coordinate measuring machines - Mitutoyo America Corporation

coordinate measuring machines - Mitutoyo America Corporation

coordinate measuring machines - Mitutoyo America Corporation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Coordinate Measuring MachinesCOORDINATE MEASURINGMACHINESBulletin No. 1598RThe Best Solutionfor 3-D MetrologyGlobal Sales and Service

<strong>Mitutoyo</strong> CMMsCNC OperationUltra-High AccuracyLegex calibration tool usingthe virtually zero thermalexpansion glass gage.Legex 500/707/910/1200The ultimate in CMM accuracy, the fixed bridgestructure and precision air bearings resting onrigid guideways ensure superior stability of motionand ultra-high <strong>measuring</strong> accuracy. It is suitable forcomplex small to medium size workpieces suchas a gear, bearing, lens, die,scroll rotor which requiredimensional accuracies.The MPP-300 probe addsscanning capability tothe standardpoint-to-pointoperation.RV-II 707/910Lower cost-per-performance versionof Legex series.High Accuracy<strong>Mitutoyo</strong> original standardglass scale (top).Virtually zero thermal expansionglass scale for Legex (top,right).Crysta-Apex C776/7106The medium sizemodels in theCrysta-Apex C series.Crysta-Apex C 544/574The smallest size model in the Crysta series.It requires minimum installation space andcost and compatible in performance to thoseof Crysta-Apex C.

<strong>Mitutoyo</strong> has built and sold over35,000 CMMs since 1968.Crysta-Apex C121210/122010/ 123010The large size models inthe Crysta-Apex C series.High AccuracyJoystick controllerCrysta-Apex C9106/9166/ 9206Designed and constructed with <strong>Mitutoyo</strong>’sexperienced CNC CMM technology, Crysta-Apex Cfeatures lightweight materials and innovativemachine structure, providing high travel stability,high accuracy, and affordability.The temperaturecorrection function (16°C to 26°C) providesaccurate measurements even on the shop floor.In addition to point-to-point measurement,the MPP-100 and Metris Laser Probe providecontact/non-contact scanning capability.*Z-axis = 800mm models (9108/9168/9208) are available.Temperature compensationsystem (photo: temperaturesensors).High AccuracyHigh PerformanceBright-STRATO707/710/ 910/ 916High performance models in theBright series. It’s a high-end, moving-bridgetype CNC CMM with upgradedkinematic accuracy.Optimum machine structurehas been determined throughthe FEM (Finite-ElementMethod) and modal analysis.

<strong>Mitutoyo</strong> CMMsWorking with Special ApplicationsMach 403/806The Mach 403/806 maximizes machining operations byperforming in-line, high speed <strong>coordinate</strong> <strong>measuring</strong> inconjunction with your CNC machine tools.These highthroughput <strong>machines</strong> can be incorporated right into themanufacturing line and can provide pre/post machiningfeedback to your machine tool for machining adjustments.InlineApplicationExamples ofMACH 403/806incorporated into themanufacturing line.Correct Plus ®(Data Feedback System)After <strong>measuring</strong> the componentsproduced by a machining center, the CorrectPlus system feeds the compensation datacalculated from the measurement result andnominal value back to the machining center.This data feedback system maintains andimproves the accuracy of machining.LargeApplicationBright-STRATO 2000/3000This giant CNC CMM provides a huge <strong>measuring</strong>range of 78.7 x 118.1 x 59.05" (2000 x 3000 x1500mm) to 118.1 x 196.9 x 78.7" (3000 x 5000x 2000mm) with the large size CMM accuracy.

<strong>Mitutoyo</strong> CMMsManual Operation and DigitizingCP Jr.Horizontal-arm typemanual CMM.Easy ManualOperationBright Manual500/700The BRT-M has been developed by<strong>Mitutoyo</strong> for low-cost, easy-to-use<strong>coordinate</strong> <strong>measuring</strong> withoutcompromising <strong>measuring</strong>accuracy.The moving bridgedesign allows unobstructedaccess to the <strong>measuring</strong> tablefor quick, easy handlingof workpieces.Allmodels are equippedwith one-touch airclamps for simpleaxis clamping.QM-Measure 333/353Flexible <strong>measuring</strong> gage/data processingsystem for workshop use, employing aunique “open space” structure.TheQM-Measure can provide "Gage-like"operation and “CMM-like” data processingcapability in temperatures from 15°C to30°C (option). From very simplemeasurements of height, depth, diameter,etc. to very complicated 3-D dimensions,QM-Measure can do it all.Bright Strato 1600<strong>Mitutoyo</strong>’s new Bright STRATO CMM,a high accuracy CNC <strong>coordinate</strong><strong>measuring</strong> machine with real-timetemperature compensation from 64.4°Fto 71.6°F (18°C to 22°C)takes you there.Now instead of taking partsto a lab, the Bright STRATOprovides both high accuracyand fast <strong>measuring</strong> speedsright on the manufacturingline.

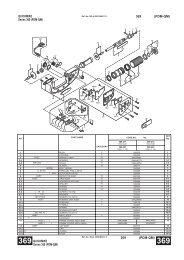

ProbesMulti-purpose probes for profile scanningand point-to-point measurementEffective screw depth<strong>measuring</strong> probeMPP-300(for Legex & RV-II)<strong>Mitutoyo</strong>’s original multi-purposeprobe system, it provides static anddynamic probing with high-accuracyMPP-100<strong>Mitutoyo</strong>’s original multi-purposeprobe system, it collects <strong>coordinate</strong>data at high speed.MPP-300 MPP-100 MPP-10MPP-10The world’s first effective screw depth<strong>measuring</strong> probe, available: for M4 to M10,and for M-12 to M20. For <strong>measuring</strong>angled screws, it can be attached to thePH10M and installed in the auto probechanging system.Touch signal probeMTP2000(for Legex & RV-II)<strong>Mitutoyo</strong>’s original high accuracytouch signal probe, it brings outthe maximum performance of thehigh-end CMM.Vision probeTP200Standard touch signal probe, availablewith Auto Stylus Changer.TP20Affordable touch signal probe,available with Auto Stylus Changer.MTP2000 TP200 TP20QVPA vision probe for CNCCMM, it makes it possibleto measure fine contours,thin and elastic workpieceswith a CMM.The QVP canbe installed in the AutoProbe Exchanger systemfor PH10MQ.Auto Stylus Changer

ProbesScanning probesLaser probesSP25MSP80SP25MCompact and versatile scanningprobe system, it delivers exceptionaldynamic performance.SoftwareSP80High performance and ultra-high accuracyscanning probe with digital readheads foruse with long styli.Line-Laser ProbePoint-Laser ProbeMICAT Series CMM SoftwareA wide variety of programs for each manufacturing step, fromdesign to production to evaluation, are available for all CMMsincluding a quality assurance program; they also include programsthat support various types of CAD data processing, inlinemeasurement, data feedback system, and processmanaging system.• General purpose program• Off-line teaching program• 3-D surface analysis program• Profile data analysis program• Gear analysis program• Statistical data processing program• Data conversion programMeasurLink ®MeasurLink supports a variety of statistical process functionsbased on the statistical method described in QS-9000, whichdefines standards for quality control in the U.S. automobileindustry. It is a tool used to identify problems in manufacturingprocesses and to analyze them efficiently in order to improvethe manufacturing process or to resolve problems.WithMeasurLink, the user can construct a <strong>measuring</strong> system bywhich to increase reliability, thereby establishing an excellentquality-assurance system on behalf of the customers.

Coordinate Measuring MachinesVision Measuring SystemsSurface Roughness, Form andContour MeasurementDigital Scale and DRO SystemsOptical Measuring MachinesSensor SystemsHardness Measuring MachinesSmall Tool Instruments andData ManagementMade to Measure<strong>Mitutoyo</strong> <strong>America</strong> <strong>Corporation</strong>Regional Offices: Michigan (734) 459-2810 Illinois (630) 978-5385 California (626) 961-9661Massachusetts (978) 692-8765 Indiana (317) 577-6070 No. Carolina (704) 875-8332www.mitutoyo.com© 2003 <strong>Mitutoyo</strong> <strong>America</strong> <strong>Corporation</strong>, Aurora IL We reserve the right to change specifications and prices without notice. 10B-11 • Printed in USA • October 2003