Surface modification for hydrophilic property of stainless steel ...

Surface modification for hydrophilic property of stainless steel ...

Surface modification for hydrophilic property of stainless steel ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

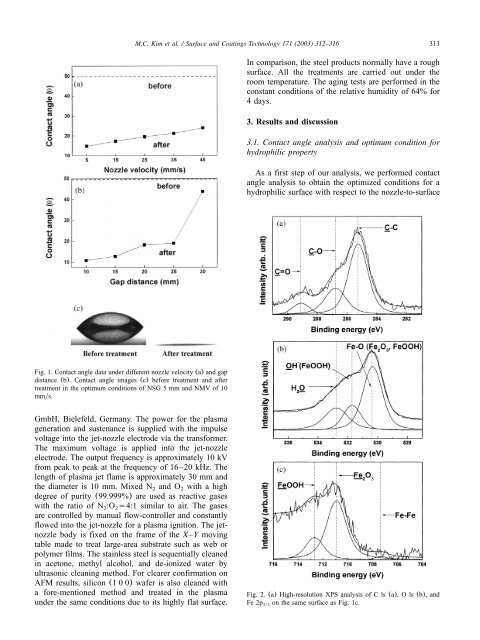

M.C. Kim et al. / <strong>Surface</strong> and Coatings Technology 171 (2003) 312–316313In comparison, the <strong>steel</strong> products normally have a roughsurface. All the treatments are carried out under theroom temperature. The aging tests are per<strong>for</strong>med in theconstant conditions <strong>of</strong> the relative humidity <strong>of</strong> 64% <strong>for</strong>4 days.3. Results and discussion3.1. Contact angle analysis and optimum condition <strong>for</strong><strong>hydrophilic</strong> <strong>property</strong>As a first step <strong>of</strong> our analysis, we per<strong>for</strong>med contactangle analysis to obtain the optimized conditions <strong>for</strong> a<strong>hydrophilic</strong> surface with respect to the nozzle-to-surfaceFig. 1. Contact angle data under different nozzle velocity (a) and gapdistance (b). Contact angle images (c) be<strong>for</strong>e treatment and aftertreatment in the optimum conditions <strong>of</strong> NSG 5 mm and NMV <strong>of</strong> 10mmys.GmbH, Bielefeld, Germany. The power <strong>for</strong> the plasmageneration and sustenance is supplied with the impulsevoltage into the jet-nozzle electrode via the trans<strong>for</strong>mer.The maximum voltage is applied into the jet-nozzleelectrode. The output frequency is approximately 10 kVfrom peak to peak at the frequency <strong>of</strong> 16–20 kHz. Thelength <strong>of</strong> plasma jet flame is approximately 30 mm andthe diameter is 10 mm. Mixed N and O with a high2 2degree <strong>of</strong> purity (99.999%) are used as reactive gaseswith the ratio <strong>of</strong> N :O s4:1 similar to air. The gases2 2are controlled by manual flow-controller and constantlyflowed into the jet-nozzle <strong>for</strong> a plasma ignition. The jetnozzlebody is fixed on the frame <strong>of</strong> the X–Y movingtable made to treat large-area substrate such as web orpolymer films. The <strong>stainless</strong> <strong>steel</strong> is sequentially cleanedin acetone, methyl alcohol, and de-ionized water byultrasonic cleaning method. For clearer confirmation onAFM results, silicon (100) wafer is also cleaned witha <strong>for</strong>e-mentioned method and treated in the plasmaunder the same conditions due to its highly flat surface.Fig. 2. (a) High-resolution XPS analysis <strong>of</strong> C ls (a), Ols(b), andFe 2p on the same surface as Fig. 1c.3y2