smart solutions

smart solutions

smart solutions

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The gARNAUT REVIEW 2011

66 B. SkalaThe squirrel cage rotor has a cooper winding which consists of bars and twoshort circuit rings. The bars and rings are brazed. Over both short circuit rings,shrung-on links are placed.a) b)Fig. 1. (a) Deformations of the bars (b) Squirrel cage rotor winding, ANSYS modelBased on the practice of the company, fatigue failure occurs sometimes onthe rotor bars, located near to the short circuited ring. The similar problem isbeing solved also by other companies, e.g. Alstom.2. THE RAILWAY ROUTE PRAGUE – CESKA TREBOVAThis three-system locomotive will be operated mainly on Czech high speedcorridors. For our purposes, the railway route from Prague to Ceska Trebovahas been chosen. The data were obtained for passenger fast train of a totalweight 450 t and a freight train of a total weight 1400 t. The length of the route is165 km, maximum allowed speed is 160 km.h -1 . Both directions were observed.Both trains stopped only two times, in Kolin and Pardubice. The braking energywas recuperated back to the trolley line.

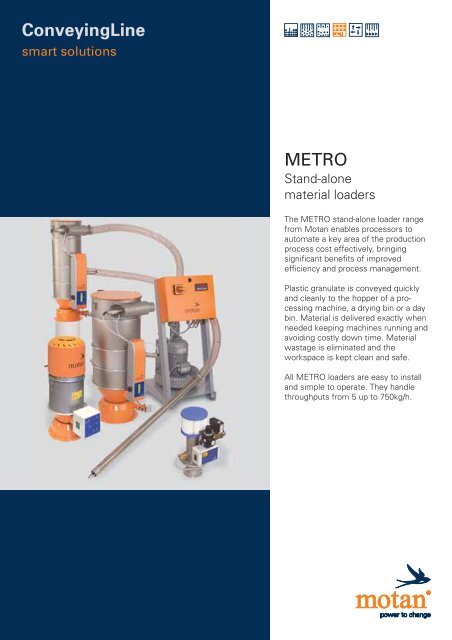

METRO VLIt is assumed that nowadays production downtimesdue to empty machine hoppers do not occur.Hopper loaders automate the material feed to themachines. The cost advantage is obvious: cleanproduction sites, no material loss due to spilled material,no risk of injury associated with manual fillingof machine hoppers, better deployment ofpersonnel and, in conjunction with material storagebins, no material mistakes. Finally, no productiondowntimes.METRO MES 10METRO VLVenturi compressed air loader for small quantities.METRO HES 50METRO MES 10Hopper loader with integrated vacuum motor, themost cost saving solution for a material throughputof up to 10kg/h.METRO HES 50Hopper loader with vacuum motor, powerful andlow noise for a material throughput of up to 50kg/h.METRO HES 250METRO HES 250Hopper loader with brushless vacuum motor,maintenance-free and powerful for a materialthroughput of up to 250kg/h.METRO HPS 06METRO HPS 06Hopper loader to be used in small systems.METRO HBS 750/2Hopper loader with a three-phase blower for highermaterial throughputs.METRO HBS 750/2METROMIXProportioning valve to add regrind may be suppliedor retrofitted as necessary.METROMIX4

METRO HBSThree-phase loadersThe METRO HBS models offer a wide choice ofloader-blower sets and are designed for higherthroughputs, from 250 up to 750kg/h.The units are supplied with a separate three-phasefloor standing blower station which is low noise andmaintenance free. The control panel is located at aconvenient height, eliminating the need to climbonto the processing machine. An alarm indicatesinsufficient material.Highly efficient automatic implosive filter cleaning isstandard on all METRO HBS loaders.METRO HBS with blowerMETRO HBS units are also available with twomaterial inlets. A separate mixing valve is notneeded, as the METRO HBS loader has an integralproportioning function for virgin and regrind material.The ratio between the materials is preciselyadjustable, so that the loader delivers a completelyhomogeneous mixture.Up to two loaders plus a blower station can becontrolled through a single control panel. In effect,processors can set up a small conveying system,with METRO HBS loaders serving either twomachines or one machine and a drying bin.METRO HBS 250/27

METRO HPS/HPGLoaders for small systemsModularity• The Motan METRO range with 0.5 to 30 litrescapacity.• Modular design allows easy adaptation.• Machine loaders replace the storage bins on theprocessing machines.• The option of either a glass or steel hopper bodyis available for most loaders.METRO HPS 06Implosion valveAll METRO HPS/HPG material loaders are fittedwith a vacuum valve. The valve opens the vacuumline when material is being conveyed and closeswith an airtight seal after the conveying phase. Thereduced pressure in the loader then causes theimplosion valve to open suddenly for a short time.The shock of this implosion cleans the materialseparation screen after each conveying cycle.METRO MPG 1.5Convey controlGRAVInet is an automated control system forhopper loaders. The integrated convey control atthe GRAVICOLOR blending units allows the controlof up to seven hopper loaders.GRAVInetGRAVInet8

Storage bin made of aluminium,120/240/360 litresConnecting piece for a suction pipe of 38 - 60mmdiametre included.Compact design and mobile with three castors.Optional mounting of a suction box is possible.Storage binVolume (l) 120 240 360Ø 1 (mm) 616 616 800Ø 2 (mm) 65 65 65Ø 3 (mm) 100 100 100H (mm) 900 1150 1165Storage binDebagging container made of aluminium,400 litresBulk material container for storing plasticsgranulates.Debagging container,standard basic container 1Standard basic container 1Hinged lid, grid insert, welded suction pipe at theside and hinged slide at the outlet included.Standard basic container 2Hinged lid, grid insert, screw socket for min.indicator, outlet flange for connection of a suctionbox or hinged slide included.Optionally available for standard basic container 2:a suction box and the connection for a Motan loader.10

METROMETRO VL*Loader typeMETRO VLConveying capacity (kg/h)** max. 100Mode of conveyingcompressed airCompressed air, oil and water free (bar) 2 - 7Air consumption (m 3 /h) max. 78Power supply 1/N/PE (V/Hz) 230/50Weight (ca. kg) 2METRO HES/MES*Loader METRO 10 METRO 50 METRO 250Type HES MES HES MES HES MESVolume (l) 1 6 6Average conveying capacity** (kg/h) 10 50 250Blower capacity/connected load (W) 700 1100 1100 brushlessFilter cleaning compressed air compressed air compressed airCompressed air, oil and water free (bar) 5 - 7 5 - 7 5 - 7Power supply 1/N/PE (V/Hz) 230/50 230/50 230/50Weight (kg) 6 5.3 11.2 10.3 11.7 10.8DimensionsH (mm) 462 576 600Ø d1 (mm) 140 214 214Ø d2 (mm) 215 100 215 145 215 145METROMIX connection - yes - yes -METRO VLMETRO HBS*Loader type METRO HBS 250 METRO HBS 350 METRO HBS 750Volume (l) 6 6 15Number of hopper loaders 1 or 2 1 or 2 1 or 2Conveying capacity (kg/h)** 250 350 750Filter cleaning implosion implosion implosionCompressed air, oil and water free (bar) 5 - 7 5 - 7 5 - 7Power supply 3/PE (V/Hz) 400/50 400/50 400/50Number of material inlets*** 1 or 2 1 or 2 1 or 2Weight (kg) 11.5 11.5 17.1DimensionsH1 (mm) 695 695 760Ø d1 (mm) 215 215 314Ø d2 (mm) 215 215 280Ø d3 (mm) 38 38 60Ø d4 (mm) 45 45 60Blower station (kW) 0.9 1.3 2.2DimensionsH2 (mm) 905 905 905B1 (mm) 410 410 410L1 (mm) 410 410 450Ø d4 (mm) 45 45 60METRO HPS/HPGFeed volume 0.5 1.5 6 10 15 30litres/cycleWeight (kg) 4.5 5 9.8 10.5 15.8 16.7Dimensions (mm)H 309 402 585 649 703 803Ø d1 135 135 215 215 315 315Ø d2 38/45 38/45 38/45/60 38/45/60 45/60 45/60Ø d3 45 45 45 45 60 60Blower stationMETROMIX* (option to METRO HES 50 and HES 250)Connecting dimension (mm) Ø 38Mixing ratio (virgin : regrind) 90:10 up to 10:90Compressed air, oil and water free (bar) 5 - 7Connected load (W) 8.5Power supply 1/N/PE (V/Hz) 230/50Weight incl. control (kg) 3.3* The following items are included with delivery: 3m material hose and a suction pipe. In addition,METRO HBS hopper loaders are delivered with 3m vacuum hose.** The conveying capacity refers to a conveying distance of 5m at a height of 3m. The information refersto materials with a bulk density of 0.6kg/dm 3 .*** When connecting two hopper loaders, a maximum of one hopper loader can be equipped with twomaterial inlets.Subject to technical changes.11

Your benefitsImproved production efficiency through• proven Motan quality for trouble-free, reliableoperation• a first step to efficient, automated production• processing machine which does not run empty– automatic alarm prompts for material supply• avoiding health and safety risks – no materialspillage, resulting in clean, safe floors andworkspace• possibility of proportioning of regrind• easy access for cleaning• automatic filter cleaningCost savings through• material savings at least 1 to 2% – no spillage• manpower savings through automated materialconveying – no manual delivery and loading• stainless steel construction – long service life• low maintenance03_08_2.9www.motan.com