Stress and Other Challenges with Evaporated Ni-Cr ... - CS Mantech

Stress and Other Challenges with Evaporated Ni-Cr ... - CS Mantech

Stress and Other Challenges with Evaporated Ni-Cr ... - CS Mantech

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

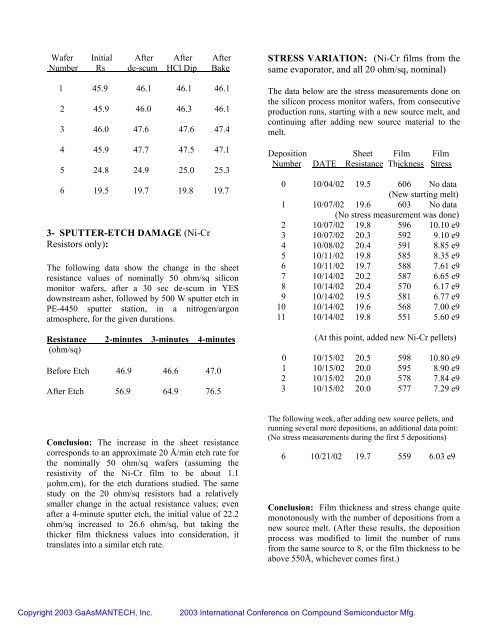

Wafer Initial After After AfterNumber Rs de-scum HCl Dip Bake1 45.9 46.1 46.1 46.12 45.9 46.0 46.3 46.13 46.0 47.6 47.6 47.44 45.9 47.7 47.5 47.15 24.8 24.9 25.0 25.36 19.5 19.7 19.8 19.73- SPUTTER-ETCH DAMAGE (<strong>Ni</strong>-<strong>Cr</strong>Resistors only):The following data show the change in the sheetresistance values of nominally 50 ohm/sq siliconmonitor wafers, after a 30 sec de-scum in YESdownstream asher, followed by 500 W sputter etch inPE-4450 sputter station, in a nitrogen/argonatmosphere, for the given durations.Resistance 2-minutes 3-minutes 4-minutes(ohm/sq)Before Etch 46.9 46.6 47.0After Etch 56.9 64.9 76.5STRESS VARIATION: (<strong>Ni</strong>-<strong>Cr</strong> films from thesame evaporator, <strong>and</strong> all 20 ohm/sq, nominal)The data below are the stress measurements done onthe silicon process monitor wafers, from consecutiveproduction runs, starting <strong>with</strong> a new source melt, <strong>and</strong>continuing after adding new source material to themelt.Deposition Sheet Film FilmNumber DATE Resistance Thickness <strong>Stress</strong>0 10/04/02 19.5 606 No data(New starting melt)1 10/07/02 19.6 603 No data(No stress measurement was done)2 10/07/02 19.8 596 10.10 e93 10/07/02 20.3 592 9.10 e94 10/08/02 20.4 591 8.85 e95 10/11/02 19.8 585 8.35 e96 10/11/02 19.7 588 7.61 e97 10/14/02 20.2 587 6.65 e98 10/14/02 20.4 570 6.17 e99 10/14/02 19.5 581 6.77 e910 10/14/02 19.6 568 7.00 e911 10/14/02 19.8 551 5.60 e9(At this point, added new <strong>Ni</strong>-<strong>Cr</strong> pellets)0 10/15/02 20.5 598 10.80 e91 10/15/02 20.0 595 8.90 e92 10/15/02 20.0 578 7.84 e93 10/15/02 20.0 577 7.29 e9Conclusion: The increase in the sheet resistancecorresponds to an approximate 20 Å/min etch rate forthe nominally 50 ohm/sq wafers (assuming theresistivity of the <strong>Ni</strong>-<strong>Cr</strong> film to be about 1.1µohm.cm), for the etch durations studied. The samestudy on the 20 ohm/sq resistors had a relativelysmaller change in the actual resistance values; evenafter a 4-minute sputter etch, the initial value of 22.2ohm/sq increased to 26.6 ohm/sq, but taking thethicker film thickness values into consideration, ittranslates into a similar etch rate.The following week, after adding new source pellets, <strong>and</strong>running several more depositions, an additional data point:(No stress measurements during the first 5 depositions)6 10/21/02 19.7 559 6.03 e9Conclusion: Film thickness <strong>and</strong> stress change quitemonotonously <strong>with</strong> the number of depositions from anew source melt. (After these results, the depositionprocess was modified to limit the number of runsfrom the same source to 8, or the film thickness to beabove 550Å, whichever comes first.)