Development of Optimal Cutting Plan using Linear ... - ijimt

Development of Optimal Cutting Plan using Linear ... - ijimt

Development of Optimal Cutting Plan using Linear ... - ijimt

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

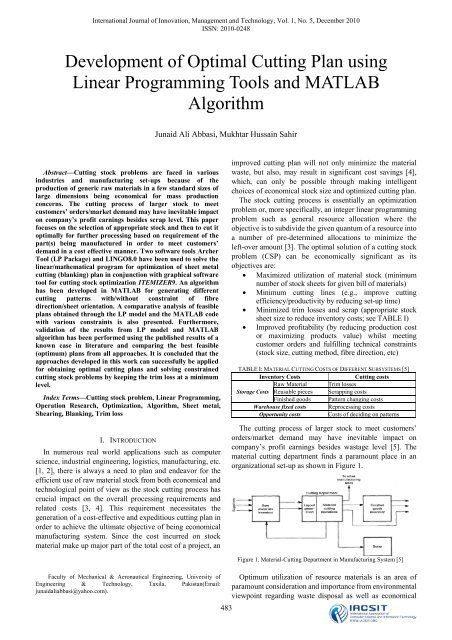

International Journal <strong>of</strong> Innovation, Management and Technology, Vol. 1, No. 5, December 2010ISSN: 2010-0248<strong>Development</strong> <strong>of</strong> <strong>Optimal</strong> <strong>Cutting</strong> <strong>Plan</strong> <strong>using</strong><strong>Linear</strong> Programming Tools and MATLABAlgorithmJunaid Ali Abbasi, Mukhtar Hussain SahirAbstract—<strong>Cutting</strong> stock problems are faced in variousindustries and manufacturing set-ups because <strong>of</strong> theproduction <strong>of</strong> generic raw materials in a few standard sizes <strong>of</strong>large dimensions being economical for mass productionconcerns. The cutting process <strong>of</strong> larger stock to meetcustomers’ orders/market demand may have inevitable impacton company’s pr<strong>of</strong>it earnings besides scrap level. This paperfocuses on the selection <strong>of</strong> appropriate stock and then to cut itoptimally for further processing based on requirement <strong>of</strong> thepart(s) being manufactured in order to meet customers’demand in a cost effective manner. Two s<strong>of</strong>tware tools ArcherTool (LP Package) and LINGO8.0 have been used to solve thelinear/mathematical program for optimization <strong>of</strong> sheet metalcutting (blanking) plan in conjunction with graphical s<strong>of</strong>twaretool for cutting stock optimization ITEMIZER9. An algorithmhas been developed in MATLAB for generating differentcutting patterns with/without constraint <strong>of</strong> fibredirection/sheet orientation. A comparative analysis <strong>of</strong> feasibleplans obtained through the LP model and the MATLAB codewith various constraints is also presented. Furthermore,validation <strong>of</strong> the results from LP model and MATLABalgorithm has been performed <strong>using</strong> the published results <strong>of</strong> aknown case in literature and comparing the best feasible(optimum) plans from all approaches. It is concluded that theapproaches developed in this work can successfully be appliedfor obtaining optimal cutting plans and solving constrainedcutting stock problems by keeping the trim loss at a minimumlevel.Index Terms—<strong>Cutting</strong> stock problem, <strong>Linear</strong> Programming,Operation Research, Optimization, Algorithm, Sheet metal,Shearing, Blanking, Trim lossI. INTRODUCTIONIn numerous real world applications such as computerscience, industrial engineering, logistics, manufacturing, etc.[1, 2], there is always a need to plan and endeavor for theefficient use <strong>of</strong> raw material stock from both economical andtechnological point <strong>of</strong> view as the stock cutting process hascrucial impact on the overall processing requirements andrelated costs [3, 4]. This requirement necessitates thegeneration <strong>of</strong> a cost-effective and expeditious cutting plan inorder to achieve the ultimate objective <strong>of</strong> being economicalmanufacturing system. Since the cost incurred on stockmaterial make up major part <strong>of</strong> the total cost <strong>of</strong> a project, animproved cutting plan will not only minimize the materialwaste, but also, may result in significant cost savings [4],which, can only be possible through making intelligentchoices <strong>of</strong> economical stock size and optimized cutting plan.The stock cutting process is essentially an optimizationproblem or, more specifically, an integer linear programmingproblem such as general resource allocation where theobjective is to subdivide the given quantum <strong>of</strong> a resource intoa number <strong>of</strong> pre-determined allocations to minimize theleft-over amount [3]. The optimal solution <strong>of</strong> a cutting stockproblem (CSP) can be economically significant as itsobjectives are:• Maximized utilization <strong>of</strong> material stock (minimumnumber <strong>of</strong> stock sheets for given bill <strong>of</strong> materials)• Minimum cutting lines (e.g., improve cuttingefficiency/productivity by reducing set-up time)• Minimized trim losses and scrap (appropriate stocksheet size to reduce inventory costs; see TABLE I)• Improved pr<strong>of</strong>itability (by reducing production costor maximizing products value) whilst meetingcustomer orders and fulfilling technical constraints(stock size, cutting method, fibre direction, etc)TABLE I: MATERIAL CUTTING COSTS OF DIFFERENT SUBSYSTEMS [5]Inventory Costs<strong>Cutting</strong> costsRaw Material Trim lossesStorage Costs Reusable pieces Scrapping costsFinished goods Pattern changing costsWarehouse fixed costs Reprocessing costsOpportunity costs Costs <strong>of</strong> deciding on patternsThe cutting process <strong>of</strong> larger stock to meet customers’orders/market demand may have inevitable impact oncompany’s pr<strong>of</strong>it earnings besides wastage level [5]. Thematerial cutting department finds a paramount place in anorganizational set-up as shown in Figure 1.Faculty <strong>of</strong> Mechanical & Aeronautical Engineering, University <strong>of</strong>Engineering & Technology, Taxila, Pakistan(Email:junaidaliabbasi@yahoo.com).483Figure 1. Material-<strong>Cutting</strong> Department in Manufacturing System [5]Optimum utilization <strong>of</strong> resource materials is an area <strong>of</strong>paramount consideration and importance from environmentalviewpoint regarding waste disposal as well as economical

International Journal <strong>of</strong> Innovation, Management and Technology, Vol. 1, No. 5, December 2010ISSN: 2010-0248concerns in many industries (e.g., wood, paper, plastic, glass,steel construction, aerospace industry, etc.). These problemstermed as ‘<strong>Cutting</strong> and Packing’ find a significant place invarious Publications/Journals like European Journal <strong>of</strong>Operational Research, International Journal <strong>of</strong> ProductionEconomics, Journal <strong>of</strong> Manufacturing Systems, InternationalJournal <strong>of</strong> Management Sciences, Ocean Engineering,Computers & Industrial Engineering. Research on cuttingstock & packing problems (knapsack) is still active withinindustrial engineering community around the world [1, 2].2-D cutting stock problem addresses allocation <strong>of</strong> arequired bill <strong>of</strong> materials onto stock sheets for minimizedtrim losses, inventory and setup costs and maximizedproduction efficiency [5-7]. The cutting stock problems canhighly degenerate as multiple solutions with the same wasteare possible because items can be moved around creatingnew patterns with no effect on waste. This problem can befixed through more constraints such asminimum-pattern-count, sequencing <strong>of</strong> the patterns to haveminimum partially completed orders at a time, type <strong>of</strong> cut(guillotine/shearing or non-guillotine e.g., stamping /punching, Sawing), number <strong>of</strong> cutting lines, maximumcut/blade length, minimum knives changes, etc [5].other useful parameters e.g., lot-sizing, due dates, sequencing,fluctuating demands and inventory control [2, 10-13], whichare very useful for industrial processes in Production,Manufacturing, Logistics, etc. Reference [14] gave amathematical modeling method, ‘mixed-integer linearprogramming’, for 1-D cutting <strong>of</strong> metallic structural tubesused in the manufacturing <strong>of</strong> agricultural light aircraftsfoc<strong>using</strong> on minimizing material trim losses by consideringthe possibility <strong>of</strong> generating reusable sized remainders(leftovers). Reference [15] proposed an optimizationalgorithm for cutting stock problems <strong>of</strong> the TFT-LCDindustry to minimize the number <strong>of</strong> glass substrates formeeting the orders and reducing production costs. Thisprovides a useful global optimum solution instead <strong>of</strong>sub-optimal feasible solution from heuristic algorithm.From the above literature survey, there is an evident needfor the formulation <strong>of</strong> analysis and evaluation mechanism <strong>of</strong>different available stock sheet sizes and anticipating optimalquantities <strong>of</strong> ordered sizes. Besides, it is also required to meetthe constraint <strong>of</strong> certain fixed quantity <strong>of</strong> some ordered sizeand direction constraint before actual cutting. This could helpchoose best stock size or otherwise propose some specificstock size for optimum utilization with minimum trim lossand scrap.Figure 2: <strong>Cutting</strong> Patterns with Guillotine Cut[5]Figure 3: <strong>Cutting</strong> Patterns with Non-Guillotine Cut[5]Mostly, manufacturing setups have to purchase rawmaterials in standard sizes, which are subsequently cut intopieces to meet market demand or requirement <strong>of</strong> the partbeing manufactured. Some need to load or pack small itemsinto large containers for transportation or storage. Although,such problems apparently seem to be different, they areactually closely related and have many aspects in common.The cutting and packing problems appear under differentnames in various publications and research/studies haveextensively been endeavored in one or more dimensions.Gilmore and Gomory’s articles on linear programmingapproaches to 1-D cutting stock problems (trim-lossminimization) were the first practical techniques published(Gilmore and Gomory 1961,1963; as cited in reference [3].Survey on 1-D/2-D cutting and packing problems and theirsolution procedures can be found in references [1, 3, 5, 6, 8,9]. <strong>Cutting</strong> stock problems have also been studied alongwith484II. RESEARCH OBJECTIVES AND METHODOLOGYThe main objective <strong>of</strong> this research work is to develop analgorithm/linear program to chalk-out cutting plan for bestutilization <strong>of</strong> steel plates <strong>of</strong> standard sizes by minimizingscrap and trim loss during the cutting process (shearing intorectangular blanks) for meeting customers’ demand in a costeffective manner. In other words, maximizing the sheet areautilization (yield); while meeting the constraints <strong>of</strong>:• <strong>Cutting</strong> direction i.e. Longitudinal or Transverse(along or across the fibre), if necessarytechnologically (i.e., length X width or L× W is notequivalent to W × L; or in other words 90° rotation isnot allowed)• No fibre direction constraint (i.e., L× W ≡ W × L; orin other words 90° sheet rotation is allowed)The optimization <strong>of</strong> cutting plan in this work will beachieved through linear programming fulfilling the objective<strong>of</strong> minimum scrap/wastage while satisfying the fibredirection constraint <strong>of</strong> stock sheet and cutting method i.e.,shearing (orthogonal rectangular cutting, edge-to-edgeguillotine cutting parallel / perpendicular to the edges <strong>of</strong> thesheet) and assuming defect-free sheet. LINGO8.0,ArcherTool (LP Package) ITEMIZER9 (Demo version),trademark s<strong>of</strong>tware tool <strong>of</strong> R&R Drummond Inc., USA, willbe employed for the LP based optimization. <strong>Development</strong> <strong>of</strong>an algorithm in MATLAB will also be considered with theaim <strong>of</strong> a comparative analysis <strong>of</strong> the results achieved fromlinear programming <strong>using</strong> LINGO8.0/ArcherTool (LPPackage) with those taken from standard cutting stockoptimization/graphics s<strong>of</strong>tware ITEMIZER9 (Demo version).In order to fully comprehend the research work, a known casefrom the published literature will be examined for validation<strong>of</strong> all approaches developed in this work by working out therespective optimal cutting plans and comparing the resultswith those <strong>of</strong> the reference [15]. Thus, it will be a unique

International Journal <strong>of</strong> Innovation, Management and Technology, Vol. 1, No. 5, December 2010ISSN: 2010-0248approach to solving the cutting stock problem as, to theauthors’ knowledge based on the literature survey; noresearch work has been carried out previously for developingthe MATLAB algorithm and validating against known casesin the published work.Figure 4 shows the schematic diagram entailing the overallprocedure adopted in this paper.whilst the area <strong>of</strong> rectangular pieces to be cut isA = L × W ; i = 1,2,3, …,n(2)i i iandor elementq is the quantity (no. <strong>of</strong> pieces) <strong>of</strong> each area segmentiA . Now, the Objective Function OB is given byi( )OB = max q A + q A + q A +… q A(3)1 1 2 2 3 3Subject to the constraints <strong>of</strong> sheet area ( cons SA ), sheetlength ( cons SL ) and sheet width ( cons SW ) ascons :( )qA+ qA + qA +…+ qA ≤ A (4)SA 1 1 2 2 3 3n nnn( )cons : qL× W W ≤ L(5)SL i i i( )cons : qW × L L ≤ W(6)SW i i iConsidering fibre direction constraint ( cons FD ), i.e.,cons : L × W ≠ W × Lleads toFD i i i i(7)qi≤ d(8)iFigure 4: Scheme <strong>of</strong> the ResearchThe approaches developed in this work not only simplifythe selection <strong>of</strong> appropriate stock sheet size whilst optimizingyield and minimizing scrap level to meet economical aspects,but also, can calculate percentage utilization and wastagefraction meeting fibre direction constraint and may be used toclosely estimate bill <strong>of</strong> material and optimum quantities <strong>of</strong>different sizes before the actual cutting process.III. MODEL DEVELOPMENT FOR OPTIMAL CUTTING STOCKPLAN (ORTHOGONAL CUTTING)A. LP ModelAn LP-based approach is employed to solvetwo-dimensional constrained cutting stock problems so as tominimize trim loss/waste (un-usable leftover) and as suchoptimize material stock utilization while meetingtechnological constraint <strong>of</strong> cutting direction (longitudinal /transverse). It is assumed that stock sheet is free <strong>of</strong> any defecthaving uniform sheet thickness.Let, total useful area A <strong>of</strong> a defect-free stock sheet <strong>of</strong>uniform thickness t is given byA = L× W ( = Length× Width)(1)where d (ratio <strong>of</strong> the two areas) for longitudinal (alongifibre direction) cutting is(( ) ( ))AA= LL × WW(9)i i ior for transverse (across fibre) direction, it becomes(( ) ( ))A A = L W × W L(10)i i iWith no fibre direction constraint ( cons FD ) it becomescons : L × W = W × L(11)thenqiFD i i i i≤ d(12)iwith the ratio <strong>of</strong> two areas ( d ) beingiA ⎛⎛ L×W ⎞ ⎛ L W ⎞ ⎛ L W ⎞⎞= max ⎜& × &×⎟A ⎜⎜ L × W ⎟ ⎜ L W ⎟ ⎜W L ⎟⎟i ⎝⎝ i i ⎠ ⎝ i i ⎠ ⎝ i i ⎠⎠(13)Further, it is assumed that integer value <strong>of</strong> the ratios <strong>of</strong> area(( L× W) ( L × W )i i) and length/width ( L L ) ( W W )ii( ),( ), ,L W W L are taken and the fractional (decimal) partsiiare ignored and that non-negative values <strong>of</strong> areas, lengths,widths and quantities are taken [5, 16, 17], i.e.,485

( )International Journal <strong>of</strong> Innovation, Management and Technology, Vol. 1, No. 5, December 2010ISSN: 2010-0248all AA , , LLWW , , , , q ≥ 0 (14)i i i iB. Matlab AlgorithmA MATLAB algorithm <strong>using</strong> linear programming hasbeen developed for seeking optimal cutting plan forcomparison and verification <strong>of</strong> the results obtained throughArcherTool (LP Package), LINGO8.0 and cutting stockoptimization s<strong>of</strong>tware ITEMIZER9. This algorithm providesthe optimal values <strong>of</strong> decision variables (quantity <strong>of</strong> items)with step-by-step display <strong>of</strong> the cutting process for anenhanced visualization <strong>of</strong> the cutting plan.A detailed layout plan for the algorithm implementation isshown in Figure 5.IV. RESULTS ANALYSIS AND DISCUSSIONIn this section, a comparative analysis <strong>of</strong> the results fromArcherTool (LP Package)/LINGO8.0 s<strong>of</strong>tware inconjunction with the those from MATLAB Algorithm andthe <strong>Cutting</strong> stock Optimization/Graphics s<strong>of</strong>tware‘ITEMIZER9’ is presented. For this, the results have beencompiled in tabular form and comparative analysis illustratedthrough graph drawn for various combinations <strong>of</strong> inputvariables and the yield.Figure 5: Scheme/Sequential Implementation <strong>of</strong> MATLAB Algorithm /codeA. Generating LP based ArcherTool/LINGO8.0 Model forSame Sized Item(s)From the TABLE II & TABLE III it is revealed that resultsobtained through LP model solved byArcherTool/LINGO8.0 in conjunction with cuttingoptimization s<strong>of</strong>tware ‘ITEMIZER9’are in agreement withthose derived from the application <strong>of</strong> MATLAB algorithm.Graphical representation shown in Figure 6 to Figure 9depicts the change in yield and their percentage values forvarious stock sheet and items sizes.TABLE II: YIELD(S) FOR DIFFERENT SHEETS WITH SAME ITEMS (ARCHERTOOL/LINGO8.0 & ITEMIZER9)Stock Size Item SizeLP Model Yield or Area utilizationOption (cm) (cm) With Fibre Direction Constraint Without OrientationRemarksL×W L × W Longitudinal TransverseConstrainti iPieces %yield Pieces %yield Pieces %yield1 300x150 30x15 100 100% 100 100% 100 100% L | L, W & W | W,Li i i i2 250x125 30x15 64 92.2% 64 92.2% 64 92.2% L? L W & W?W Li i i i3 240x120 30x15 64 100% 64 100% 64 100% L | L, W & W | W,Li i i i4 300x150 50x40 18 80% 21 93.3% 21 93.3% L , W | L & L , W W5 300x150 40x30 35 93.3% 30 80% 37 98.7% L , W | W & L , W L6 300x150 30x20 70 93.3% 75 100% 75 100% L, W | L, L| W, WWiii i i7 300x150 40x20 49 87.1% 45 80% 52 92.4% L | W, L? L W?W Li i i i8 300x150 25x15 120 100% 120 100% 120 100% L | L, W & W | W,Li i i iii486

International Journal <strong>of</strong> Innovation, Management and Technology, Vol. 1, No. 5, December 2010ISSN: 2010-0248TABLE III: YIELD(S) FOR DIFFERENT SHEETS WITH SAME ITEMS (MATLAB ALGORITHM)Stock Size Item SizeYield or Area utilizationRemarksOption (cm) (cm) With Fibre Direction Constraint Without Orientation(| ≡ divisibility &L×W L × W Longitudinal TransverseConstraint† ≡ non-divisibility)i iPieces %yield Pieces %yield Pieces %yield1 300x150 30x15 100 100% 100 100% 100 100% L | L, W & W | W,Li i i i2 250x125 30x15 64 92.2% 64 92.2% 64 92.2% L? L W & W?W Li i i i3 240x120 30x15 64 100% 64 100% 64 100% L | L, W & W | W,Li i i i4 300x150 50x40 18 80% 21 93.3% 21 93.3% L , W | L & L , W W5 300x150 40x30 35 93.3% 30 80% 37 98.7% L , W | W & L , W L6 300x150 30x20 70 93.3% 75 100% 75 100% L, W | L, L| W, WWiii i i7 300x150 40x20 49 87.1% 45 80% 52 92.4% L | W, L? L W?W Li i i i8 300x150 25x15 120 100% 120 100% 120 100% L | L, W & W | W,Li i i iiiFigure 6: Change in Yield with Stock Size for Same Sized ItemsFigure 7: Change in Percentage Yield with Stock Size for Same Sized ItemsFigure 8: Change in Yield with Items’ Size for Same Sized StockB. LP based ArcherTool/LINGO8.0 Model forCombinations <strong>of</strong> Different ItemsFrom the TABLE IV & TABLE V, it is revealed fromFigure 9: Change in Percentage Yield with Items’ Size for Same Sized Stock487results obtained through that LP model solved throughArcherTool/LINGO8.0 are in agreement with those derivedfrom the application <strong>of</strong> S<strong>of</strong>tware ‘ITEMIZER9’. This verifiesour LP model developed for the optimal cutting plan.

International Journal <strong>of</strong> Innovation, Management and Technology, Vol. 1, No. 5, December 2010ISSN: 2010-0248OptionStock Size(cm)L×WTABLE IV: YIELD(S) FOR CUTTING DIFFERENT SIZED ITEMS (ARCHERTOOL/LINGO8.0)Item Size (cm)LP Model Yield or Area utilization with Fibre Direction ConstraintLongitudinalTransverseL × W L × WPiecesPieces1 12 2% Yield% Yieldq11 300x150 30x15 20x10 100 0 100% 100 0 100%2 300x150 40x20 70x40 49 2 99.56% 42 4 99.56%3 300x150 25x15 15x10 120 0 100% 120 0 100%4 300x150 30x15 15x10 100 0 100% 100 0 100%OptionStock Size(cm)L×Wq2TABLE V: YIELD(S) FOR CUTTING DIFFERENT SIZED ITEMS (ITEMIZER9)Item Size (cm)LP Model Yield or Area utilization with Fibre Direction ConstraintLongitudinalTransverseL × W L × WPiecesPieces1 12 2% yield% yieldq11 300x150 30x15 20x10 100 0 100% 100 0 100%2 300x150 40x20 70x40 49 2 99.56% 42 4 99.56%3 300x150 25x15 15x10 120 0 100% 120 0 100%4 300x150 30x15 15x10 100 0 100% 100 0 100%q2q1q1q2q2V. VERIFICATION/VALIDATION OF MATLAB ALGORITHMAND LP MODELResults from the MATLAB algorithm have been comparedand found consistent with those from ArcherTool, LINGO8.0and ITEMIZER9.In order to further verify/validate the functionality <strong>of</strong> theMATLAB algorithm as well as LP model against somedocumented cutting stock problem, a case from the reference[15] has been taken whose solution is already known,. Then,solution from all approaches are obtained <strong>using</strong> the referenceinput values <strong>of</strong> the stock sheet and the items to be cut, asgiven in TABLE 6. The reference optimal cutting plan will bea baseline against which the optimal cutting plans from themethods <strong>of</strong> this paper will be compared and evaluated.Thus, if the results <strong>of</strong> the approaches match with those fromthe reference paper, their validity will be established and viceversa.A. Comparison <strong>of</strong> ResultsFigure 10 shows the pictorial view <strong>of</strong> the optimal cuttingplan from the reference paper [15] for the said case whilst theoptimal cutting plan from MATLAB algorithm is shown inthe Figure 11 and Figure 12. Moreover, cutting plan and theirresults screen shots <strong>of</strong> all LP model approaches are shown inFigure 13 and Figure 14 whilst Figure 15 shows the screenshot <strong>of</strong> the result obtained through the <strong>Cutting</strong> OptimizationS<strong>of</strong>tware: ITEMIZER9.For the sake <strong>of</strong> a quick and better comparison <strong>of</strong> the resultsfrom all approaches, the output values are tabulated inTABLE VI including those from the original paper. It isevident from the results that all approaches are in compliancewith each other and lead to the same results. Hence it can beinferred that the MATLAB algorithm as well as LP model foroptimal cutting plan developed in this work are valid andconsistent with each other.B. Graphical Representation <strong>of</strong> ResultsResults from the original paper and those from theapproaches <strong>of</strong> this paper are shown below.TABLE VI: COMPARISON RESULTS FROM ALL APPROACHES WITH THE REFERENCE CASEStock Size (cm) 180x150 Item Size (cm) 90x56<strong>Optimal</strong> <strong>Cutting</strong> Solution No. <strong>of</strong> Items Objective Value PercentageWasteApproach UsedCut(Yield)YieldFractionReference Case[15]5 25200 93.33% 0.067MATLAB Algorithm – Cut Across Then AlongFibre (Sheet Rotated)5 25200 93.33% 0.067ArcherTool LP Model –No Direction Constraint5 25200 93.33% 0.067LINGO8.0 LP Model –No Direction Constraint5 25200 93.33% 0.067ITEMIZER9 Graphic Solution –CSP Optimization5 25200 93.33% 0.067488

International Journal <strong>of</strong> Innovation, Management and Technology, Vol. 1, No. 5, December 2010ISSN: 2010-0248Figure 10: <strong>Optimal</strong> <strong>Cutting</strong> <strong>Plan</strong> from the Reference [15]Figure 11: Sequence <strong>of</strong> MATLAB Algorithm (Sheet Rotated 90°)150135120105<strong>Cutting</strong> along fibre180162144126<strong>Cutting</strong> across fibreWidth - Across Fibre (cm) →9075604530150Length - Along Fibre (cm) →108907254361800 18 36 54 72 90 108 126 144 162 1800 15 30 45 60 75 90 105 120 135 150Length - Along Fibre (cm) →Width - Across Fibre (cm) →Figure 12: All Possible <strong>Cutting</strong> <strong>Plan</strong>s from MATLAB Algorithm (Sheet Rotated 90°)489

International Journal <strong>of</strong> Innovation, Management and Technology, Vol. 1, No. 5, December 2010ISSN: 2010-0248Figure 13: ArcherTool LP Model Solution Screen Shots - No Direction Constraint490

International Journal <strong>of</strong> Innovation, Management and Technology, Vol. 1, No. 5, December 2010ISSN: 2010-0248Figure 14: LINGO8.0 LP Model Solution Screen Shots - No Direction ConstraintFigure 15: ITEMIZER9 Graphic Solution Screen for <strong>Cutting</strong> Stock OptimizationVI. CONCLUSIONSFrom the tables & graphs compiled in earlier sections, it isevident that larger sizes <strong>of</strong> stock sheet can yield into higherutilization with lesser wastage as obvious. The percentageyield is at maximum when stock sheet size is integral multiple<strong>of</strong> the Least Common Multiple (L.C.M.) <strong>of</strong> lengths & widths<strong>of</strong> items being cut. Moreover, it is revealed that total yieldand, hence, wastage fraction depends upon the cuttingdirection, orientation and divisibility <strong>of</strong> respective stock anditem length and width.LINGO8.0 has an advantage <strong>of</strong> integer constraint optionon the decision variable, which is not available from ArcherTool (LP Package). On the other hand, the latter isuser-friendly and easy-to-use as no specific programmingsyntax is required and the only input required is <strong>of</strong> the value<strong>of</strong> coefficients <strong>of</strong> decision variables. The MATLABalgorithm provides the optimal value <strong>of</strong> the decisionvariables with the layout display for enhanced visualization<strong>of</strong> the cutting plan whilst the ITEMIZER9 requires thequantity input <strong>of</strong> the decision variables and then displays thecorresponding layout <strong>of</strong> the cutting plan. In addition toconformity <strong>of</strong> the results from MATLAB Algorithm withother approaches, further verification/validation <strong>of</strong> allapproaches has been achieved through comparison with aknown case in reference [15].Blanking outline size from large stock size for specificcomponent is very common in almost all types <strong>of</strong>manufacturing set-ups from woodworking, steel fabricationto aerospace industry. So, this work will help enhanceproductivity and pr<strong>of</strong>itability <strong>of</strong> a manufacturing industrythrough optimum utilization <strong>of</strong> available material,minimizing scrap/trim losses and inventory storage costs bymeeting applicable constraints and customer’s needs.This work may also be utilized for assessing differentstock sizes or to order specific stock sheet size yieldingmaximum utilization and minimum waste while meetingcustomer’s demand. As the MATLAB code/LP model can beapplied prior to actual cutting/placing <strong>of</strong> procurement orderfor appropriate stock sheet, one can save precious materialand curtail its budget keeping in view the worldwideeconomic crisis.491

International Journal <strong>of</strong> Innovation, Management and Technology, Vol. 1, No. 5, December 2010ISSN: 2010-0248ACKNOWLEDGMENTThe first author is thankful to Dr. Asim Ali Abbasi andEngr. Aamir Raza for providing valuable help in manyconceptual and computational aspects <strong>of</strong> this work.REFERENCES[1] Cheng, C.H., B.R. Feiring, and T.C.E. Cheng, The cutting stockproblem — a survey. International Journal <strong>of</strong> Production Economics,1994. 36(3): p. 291-305.[2] Gramani, M.C.N. and P.M. Franca, The combined cutting stock andLot-sizing problem in industrial processes. European Journal <strong>of</strong>Operational Research, 2006. 174(1): p. 509-521.[3] Haessler, R.W. and P.E. Sweeney, <strong>Cutting</strong> stock problems and solutionprocedures. European Journal <strong>of</strong> Operational Research, 1991. 54(2): p.141-150.[4] http://www.scoop-project.net (Accessed on April 01, 2010).[5] Israni, S. and J. Sanders, Two-dimensional cutting stock problemresearch: A review and a new rectangular layout algorithm. Journal <strong>of</strong>Manufacturing Systems, 1982. 1(2): p. 169-182.[6] Blazewicz, J., et al., Two-Dimensional <strong>Cutting</strong> Problem, BasicComplexity Results and Algorithms for Irregular Shapes. Foundations<strong>of</strong> Control Engineering, 1989. 14(4): p. 137-160.[7] Cui, Y., D. He, and X. Song, Generating <strong>Optimal</strong> Two-Sectional<strong>Cutting</strong> Patterns for Rectangular Blanks. Journal <strong>of</strong> Computers &Operations Research, 2006. 33(1): p. 1505-1520.[8] Wäscher, G., An LP-based approach to cutting stock problems withmultiple objectives. European Journal <strong>of</strong> Operational Research, 1990.44(2): p. 175-184.[9] Haessler, R.W., One-Dimensional <strong>Cutting</strong> Stock Problems andSolution Procedures. Mathl. Comput. Modelling, 1992. 16(1): p. 1-8.[10] Yanasse, H.H. and M.J.P. Lamosa, An Integrated <strong>Cutting</strong> Stock andSequencing Problem. European Journal <strong>of</strong> Operational Research, 2007.183(1): p. 1353-1370.[11] Trkman, P. and M. Gradisar, One-Dimensional <strong>Cutting</strong> StockOptimization in Consecutive Time Periods. European Journal <strong>of</strong>Operational Research, 2007. 179(1): p. 291-301.[12] Cui, Y., T. Gu, and W. Hu, A cutting-and-inventory control problem inthe manufacturing industry <strong>of</strong> stainless steel wares. Omega, TheInternational Journal <strong>of</strong> Management Science, 2009. 37(1): p. 864-875.[13] Reinertsen, H. and T.W.M. Vossen, The One-Dimensional <strong>Cutting</strong>Stock Problems with Due Dates. European Journal <strong>of</strong> OperationalResearch, 2010. 201(3): p. 701-711.[14] Abuabara, A. and R. Morabito, <strong>Cutting</strong> Optimization <strong>of</strong> StructuralTubes to Build Agricultural Light Aircraft. Ann Oper Res, 2009.169(1): p. 149-165.[15] Tsai, J.-F., P.L. Hsieh, and Y.-H. Huang, An Optimization Algorithmfor <strong>Cutting</strong> Stock problems in the TFT-LCD industry. Journal <strong>of</strong>Computers & Industrial Engineering, 2009. 57(3): p. 913-919.[16] Hifi, M. and R.M. Hallah, Strip Generation Algorithms for constrainedTwo-dimensional two-staged cutting problems. European Journal <strong>of</strong>Operational Research, 2006. 172 (1): p. 515-527.[17] Dikili, A.C., A.C. Takinaci, and N.A. Pek, A new Heuristic approach toone-dimensional stock-cutting problems with multiple stock lengths inship production. Ocean Engineering, 2008. 35 (1): p. 637-645.492