SERVICE BULLETIN - Carrier

SERVICE BULLETIN - Carrier

SERVICE BULLETIN - Carrier

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

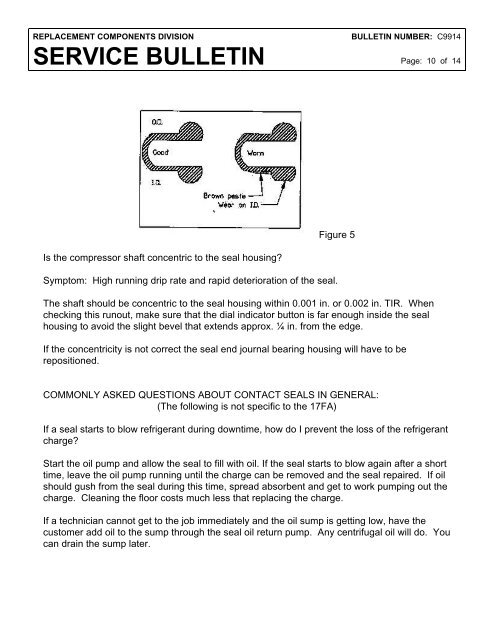

REPLACEMENT COMPONENTS DIVISION<strong>SERVICE</strong> <strong>BULLETIN</strong><strong>BULLETIN</strong> NUMBER: C9914Page: 10 of 14Figure 5Is the compressor shaft concentric to the seal housing?Symptom: High running drip rate and rapid deterioration of the seal.The shaft should be concentric to the seal housing within 0.001 in. or 0.002 in. TIR. Whenchecking this runout, make sure that the dial indicator button is far enough inside the sealhousing to avoid the slight bevel that extends approx. ¼ in. from the edge.If the concentricity is not correct the seal end journal bearing housing will have to berepositioned.COMMONLY ASKED QUESTIONS ABOUT CONTACT SEALS IN GENERAL:(The following is not specific to the 17FA)If a seal starts to blow refrigerant during downtime, how do I prevent the loss of the refrigerantcharge?Start the oil pump and allow the seal to fill with oil. If the seal starts to blow again after a shorttime, leave the oil pump running until the charge can be removed and the seal repaired. If oilshould gush from the seal during this time, spread absorbent and get to work pumping out thecharge. Cleaning the floor costs much less that replacing the charge.If a technician cannot get to the job immediately and the oil sump is getting low, have thecustomer add oil to the sump through the seal oil return pump. Any centrifugal oil will do. Youcan drain the sump later.