Notes of practical application of ion exchange resins in ... - Purolite

Notes of practical application of ion exchange resins in ... - Purolite

Notes of practical application of ion exchange resins in ... - Purolite

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

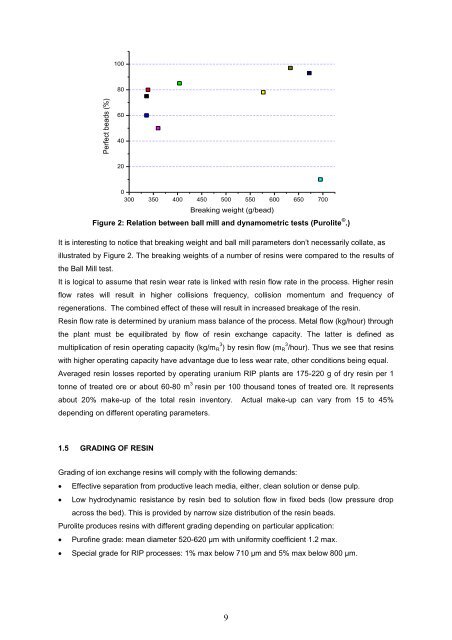

Perfect beads (%)100806040200300 350 400 450 500 550 600 650 700Break<strong>in</strong>g weight (g/bead)Figure 2: Relat<strong>ion</strong> between ball mill and dynamometric tests (<strong>Purolite</strong> © .)It is <strong>in</strong>terest<strong>in</strong>g to notice that break<strong>in</strong>g weight and ball mill parameters don’t necessarily collate, asillustrated by Figure 2. The break<strong>in</strong>g weights <strong>of</strong> a number <strong>of</strong> <strong>res<strong>in</strong>s</strong> were compared to the results <strong>of</strong>the Ball Mill test.It is logical to assume that res<strong>in</strong> wear rate is l<strong>in</strong>ked with res<strong>in</strong> flow rate <strong>in</strong> the process. Higher res<strong>in</strong>flow rates will result <strong>in</strong> higher collis<strong>ion</strong>s frequency, collis<strong>ion</strong> momentum and frequency <strong>of</strong>regenerat<strong>ion</strong>s. The comb<strong>in</strong>ed effect <strong>of</strong> these will result <strong>in</strong> <strong>in</strong>creased breakage <strong>of</strong> the res<strong>in</strong>.Res<strong>in</strong> flow rate is determ<strong>in</strong>ed by uranium mass balance <strong>of</strong> the process. Metal flow (kg/hour) throughthe plant must be equilibrated by flow <strong>of</strong> res<strong>in</strong> <strong>exchange</strong> capacity. The latter is def<strong>in</strong>ed asmultiplicat<strong>ion</strong> <strong>of</strong> res<strong>in</strong> operat<strong>in</strong>g capacity (kg/m 3 R ) by res<strong>in</strong> flow (m 3 R /hour). Thus we see that <strong>res<strong>in</strong>s</strong>with higher operat<strong>in</strong>g capacity have advantage due to less wear rate, other condit<strong>ion</strong>s be<strong>in</strong>g equal.Averaged res<strong>in</strong> losses reported by operat<strong>in</strong>g uranium RIP plants are 175-220 g <strong>of</strong> dry res<strong>in</strong> per 1tonne <strong>of</strong> treated ore or about 60-80 m 3 res<strong>in</strong> per 100 thousand tones <strong>of</strong> treated ore. It representsabout 20% make-up <strong>of</strong> the total res<strong>in</strong> <strong>in</strong>ventory. Actual make-up can vary from 15 to 45%depend<strong>in</strong>g on different operat<strong>in</strong>g parameters.1.5 GRADING OF RESINGrad<strong>in</strong>g <strong>of</strong> <strong>ion</strong> <strong>exchange</strong> <strong>res<strong>in</strong>s</strong> will comply with the follow<strong>in</strong>g demands: Effective separat<strong>ion</strong> from productive leach media, either, clean solut<strong>ion</strong> or dense pulp. Low hydrodynamic resistance by res<strong>in</strong> bed to solut<strong>ion</strong> flow <strong>in</strong> fixed beds (low pressure dropacross the bed). This is provided by narrow size distribut<strong>ion</strong> <strong>of</strong> the res<strong>in</strong> beads.<strong>Purolite</strong> produces <strong>res<strong>in</strong>s</strong> with different grad<strong>in</strong>g depend<strong>in</strong>g on particular <strong>applicat<strong>ion</strong></strong>: Pur<strong>of</strong><strong>in</strong>e grade: mean diameter 520-620 μm with uniformity coefficient 1.2 max. Special grade for RIP processes: 1% max below 710 μm and 5% max below 800 μm.9