Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

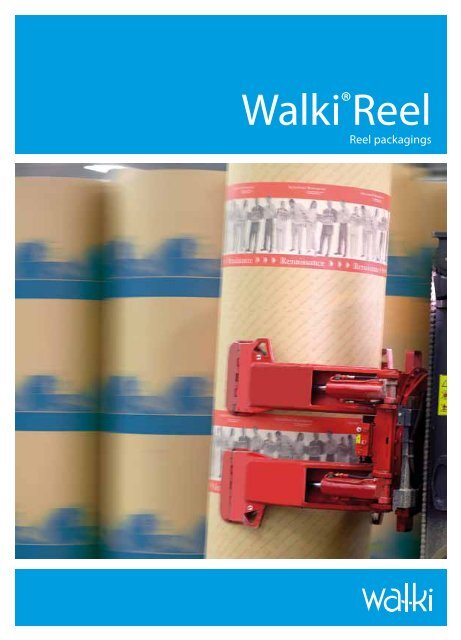

Walki ® <strong>Reel</strong><strong>Reel</strong> packagings

Damage can be preventedChoosing the proper wrapper<strong>Reel</strong> packaging offers effective protectionfor paper reels. Walki is the world’s leadingmanufacturer of reel wraps and end discs,boasting over forty years of experience inthe field.Walki ® <strong>Reel</strong>Our reel wraps consist of carefully selected paper laminated with a layerof PE. They protect reels during storage and handling not only againstmechanical damage but also against dirt and moisture.Damage to reel, amount lost from reel100 mm, 36 %80 mm, 30 %60 mm, 23 %45 mm, 17 %35 mm, 14 %25 mm, 10 %Ø 1, 000 mmWalki®<strong>Reel</strong> MaxiDeveloped for highly demanding conditions, Maxi provides the best possibleprotection against moisture and mechanical damage. It is ideally suited for bigreels. The wrap combines maximum strength with the lowest possible materialconsumption.Walki®<strong>Reel</strong> ClassicClassic is the optimum wrapper for common-sized reels transported undernormal conditions. It provides excellent protection against moisture andmechanical damage.Walki®<strong>Reel</strong> MultiBest suited for light transports that demand less mechanical protection,Multi also offers a high level of moisture protection.Several aspects must be taken intoconsideration when selecting a wrapper,such as reel weight, number of handlingphases, transport method, transportduration and paper grade. Demandingtransports, large reels and valuable papercall for strong wrappers, while shorttransports can usually do with weakeralternatives. Walki offers five differentstrengths of the Walki®<strong>Reel</strong> wrapperlaminate. Special wrappers are alsoavailable for the Hotpack process. Thebroad product range offers a suitablewrapper for every need.Walki ® DiscEnd discs are an important element of packaging. Even minimaldamage to the end of a reel can severely harm its content: a gashtwo centimetres deep may affect nearly ten per cent of the paper.Walki manufactures a special inner disc for jumbo reels. Outerdiscs seal the packaging and protect reel ends against moisture andmechanical strain during transport and handling. The Walki®Disc rangeoffers several versions of outer discs.Walki®<strong>Reel</strong> Eco and Walki®<strong>Reel</strong> RecyEco and Recy are excellent for short, less demanding transports and lesssensitive products. They are usually made of 100 % recycled fibre.Walki®<strong>Reel</strong> HotThe PE layer of this wrapper has been developed especially with the Hotpacksealing method in mind.

Simple means, big improvementsFor every machine and methodProminent advertA printed reel wrap is an excellent way to boost your brand. Bycreating an identity for reels, the printed design converts them intohuge adverts for the customers. Walki’s wrappers can be printed usingadvanced techniques to a maximum width of 4,200 millimetres.Conventional reel packagingThe conventional method results in optimum use of thereel wrap. Print is easy to design since the width of the wrapis tailored to that of the customer’s reels. Hot melt is the mostcommon sealing method, but Hotpack can also be used.Enhanced safetyPrint also offers other advantages. It improves safety when handlingreels especially in poor lighting making it easier to see where one reelends and the next one begins. Print can also provide end-customerswith valuable information such as the direction in which the reel opens.Moreover, experience has shown that printed wraps are handledwith more care than unprinted ones simply because they look morevaluable.Overlapping reel packagingThe overlapping technique enables packaging machines tobe made more compact and saves storage space sinceonly a few different widths are needed. Using two or threeoverlapping wrappers makes it easier to package wide reels.The method can be used for traditional reel wrappers as well asHotpack wrappers.Not too much moisture…An unwrapped paper reel can freely absorb moisture from thesurroundings. This results in what is known as ‘piping’. These are streaksthat may penetrate several centimetres into the reel and that cannot beeliminated from individual sheets of paper. The PE layer of reel wrapperseffectively hinders this process. Under normal storage conditions reelsshow no trace of piping when unwrapped.…but not too little eitherFor a reel wrap to offer optimum functionality its moisture contentmust be in equilibrium with the relative air humidity at the packagingmachine. This is particularly important when dealing with lessfrequently used wrap widths. The moisture content of reel wrappersis typically 8–12 % on delivery. This calls for air humidity around 40 %at the packaging machine. If the relative air humidity is too low thewrapper dries out and its strength properties begin to deteriorate. Therisk for creasing and curling also increases.Spiral reel packagingThe spiral method uses only one wrap width and is best suitedfor packaging carried out in limited space and involving manydifferent reel widths. Spiral packaging uses traditional reelwraps that are wound around the reel until it is fully packed.Sealing the reelWalki supplies reelpackaging for everyconceivable packagingmachine and method.Good cooperationwith machine suppliersenables us to offerflexible solutionsto our customers.Hot meltPipingPiping quickly appears on unpacked reelsUnpacked reelPacked reelTimeRelationship between moisture content and air humidity20Moisture content of reel wrappers (%)161284020 40 60 80Relative humidity (% RH)This is the traditional sealing method for reel wrappers,consisting of two paper layers with PE in between. The reelpackage is sealed with hot melt adhesive, which is appliedto the edges and both ends of the package.HotpackThe Hotpack heat sealing method is based on a reel packagemade of PE-coated paper. The plastic layer on the inner surfaceof the reel is melted using infrared heat to form highly durablesealing.

Perfect for recyclingWalki’s entire reel wraps and end discs are fully recyclable. The paper andplastic can be completely separated using mechanical methods.<strong>Reel</strong> packages usually consist of 90 per cent high-quality virgin fibre and10 per cent pure PE. Recycling makes sense, taking into consideration thesuperb quality of the paper fibre.Walki’s reel wraps and end discs comply with EU’s directive forpackaging and packaging waste (92/62/EC). The content of heavy metalsin our products is less than 100 ppm in compliance with Article 11 ofDirective 94/62/EC. The products are suitable for material or energyrecycling according to EN 13430 and EN 13431.<strong>Reel</strong> packagingsRecycling separates plastic frompaper. The recycled paper fibre isused to make, for example, strongboard for paper reel cores.Walki ® <strong>Reel</strong> MaxiWalki ® <strong>Reel</strong> ClassicWalki ® <strong>Reel</strong> MultiWalki ® <strong>Reel</strong> EcoWalki ® <strong>Reel</strong> RecyWalki ® <strong>Reel</strong> HotWalki ® DiscWalki ® Disc JumboPE reject 10 %High-quality fibre 90 % Core board Cores

Walki in briefWalki produces wrappings for the paper andmetal industries, food and consumer packagingmaterials, decorative and functional laminates,barrier liners for solid and corrugated packaging,facings for the insulation and constructionindustries and solutions for technical applications.Walki’s production units in Finland, Sweden,Germany, Poland, the UK and China have annualnet sales of about 300 million Euros and aworkforce of approximately 1,000 employees.Walki consists ofthree business areas<strong>Reel</strong> packagingPaper <strong>Packaging</strong>Ream wrappingConsumer BoardLayout: Studio PAP. Photo: Pertti Puranen. Print: Forsberg 2009.Barrier boardBarrier LiningTechnical ProductsFlexible packagingHeavy duty wrappingWalki GroupP.O. Box 40FI-37601 Valkeakoski, FinlandTel. +358 (0)205 36 3111Fax +358 (0)205 36 3090walki@walki.comInsulationand constructionfacing materialsTechnicalindustrial paperswww.walki.com