Contacting Solutions for Reliable, Repeatable Test ... - Johnstech

Contacting Solutions for Reliable, Repeatable Test ... - Johnstech

Contacting Solutions for Reliable, Repeatable Test ... - Johnstech

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

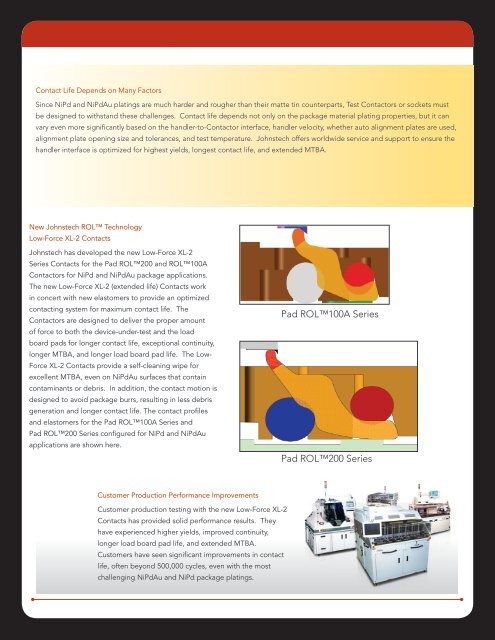

Contact Life Depends on Many FactorsSince NiPd and NiPdAu platings are much harder and rougher than their matte tin counterparts, <strong>Test</strong> Contactors or sockets mustbe designed to withstand these challenges. Contact life depends not only on the package material plating properties, but it canvary even more significantly based on the handler-to-Contactor interface, handler velocity, whether auto alignment plates are used,alignment plate opening size and tolerances, and test temperature. <strong>Johnstech</strong> offers worldwide service and support to ensure thehandler interface is optimized <strong>for</strong> highest yields, longest contact life, and extended MTBA.New <strong>Johnstech</strong> ROL TechnologyLow-Force XL-2 Contacts<strong>Johnstech</strong> has developed the new Low-Force XL-2Series Contacts <strong>for</strong> the Pad ROL200 and ROL100AContactors <strong>for</strong> NiPd and NiPdAu package applications.The new Low-Force XL-2 (extended life) Contacts workin concert with new elastomers to provide an optimizedcontacting system <strong>for</strong> maximum contact life. TheContactors are designed to deliver the proper amountof <strong>for</strong>ce to both the device-under-test and the loadboard pads <strong>for</strong> longer contact life, exceptional continuity,longer MTBA, and longer load board pad life. The Low-Force XL-2 Contacts provide a self-cleaning wipe <strong>for</strong>excellent MTBA, even on NiPdAu surfaces that containcontaminants or debris. In addition, the contact motion isdesigned to avoid package burrs, resulting in less debrisgeneration and longer contact life. The contact profilesand elastomers <strong>for</strong> the Pad ROL100A Series andPad ROL200 Series configured <strong>for</strong> NiPd and NiPdAuapplications are shown here.Pad ROL100A SeriesPad ROL200 SeriesCustomer Production Per<strong>for</strong>mance ImprovementsCustomer production testing with the new Low-Force XL-2Contacts has provided solid per<strong>for</strong>mance results. Theyhave experienced higher yields, improved continuity,longer load board pad life, and extended MTBA.Customers have seen significant improvements in contactlife, often beyond 500,000 cycles, even with the mostchallenging NiPdAu and NiPd package platings.