SERVICE BULLETIN - Carrier

SERVICE BULLETIN - Carrier

SERVICE BULLETIN - Carrier

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

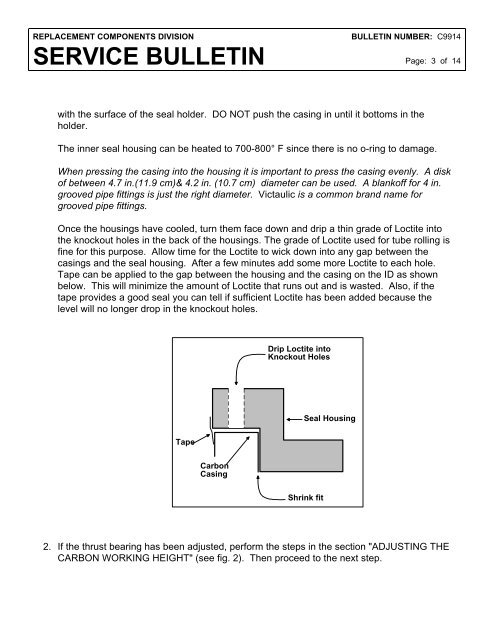

REPLACEMENT COMPONENTS DIVISION<strong>SERVICE</strong> <strong>BULLETIN</strong><strong>BULLETIN</strong> NUMBER: C9914Page: 3 of 14with the surface of the seal holder. DO NOT push the casing in until it bottoms in theholder.The inner seal housing can be heated to 700-800° F since there is no o-ring to damage.When pressing the casing into the housing it is important to press the casing evenly. A diskof between 4.7 in.(11.9 cm)& 4.2 in. (10.7 cm) diameter can be used. A blankoff for 4 in.grooved pipe fittings is just the right diameter. Victaulic is a common brand name forgrooved pipe fittings.Once the housings have cooled, turn them face down and drip a thin grade of Loctite intothe knockout holes in the back of the housings. The grade of Loctite used for tube rolling isfine for this purpose. Allow time for the Loctite to wick down into any gap between thecasings and the seal housing. After a few minutes add some more Loctite to each hole.Tape can be applied to the gap between the housing and the casing on the ID as shownbelow. This will minimize the amount of Loctite that runs out and is wasted. Also, if thetape provides a good seal you can tell if sufficient Loctite has been added because thelevel will no longer drop in the knockout holes.Drip Loctite intoKnockout HolesSeal HousingTapeCarbonCasingShrink fit2. If the thrust bearing has been adjusted, perform the steps in the section "ADJUSTING THECARBON WORKING HEIGHT" (see fig. 2). Then proceed to the next step.