Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

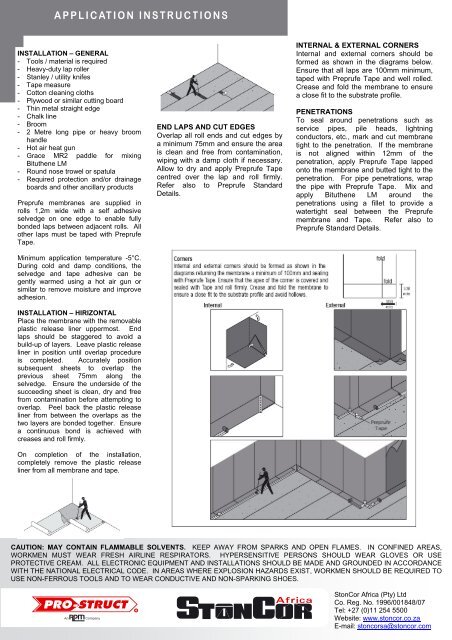

A P P L I C AT I O N I N S T R U C T I O N SINSTALLATION – GENERAL- Tools / material is required- Heavy-duty lap roller- Stanley / utility knifes- Tape measure- Cotton cleaning cloths- Plywood or similar cutting board- Thin metal straight edge- Chalk line- Broom- 2 Metre long pipe or heavy broomhandle- Hot air heat gun- Grace MR2 paddle for mixingBituthene LM- Round nose trowel or spatula- Required protection and/or drainageboards and other ancillary productsPreprufe membranes are supplied inrolls 1,2m wide with a self adhesiveselvedge on one edge to enable fullybonded laps between adjacent rolls. Allother laps must be taped with PreprufeTape.Minimum application temperature -5°C.During cold and damp conditions, theselvedge and tape adhesive can begently warmed using a hot air gun orsimilar to remove moisture and improveadhesion.INSTALLATION – HIRIZONTALPlace the membrane with the removableplastic release liner uppermost. Endlaps should be staggered to avoid abuild-up of layers. Leave plastic releaseliner in position until overlap procedureis completed. Accurately positionsubsequent sheets to overlap theprevious sheet 75mm along theselvedge. Ensure the underside of thesucceeding sheet is clean, dry and freefrom contamination before attempting tooverlap. Peel back the plastic releaseliner from between the overlaps as thetwo layers are bonded together. Ensurea continuous bond is achieved withcreases and roll firmly.On completion of the installation,completely remove the plastic releaseliner from all membrane and tape.END LAPS AND CUT EDGESOverlap all roll ends and cut edges bya minimum 75mm and ensure the areais clean and free from contamination,wiping with a damp cloth if necessary.Allow to dry and apply Preprufe Tapecentred over the lap and roll firmly.Refer also to Preprufe StandardDetails.INTERNAL & EXTERNAL CORNERSInternal and external corners should beformed as shown in the diagrams below.Ensure that all laps are 100mm minimum,taped with Preprufe Tape and well rolled.Crease and fold the membrane to ensurea close fit to the substrate profile.PENETRATIONSTo seal around penetrations such asservice pipes, pile heads, lightningconductors, etc., mark and cut membranetight to the penetration. If the membraneis not aligned within 12mm of thepenetration, apply Preprufe Tape lappedonto the membrane and butted tight to thepenetration. For pipe penetrations, wrapthe pipe with Preprufe Tape. Mix andapply Bituthene LM around thepenetrations using a fillet to provide awatertight seal between the Preprufemembrane and Tape. Refer also toPreprufe Standard Details.CAUTION: MAY CONTAIN FLAMMABLE SOLVENTS. KEEP AWAY FROM SPARKS AND OPEN FLAMES. IN CONFINED AREAS,WORKMEN MUST WEAR FRESH AIRLINE RESPIRATORS. HYPERSENSITIVE PERSONS SHOULD WEAR GLOVES OR USEPROTECTIVE CREAM. ALL ELECTRONIC EQUIPMENT AND INSTALLATIONS SHOULD BE MADE AND GROUNDED IN ACCORDANCEWITH THE NATIONAL ELECTRICAL CODE. IN AREAS WHERE EXPLOSION HAZARDS EXIST, WORKMEN SHOULD BE REQUIRED TOUSE NON-FERROUS TOOLS AND TO WEAR CONDUCTIVE AND NON-SPARKING SHOES.<strong>StonCor</strong> <strong>Africa</strong> (Pty) LtdCo. Reg. No. 1996/001848/07Tel: +27 (0)11 254 5500Website: www.stoncor.co.zaE-mail: stoncorsa@stoncor.com