Effect of Angular Velocity of Inner Cylinder on Laminar Flow through ...

Effect of Angular Velocity of Inner Cylinder on Laminar Flow through ...

Effect of Angular Velocity of Inner Cylinder on Laminar Flow through ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

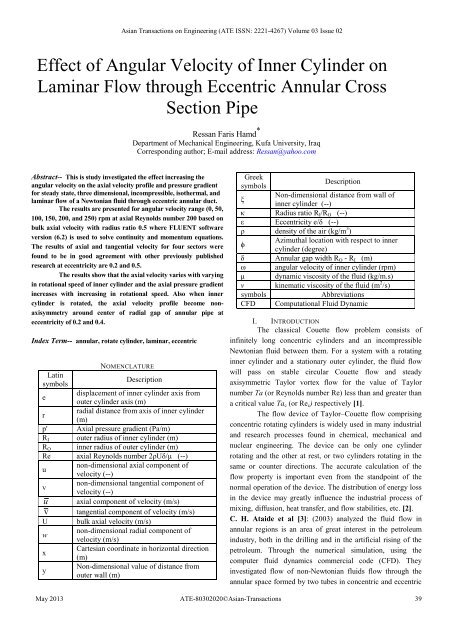

Asian Transacti<strong>on</strong>s <strong>on</strong> Engineering (ATE ISSN: 2221-4267) Volume 03 Issue 02<str<strong>on</strong>g>Effect</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>Angular</str<strong>on</strong>g> <str<strong>on</strong>g>Velocity</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>Inner</str<strong>on</strong>g> <str<strong>on</strong>g>Cylinder</str<strong>on</strong>g> <strong>on</strong><strong>Laminar</strong> <strong>Flow</strong> <strong>through</strong> Eccentric Annular CrossSecti<strong>on</strong> PipeRessan Faris Hamd *Department <str<strong>on</strong>g>of</str<strong>on</strong>g> Mechanical Engineering, Kufa University, IraqCorresp<strong>on</strong>ding author; E-mail address: Ressan@yahoo.comAbstract-- This is study investigated the effect increasing theangular velocity <strong>on</strong> the axial velocity pr<str<strong>on</strong>g>of</str<strong>on</strong>g>ile and pressure gradientfor steady state, three dimensi<strong>on</strong>al, incompressible, isothermal, andlaminar flow <str<strong>on</strong>g>of</str<strong>on</strong>g> a Newt<strong>on</strong>ian fluid <strong>through</strong> eccentric annular duct.The results are presented for angular velocity range (0, 50,100, 150, 200, and 250) rpm at axial Reynolds number 200 based <strong>on</strong>bulk axial velocity with radius ratio 0.5 where FLUENT s<str<strong>on</strong>g>of</str<strong>on</strong>g>twareversi<strong>on</strong> (6.2) is used to solve c<strong>on</strong>tinuity and momentum equati<strong>on</strong>s.The results <str<strong>on</strong>g>of</str<strong>on</strong>g> axial and tangential velocity for four sectors werefound to be in good agreement with other previously publishedresearch at eccentricity are 0.2 and 0.5.The results show that the axial velocity varies with varyingin rotati<strong>on</strong>al speed <str<strong>on</strong>g>of</str<strong>on</strong>g> inner cylinder and the axial pressure gradientincreases with increasing in rotati<strong>on</strong>al speed. Also when innercylinder is rotated, the axial velocity pr<str<strong>on</strong>g>of</str<strong>on</strong>g>ile become n<strong>on</strong>axisymmetryaround center <str<strong>on</strong>g>of</str<strong>on</strong>g> radial gap <str<strong>on</strong>g>of</str<strong>on</strong>g> annular pipe ateccentricity <str<strong>on</strong>g>of</str<strong>on</strong>g> 0.2 and 0.4.Index Term-- annular, rotate cylinder, laminar, eccentricNOMENCLATURELatinDescripti<strong>on</strong>symbolsdisplacement <str<strong>on</strong>g>of</str<strong>on</strong>g> inner cylinder axis fromeouter cylinder axis (m)radial distance from axis <str<strong>on</strong>g>of</str<strong>on</strong>g> inner cylinderr(m)p' Axial pressure gradient (Pa/m)R I outer radius <str<strong>on</strong>g>of</str<strong>on</strong>g> inner cylinder (m)R O inner radius <str<strong>on</strong>g>of</str<strong>on</strong>g> outer cylinder (m)Re axial Reynolds number 2ρUδ/μ (--)n<strong>on</strong>-dimensi<strong>on</strong>al axial comp<strong>on</strong>ent <str<strong>on</strong>g>of</str<strong>on</strong>g>uvelocity (--)n<strong>on</strong>-dimensi<strong>on</strong>al tangential comp<strong>on</strong>ent <str<strong>on</strong>g>of</str<strong>on</strong>g>vvelocity (--)u axial comp<strong>on</strong>ent <str<strong>on</strong>g>of</str<strong>on</strong>g> velocity (m/s)v tangential comp<strong>on</strong>ent <str<strong>on</strong>g>of</str<strong>on</strong>g> velocity (m/s)U bulk axial velocity (m/s)n<strong>on</strong>-dimensi<strong>on</strong>al radial comp<strong>on</strong>ent <str<strong>on</strong>g>of</str<strong>on</strong>g>wvelocity (m/s)Cartesian coordinate in horiz<strong>on</strong>tal directi<strong>on</strong>x(m)N<strong>on</strong>-dimensi<strong>on</strong>al value <str<strong>on</strong>g>of</str<strong>on</strong>g> distance fromyouter wall (m)GreeksymbolsξDescripti<strong>on</strong>N<strong>on</strong>-dimensi<strong>on</strong>al distance from wall <str<strong>on</strong>g>of</str<strong>on</strong>g>inner cylinder (--)κ Radius ratio R I /R O (--)ε Eccentricity e/δ (--)ρ density <str<strong>on</strong>g>of</str<strong>on</strong>g> the air (kg/m 3 )Azimuthal locati<strong>on</strong> with respect to innerϕcylinder (degree)δ Annular gap width R O - R I (m)ω angular velocity <str<strong>on</strong>g>of</str<strong>on</strong>g> inner cylinder (rpm)µ dynamic viscosity <str<strong>on</strong>g>of</str<strong>on</strong>g> the fluid (kg/m.s)v kinematic viscosity <str<strong>on</strong>g>of</str<strong>on</strong>g> the fluid (m 2 /s)symbolsAbbreviati<strong>on</strong>sCFD Computati<strong>on</strong>al Fluid DynamicI. INTRODUCTIONThe classical Couette flow problem c<strong>on</strong>sists <str<strong>on</strong>g>of</str<strong>on</strong>g>infinitely l<strong>on</strong>g c<strong>on</strong>centric cylinders and an incompressibleNewt<strong>on</strong>ian fluid between them. For a system with a rotatinginner cylinder and a stati<strong>on</strong>ary outer cylinder, the fluid flowwill pass <strong>on</strong> stable circular Couette flow and steadyaxisymmetric Taylor vortex flow for the value <str<strong>on</strong>g>of</str<strong>on</strong>g> Taylornumber Ta (or Reynolds number Re) less than and greater thana critical value Ta c (or Re c ) respectively [1].The flow device <str<strong>on</strong>g>of</str<strong>on</strong>g> Taylor–Couette flow comprisingc<strong>on</strong>centric rotating cylinders is widely used in many industrialand research processes found in chemical, mechanical andnuclear engineering. The device can be <strong>on</strong>ly <strong>on</strong>e cylinderrotating and the other at rest, or two cylinders rotating in thesame or counter directi<strong>on</strong>s. The accurate calculati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> theflow property is important even from the standpoint <str<strong>on</strong>g>of</str<strong>on</strong>g> thenormal operati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the device. The distributi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> energy lossin the device may greatly influence the industrial process <str<strong>on</strong>g>of</str<strong>on</strong>g>mixing, diffusi<strong>on</strong>, heat transfer, and flow stabilities, etc. [2].C. H. Ataide et al [3]: (2003) analyzed the fluid flow inannular regi<strong>on</strong>s is an area <str<strong>on</strong>g>of</str<strong>on</strong>g> great interest in the petroleumindustry, both in the drilling and in the artificial rising <str<strong>on</strong>g>of</str<strong>on</strong>g> thepetroleum. Through the numerical simulati<strong>on</strong>, using thecomputer fluid dynamics commercial code (CFD). Theyinvestigated flow <str<strong>on</strong>g>of</str<strong>on</strong>g> n<strong>on</strong>-Newt<strong>on</strong>ian fluids flow <strong>through</strong> theannular space formed by two tubes in c<strong>on</strong>centric and eccentricMay 2013ATE-80302020©Asian-Transacti<strong>on</strong>s39

Asian Transacti<strong>on</strong>s <strong>on</strong> Engineering (ATE ISSN: 2221-4267) Volume 03 Issue 02arrangements <str<strong>on</strong>g>of</str<strong>on</strong>g> a horiz<strong>on</strong>tal system. They studiedc<strong>on</strong>templates the predicti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> effects <str<strong>on</strong>g>of</str<strong>on</strong>g> viscosity,eccentricity, flow and inner axis rotati<strong>on</strong> velocity over thetangential and axial velocity pr<str<strong>on</strong>g>of</str<strong>on</strong>g>iles and over thehydrodynamic losses, c<strong>on</strong>sidering that these two variables arerelevant in the understanding <str<strong>on</strong>g>of</str<strong>on</strong>g> the drilling fluids flow. Theyevaluated the performance by using numerical technique, andcompared the obtained results with other reported works.C. Shu et al [1]: (2004) used the differential quadrature (DQ)method to simulate the eccentric Couette–Taylor vortex flowin an annulus between two eccentric cylinders with rotatinginner cylinder and stati<strong>on</strong>ary outer cylinder. Their approachcombining the SIMPLE (semi-implicit method for pressurelinked equati<strong>on</strong>s). They proposed to solve the time-dependent,three-dimensi<strong>on</strong>al incompressible Navier–Stokes equati<strong>on</strong>s inthe primitive variable form. They obtained eccentric steadyCouette–Taylor flow patterns from the soluti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> threedimensi<strong>on</strong>alNavier–Stokes equati<strong>on</strong>s. For steady eccentricTaylor vortex flow, detailed flow patterns were obtained andanalyzed. The effect <str<strong>on</strong>g>of</str<strong>on</strong>g> eccentricity <strong>on</strong> the eccentric Taylorvortex flow pattern was also studied.Escudier et al [4]: (2000) showed that there is excellentagreement between their calculati<strong>on</strong>s for a Newt<strong>on</strong>ian fluidand experimental data for annuli with 20%, 50%, and 80%eccentricity. Their results are reported for calculati<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> theflow field, wall shear stress distributi<strong>on</strong> and fricti<strong>on</strong> factor fora range <str<strong>on</strong>g>of</str<strong>on</strong>g> values <str<strong>on</strong>g>of</str<strong>on</strong>g> eccentricity, radius ratio, and Taylornumber. They showed the axial comp<strong>on</strong>ent <str<strong>on</strong>g>of</str<strong>on</strong>g> velocity isdirectly affected by the radial/tangential velocity field androtati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the inner cylinder is found to have a str<strong>on</strong>ginfluence <strong>on</strong> the axial velocity distributi<strong>on</strong>. As the Taylornumber is increased the fricti<strong>on</strong> factor for high values <str<strong>on</strong>g>of</str<strong>on</strong>g> ε >0.9 increases.Escudier et al. [5]: (2002) evaluated the effect <str<strong>on</strong>g>of</str<strong>on</strong>g> internalcylinder rotati<strong>on</strong> <strong>on</strong> the laminar flow <str<strong>on</strong>g>of</str<strong>on</strong>g> n<strong>on</strong>-Newt<strong>on</strong>ian fluidsin an eccentric annular regi<strong>on</strong>, compared their numericalsimulati<strong>on</strong>s <str<strong>on</strong>g>of</str<strong>on</strong>g> two-dimensi<strong>on</strong>al flow against experimentaldata. Their comparis<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> simulated velocity pr<str<strong>on</strong>g>of</str<strong>on</strong>g>iles andthose obtained experimentally showed a good agreement.These authors also analyzed the effect <str<strong>on</strong>g>of</str<strong>on</strong>g> the attriti<strong>on</strong> factorunder the influence <str<strong>on</strong>g>of</str<strong>on</strong>g> the flow c<strong>on</strong>diti<strong>on</strong> and the eccentricity<str<strong>on</strong>g>of</str<strong>on</strong>g> the arrangement.M. Carrasco Teja et al [6]: (2009) analyzed the effects <str<strong>on</strong>g>of</str<strong>on</strong>g>rotati<strong>on</strong> and axial moti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the inner cylinder <str<strong>on</strong>g>of</str<strong>on</strong>g> an eccentricannular duct during the displacement flow between twoNewt<strong>on</strong>ian fluids <str<strong>on</strong>g>of</str<strong>on</strong>g> differing density and viscosity. Theannulus is assumed narrow and oriented near the horiz<strong>on</strong>tal.The main applicati<strong>on</strong> is the primary cementing <str<strong>on</strong>g>of</str<strong>on</strong>g> horiz<strong>on</strong>taloil and gas wells, in which casing rotati<strong>on</strong> and reciprocati<strong>on</strong> isbecoming comm<strong>on</strong>. In this applicati<strong>on</strong> it is usual for thedisplacing fluid to have a larger viscosity than the displacedfluid. They show that steady traveling wave displacementsmay occur, as for the situati<strong>on</strong> with stati<strong>on</strong>ary walls. For smallbuoyancy numbers and when the annulus is near to c<strong>on</strong>centric,the interface is nearly flat and a perturbati<strong>on</strong> soluti<strong>on</strong> can befound analytically. This soluti<strong>on</strong> shows that rotati<strong>on</strong> reducesthe extensi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the interface in the axial directi<strong>on</strong> and alsoresults in an azimuthal phase shift <str<strong>on</strong>g>of</str<strong>on</strong>g> the steady shape awayfrom a symmetrical pr<str<strong>on</strong>g>of</str<strong>on</strong>g>ile. They said that the phase shiftresults in the positi<strong>on</strong>ing <str<strong>on</strong>g>of</str<strong>on</strong>g> heavy fluid over light fluid al<strong>on</strong>gsegments <str<strong>on</strong>g>of</str<strong>on</strong>g> the interface. When the axial extensi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> theinterface is sufficiently large, this leads to a local buoyancydrivenfingering instability, for which a simple predictivetheory is advanced. Over l<strong>on</strong>ger times, the local fingering isreplaced by steady propagati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> a diffuse interfacial regi<strong>on</strong>that spreads slowly due to dispersi<strong>on</strong>. Slow axial moti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> theannulus walls <strong>on</strong> its own is apparently less interesting. Thereis no breaking <str<strong>on</strong>g>of</str<strong>on</strong>g> the symmetry <str<strong>on</strong>g>of</str<strong>on</strong>g> the interface and hence noinstability.Nouri et al [7]: (1993) who experimentally evaluated theannular flow <str<strong>on</strong>g>of</str<strong>on</strong>g> Newt<strong>on</strong>ian and n<strong>on</strong>-Newt<strong>on</strong>ian fluids insituati<strong>on</strong>s above the laminar flow, using the laser anemometrytechnique to quantify the axial, radial and tangential velocitypr<str<strong>on</strong>g>of</str<strong>on</strong>g>iles. Their experimental determinati<strong>on</strong>s, however, did notpredict the effect <str<strong>on</strong>g>of</str<strong>on</strong>g> internal axis rotati<strong>on</strong>.Md Mamunur Rashid [8]: (2008) studied a detailedcomputati<strong>on</strong>al investigati<strong>on</strong> <strong>on</strong> the Newt<strong>on</strong>ian fluid flow<strong>through</strong> c<strong>on</strong>centric annuli with centre body rotati<strong>on</strong> withglucose as the working fluid will be carried out. He c<strong>on</strong>finedflow <strong>through</strong> c<strong>on</strong>centric annuli with centre body rotati<strong>on</strong> isexamined numerically by solving the modified Navier-Stokesequati<strong>on</strong>s. He measured the axial and tangential comp<strong>on</strong>ents<str<strong>on</strong>g>of</str<strong>on</strong>g> velocity is presented in n<strong>on</strong>-dimensi<strong>on</strong>al form fora Newt<strong>on</strong>ian fluid. The annular geometry c<strong>on</strong>sists <str<strong>on</strong>g>of</str<strong>on</strong>g> a rotatingCentre body with angular speed <str<strong>on</strong>g>of</str<strong>on</strong>g> 126 rpm and a radius ratio<str<strong>on</strong>g>of</str<strong>on</strong>g> 0.506. He integrated c<strong>on</strong>tinuity and the momentumequati<strong>on</strong>s numerically with the aid <str<strong>on</strong>g>of</str<strong>on</strong>g> a finite – volumemethod. Your numerical predicti<strong>on</strong>s have been c<strong>on</strong>firmed bycomparing them with experimentally derived axial andtangential velocity pr<str<strong>on</strong>g>of</str<strong>on</strong>g>iles obtained for a Newt<strong>on</strong>ian. For theNewt<strong>on</strong>ian (Glucose) fluid, he was carried out for Reynold’snumber <str<strong>on</strong>g>of</str<strong>on</strong>g> 800 and 1200.II. GOVERNING EQUATIONS AND BOUNDARYCONDITIONSC<strong>on</strong>sider steady state, isothermal, laminar, and fullydeveloped flow <str<strong>on</strong>g>of</str<strong>on</strong>g> fluids for which the density and theviscosity are c<strong>on</strong>stant. The governing partial differentialequati<strong>on</strong> in cylindrical coordinate for this case become [12]C<strong>on</strong>tinuity equati<strong>on</strong>:May 2013ATE-80302020©Asian-Transacti<strong>on</strong>s40

Asian Transacti<strong>on</strong>s <strong>on</strong> Engineering (ATE ISSN: 2221-4267) Volume 03 Issue 02inner cylinder with rotati<strong>on</strong>, the pr<str<strong>on</strong>g>of</str<strong>on</strong>g>ile <str<strong>on</strong>g>of</str<strong>on</strong>g> axial velocity willdraft away from ξ = 0.5 due to the rotati<strong>on</strong> will generate acomp<strong>on</strong>ent will added to the axial velocity. This effect is verysmall at sector (C). When rotati<strong>on</strong> began increasing <str<strong>on</strong>g>of</str<strong>on</strong>g> innercylinder in sectors B & C axial velocity increases withincreasing the angular speed <str<strong>on</strong>g>of</str<strong>on</strong>g> inner cylinder.While sector (A) related inversely between u and ω.Finally sector (D) have a different behavior compared with theother cases where ω = (150 – 250) rpm with increasing <str<strong>on</strong>g>of</str<strong>on</strong>g>axial velocity.Finally Figs. (13 & 18) shows increasing the pressuredrop with angular speed increase in both cases i.e., ε = 0.2 &0.4, note increasing in pressure drop at ε = 0.2 greater than it'sat ε = 0.4.The nature <str<strong>on</strong>g>of</str<strong>on</strong>g> the increase in the axial pressuregradient is clearly a functi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the geometry <str<strong>on</strong>g>of</str<strong>on</strong>g> the annulus.The effect <str<strong>on</strong>g>of</str<strong>on</strong>g> inertia <strong>on</strong> the axial pressure gradient,briefly, the effect <str<strong>on</strong>g>of</str<strong>on</strong>g> inertia is to increase the magnitude <str<strong>on</strong>g>of</str<strong>on</strong>g> theaxial pressure gradient, and the size <str<strong>on</strong>g>of</str<strong>on</strong>g> this increase is afuncti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> inner-cylinder rotati<strong>on</strong> speed and the geometry <str<strong>on</strong>g>of</str<strong>on</strong>g>the annulus in questi<strong>on</strong>. Ultimately, these inertial effects mustarise from the coupling <str<strong>on</strong>g>of</str<strong>on</strong>g> the equati<strong>on</strong>s in the Navier–Stokesset as the flow is three-dimensi<strong>on</strong>al [9].Thus two graphs are shown that increasing <str<strong>on</strong>g>of</str<strong>on</strong>g> angularspeed <str<strong>on</strong>g>of</str<strong>on</strong>g> inner cylinder lead to increase in pressure drop <strong>on</strong>two extreme edge <str<strong>on</strong>g>of</str<strong>on</strong>g> pipe.VI. CONCLUSIONS1. The results gave good agreement with other publishedresearchers.2. Axial velocity at sector (A) increase with increasing <str<strong>on</strong>g>of</str<strong>on</strong>g>angular speed <str<strong>on</strong>g>of</str<strong>on</strong>g> inner cylinder at ε = 0.2 and 0.4.3. Axial velocity decrease with increasing <str<strong>on</strong>g>of</str<strong>on</strong>g> angular speed <str<strong>on</strong>g>of</str<strong>on</strong>g>inner cylinder in sector (C) at ε = 0.2, also in sectors (B, C) atε = 0.4.4. When inner cylinder start to rotate axial velocity pr<str<strong>on</strong>g>of</str<strong>on</strong>g>ilebecome n<strong>on</strong>-symmetrical about centerline radial gap <str<strong>on</strong>g>of</str<strong>on</strong>g>passage.5. Pressure gradient increase with increasing <str<strong>on</strong>g>of</str<strong>on</strong>g> angular speedin both case i.e., ε = 0.2, 0.4 but at ε = 0.2 greater than at ε =0.4 al<strong>on</strong>g range <str<strong>on</strong>g>of</str<strong>on</strong>g> angular speed i.e., ω = (0 to 250) rpm.Process Systems Engineering, ENPROMER, Costa Veroe-Rj-Brazil,2003.[4] Escudier, M.P., Goulds<strong>on</strong>, I.W., Oliveira, P.J., Pinho, F.T., "<str<strong>on</strong>g>Effect</str<strong>on</strong>g>s <str<strong>on</strong>g>of</str<strong>on</strong>g>inner cylinder rotati<strong>on</strong> <strong>on</strong> laminar flow <str<strong>on</strong>g>of</str<strong>on</strong>g> a Newt<strong>on</strong>ian fluid <strong>through</strong> aneccentric annulus", Int. J. Heat Fluid <strong>Flow</strong>, Vol. 21, p. 92–103, 2000.[5] Escudier, M. P.; Oliveira, P. J.; Pinho, F. T.; Simth, S., "Fully developedlaminar flow <str<strong>on</strong>g>of</str<strong>on</strong>g> purely viscous n<strong>on</strong>-Newt<strong>on</strong>ian liquids annuli, Includingthe effects <str<strong>on</strong>g>of</str<strong>on</strong>g> eccentricity and inner – cylinder rotati<strong>on</strong>", Internati<strong>on</strong>alJournal <str<strong>on</strong>g>of</str<strong>on</strong>g> Heat and Fluid <strong>Flow</strong>, Vol. 33, p. 52-73, 2002.[6] M. Carrasco Teja & I. A. Frigaard, "Displacement flows in horiz<strong>on</strong>tal,narrow, eccentric annuli with a moving inner cylinder", Physic <str<strong>on</strong>g>of</str<strong>on</strong>g> Fluids,Vol. 21, 073102, 2009.[7] J.M. Nouri, H. Umur; J.H. Whitelaw, "<strong>Flow</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Newt<strong>on</strong>ian and n<strong>on</strong>-Newt<strong>on</strong>ian fluids in c<strong>on</strong>centric and eccentric annuli", J. Fluid Mech.,Vol. 253, pp. 617-641, 1993.[8] Md Mamunur Rashid, "CFD for Newt<strong>on</strong>ian Glucose fluid flow <strong>through</strong>c<strong>on</strong>centric annuli with centre body rotati<strong>on</strong>", Internati<strong>on</strong>al Journal <strong>on</strong>Science and Technology (IJSAT) Vol. II, Issue V, pp. 180 – 186, 2008.[9] S.Wan, D. Morris<strong>on</strong>, and I.G. Bryden, "The <strong>Flow</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Newt<strong>on</strong>ian AndInelastic N<strong>on</strong>-Newt<strong>on</strong>ian Fluids in Eccentric Annuli With <str<strong>on</strong>g>Inner</str<strong>on</strong>g>-<str<strong>on</strong>g>Cylinder</str<strong>on</strong>g> Rotati<strong>on</strong>", Theoret. Comput. Fluid Dynamics, Vol. 13, pp.349–359, 2000.RECOMMENDATIONSAn extensi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the present work is recommended fora future works includes:1. Investigati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the unsteady flow and study the vortexshedding process.2. Study effect <str<strong>on</strong>g>of</str<strong>on</strong>g> rotati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> outer cylinder as well asrotati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> inner cylinder.3. Study effect <str<strong>on</strong>g>of</str<strong>on</strong>g> entrance length that happened beforefully developed flow regi<strong>on</strong>.4. Insert effect <str<strong>on</strong>g>of</str<strong>on</strong>g> gravity <str<strong>on</strong>g>of</str<strong>on</strong>g> fluid <strong>on</strong> the pressure andvelocity pr<str<strong>on</strong>g>of</str<strong>on</strong>g>ile.5. Take in c<strong>on</strong>sider the inner cylinder rotates at highrotati<strong>on</strong>al speed (turbulence model).REFERENCES[1] C. Shu, L. Wang, Y. T. Chew, N. Zhao, "Numerical Study <str<strong>on</strong>g>of</str<strong>on</strong>g> EccentricCouette – Taylor <strong>Flow</strong>s and <str<strong>on</strong>g>Effect</str<strong>on</strong>g> <str<strong>on</strong>g>of</str<strong>on</strong>g> Eccentricity <strong>on</strong> <strong>Flow</strong> Patterns",Theoretical Computati<strong>on</strong>al Fluid Dynamics, Vol. 18, pp. 43 – 59, 2004.[2] Hua-Shu Dou, Boo Che<strong>on</strong>g Khoo, Kho<strong>on</strong> Seng Yeo, "Energy lossdistributi<strong>on</strong> in the plane Couette flow and the Taylor–Couette flowbetween c<strong>on</strong>centric rotating cylinders", Internati<strong>on</strong>al Journal <str<strong>on</strong>g>of</str<strong>on</strong>g> ThermalSciences Vol. 46, pp. 262–275, 2007.[3] C. H. Ataíde, F. A. R. Pereira e M. A. S. Barrozo, "CFD Predicti<strong>on</strong>s OfDrilling Fluids <str<strong>on</strong>g>Velocity</str<strong>on</strong>g> Pr<str<strong>on</strong>g>of</str<strong>on</strong>g>iles In Horiz<strong>on</strong>tal Annular <strong>Flow</strong>", 2 ndMercosur C<strong>on</strong>gress <strong>on</strong> Chemical Engineering, 4 th Mercosur C<strong>on</strong>gress <strong>on</strong>May 2013ATE-80302020©Asian-Transacti<strong>on</strong>s42

uAsian Transacti<strong>on</strong>s <strong>on</strong> Engineering (ATE ISSN: 2221-4267) Volume 03 Issue 02Fig. 1. Grid generati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> ε = 0.2, κ = 0.5Bωr, ϕCR IeϕAR OFig. 2. Annular secti<strong>on</strong> in two dimensi<strong>on</strong>s with cylindrical coordinateD21.5ACA[4]C [4]10.500 0.2 0.4 z 0.6 0.8 1Fig. 3. Comparis<strong>on</strong> between present study and Ref. [4] <str<strong>on</strong>g>of</str<strong>on</strong>g> n<strong>on</strong>-dimensi<strong>on</strong>al axial velocity pr<str<strong>on</strong>g>of</str<strong>on</strong>g>ile for Re = 105, ε = 0.2 at sectors A and CMay 2013ATE-80302020©Asian-Transacti<strong>on</strong>s43

vvuAsian Transacti<strong>on</strong>s <strong>on</strong> Engineering (ATE ISSN: 2221-4267) Volume 03 Issue 0221.5B [4]D [4]BD10.500 0.2 0.4 z 0.6 0.8 1Fig. 4. Comparis<strong>on</strong> between present study and Ref. [4] <str<strong>on</strong>g>of</str<strong>on</strong>g> n<strong>on</strong>-dimensi<strong>on</strong>al axial velocity pr<str<strong>on</strong>g>of</str<strong>on</strong>g>ile for Re = 105, ε = 0.2 at sectors B and D10.80.6A [4]C [4]AC0.40.200 0.2 0.4 z 0.6 0.8 1Fig. 5. Comparis<strong>on</strong> between present study and Ref. [4] <str<strong>on</strong>g>of</str<strong>on</strong>g> n<strong>on</strong>-dimensi<strong>on</strong>al tangential velocity pr<str<strong>on</strong>g>of</str<strong>on</strong>g>ile for Re = 105, ε = 0.2 at sectors A and C10.80.6B [4]D [4]BD0.40.200 0.2 0.4 z 0.6 0.8 1May 2013ATE-80302020©Asian-Transacti<strong>on</strong>s44

uvuAsian Transacti<strong>on</strong>s <strong>on</strong> Engineering (ATE ISSN: 2221-4267) Volume 03 Issue 02Fig. 6. Comparis<strong>on</strong> between present study and Ref. [4] <str<strong>on</strong>g>of</str<strong>on</strong>g> n<strong>on</strong>-dimensi<strong>on</strong>al tangential velocity pr<str<strong>on</strong>g>of</str<strong>on</strong>g>ile for Re = 105, ε = 0.2 at sectors B and D2.521.5A [4]C [4]AC10.500 0.2 0.4 0.6 0.8 1zFig. 7. Comparis<strong>on</strong> between present study and Ref. [4] <str<strong>on</strong>g>of</str<strong>on</strong>g> n<strong>on</strong>-dimensi<strong>on</strong>al axial velocity pr<str<strong>on</strong>g>of</str<strong>on</strong>g>ile for Re = 105, ε = 0.5 at sectors A and C10.80.6A [4]C [4]AC0.40.20-0.20 0.2 0.4 0.6 0.8 1zFig. 8. Comparis<strong>on</strong> between present study and Ref. [4] <str<strong>on</strong>g>of</str<strong>on</strong>g> n<strong>on</strong>-dimensi<strong>on</strong>al tangential velocity pr<str<strong>on</strong>g>of</str<strong>on</strong>g>ile for Re = 105, ε = 0.5 at sectors A and C21.510.500 0.2 0.4 z 0.6 0.8 1Fig. 9. N<strong>on</strong>-dimensi<strong>on</strong>al axial velocity <str<strong>on</strong>g>of</str<strong>on</strong>g> sector (A) vs. n<strong>on</strong>-dimensi<strong>on</strong>al distance from wall <str<strong>on</strong>g>of</str<strong>on</strong>g> inner to outer cylinder (radial gap) at ε = 0.2 and κ = 0.5May 2013ATE-80302020©Asian-Transacti<strong>on</strong>s45

uuuAsian Transacti<strong>on</strong>s <strong>on</strong> Engineering (ATE ISSN: 2221-4267) Volume 03 Issue 021.81.61.41.210.80.60.40.200 0.2 0.4 z 0.6 0.8 1Fig. 10. N<strong>on</strong>-dimensi<strong>on</strong>al axial velocity <str<strong>on</strong>g>of</str<strong>on</strong>g> sector (B) vs. n<strong>on</strong>-dimensi<strong>on</strong>al distance from wall <str<strong>on</strong>g>of</str<strong>on</strong>g> inner to outer cylinder (radial gap) at ε = 0.2 and κ = 0.51.41.210.80.60.40.200 0.2 0.4 z 0.6 0.8 1Fig. 11. N<strong>on</strong>-dimensi<strong>on</strong>al axial velocity <str<strong>on</strong>g>of</str<strong>on</strong>g> sector (C) vs. n<strong>on</strong>-dimensi<strong>on</strong>al distance from wall <str<strong>on</strong>g>of</str<strong>on</strong>g> inner to outer cylinder (radial gap) at ε = 0.2 and κ = 0.51.61.41.210.80.60.40.200 0.2 0.4 z 0.6 0.8 1May 2013ATE-80302020©Asian-Transacti<strong>on</strong>s46

uupAsian Transacti<strong>on</strong>s <strong>on</strong> Engineering (ATE ISSN: 2221-4267) Volume 03 Issue 02Fig. 12. N<strong>on</strong>-dimensi<strong>on</strong>al axial velocity <str<strong>on</strong>g>of</str<strong>on</strong>g> sector (D) vs. n<strong>on</strong>-dimensi<strong>on</strong>al distance from wall <str<strong>on</strong>g>of</str<strong>on</strong>g> inner to outer cylinder (radial gap) at ε = 0.2 and κ = 0.5240023502300p225022000 50 100 150 200 250Fig. 13. Axial pressure gradient (Pa/m) vs. inner cylinder rotati<strong>on</strong> (rpm) at ε = 0.2, κ = 0.52.521.510.500 0.2 0.4 0.6 0.8 1zFig. 14. N<strong>on</strong>-dimensi<strong>on</strong>al axial velocity <str<strong>on</strong>g>of</str<strong>on</strong>g> sector (A) vs. n<strong>on</strong>-dimensi<strong>on</strong>al distance from wall <str<strong>on</strong>g>of</str<strong>on</strong>g> inner to outer cylinder (radial gap) at ε = 0.4 and κ = 0.51.81.61.41.210.80.60.40.200 0.2 0.4 0.6 0.8 1zFig. 15. N<strong>on</strong>-dimensi<strong>on</strong>al axial velocity <str<strong>on</strong>g>of</str<strong>on</strong>g> sector (B) vs. n<strong>on</strong>-dimensi<strong>on</strong>al distance from wall <str<strong>on</strong>g>of</str<strong>on</strong>g> inner to outer cylinder (radial gap) at ε = 0.4 and κ = 0.5May 2013ATE-80302020©Asian-Transacti<strong>on</strong>s47

puuAsian Transacti<strong>on</strong>s <strong>on</strong> Engineering (ATE ISSN: 2221-4267) Volume 03 Issue 021.210.80.60.40.200 0.2 0.4 z 0.6 0.8 1Fig. 16. N<strong>on</strong>-dimensi<strong>on</strong>al axial velocity <str<strong>on</strong>g>of</str<strong>on</strong>g> sector (C) vs. n<strong>on</strong>-dimensi<strong>on</strong>al distance from wall <str<strong>on</strong>g>of</str<strong>on</strong>g> inner to outer cylinder (radial gap) at ε = 0.4 and κ = 0.51.210.80.60.40.200 0.2 0.4 z 0.6 0.8 1Fig. 17. N<strong>on</strong>-dimensi<strong>on</strong>al axial velocity <str<strong>on</strong>g>of</str<strong>on</strong>g> sector (D) vs. n<strong>on</strong>-dimensi<strong>on</strong>al distance from wall <str<strong>on</strong>g>of</str<strong>on</strong>g> inner to outer cylinder (radial gap) at ε = 0.4 and κ = 0.524002300220021002000190018000 50 100 150 200 250Fig. 18. Axial pressure gradient (Pa/m) vs. inner cylinder rotati<strong>on</strong> (rpm) at ε = 0.4, κ = 0.pMay 2013ATE-80302020©Asian-Transacti<strong>on</strong>s48