You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

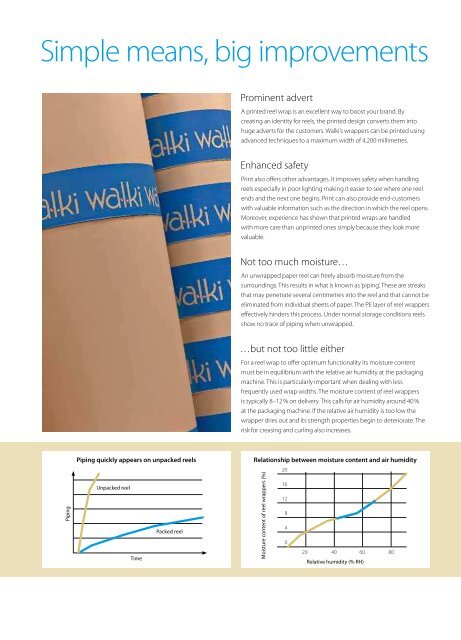

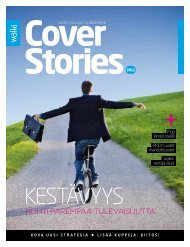

Simple means, big improvementsFor every machine and methodProminent advertA printed reel wrap is an excellent way to boost your brand. Bycreating an identity for reels, the printed design converts them intohuge adverts for the customers. Walki’s wrappers can be printed usingadvanced techniques to a maximum width of 4,200 millimetres.Conventional reel packagingThe conventional method results in optimum use of thereel wrap. Print is easy to design since the width of the wrapis tailored to that of the customer’s reels. Hot melt is the mostcommon sealing method, but Hotpack can also be used.Enhanced safetyPrint also offers other advantages. It improves safety when handlingreels especially in poor lighting making it easier to see where one reelends and the next one begins. Print can also provide end-customerswith valuable information such as the direction in which the reel opens.Moreover, experience has shown that printed wraps are handledwith more care than unprinted ones simply because they look morevaluable.Overlapping reel packagingThe overlapping technique enables packaging machines tobe made more compact and saves storage space sinceonly a few different widths are needed. Using two or threeoverlapping wrappers makes it easier to package wide reels.The method can be used for traditional reel wrappers as well asHotpack wrappers.Not too much moisture…An unwrapped paper reel can freely absorb moisture from thesurroundings. This results in what is known as ‘piping’. These are streaksthat may penetrate several centimetres into the reel and that cannot beeliminated from individual sheets of paper. The PE layer of reel wrapperseffectively hinders this process. Under normal storage conditions reelsshow no trace of piping when unwrapped.…but not too little eitherFor a reel wrap to offer optimum functionality its moisture contentmust be in equilibrium with the relative air humidity at the packagingmachine. This is particularly important when dealing with lessfrequently used wrap widths. The moisture content of reel wrappersis typically 8–12 % on delivery. This calls for air humidity around 40 %at the packaging machine. If the relative air humidity is too low thewrapper dries out and its strength properties begin to deteriorate. Therisk for creasing and curling also increases.Spiral reel packagingThe spiral method uses only one wrap width and is best suitedfor packaging carried out in limited space and involving manydifferent reel widths. Spiral packaging uses traditional reelwraps that are wound around the reel until it is fully packed.Sealing the reelWalki supplies reelpackaging for everyconceivable packagingmachine and method.Good cooperationwith machine suppliersenables us to offerflexible solutionsto our customers.Hot meltPipingPiping quickly appears on unpacked reelsUnpacked reelPacked reelTimeRelationship between moisture content and air humidity20Moisture content of reel wrappers (%)161284020 40 60 80Relative humidity (% RH)This is the traditional sealing method for reel wrappers,consisting of two paper layers with PE in between. The reelpackage is sealed with hot melt adhesive, which is appliedto the edges and both ends of the package.HotpackThe Hotpack heat sealing method is based on a reel packagemade of PE-coated paper. The plastic layer on the inner surfaceof the reel is melted using infrared heat to form highly durablesealing.