You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

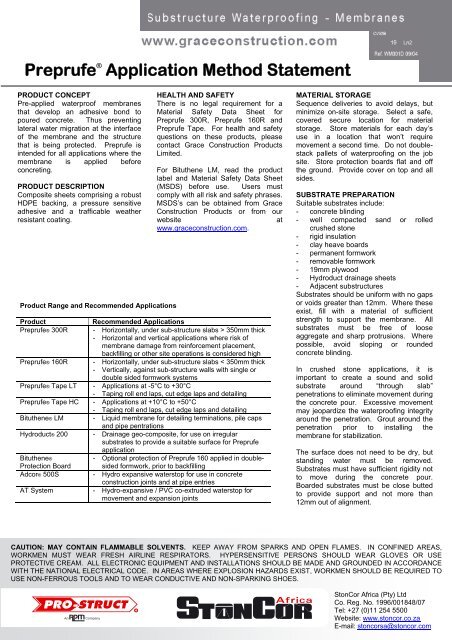

Preprufe ® Application Method StatementPRODUCT CONCEPTPre-applied waterproof membranesthat develop an adhesive bond topoured concrete. Thus preventinglateral water migration at the interfaceof the membrane and the structurethat is being protected. Preprufe isintended for all applications where themembrane is applied beforeconcreting.PRODUCT DESCRIPTIONComposite sheets comprising a robustHDPE backing, a pressure sensitiveadhesive and a trafficable weatherresistant coating.Product Range and Recommended ApplicationsProduct<strong>Preprufe®</strong> <strong>300R</strong><strong>Preprufe®</strong> 160R<strong>Preprufe®</strong> Tape LT<strong>Preprufe®</strong> Tape HCBituthene® LMHydroduct® 200Bituthene®Protection BoardAdcor® 500SAT SystemHEALTH AND SAFETYThere is no legal requirement for aMaterial Safety Data Sheet forPreprufe <strong>300R</strong>, Preprufe 160R andPreprufe Tape. For health and safetyquestions on these products, pleasecontact Grace Construction ProductsLimited.For Bituthene LM, read the productlabel and Material Safety Data Sheet(MSDS) before use. Users mustcomply with all risk and safety phrases.MSDS’s can be obtained from GraceConstruction Products or from ourwebsiteatwww.graceconstruction.com.Recommended Applications- Horizontally, under sub-structure slabs > 350mm thick- Horizontal and vertical applications where risk ofmembrane damage from reinforcement placement,backfilling or other site operations is considered high- Horizontally, under sub-structure slabs < 350mm thick- Vertically, against sub-structure walls with single ordouble sided formwork systems- Applications at -5°C to +30°C- Taping roll end laps, cut edge laps and detailing- Applications at +10°C to +50°C- Taping roll end laps, cut edge laps and detailing- Liquid membrane for detailing terminations, pile capsand pipe pentrations- Drainage geo-composite, for use on irregularsubstrates to provide a suitable surface for Preprufeapplication- Optional protection of Preprufe 160 applied in doublesidedformwork, prior to backfilling- Hydro expansive waterstop for use in concreteconstruction joints and at pipe entries- Hydro-expansive / PVC co-extruded waterstop formovement and expansion jointsMATERIAL STORAGESequence deliveries to avoid delays, butminimize on-site storage. Select a safe,covered secure location for materialstorage. Store materials for each day’suse in a location that won’t requiremovement a second time. Do not doublestackpallets of waterproofing on the jobsite. Store protection boards flat and offthe ground. Provide cover on top and allsides.SUBSTRATE PREPARATIONSuitable substrates include:- concrete blinding- well compacted sand or rolledcrushed stone- rigid insulation- clay heave boards- permanent formwork- removable formwork- 19mm plywood- Hydroduct drainage sheets- Adjacent substructuresSubstrates should be uniform with no gapsor voids greater than 12mm. Where theseexist, fill with a material of sufficientstrength to support the membrane. Allsubstrates must be free of looseaggregate and sharp protrusions. Wherepossible, avoid sloping or roundedconcrete blinding.In crushed stone applications, it isimportant to create a sound and solidsubstrate around “through slab”penetrations to eliminate movement duringthe concrete pour. Excessive movementmay jeopardize the waterproofing integrityaround the penetration. Grout around thepenetration prior to installing themembrane for stabilization.The surface does not need to be dry, butstanding water must be removed.Substrates must have sufficient rigidity notto move during the concrete pour.Boarded substrates must be close buttedto provide support and not more than12mm out of alignment.CAUTION: MAY CONTAIN FLAMMABLE SOLVENTS. KEEP AWAY FROM SPARKS AND OPEN FLAMES. IN CONFINED AREAS,WORKMEN MUST WEAR FRESH AIRLINE RESPIRATORS. HYPERSENSITIVE PERSONS SHOULD WEAR GLOVES OR USEPROTECTIVE CREAM. ALL ELECTRONIC EQUIPMENT AND INSTALLATIONS SHOULD BE MADE AND GROUNDED IN ACCORDANCEWITH THE NATIONAL ELECTRICAL CODE. IN AREAS WHERE EXPLOSION HAZARDS EXIST, WORKMEN SHOULD BE REQUIRED TOUSE NON-FERROUS TOOLS AND TO WEAR CONDUCTIVE AND NON-SPARKING SHOES.<strong>StonCor</strong> <strong>Africa</strong> (Pty) LtdCo. Reg. No. 1996/001848/07Tel: +27 (0)11 254 5500Website: www.stoncor.co.zaE-mail: stoncorsa@stoncor.com