Notes of practical application of ion exchange resins in ... - Purolite

Notes of practical application of ion exchange resins in ... - Purolite

Notes of practical application of ion exchange resins in ... - Purolite

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

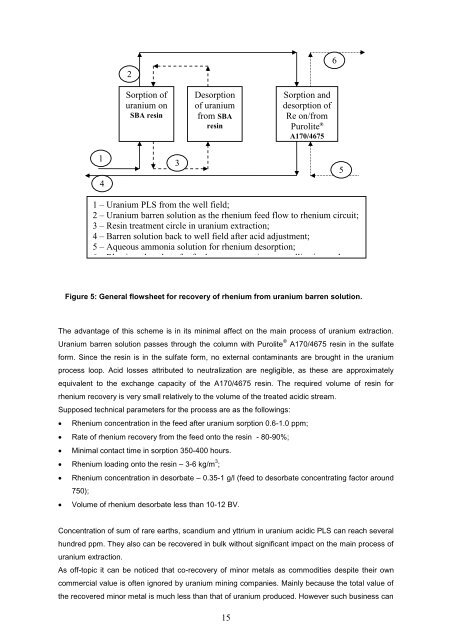

2Sorpt<strong>ion</strong> <strong>of</strong>uranium onSBA res<strong>in</strong>Desorpt<strong>ion</strong><strong>of</strong> uraniumfrom SBAres<strong>in</strong>Sorpt<strong>ion</strong> anddesorpt<strong>ion</strong> <strong>of</strong>Re on/from<strong>Purolite</strong> ®A170/4675614351 – Uranium PLS from the well field;2 – Uranium barren solut<strong>ion</strong> as the rhenium feed flow to rhenium circuit;3 – Res<strong>in</strong> treatment circle <strong>in</strong> uranium extract<strong>ion</strong>;4 – Barren solut<strong>ion</strong> back to well field after acid adjustment;5 – Aqueous ammonia solut<strong>ion</strong> for rhenium desorpt<strong>ion</strong>;6 – Rhenium desorbate for further concentrat<strong>in</strong>g, crystallizat<strong>ion</strong> andpack<strong>in</strong>g.Figure 5: General flowsheet for recovery <strong>of</strong> rhenium from uranium barren solut<strong>ion</strong>.The advantage <strong>of</strong> this scheme is <strong>in</strong> its m<strong>in</strong>imal affect on the ma<strong>in</strong> process <strong>of</strong> uranium extract<strong>ion</strong>.Uranium barren solut<strong>ion</strong> passes through the column with <strong>Purolite</strong> ® A170/4675 res<strong>in</strong> <strong>in</strong> the sulfateform. S<strong>in</strong>ce the res<strong>in</strong> is <strong>in</strong> the sulfate form, no external contam<strong>in</strong>ants are brought <strong>in</strong> the uraniumprocess loop. Acid losses attributed to neutralizat<strong>ion</strong> are negligible, as these are approximatelyequivalent to the <strong>exchange</strong> capacity <strong>of</strong> the A170/4675 res<strong>in</strong>. The required volume <strong>of</strong> res<strong>in</strong> forrhenium recovery is very small relatively to the volume <strong>of</strong> the treated acidic stream.Supposed technical parameters for the process are as the follow<strong>in</strong>gs: Rhenium concentrat<strong>ion</strong> <strong>in</strong> the feed after uranium sorpt<strong>ion</strong> 0.6-1.0 ppm; Rate <strong>of</strong> rhenium recovery from the feed onto the res<strong>in</strong> - 80-90%; M<strong>in</strong>imal contact time <strong>in</strong> sorpt<strong>ion</strong> 350-400 hours. Rhenium load<strong>in</strong>g onto the res<strong>in</strong> – 3-6 kg/m 3 ; Rhenium concentrat<strong>ion</strong> <strong>in</strong> desorbate – 0.35-1 g/l (feed to desorbate concentrat<strong>in</strong>g factor around750); Volume <strong>of</strong> rhenium desorbate less than 10-12 BV.Concentrat<strong>ion</strong> <strong>of</strong> sum <strong>of</strong> rare earths, scandium and yttrium <strong>in</strong> uranium acidic PLS can reach severalhundred ppm. They also can be recovered <strong>in</strong> bulk without significant impact on the ma<strong>in</strong> process <strong>of</strong>uranium extract<strong>ion</strong>.As <strong>of</strong>f-topic it can be noticed that co-recovery <strong>of</strong> m<strong>in</strong>or metals as commodities despite their owncommercial value is <strong>of</strong>ten ignored by uranium m<strong>in</strong><strong>in</strong>g companies. Ma<strong>in</strong>ly because the total value <strong>of</strong>the recovered m<strong>in</strong>or metal is much less than that <strong>of</strong> uranium produced. However such bus<strong>in</strong>ess can15