The aXcessaustralia Hybrid Electric Car Project

The aXcessaustralia Hybrid Electric Car Project

The aXcessaustralia Hybrid Electric Car Project

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

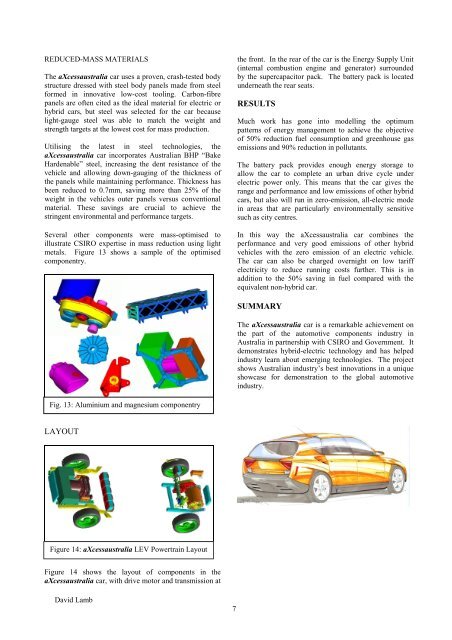

REDUCED-MASS MATERIALS<strong>The</strong> <strong>aXcessaustralia</strong> car uses a proven, crash-tested bodystructure dressed with steel body panels made from steelformed in innovative low-cost tooling. <strong>Car</strong>bon-fibrepanels are often cited as the ideal material for electric orhybrid cars, but steel was selected for the car becauselight-gauge steel was able to match the weight andstrength targets at the lowest cost for mass production.Utilising the latest in steel technologies, the<strong>aXcessaustralia</strong> car incorporates Australian BHP “BakeHardenable” steel, increasing the dent resistance of thevehicle and allowing down-gauging of the thickness ofthe panels while maintaining performance. Thickness hasbeen reduced to 0.7mm, saving more than 25% of theweight in the vehicles outer panels versus conventionalmaterial. <strong>The</strong>se savings are crucial to achieve thestringent environmental and performance targets.Several other components were mass-optimised toillustrate CSIRO expertise in mass reduction using lightmetals. Figure 13 shows a sample of the optimisedcomponentry.the front. In the rear of the car is the Energy Supply Unit(internal combustion engine and generator) surroundedby the supercapacitor pack. <strong>The</strong> battery pack is locatedunderneath the rear seats.RESULTSMuch work has gone into modelling the optimumpatterns of energy management to achieve the objectiveof 50% reduction fuel consumption and greenhouse gasemissions and 90% reduction in pollutants.<strong>The</strong> battery pack provides enough energy storage toallow the car to complete an urban drive cycle underelectric power only. This means that the car gives therange and performance and low emissions of other hybridcars, but also will run in zero-emission, all-electric modein areas that are particularly environmentally sensitivesuch as city centres.In this way the <strong>aXcessaustralia</strong> car combines theperformance and very good emissions of other hybridvehicles with the zero emission of an electric vehicle.<strong>The</strong> car can also be charged overnight on low tariffelectricity to reduce running costs further. This is inaddition to the 50% saving in fuel compared with theequivalent non-hybrid car.SUMMARY<strong>The</strong> <strong>aXcessaustralia</strong> car is a remarkable achievement onthe part of the automotive components industry inAustralia in partnership with CSIRO and Government. Itdemonstrates hybrid-electric technology and has helpedindustry learn about emerging technologies. <strong>The</strong> projectshows Australian industry’s best innovations in a uniqueshowcase for demonstration to the global automotiveindustry.Fig. 13: Aluminium and magnesium componentryLAYOUTFigure 14: <strong>aXcessaustralia</strong> LEV Powertrain LayoutFigure 14 shows the layout of components in the<strong>aXcessaustralia</strong> car, with drive motor and transmission atDavid Lamb7