225771-global spreader broch

225771-global spreader broch

225771-global spreader broch

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

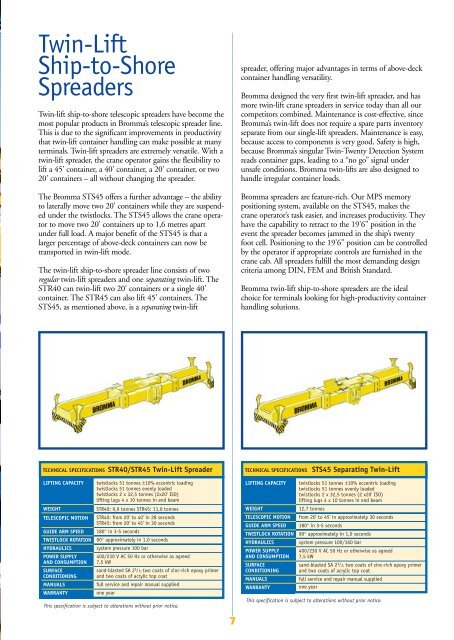

Twin-LiftShip-to-ShoreSpreadersTwin-lift ship-to-shore telescopic <strong>spreader</strong>s have become themost popular products in Bromma’s telescopic <strong>spreader</strong> line.This is due to the significant improvements in productivitythat twin-lift container handling can make possible at manyterminals. Twin-lift <strong>spreader</strong>s are extremely versatile. With atwin-lift <strong>spreader</strong>, the crane operator gains the flexibility tolift a 45' container, a 40' container, a 20' container, or two20' containers – all without changing the <strong>spreader</strong>.The Bromma STS45 offers a further advantage – the abilityto laterally move two 20' containers while they are suspendedunder the twistlocks. The STS45 allows the crane operatorto move two 20' containers up to 1,6 metres apartunder full load. A major benefit of the STS45 is that alarger percentage of above-deck containers can now betransported in twin-lift mode.The twin-lift ship-to-shore <strong>spreader</strong> line consists of tworegular twin-lift <strong>spreader</strong>s and one separating twin-lift. TheSTR40 can twin-lift two 20' containers or a single 40'container. The STR45 can also lift 45' containers. TheSTS45, as mentioned above, is a separating twin-lift<strong>spreader</strong>, offering major advantages in terms of above-deckcontainer handling versatility.Bromma designed the very first twin-lift <strong>spreader</strong>, and hasmore twin-lift crane <strong>spreader</strong>s in service today than all ourcompetitors combined. Maintenance is cost-effective, sinceBromma’s twin-lift does not require a spare parts inventoryseparate from our single-lift <strong>spreader</strong>s. Maintenance is easy,because access to components is very good. Safety is high,because Bromma’s singular Twin-Twenty Detection Systemreads container gaps, leading to a “no go” signal underunsafe conditions. Bromma twin-lifts are also designed tohandle irregular container loads.Bromma <strong>spreader</strong>s are feature-rich. Our MPS memorypositioning system, available on the STS45, makes thecrane operator’s task easier, and increases productivity. Theyhave the capability to retract to the 19'6" position in theevent the <strong>spreader</strong> becomes jammed in the ship’s twentyfoot cell. Positioning to the 19'6" position can be controlledby the operator if appropriate controls are furnished in thecrane cab. All <strong>spreader</strong>s fulfill the most demanding designcriteria among DIN, FEM and British Standard.Bromma twin-lift ship-to-shore <strong>spreader</strong>s are the idealchoice for terminals looking for high-productivity containerhandling solutions.TECHNICAL SPECIFICATIONS STR40/STR45 Twin-Lift SpreaderLIFTING CAPACITYWEIGHTTELESCOPIC MOTIONGUIDE ARM SPEEDTWISTLOCK ROTATIONHYDRAULICSPOWER SUPPLYAND CONSUMPTIONSURFACECONDITIONINGMANUALSWARRANTYtwistlocks 51 tonnes ±10% eccentric loadingtwistlocks 51 tonnes evenly loadedtwistlocks 2 x 32,5 tonnes (2x20' ISO)lifting lugs 4 x 10 tonnes in end beamSTR40: 9,9 tonnes STR45: 11,0 tonnesSTR40: from 20' to 40' in 28 secondsSTR45: from 20' to 45' in 30 seconds180° in 3-5 seconds90° approximately in 1,0 secondssystem pressure 100 bar400/230 V AC 50 Hz or otherwise as agreed7,5 kWsand-blasted SA 2 1 ⁄ 2; two coats of zinc-rich epoxy primerand two coats of acrylic top coatfull service and repair manual suppliedone yearThis specification is subject to alterations without prior notice.7TECHNICAL SPECIFICATIONS STS45 Separating Twin-LiftLIFTING CAPACITYWEIGHTTELESCOPIC MOTIONGUIDE ARM SPEEDTWISTLOCK ROTATIONHYDRAULICSPOWER SUPPLYAND CONSUMPTIONSURFACECONDITIONINGMANUALSWARRANTYtwistlocks 51 tonnes ±10% eccentric loadingtwistlocks 51 tonnes evenly loadedtwistlocks 2 x 32,5 tonnes (2 x20' ISO)lifting lugs 4 x 10 tonnes in end beam12,7 tonnesfrom 20' to 45' in approximately 30 seconds180° in 3-5 seconds90° approximately in 1,0 secondssystem pressure 100/160 bar400/230 V AC 50 Hz or otherwise as agreed7,5 kWsand-blasted SA 2 1 ⁄ 2; two coats of zinc-rich epoxy primerand two coats of acrylic top coatfull service and repair manual suppliedone yearThis specification is subject to alterations without prior notice.