.48 1.08 1.26 1.05 1.121. Velocity Pressure from Chart II at 3600 FPM = .8082. Velocity Pressure =.808 = .2Static Pressure 4.03. From Chart III multiply RPM by 1.04 <strong>and</strong> multiply BHP by 1.15PAGE 4