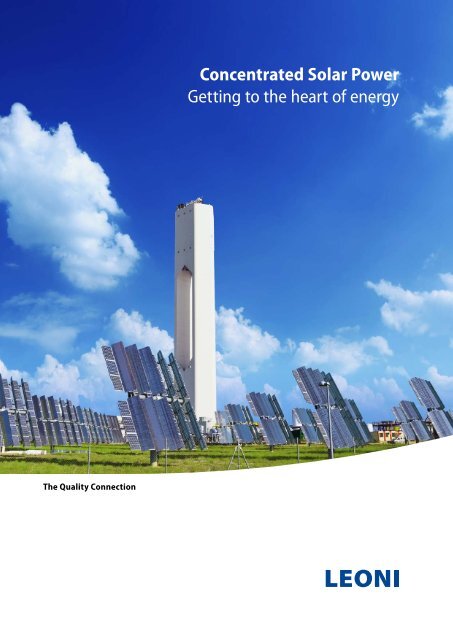

Concentrated Solar Power, Getting to the heart of energy - LEONI

Concentrated Solar Power, Getting to the heart of energy - LEONI

Concentrated Solar Power, Getting to the heart of energy - LEONI

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Our vision is <strong>to</strong> create sustainable connections intechnological harmony with <strong>the</strong> natural resources.The cycle <strong>of</strong> nature gives us <strong>the</strong> best model <strong>to</strong>emulate. It is our responsibility <strong>to</strong> learn from natureand make use <strong>of</strong> it while conserving it and treatingit with care.We meet <strong>the</strong> needs <strong>of</strong> <strong>to</strong>morrow already <strong>to</strong>day.

<strong>Concentrated</strong> solar power.<strong>Getting</strong> <strong>to</strong> <strong>the</strong> <strong>heart</strong> <strong>of</strong> <strong>energy</strong>.The <strong>energy</strong> market <strong>of</strong> <strong>the</strong> 21 st century calls for approaches <strong>to</strong>alternative energies, increased <strong>energy</strong> efficiency and <strong>the</strong> reduction<strong>of</strong> pollutants. The continuing rapid growth <strong>of</strong> <strong>energy</strong> consumptionworldwide leads <strong>to</strong> higher CO2 emissions and a constantlyaccelerating increase in global warming. Not least for economicreasons, rising prices for fossil fuels contribute <strong>to</strong> <strong>the</strong> streng<strong>the</strong>ningand fur<strong>the</strong>r development <strong>of</strong> industrial solutions for <strong>the</strong> use <strong>of</strong>regenerative energies as an alternative <strong>to</strong> <strong>the</strong> conventional ones.The global <strong>energy</strong> supply can only be guaranteed by implementingsustainable, forwardlooking solution. In this situation, itseems natural <strong>to</strong> use alternative energies which conserve <strong>the</strong>natural resources.The production <strong>of</strong> <strong>energy</strong> from solar power is <strong>the</strong> natural <strong>energy</strong>resource with <strong>the</strong> greatest potential <strong>to</strong> be an alternative withlong-term prospects. The <strong>energy</strong> <strong>of</strong> <strong>the</strong> sunhitting <strong>the</strong> Earth as awhole each year exceeds <strong>the</strong> global consumption <strong>of</strong> <strong>energy</strong> by afac<strong>to</strong>r <strong>of</strong> 60‘000. This is a good reason for us <strong>to</strong> increase our commitment<strong>to</strong> this source <strong>of</strong> <strong>energy</strong>.<strong>Concentrated</strong> solar power is ano<strong>the</strong>r way <strong>of</strong> using <strong>the</strong> sun’s<strong>energy</strong> besides pho<strong>to</strong>voltaics. The <strong>energy</strong> concentrated in industrialsolar <strong>to</strong>wers and parabolic trough power plants can be used<strong>to</strong> produce electricity directly via turbines or be s<strong>to</strong>red in <strong>the</strong> heattransfer medium. Besides a reliable supply <strong>of</strong> <strong>energy</strong>, concentratedsolar power ensures grid stability and is <strong>the</strong> only regenerativetechnology which can also be used <strong>to</strong> cover <strong>the</strong> primary load.It thus fulfils <strong>the</strong> three chief aims <strong>of</strong> <strong>the</strong> triangle used <strong>to</strong> define <strong>the</strong>basic political conditions for <strong>the</strong> <strong>energy</strong> industry <strong>of</strong> <strong>the</strong> future:reasonable price, environmental compatibility and constantavailability <strong>of</strong> <strong>energy</strong>.The development <strong>of</strong> regions with large amounts <strong>of</strong> sunshine vialarge-scale projects such as DESERTEC as well as solar and windparks coincides with a higher awareness for <strong>energy</strong> and <strong>the</strong> environmen<strong>to</strong>n all levels. Effective methods <strong>of</strong> meeting <strong>the</strong> increasingenvironmental requirements are <strong>the</strong> use <strong>of</strong> more sustainableproducts which conserve natural resources, <strong>energy</strong> transportpaths with less losses and, last but not least, <strong>the</strong> more efficientuse <strong>of</strong> <strong>energy</strong> by <strong>the</strong> final user himself.For us at <strong>LEONI</strong>, this is <strong>the</strong> benchmark for all our efforts.

Our company aim is <strong>to</strong>combine innovation withsustainability.<strong>LEONI</strong> doesn’t just pay lip service <strong>to</strong> sustainability – it is an integralpart <strong>of</strong> group policy. We are <strong>the</strong> first cable manufacturer in<strong>the</strong> world <strong>to</strong> develop a holistic concept for “green technology”.For us, this includes all products, system solutions and servicesallowing us <strong>to</strong> work more <strong>energy</strong>-efficiently while simultaneouslyconserving <strong>the</strong> natural resources more carefully and loweringemissions, thus reducing <strong>the</strong> burden on <strong>the</strong> environment. Wehave set ourselves <strong>the</strong> goal <strong>of</strong> becoming <strong>the</strong> leading and mostinnovative producer <strong>of</strong> cables for environmental technologies.<strong>LEONI</strong> as a global player and <strong>the</strong> leading European supplier <strong>of</strong>wires, optical fibres, cables and cable systems for communicationand infrastructure projects has a vital interest in detecting <strong>the</strong>needs and requirements <strong>of</strong> <strong>to</strong>morrow <strong>to</strong>day and supplying <strong>the</strong>markets <strong>of</strong> <strong>the</strong> future with sustainable, future-pro<strong>of</strong> solutions.The growing scarcity <strong>of</strong> <strong>the</strong> natural resources and <strong>the</strong> increasingburden on <strong>the</strong> environment require a rethink on all levels <strong>of</strong> society.Industry is called upon <strong>to</strong> develop techniques, products andapplications which are sustainable, <strong>energy</strong>-saving and environmentallycompatible. <strong>LEONI</strong> has combined its efforts <strong>to</strong> improve<strong>the</strong> value-added chain under ecological aspects and supply productsfor use in designated environmental technologies <strong>to</strong> form<strong>the</strong> “green technology” concept.We endeavour <strong>to</strong> fur<strong>the</strong>r increase <strong>the</strong> proportion <strong>of</strong> low-emission,environmentally compatible raw materials in our cableproducts as well as <strong>the</strong> recycling possibilities <strong>of</strong> <strong>the</strong> materialsand/or components used. We constantly work at optimizing <strong>the</strong>efficiency with which resources are used in <strong>the</strong> manufacturingprocess by deploying <strong>energy</strong>-efficient machines or taking heatrecovery measures. More and more locations in our global productionnetwork are environmentally certified according <strong>to</strong> <strong>the</strong>ISO 14001 standard.We <strong>of</strong>fer an increasing number <strong>of</strong> products and solutions whichare applied in well-defined markets and applications or used aspreliminary products and/or components for ecologically soundfinal applications.In conjunction with <strong>the</strong> ecological compatibility, future technologiesare measured in terms <strong>of</strong> efficiency, service life, emission reductionand <strong>the</strong> conservation <strong>of</strong> natural resources. Innovativecable products and systems, holistic solutions and maximumperformance in project management are <strong>the</strong> added value whichwe <strong>of</strong>fer <strong>to</strong> our cus<strong>to</strong>mers and business partners. These are alsoour corners<strong>to</strong>nes for strong connections in<strong>to</strong> <strong>the</strong> future.

The <strong>LEONI</strong> GroupCable competence for different industrial markets.www.leoni-communication-infrastructure.com<strong>LEONI</strong> is a leading supplier <strong>of</strong> cable systems and relatedservices for <strong>the</strong> au<strong>to</strong>motive industry and various o<strong>the</strong>rindustrial sec<strong>to</strong>rs.Our group <strong>of</strong> companies employs more than 60,000 people in32 countries. Corporate vision, highest quality and innovativepower have made us one <strong>of</strong> <strong>the</strong> leading cable manufacturers inEurope. <strong>LEONI</strong> develops and produces technically sophisticatedproducts ranging from wire and optical fibers <strong>to</strong> cables through<strong>to</strong> complete cable systems and also <strong>of</strong>fers <strong>the</strong> related services.Moreover, <strong>the</strong> product portfolio comprises strands, standardisedcables, hybrid cables, glass fiber as well as special cables,cable harnesses, wiring systems components and fully assembledsystems for applications in various industrial markets.Your markets – our strength.As diverse as our product and service range are <strong>the</strong> markets andsec<strong>to</strong>rs <strong>LEONI</strong> is supplying. We focus our activities on cus<strong>to</strong>mersin <strong>the</strong> fields <strong>of</strong> Au<strong>to</strong>motive & Commercial Vehicles, Industry &Healthcare, Communication & Infrastructure, Electrical Appliancesand Conduc<strong>to</strong>rs & Copper Solutions.We are among <strong>the</strong> leading European suppliers in <strong>the</strong> Communication& Infrastructure market <strong>to</strong> which at <strong>LEONI</strong> as a cable manufactureralso belong activities in <strong>the</strong> fields <strong>of</strong> infrastructure &data communications, industrial plant projects, solar- and windpower, <strong>energy</strong> & telecommunications, irradiation cross-linkingand traffic engineering. Our cus<strong>to</strong>mers benefit worldwide frominnovative as well as reliable and long-lasting products <strong>of</strong> highquality. <strong>LEONI</strong> – we create <strong>the</strong> best connection for your future.for fur<strong>the</strong>r informations www.leoni.comProducts and services portfolio at a glanceServiceCable harnessesCable systems / Wiring SystemsSensorsRelay and safety systemsEngineeringCopper cablesWires & strandsHybrid cablesOptical fibersOptical cablesConnec<strong>to</strong>rs<strong>LEONI</strong>‘s core marketsAu<strong>to</strong>motive&Commercial VehiclesIndustry&HealthcareCommunication&InfrastructureElectricalAppliancesConduc<strong>to</strong>rs&Copper Solutions

www.leoni-communication-infrastructure.com11ContentCable plastics 14ICON® Instrumentation CablesEN 50288-7 300 VRE-2X(St)H 16RE-2X(St)H PiMF 18RE-2X(St)HX 20RE-2X(St)HX PiMF 22RE-2X(St)HSWAH 24RE-2X(St)HSWAH PiMF 26RE-2X(St)HSWAHX 28RE-2X(St)HSWAHX PiMF 30UL 13 300 VRE-2X(St)H 32RE-2X(St)H PiMF 34RE-2X(St)HSWAH 36RE-2X(St)HSWAH PiMF 38<strong>Power</strong> and Control CablesIEC 60502-12XH 402XHX 422XHRH 442XHRHX 46Connection and <strong>Power</strong> CablesBETAflam® 145 flex 64BETAflam® 145 C-flex 66R<strong>of</strong>lex® 70BETAdrive C-flex 72Control CablesBETAtrans® GKW flex R 74BETAtrans® GKW C-flex R 76Medium Voltage CablesTRI-DELTA® MONO 78TRI-DELTA® XDALZ-MONO 80TRI-DELTA® XDMZ-Z 82TRI-DELTA® XDALZ-Z 84XFLEX-MONO 86Technical Information 89<strong>Solar</strong>-Hybrid-CablesSK-v2XHX 48Optical Fiber CablesKL-A-DQ(ZN)BHSWAH 50KL-AT-VQ(ZN)HSWAH 52ICON® Fieldbus CablesFB-v2XCeHX PiMF 54Technic & Support / Design options 56Pho<strong>to</strong>voltaic <strong>Power</strong> CablesBETAflam® <strong>Solar</strong> 125 RV flex FRNC 58BETAflam® <strong>Solar</strong> 125 flex UL 4703 60BETAflam® <strong>Solar</strong> 125 flex UL 4703/1000V 62BETAflam® <strong>Solar</strong> 125 AC flex FRNC 63

www.leoni-communication-infrastructure.com13Products & Solutions

14 Products & Solutionswww.leoni-communication-infrastructure.comCable plasticsCables and plastics are inseparable nowadays, but this has notalways been <strong>the</strong> case. The first-ever copper conduc<strong>to</strong>rs were laidin wooden channels in <strong>the</strong> 17 th century, but it was soon discoveredthat natural rubber in vulkanized (cross-linked) form is anexcellent insula<strong>to</strong>r. Gutta-percha, a close relative <strong>of</strong> rubber, verysoon <strong>to</strong>ok over this task when <strong>the</strong> extruder we know <strong>to</strong>day wasinvented in a basic form in 1846.Rigid PVC was used as a replacement for horn until it was plasticizedfor <strong>the</strong> first time in 1935, after which PVC went from strength<strong>to</strong> strength. In 1948, PVC was <strong>the</strong> most-produced plastic in <strong>the</strong>world, and it has remained so until this day. Then, when even recordswere made <strong>of</strong> PVC, which ultimately replaced shellac, everychild knew what it was. This is why <strong>the</strong> classical record is stillknown as “vinyl” <strong>to</strong>day.Like so many o<strong>the</strong>r things in life, PVC can be a blessing and acurse. The advantage <strong>of</strong> rigid PVC as a very stable chemical compound– and <strong>the</strong> resulting durability – is also its biggest disadvantage.PVC does not rot. Sunlight does not decompose <strong>the</strong>surface and <strong>the</strong> mechanical properties are not impaired. Seawaterand air have virtually no effect on rigid PVC. For this reasonand as a result <strong>of</strong> <strong>the</strong> reasonable costs for raw materials, rigid PVCis still <strong>the</strong> principal material used for products with a long servicelife such as window-frames or drainpipes.Catastrophic fires in <strong>the</strong> 1980s and 1990s led <strong>to</strong> a rethink <strong>of</strong> <strong>the</strong>use <strong>of</strong> PVC as <strong>the</strong> material <strong>of</strong> choice for cables <strong>of</strong> all types. Chlorinereleased during a fire can react with water or atmospherichumidity <strong>to</strong> become hydrochloric acid, releasing highly poisonous,corrosive combustion gases in <strong>the</strong> process. For this reason,<strong>the</strong> European countries have banned PVC cables from high-risk,high-investment buildings (airports, shopping centres, hospitalsetc.). Polyethylene was out <strong>of</strong> <strong>the</strong> question as a replacement – incontrast <strong>to</strong> PVC, PE is not flame-retardant and has a very high<strong>the</strong>rmal load.

www.leoni-communication-infrastructure.comProducts & Solutions15The development <strong>of</strong> irradiation cross-linking in <strong>the</strong> 1960s and <strong>the</strong>industrial implementation <strong>of</strong> this technology in <strong>the</strong> 1970s and1980s ushered in <strong>the</strong> heyday <strong>of</strong> halogen-free cables. The halogen-free,flame-retardant and <strong>the</strong>rmoplastic plastics availableuntil <strong>the</strong>n had limited <strong>the</strong>rmal and mechanical capabilities, making<strong>the</strong>m unusable for many applications.The cross-linking <strong>of</strong> <strong>the</strong> polymer chains which forms a <strong>the</strong>rmally,mechanically and chemically highly stable structure has paved<strong>the</strong> way for <strong>the</strong> halogen-free, flame-retardant plastics <strong>of</strong> <strong>to</strong>daywhich open up completely new opportunities for producinghigh.-quality, environmentally compatible cables. This resulted ina major shift <strong>to</strong> halogen-free cables.Depending on <strong>the</strong> requirements, halogen-free polymers as wellas PVC continue <strong>to</strong> be used. The correct use <strong>of</strong> PVC and halogenfreecompounds allows <strong>the</strong> advantages <strong>of</strong> both plastics <strong>to</strong> beused in an optimum way. In this connection, <strong>the</strong> Leoni Group continues<strong>to</strong> provide <strong>the</strong> optimum product groups in each case inorder <strong>to</strong> <strong>of</strong>fer <strong>the</strong> cus<strong>to</strong>mer a package which is as efficient as possible.

16 ICON Instrumentation Cableswww.leoni-communication-infrastructure.comInstrumentation CableRE-2X(St)H, 300 V, EN 50288-7, Single & Multi-Pair, Collective ScreenAdvantagesHalogen freeFlame retardantUV resistantOil resistantApplicationFor transmission <strong>of</strong> analogue and digital signals in instrumentand control systems; where people are potentially endangeredin case <strong>of</strong> fire. Not allowed for direct connection <strong>to</strong> lowimpendance source. Recommended for indoor and outdoorinstallation in dry and wet locations. Not for direct burial.ConstructionConduc<strong>to</strong>r: plain annealed copper wire, stranded, size: 1 mm²Insulation: cross-linked polyethylene XLPEColour code: black / white, continuously numbered on whitecore (1, 2, …) for multielement cableWrapping: at least 1 layer <strong>of</strong> plastic tapeCollective screen: 24 µm aluminium / PETP tape over tinnedcopper drain wire, 0.5 mm²Outer sheath: low smoke zero halogen flame retardantcompound LSZH, blackTechnical dataFlame propagation:Test on sigle cable IEC 60332-1-2Test on bunched cables IEC 60332-3-24 (Cat.C)Smoke density: IEC 61034-2 (L.T. > 60 %)Limiting Oxygen Index (LOI): ASTM D 2863 (min. 30 %)Flammability temperature (FT): ISO 4589-3 ann. A(min. + 250 °C)Amount <strong>of</strong> halogen acid gas: IEC 60754-1 (0 %)Degree <strong>of</strong> acidity <strong>of</strong> gases: IEC 60754-2 (pH > 4.3,C < 10µS/mm)Oil resistance: ICEA S-73-532*Sunlight resistance: UL 1581 Section 1200Temperature range:(during operation) – 30 °C up <strong>to</strong> + 90 °C(during installation) – 5 °C up <strong>to</strong> + 50 °CMinimum bending radius: 7.5 × cable diameter*(Test temperature: + 60 °C; test duration 4 h. Tensile strength and elongation atbreak: at least 60 % <strong>of</strong> <strong>the</strong> values before aging)

www.leoni-communication-infrastructure.comICON Instrumentation Cables17Electrical Properties at 20 °CConduc<strong>to</strong>r resistance: max. 18,5 Ω/kmInsulation resistance: min. 5000 MΩ × kmMutual capacitance: max. 150 nF/kmInductance: max. 1 mH/kmCapacitance unbalance: max. 500 pF/500 mL/R Ratio: max. 25 µH/ΩTest voltage U rms(core : core):Test voltage U rms(core : screen):Operating voltage:1500 V1500 V300 VGeometrical dataNo. <strong>of</strong> elements RT <strong>of</strong> insulation RT <strong>of</strong> outer sheath Outer dia. Weightnom. nom. approx. approx.1 mm²/7 (mm) (mm) (mm) (kg/km)1 0.40 0.9 6.3 562 0.40 1.0 9.4 1034 0.40 1.1 11.1 1556 0.40 1.0 13.0 21710 0.40 1.1 15.9 325RT = Radial ThicknessRE = Instrumentation2X = XLPE Insulation(St) = Collective ScreenH = LSZH Outer sheath

18 ICON Instrumentation Cableswww.leoni-communication-infrastructure.comInstrumentation CableRE-2X(St)H PiMF Single- & Mulit-Pair, Individual & Collective Screen, 300 V, EN 50288-7AdvantagesHalogen freeFlame retardantUV resistantOil resistantApplicationFor transmission <strong>of</strong> analogue and digital signal in instrumentand control systems; where people are potentially endangeredin case <strong>of</strong> fire. Not allowed for direct connection <strong>to</strong> lowimpendance source. Recommended for indoor and outdoorinstallation, in dry and wet locations. Not for direct burial.ConstructionConduc<strong>to</strong>r: plain annealed copper wire, stranded,size: 1 mm²Insulation: cross-linked polyethylene XLPEColour code: black / white, continuously numbered on whitecore (1, 2, …) for multielement cable 24 µm aluminium / PETPtape over tinned copper drain wire, 0.6 mm dia., plastic tapeunder and above screenWrapping: at least 1 layer <strong>of</strong> plastic tapeIndividual screen: 24 µm aluminium / PETP tape over tinnedcopper drain wire, 0.6 mm² dia. plastic tape underand above screenCollective screen: 24 µm aluminium / PETP tape over tinnedcopper drain wire, 0.5 mm²Outer sheath: low smoke zero halogen flame retardantcompound LSZH, blackTechnical dataFlame propagation:Test on single cable IEC 60332-1-2Test on bunched cables IEC 60332-3-24 (Cat.C)Smoke density: IEC 61034-2 (L.T. > 60 %)Limiting Oxygen Index (LOI): ASTM D 2863 (min. 30 %)Flammability temperature (FT): ISO 4589-3 ann. A(min. + 250 °C)Amount <strong>of</strong> halogen acid gas: IEC 60754-1 (0 %)Degree <strong>of</strong> acidity <strong>of</strong> gases: IEC 60754-2 (pH > 4.3,C < 10µS/mm)Oil resistance: ICEA S-73-532*Sunlight resistance: UL 1581 Section 1200Temperature range:(during operation) – 30 °C up <strong>to</strong> + 90 °C(during installation) – 5 °C up <strong>to</strong> + 50 °CMinimum bending radius: 7.5 × cable diamete*(Test temperature: + 60 °C; test duration 4 h. Tensile strength and elongation atbreak: at least 60 % <strong>of</strong> <strong>the</strong> values before aging)

www.leoni-communication-infrastructure.comICON Instrumentation Cables19Electrical Properties at 20 °CConduc<strong>to</strong>r: nom. 1 mm²Conduc<strong>to</strong>r resistance: max. 18,5 Ω/kmInsulation resistance: min. 5000 MΩ × kmMutual capacitance: max. 150 nF/kmInductance: max. 1 mH/kmL/R Ratio: max. 25 µH/ΩTest voltage U rms(core : core):Test voltage U rms(core : screen):Operating voltage:1500 V1500 V300 VGeometrical dataNo. <strong>of</strong> elements RT <strong>of</strong> insulation RT <strong>of</strong> outer sheath Outer dia. Weightnom. nom. approx. approx.1 mm²/7 (mm) (mm) (mm) (kg/km)2 0.40 1.0 10.4 1194 0.40 1.1 12.3 1806 0.40 1.2 14.9 26610 0.40 1.3 18.2 401RT = Radial ThicknessRE = Instrumentation2X = XLPE Insulation(St) = Collective ScreenH = LSZH Outer sheathPiMF = Pair in Metal Foil

20 ICON Instrumentation Cableswww.leoni-communication-infrastructure.comInstrumentation CableRE-2X(St)HX, Single & Multi-Pair, Collective Screen, 300 V, EN 50288-7AdvantagesHalogen freeFlame retardantUV resistantOil resistantElectron-Beam cross-linkedApplicationFor transmission <strong>of</strong> analogue and digital signals in instrumentand control systems; where people are potentially endangeredin case <strong>of</strong> fire. Not allowed for direct connection <strong>to</strong> lowimpendance source. Recommended for indoor and outdoorinstallation in dry and wet locations. Not for direct burial.ConstructionConduc<strong>to</strong>r: plain annealed copper wire, stranded,size: 1 mm²Insulation: cross-linked polyethylene XLPEColour code: black / white, continuously numbered on whitecore (1, 2, …) for multielement cableWrapping: at least 1 layer <strong>of</strong> plastic tapeCollective screen: 24 µm aluminium / PETP tape over tinnedcopper drain wire, 0.6 mm², plastic tape under and abovescreenOuter sheath: cross-linked low smoke zero halogen flameretardant compound LSZH, blackTechnical dataFlame propagation:Test on single cable IEC 60332-1-2Test on bunched cableIEC 60332-3-24 (Cat.C)Smoke density: IEC 61034-2 (L.T. > 60 %)Limiting Oxygen Index (LOI): ASTM D 2863 (min. 30 %)Flammability temperature (FT): ISO 4589-3 ann. A(min. + 250 °C)Amount <strong>of</strong> halogen acid gas: IEC 60754-1 (0 %)Degree <strong>of</strong> acidity <strong>of</strong> gases: IEC 60754-2 (pH > 4.3,C < 10µS/mm)Oil resistance: IEC 60092-359 (SHF 2)Sunlight resistance: UL 1581 Section 1200Temperature range:(during operation) – 30 °C up <strong>to</strong> + 90 °C(during installation) – 5 °C up <strong>to</strong> + 50 °CMinimum bending radius: 7.5 × cable diameter

www.leoni-communication-infrastructure.comICON Instrumentation Cables21Electrical Properties at 20 °CConduc<strong>to</strong>r resistance: max. 18,5 Ω/kmInsulation resistance: min. 5000 MΩ × kmMutual capacitance: max. 150 nF/kmInductance: max. 1 mH/kmCapacitance unbalance: max. 500 pF/500 mL/R ratio: max. 25 µH/ΩTest voltage U rms(core : core):Test voltage U rms(core : screen):Operating voltage:1500 V1500 V300 VGeometrical dataNo. <strong>of</strong> elements RT <strong>of</strong> insulation RT <strong>of</strong> outer sheath Outer dia. Weightnom. nom. approx. approx.1 mm²/7 (mm) (mm) (mm) (kg/km)1 0.40 0.9 6.3 562 0.40 1.0 9.4 1034 0.40 1.1 11.1 1556 0.40 1.0 13.0 21710 0.40 1.1 15.9 325RT = Radial ThicknessRE = Instrumentation2X = XLPE Insulation(St) = Collective ScreenH = LSZH Outer sheath

22 ICON Instrumentation Cableswww.leoni-communication-infrastructure.comInstrumentation CableRE-2X(St)HX PiMF, Single & Multi-Pair, Individual & Collective Screen, 300 V, EN 50288-7AdvantagesHalogen freeFlame retardantUV resistantOil resistantElectron-Beam cross-linkedApplicationFor transmission <strong>of</strong> analogue and digital signals in instrumentand control systems; where people are potentially endangeredin case <strong>of</strong> fire. Not allowed for direct connection <strong>to</strong> lowimpendance source. Recommended for indoor and outdoorinstallation in dry and wet locations. Not for direct burial.ConstructionConduc<strong>to</strong>r: plain annealed copper wire, stranded,size: 1 mm²Insulation: cross-linked polyethylene XLPEColour code: black / white, continuously numbered on whitecore (1, 2, …) for multielement cableWrapping: at least 1 layer <strong>of</strong> plastic tapeIndividual screen: 24 µm aluminium / PETP tape over tinnedcopper drain wire, 0.6 mm Ø, plastic tape under and abovescreenCollective screen: 24 µm aluminium / PETP tape over tinnedcopper drain wire, 0.5 mm²Outer sheath: cross-linked low smoke zero halogen flameretardant compound LSZH, blackTechnical dataFlame propagation:Test on single cable IEC 60332-1-2Test on bunched cables IEC 60332-3-24 (Cat.C)Smoke density: IEC 61034-2 (L.T. > 60 %)Limiting Oxygen Index (LOI): ASTM D 2863 (min. 30 %)Flammability temperature (FT): ISO 4589-3 ann. A(min. + 250 °C)Amount <strong>of</strong> halogen acid gas: IEC 60754-1 (0 %)Degree <strong>of</strong> acidity <strong>of</strong> gases: IEC 60754-2 (pH > 4.3,C < 10µS/mm)Oil resistance: IEC 60092-359 (SHF 2)Sunlight resistance: UL 1581 Section 1200Temperature range:(during operation) – 30 °C up <strong>to</strong> + 90 °C(during installation) – 5 °C up <strong>to</strong> + 50 °CMinimum bending radius: 7.5 × cable diameter

www.leoni-communication-infrastructure.comICON Instrumentation Cables23Electrical Properties at 20 °CConduc<strong>to</strong>r: nom. 1 mm²Conduc<strong>to</strong>r resistance: max. 18,5 Ω/kmInsulation resistance: min. 5000 MΩ × kmMutual capacitance: max. 150 nF/kmInductance: max. 1 mH/kmL/R ratio: max. 25 µH/ΩTest voltage U rms(core : core):Test voltage U rms(core : screen):Operating voltage:1500 V1500 V300 VGeometrical dataNo. <strong>of</strong> elements RT <strong>of</strong> insulation RT <strong>of</strong> outer sheath Outer dia. Weightnom. nom. approx. approx.1 mm²/7 (mm) (mm) (mm) (kg/km)2 0.40 1.0 10.4 1194 0.40 1.1 12.3 1806 0.40 1.2 14.9 26610 0.40 1.3 18.2 401RT = Radial ThicknessRE = Instrumentation2X = XLPE Insulation(St) = Collective ScreenHX = cross-linked LSZH Outer sheathPiMF = Pair in Metal Foil

24 ICON Instrumentation Cableswww.leoni-communication-infrastructure.comInstrumentation CableRE-2X(St)HSWAH, Single & Multi-Pair, Collective Screen, 300 V, EN 50288-7AdvantagesHalogen freeFlame retardantUV resistantOil resistantMechanical protection via steel round wireApplicationFor transmission <strong>of</strong> analogue and digital signals in instrumentand control systems; where people are potentially endangeredin case <strong>of</strong> fire. Not allowed for direct connection <strong>to</strong> lowimpendance source. Recommended fpr indoor and outdoorinstallation in dry and wet locations. For direct burial.ConstructionConduc<strong>to</strong>r: plain annealed copper wire, stranded,size: 1 mm²Insulation: cross-linked polyethylene XLPEColour code: black / white, continuously numbered on whitecore (1, 2, …) for multielement cableWrapping: at least 1 layer <strong>of</strong> plastic tapeCollective screen: 24 µm aluminium / PETP tape over tinnedcopper drain wire, 0.5 mm²Inner sheath: low smoke zero halogen flame retardantcompound LSZH, blackArmour: galvanised round steel wiresOu<strong>the</strong>r sheath: low smoke zero halogen flame retardantcompound LSZH, blackTechnical dataFlame propagation:Test on single cable IEC 60332-1-2Test on bunched cables IEC 60332-3-24 (Cat.C)Smoke density: IEC 61034-2 (L.T. > 60 %)Limiting Oxygen Index (LOI): ASTM D 2863 (min. 30 %)Flammability temperature (FT): ISO 4589-3 ann. A(min. + 250 °C)Amount <strong>of</strong> halogen acid gas: IEC 60754-1 (0 %)Degree <strong>of</strong> acidity <strong>of</strong> gases: IEC 60754-2 (pH > 4.3,C < 10µS/mm)Oil resistance: ICEA S-73-532*Sunlight resistance: UL 1581 Section 1200Temperature range:(during operation) – 30 °C up <strong>to</strong> + 90 °C(during installation) – 5 °C up <strong>to</strong> + 50 °CMinimum bending radius: 10 × cable diameter*(Test temperature: + 60 °C; test duration 4 h. Tensile strength and elongation atbreak: at least 60 % <strong>of</strong> <strong>the</strong> values before aging)

www.leoni-communication-infrastructure.comICON Instrumentation Cables25Electrical Properties at 20 °CConduc<strong>to</strong>r resistance: max. 18,5 Ω/kmInsulation resistance: min. 5000 MΩ × kmMutual capacitance: max. 150 nF/kmInductance: max. 1 mH/kmCapacitance unbalance: max. 500 pF/500 mL/R ratio: max. 25 µH/ΩTest voltage U rms(core : core):1500 VTest voltage U rms(core : screen):1500 VOperating voltage:300 VGeometrical dataNo. <strong>of</strong> elements RT <strong>of</strong> insulation RT <strong>of</strong> inner sheathDia. over innersheath 1Dia. <strong>of</strong> armourwireRT <strong>of</strong> outer sheath Outer dia. Weightnom. nom. approx. nom. nom. approx. approx.1 mm²/7 (mm) (mm) (mm) (mm) (mm) (mm) (kg/km)1 0.40 0.9 6.3 0.9 1.3 10.7 2212 0.40 0.9 9.2 0.9 1.4 13.8 3334 0.40 1.0 10.9 0.9 1.4 15.5 4256 0.40 1.0 13.0 0.9 1.4 17.6 53810 0.40 1.3 16.3 1.25 1.6 22.0 863RT = Radial ThicknessRE = Instrumentation2X = XLPE Insulation(St) = Collective ScreenH = LSZH inner and outer sheathSWA = Steel round wire armouring

28 ICON Instrumentation Cableswww.leoni-communication-infrastructure.comInstrumentation CableRE-2X(St)HSWAHX, Single & Multi-Pair, Collective screen, 300 V, EN 50288-7AdvantagesHalogen free and flame retardantUV resistantElectron-beam cross-linkedOil resistantMechanical protection via steel round wireApplicationFor transmission <strong>of</strong> analogue and digital signals in instrumentand control systems; where people are potentially endangeredin case <strong>of</strong> fire. Not allowed for direct connection <strong>to</strong> lowimpendance source. Recommended for indoor and outdoorinstallation in dry and wet locations. For direct burial.ConstructionConduc<strong>to</strong>r: plain annealed copper wire, stranded,size: 1 mm²Insulation: cross-linked polyethylene XLPEColour code: black / white, continuously numbered on whitecore (1, 2, …) for multielement cableWrapping: at least 1 layer <strong>of</strong> plastic tapeCollective screen: 24 µm aluminium / PETP tape over tinnedcopper drain wire, 0.5 mm²Inner sheath: low smoke zero halogen flame retardantcompound LSZH, blackArmour: galvanised round steel wiresOuter sheath: cross linked low smoke zero halogen flameretardant compound LSZH, blackTechnical dataFlame propagation:Test on single cable IEC 60332-1-2Test on bunched cables IEC 60332-3-24 (Cat.C)Smoke density: IEC 61034-2 (L.T. > 60 %)Limiting Oxygene Index (LOI): ASTM D 2863 (min. 30 %)Flammability temperature (FT): ISO 4589-3 ann. A(min. + 250 °C)Amount <strong>of</strong> halogen acid gas: IEC 60754-1 (0 %)Degree <strong>of</strong> acidity <strong>of</strong> gases: IEC 60754-2 (pH > 4.3,C < 10µS/mm)Oil resistance: IEC 60092-359 (SHF 2)Sunlight resistance: UL 1581 Section 1200Temperature range:(during operation) – 30 °C up <strong>to</strong> + 90 °C(during installation) – 5 °C up <strong>to</strong> + 50 °CMinimum bending radius: 10 × cable diameter

www.leoni-communication-infrastructure.comICON Instrumentation Cables29Electrical Propertiesaften at 20 °CConduc<strong>to</strong>r resistance: max. 18,5 Ω/kmInsulation resistance: min. 5000 MΩ × kmMutual capacitance: max. 150 nF/kmInductance: max. 1 mH/kmCapacitance unbalance: max. 500 pF/500 mL/R ratio: max. 25 µH/ΩTest voltage U rms(core : core):1500 VTest voltage U rms(core : screen):1500 VOperating voltage:300 VGeometrical dataNo. <strong>of</strong> elements RT <strong>of</strong> insulation RT <strong>of</strong> inner sheathDia. over innersheath 1Dia. <strong>of</strong> armourwireRT <strong>of</strong> outer sheath Outer dia. Weightnom. nom. approx. nom. nom. approx. approx.1 mm²/7 (mm) (mm) (mm) (mm) (mm) (mm) (kg/km)1 0,40 0.9 6.3 0.9 1.3 10.7 2212 0.40 0.9 9.2 0.9 1.4 13.8 3334 0.40 1.0 10.9 0.9 1.4 15.5 4256 0.40 1.0 13.0 0.9 1.4 17.6 53810 0.40 1.3 16.3 1.25 1.6 22.0 863RT = Radial ThicknessRE = Instrumentation2X = XLPE Insulation(St) = Collective ScreenH = LSZH inner and outer sheathSWA = Steel round wire armouringHX = cross-linked LSZH Outer sheath

30 ICON Instrumentation Cableswww.leoni-communication-infrastructure.comInstrumentation CableRE-2X(St)HSWAHX PiMF, Multi-Pair, Individual & Collective screen, 300 V, EN 50288-7AdvantagesHalogen free and flame retardantUV resistantElectron-beam cross-linkedOil resistantMechanical protection via steel round wireApplicationFor transmission <strong>of</strong> analogue and digital signals in instrumentand control systems; where people are potentially endangeredin case <strong>of</strong> fire. Not allowed for direct connection <strong>to</strong> lowimpendance source. Recommended for indoor and outdoorinstallation in dry and wet locations. For direct burial.ConstructionConduc<strong>to</strong>r: plain annealed copper wire, stranded,size: 1 mm²Insulation: cross-linked polyethylene XLPEColour code: black / white, continuously numbered on whitecore (1, 2, …) for multielement cableWrapping: at least 1 layer <strong>of</strong> plastic tapeIndividual screen: 24 µm aluminium / PETP tape over tinnedcopper drain wire, 0.6 mm Ø, plastic tape under and abovescreenCollective screen: 24 µm aluminium / PETP tape over tinnedcopper drain wire, 0.5 mm²Inner sheath: low smoke zero halogen flame retardantcompound LSZH, blackArmour: galvanised round steel wiresOuter sheath: cross linked low smoke zero halogen flameretardant compound LSZH, blackTechnical dataFlame propagation:Test on single cable IEC 60332-1-2Test on bunched cables IEC 60332-3-24 (Cat.C)Smoke density: IEC 61034-2 (L.T. > 60 %)Limiting Oxygene Index (LOI): ASTM D 2863 (min. 30 %)Flammability temperature (FT): ISO 4589-3 ann. Amin. + 250 °C)Amount <strong>of</strong> halogen acid gas: IEC 60754-1 (0 %)Degree <strong>of</strong> acidity <strong>of</strong> gases: IEC 60754-2 (pH > 4.3,C < 10µS/mm)Oil resistance: IEC 60092-359 (SHF 2)Sunlight resistance: UL 1581 Section 1200Temperature range:(during operation) – 30 °C up <strong>to</strong> + 90 °C(during installation) – 5 °C up <strong>to</strong> + 50 °CMinimum bending radius: 10 × cable diameter

www.leoni-communication-infrastructure.comICON Instrumentation Cables31Electrical Properties at 20 °CConduc<strong>to</strong>r resistance: max. 18,5 Ω/kmInsulation resistance: min. 5000 MΩ × kmMutual capacitance: max. 150 nF/kmInductance: max. 1 mH/kmL/R ratio: max. 25 µH/ΩTest voltage U rms(core : core):1500 VTest voltage U rms(core : screen):1500 VOperating voltage:300 VGeometrical dataNo. <strong>of</strong> elements RT <strong>of</strong> insulation RT <strong>of</strong> inner sheathDia. over innersheath 1Dia. <strong>of</strong> armourwireRT <strong>of</strong> outer sheath Outer dia. Weightnom. nom. approx. nom. nom. approx. approx.1 mm²/7 (mm) (mm) (mm) (mm) (mm) (mm) (kg/km)2 0.40 1.0 10.4 0.9 1.4 15.0 3854 0.40 1.0 12.1 0.9 1.4 16.7 4776 0.40 1.2 14.9 0.9 1.6 19.9 64710 0.40 1.3 18.2 1.25 1.7 24.1 995RT = Radial ThicknessRE = Instrumentation2X = XLPE Insulation(St) = Collective ScreenH = LSZH inner and outer sheathSWA = Steel round wire armouringHX = cross-linked LSZH Outer sheathPiMF = Pair in Metal Foil

32 ICON Instrumentation Cableswww.leoni-communication-infrastructure.comInstrumentation Cable PLTC/ITCRE-2X(St)H, Single & Multi-Pair, Collective screen, 300 V, UL 13/UL2250AdvantagesHalogen freeFlame retardantUV resistantOil resistantApplicationUL-listed power limited tray cable in compliance with NEC article725.154, for use in hazardous classified locations class I and classII division 2 acc. <strong>to</strong> NEC 501.10(B) and NEC 502.10(B).Recommended for indoor and outdoor installation, in dry andwet locations. Not for direct burial.ConstructionConduc<strong>to</strong>r: plain annealed copper wire, stranded,size: AWG 18 / 7Insulation: cross-linked polyethylene XLPEColour code: black / white, continuously numbered on whitecore (1, 2, …) for multielement cableWrapping: at least 1 layer <strong>of</strong> plastic tapeCollective screen: plastic coated aluminium tape in contactwith tinned copper drain wireOuter sheath: low smoke zero halogen flame retardantcompound LSZH, blackTechnical dataFlame propagation:Test on single cableUL13 (VW-1)Test on bunched cables UL 1685 (vertical tray)Gas/vapour tightness outer sheath: NEC 501,15 (D) und (E)Limiting Oxygen Index (LOI): ASTM D 2863 (min. 30 %)Flammability temperature (FT): ISO 4589-3 ann. A(min. + 250 °C)Amount <strong>of</strong> halogen acid gas: IEC 60754-1 (0 %)Degree <strong>of</strong> acidity <strong>of</strong> gases: IEC 60754-2 (pH > 4.3,C < 10µS/mm)Oil resistance: ICEA S-73-532Sunlight resistance: UL 1581 Section 1200Temperatur range:(during operation) – 40 °C up <strong>to</strong> + 90 °C(during installation) – 5 °C up <strong>to</strong> + 50 °CMinimum bending radius: 7.5 × cable diameter*(Test temperature: + 60 °C; test duration 4 h. Tensile strength and elongation atbreak: at least 60 % <strong>of</strong> <strong>the</strong> values before aging)

www.leoni-communication-infrastructure.comICON Instrumentation Cables33Electrical properties at 20 °CConduc<strong>to</strong>r resistance: max. 22,8Ω/km / 6,93 Ω/1000 ftInsulation resistance:Mutual capacitance30,5 MΩ × km / 100 MΩ × 1000 ft(with 15,6 °C)1 Element: 125 nF/km / 39 nF/1000 ft2 <strong>to</strong> 4 Elements: 95 nF/km / 29 nF/1000 ftabove 4 Elements:80 nF/km / 25 nF/1000 ftInductance: max. 1 mH/kmL/R ratio: max. 25 µH/ΩTest voltage U rms(core : core):Test voltage U rms(core : screen):Operating voltage:1500 V1500 V300 VGeometrical dataNo. <strong>of</strong> elements RT <strong>of</strong> insulation RT <strong>of</strong> outer sheath Outer dia. Weightnom. nom. approx. approx.AWG 18 /7 (mm / mils) (mm / mils) (mm / in) (kg/km / lbs/1000 ft)1 0.38 / 15 0.89 / 35 6.0 / 0.24 54 / 402 0.38 / 15 1.02 / 40 9.0 / 0.35 101 / 708 0.38 / 15 1.27 / 50 13.6 / 0.54 265 / 18512 0.38 / 15 1.52 / 60 16.6 / 0.65 393 / 270RT = Radial ThicknessRE = Instrumentation2X = XLPE Insulation(St) = Collective ScreenH = LSZH Outer sheath

34 ICON Instrumentation Cableswww.leoni-communication-infrastructure.comIntrumentation Cable PLTC/ITCRE-2X(St)H PiMF, Multi-Pair, Individual & Collective screen, 300 V, UL 13/UL2250AdvantagesHalogen freeFlame retardantUV resistantOil resistantApplicationUL-listed power limited tray cable in compliance with NEC article725.154, for use in hazardous classified locations class I and classII division 2 acc. <strong>to</strong> NEC 501.10(B) and NEC 502.10(B).Recommended for indoor and outdoor installation, in dry andwet locations. Not for direct burial.ConstructionConduc<strong>to</strong>r: plain annealed copper wire, stranded,size: AWG 18 / 7Insulation: cross-linked polyethylene XLPEColour code: black / white, continuously numbered on whitecore (1, 2, …) for multielement cableWrapping: at least 1 layer <strong>of</strong> plastic tapeIndividual screen: plastic coated aluminium tape in contactwith tinned copper drain wireCollective screen: plastic coated aluminium tape in contactwith tinned copper drain wireOuter sheath: low smoke zero halogen flame retardantcompound LSZH, blackTechnical dataFlame propagation:Test on single cableUL13 (VW-1)Test on bunched cables UL 1685 (vertical tray)Gas/vapour tightness outer sheath: NEC 501,15 (D) und (E)Limiting Oxygen Index (LOI): ASTM D 2863 (min. 30 %)Flammability temperature (FT): ISO 4589-3 ann. A(min. + 250 °C)Amount <strong>of</strong> halogen acid gas: IEC 60754-1 (0 %)Degree <strong>of</strong> acidity <strong>of</strong> gases: IEC 60754-2 (pH > 4.3,C < 10µS/mm)Oil resistance: ICEA S-73-532Sunlight resistance: UL 1581 Section 1200Temperatur range:(during operation) – 40 °C up <strong>to</strong> + 90 °C(during installation) – 5 °C up <strong>to</strong> + 50 °CMinimum bending radius: 7.5 × cable diameter*(Test temperature: + 60 °C; test duration 4 h. Tensile strength and elongation atbreak: at least 60 % <strong>of</strong> <strong>the</strong> values before aging)

www.leoni-communication-infrastructure.comICON Instrumentation Cables35Electrical Properties at 20 °CConduc<strong>to</strong>r resistance: max.22,8 Ω/km / 6,93 Ω/1000 ftInsulation resistance: min. 30,5 MΩ × km /100 MΩ × 1000 ft(with 15,6 °C)Mutual capacitance: nom. 125 nF/km / 39 nF/1000 ftInductance: max. 1 mH/kmL/R ratio: max. 25 µH/ΩTest voltage U rms(core : core):Test voltage U rms(core : screen):Operating voltage:1500 V1500 V300 VGeometrical dataNo. <strong>of</strong> elements RT <strong>of</strong> insulation RT <strong>of</strong> outer sheath Outer dia. Weightnom. nom. approx. approx.AWG 18 /7 (mm / mils) (mm / mils) (mm / in) (kg/km / lbs/1000 ft)2 0.38 / 15 1.27 / 50 10.8 / 0.43 138 / 958 0.38 / 15 1.52 / 60 16.3 / 0.64 368 / 25012 0.38 / 15 1.52 / 60 19.2 / 0.76 497 / 340RT = Radial ThicknessRE = Instrumentation2X = XLPE Insulation(St) = Collective ScreenH = LSZH Outer sheathPiMF = Pair in Metal Foil

36 ICON Instrumentation Cableswww.leoni-communication-infrastructure.comInstrumentation Cable PLTC/ITCRE-2X(St)HSWAH, Single & Multi-Pair, Collective screen, 300 V, UL 13/UL2250AdvantagesHalogen free and flame retardantUV resistantOil resistantMechanical protection via steel round wireApplicationUL-listed power limited tray cable in compliance with NEC article725.154, for use in hazardous classified locations class I and classII division 2 acc. <strong>to</strong> NEC 501.10(B) and NEC 502.10(B).Recommended for indoor and outdoor installation, in dry andwet locations. Not for direct burial.ConstructionConduc<strong>to</strong>r: plain annealed copper wire, stranded,size: AWG 18/ 7Insulation: cross-linked polyethylene XLPEColour code: black / white, continuously numbered on whitecore (1, 2, …) for multielement cableWrapping: at least 1 layer <strong>of</strong> plastic tapeCollective screen: plastic coated aluminium tape in contactwith tinned copper drain wireInner sheath: low smoke zero halogen flame retardantcompound LSZH, blackArmour: galvanised round steel wiresOuter sheath: low smoke zero halogen flame retardantcompound LSZH, blackTechnical dataFlame propagation:Test on single cableUL13 (VW-1)Test on bunched cables UL 1685 (vertical tray)Gas/vapour tightness outer sheath: NEC 501,15 (D) und (E)Limiting Oxygen Index (LOI): ASTM D 2863 (min. 30 %)Flammability temperature (FT): ISO 4589-3 ann. A(min. + 250 °C)Amount <strong>of</strong> halogen acid gas: IEC 60754-1 (0 %)Degree <strong>of</strong> acidity <strong>of</strong> gases: IEC 60754-2 (pH > 4.3,C < 10µS/mm)Oil resistance: ICEA S-73-532*Sunlight resistance: UL 1581 Section 1200Temperatur range:(during operation) – 40 °C up <strong>to</strong> + 90 °C(during installation) – 5 °C up <strong>to</strong> + 50 °CMinimum bending radius: 10 × cable diameter*(Test temperature: + 60 °C; test duration 4 h. Tensile strength and elongation atbreak: at least 60 % <strong>of</strong> <strong>the</strong> values before aging)

www.leoni-communication-infrastructure.comICON Instrumentation Cables37Electrical Properties at 20 °CConduc<strong>to</strong>r resistance: max. 22,8 Ω/km / 6,93 Ω/1000 ftInsulation resistance: min. 30,5 MΩ × km / 100 MΩ × 1000 ftMutual capacitance(with 15,6 °C)1 Element: 125 nF/km / 39 nF/1000 ft2 <strong>to</strong> 4 Elements: 95 nF/km / 29 nF/1000 ftabove 4 Elements:80 nF/km / 25 nF/1000 ftInductance: max. 1 mH/kmL/R ratio: max. 25 µH/ΩTest voltage U rms(core : core):Test voltage U rms(core : screen):Operating voltage:1500 V1500 V300 VGeometrical dataNo. <strong>of</strong> elements RT <strong>of</strong> insulation RT <strong>of</strong> inner sheathDia. over innersheathDia. <strong>of</strong> armourwireRT <strong>of</strong> outersheathOuter Dia.nom. nom. nom. nom. nom. approx. approx.1 mm2/7 (mm / mils) (mm / mils) (mm / in) (mm) (mm / mils) (mm / in) (kg/km / lbs/1000 ft)1 0.38 / 15 0.89 / 35 6.10 / 0.24 0.9 1.27 / 50 10.3 / 0.41 217 / 1502 0.38 / 15 1.2 / 40 9.10 / 0.35 0.9 1.27 / 50 13.4 / 0.52 341 / 2358 0.38 / 15 1.27 / 50 13.6 / 0.54 0.9 1.52 / 60 18.5 / 0.72 628 / 42512 0.38 / 15 1.52 / 60 16.6 / 0.65 1.25 1.78 / 70 22.7 / 0.89 972 / 675WeightRT = Radial ThicknessRE = Instrumentation2X = XLPE Insulation(St) = Collective ScreenH = LSZH inner and outer sheathSWA = Steel round wire armouringH = LSZH Outer sheath

38 ICON Instrumentation Cableswww.leoni-communication-infrastructure.comInstrumentation Cable PLTC/ITCRE-2X(St)HSWAH PiMF, Multi-Pair, Individual & Collective screen, 300 V, UL 13/UL2250AdvantagesHalogen freeFlame retardantUV resistantOil resistantMechanical protection via steel round wireApplicationUL-listed power limited tray cable in compliance with NEC article725.154, for use in hazardous classified locations class I and classII division 2 acc. <strong>to</strong> NEC 501.10(B) and NEC 502.10(B).Recommended for indoor and outdoor installation, in dry andwet locations. Not for direct burial.ConstructionConduc<strong>to</strong>r: plain annealed copper wire, stranded,size: AWG 18 / 7Insulation: cross-linked polyethylene XLPEColour code: black / white, continuously numbered on whitecore (1, 2, …) for multielement cableWrapping: at least 1 layer <strong>of</strong> plastic tapeIndividual screen: plastic coated aluminium tape in contactwith tinned copper drain wireCollective screen: plastic coated aluminium tape in contactwith tinned copper drain wireInner sheath: low smoke zero halogen flame retardantcompound LSZH, blackArmour: galvanised round steel wiresOuter sheath: low smoke zero halogen flame retardantcompound LSZH, blackTechnical dataFlame propagation:Test on single cable UL13 (VW-1)Test on bunched cables UL 1685 (vertical tray)Gas/vapour tightness outer sheath: NEC 501,15 (D) und (E)Limiting Oxygen Index (LOI): ASTM D 2863 (min. 30 %)Flammability temperature (FT): ISO 4589-3 ann. A(min. + 250 °C)Amount <strong>of</strong> halogen acid gas: IEC 60754-1 (0 %)Degree <strong>of</strong> acidity <strong>of</strong> gases: IEC 60754-2 (pH > 4.3,C < 10µS/mm)Oil resistance: ICEA S-73-532*Sunlight resistance: UL 1581 Section 1200Temperatur range:(during operation) – 40 °C up <strong>to</strong> + 90 °C(during installation) – 5 °C up <strong>to</strong> + 50 °CMinimum bending radius: 10 × cable diameter*(Test temperature: + 60 °C; test duration 4 h. Tensile strength and elongation atbreak: at least 60 % <strong>of</strong> <strong>the</strong> values before aging)

www.leoni-communication-infrastructure.comICON Instrumentation Cables39Electrical Properties at 20 °CConduc<strong>to</strong>r resistance:max. 22,8 Ω/km / 6,93 Ω/1000 ftInsulation resistance: min. 30,5 MΩ × km / 100 MΩ × 1000 ft(with 15,6 °C)Mutual capacitance: nom. 125 nF/km / 39 nF/1000 ftInductance: max. 1 mH/kmL/R ratio: max. 25 µH/ΩTest voltage U rms(core : core):Test voltage U rms(core : screen):Operating voltage:1500 V1500 V300 VGeometrical dataNo. <strong>of</strong> elements RT <strong>of</strong> insulation RT <strong>of</strong> inner sheathDia. over innersheathDia. <strong>of</strong> armourwireRT <strong>of</strong> outer sheath Outer dia. Weightnom. nom. nom. nom. nom. approx. approx.AWG 18 /7 (mm / mils) (mm / mils) (mm / in) (mm) (mm / mils) (mm / in) (kg/km / lbs/1000 ft)2 0.38 / 15 1.27 / 50 10.8 / 0.43 0.9 1.27 / 50 15.2 / 0.59 408 / 2808 0.38 / 15 1.52 / 60 16.3 / 0.64 1.25 1.52 / 60 21.9 / 0.86 904 / 61012 0.38 / 15 1.52 / 60 19.2 / 0.76 1.25 1.78 / 70 25.3 / 1.00 1156 / 800RT = Radial ThicknessRE = Instrumentation2X = XLPE Insulation(St) = Collective ScreenH = LSZH inner and outer sheathSWA = Steel round wire armouringPiMF = Pair in Metal Foil

40 <strong>Power</strong> and Control Cableswww.leoni-communication-infrastructure.com<strong>Power</strong> and Control Cable2XH 600/1000 V, Multi-Pair, IEC 60502-1AdvantagesHalogen freeFlame retardantUV resistantOil resistantApplicationFor electricity supply and control in public networks and industrialplants or public buildings, where people are potentiallyendangered in case <strong>of</strong> fire. Recommended for indoor andoutdoor installation, in dry and wet locations. For direct burial.ConstructionConduc<strong>to</strong>r: plain annealed copper wire, circular stranded(RM), according <strong>to</strong> IEC 60228Insulation: cross-linked polyethylene XLPEColour code:2-core: blue / brown3-core: brown / black / grey4-core: blue / brown / black / grey5-core: blue / brown / black / grey / black(o<strong>the</strong>r colours on request)Laying up: cores twisted in layersFilling material: extruded filler <strong>of</strong> regenerated rubberOuter sheath: cross-linked low smoke zero halogen retardantcompound LSZH, blackTechnical dataFlame propagation:Test on single cable IEC 60332-1-2Test on bunched cables IEC 60332-3-24 (Cat.C)Smoke density: IEC 61034-2 (L.T. > 60 %)Limiting Oxygen Index (LOI): ASTM D 2863 (min. 30 %)Flammability temperature (FT): ISO 4589-3 ann. A(min. + 250 °C)Amount <strong>of</strong> halogen acid gas: IEC 60754-1 (0 %)Degree <strong>of</strong> acidity <strong>of</strong> gases: IEC 60754-2 (pH > 4.3,C < 10µS/mm)Oil resistance: IEC 60092-359 (SHF-2)*Sunlight resistance: UL 1581 Section 1200Temperatur range:(during operation) – 30 °C up <strong>to</strong> + 90 °C(during installation) – 5 °C up <strong>to</strong> + 50 °C(under short circuit) max. + 250 °CMinimum bending radius: 8 × cable diameter*(Test temperature: + 60 °C; test duration 4 h. Tensile strength and elongation atbreak: at least 60 % <strong>of</strong> <strong>the</strong> values before aging)

www.leoni-communication-infrastructure.com<strong>Power</strong> and Control Cables41Electrical Properties at 20 °CConduc<strong>to</strong>r resistance: according <strong>to</strong> IEC 60228Test voltage U rms(core : core):Nominal voltage U o/ U:3500 V600/1000 VHighest system voltage U m: max. 1200 V(for 3-phase systems)Geometrical dataSize RT <strong>of</strong> insulation RT <strong>of</strong> outer sheath Outer dia. Weightnom. nom. approx. approx.1,5 mm² (mm) (mm) (mm) (kg/km)2 × 1.5 RM 0.70 1.8 10.2 1513 × 1.5 RM 0.70 1.8 10.7 1734 × 1.5 RM 0.70 1.8 11.4 1905 × 1.5 RM 0.70 1.8 11.9 205nom. nom. approx. approx.2.5 mm² (mm) (mm) (mm) (kg/km)2 × 2.5 RM 0.70 1.8 11.0 1853 × 2.5 RM 0.70 1.8 11.6 2134 × 2.5 RM 0.70 1.8 12.4 2495 × 2.5 RM 0.70 1.8 13.0 260RT = Radial Thickness2X = XLPE InsulationH = LSZH Outer sheath

42 <strong>Power</strong> and Control Cableswww.leoni-communication-infrastructure.com<strong>Power</strong> and Control Cable2XHX, Multi-Pair, 600/1000 V, IEC 60502-1AdvantagesHalogen freeFlame retardantUV resistantOil resistantElectron-beam cross-linkedApplicationFor electricity supply and control in public networks and industrialplants or public buildings, where people are potentiallyendangered in case <strong>of</strong> fire. Recommended for indoor andoutdoor installation, in dry and wet locations. For direct burial.ConstructionConduc<strong>to</strong>r: plain annealed copper wire, circular stranded(RM), according <strong>to</strong> IEC 60228Insulation: cross-linked polyethylene XLPEColour code:2-core: blue / brown3-core: brown / black / grey4-core: blue / brown / black / grey5-core: blue / brown / black / grey / black(o<strong>the</strong>r colours on request)Laying up: cores twisted in layersFilling material: extruded filler <strong>of</strong> regenerated rubberOuter sheath: cross-linked low smoke zero halogen retardantcompound LSZH, blackTechnical dataFlame propagation:Test on single cable IEC 60332-1-2Test on bunched cables IEC 60332-3-24 (Cat.C)Smoke density: IEC 61034-2 (L.T. > 60 %)Limiting Oxygen Index (LOI): ASTM D 2863 (min. 30 %)Flammability temperature (FT): ISO 4589-3 ann. A(min. + 250 °C)Amount <strong>of</strong> halogen acid gas: IEC 60754-1 (0 %)Degree <strong>of</strong> acidity <strong>of</strong> gases: IEC 60754-2 (pH > 4.3,C < 10µS/mm)Oil resistance: IEC 60092-359 (SHF-2)Sunlight resistance: UL 1581 Section 1200Temperatur range:(during operation) – 30 °C up <strong>to</strong> + 90 °C(during installation) – 5 °C up <strong>to</strong> + 50 °C(under short circuit) max. + 250 °CMinimum bending radius: 8 × cable diameter

www.leoni-communication-infrastructure.com<strong>Power</strong> and Control Cables43Electrical Properties at 20 °CConduc<strong>to</strong>r resistance: according <strong>to</strong> IEC 60228Test voltage U rms(core : core):3500 VNominal voltage U o/ U:600/1000 VHighest system voltage U m: max. 1200 V(for 3-phase systems)Geometrical dataSize RT <strong>of</strong> insulation RT <strong>of</strong> outer sheath Outer dia. Weightnom. nom. approx. approx.1,5 mm² (mm) (mm) (mm) (kg/km)3 × 1.5 RM 0.70 1.8 10.2 1513 × 1.5 RM 0.70 1.8 10.7 1733 × 1.5 RM 0.70 1.8 11.4 1903 × 1.5 RM 0.70 1.8 11.9 2052.5 mm²2 × 2.5 RM 0.70 1.8 11.0 1853 × 2.5 RM 0.70 1.8 11.6 2134 × 2.5 RM 0.70 1.8 12.4 2495 × 2.5 RM 0.70 1.8 13.0 260RT = Radial Thickness2X = XLPE InsulationHX = cross-linked LSZH Outer sheath

44 <strong>Power</strong> and Control Cableswww.leoni-communication-infrastructure.com<strong>Power</strong> and Control Cable2XHRH, Multi-Pair, 600/1000 V, IEC 60502-1AdvantagesHalogen freeFlame retardantUV resistantOil resistantMechanical protection SWAApplicationFor electricity supply and control in public networks and industrialplants or public buildings, where people are potentiallyendangered in case <strong>of</strong> fire. Recommended for indoor andoutdoor installation, in dry and wet locations. For direct burial.ConstructionConduc<strong>to</strong>r: plain annealed copper wire, circular stranded(RM), according <strong>to</strong> IEC 60228Insulation: cross-linked polyethylene XLPEColour code:2-core: blue / brown3-core: brown / black / grey4-core: blue / brown / black / grey5-core: blue / brown / black / grey / black(o<strong>the</strong>r colours on request)Laying up: cores twisted in layersCollective screen: plastic coated aluminium tape in contactwith tinned copper drain wireWrapping: at least 1 layer <strong>of</strong> plastic tapeInner sheath: low smoke zero halogen flame retardantcompound LSZH, blackArmour: galvanised round steel wiresOuter sheath: low smoke zero halogen flame retardantcompound LSZH, blackTest on single cable IEC 60332-1-2Test on bunched cables IEC 60332-3-24 (Cat.C)Smoke density: IEC 61034-1 and 2 (L. T. > 60 %)Limiting Oxygen Index (LOI): ASTM D 2863 (min. 30 %)Flammability temperature (FT): ISO 4589-3 ann. A(min. + 250 °C)Amount <strong>of</strong> halogen acid gas: IEC 60754-1 (0 %)Degree <strong>of</strong> acidity <strong>of</strong> gases: IEC 60754-2 (pH > 4.3,C < 10µS/mm)Oil resistance: ICEA S-73-532*Sunlight resistance: UL 1581 Section 1200Temperatur range:(during operation) – 30 °C up <strong>to</strong> + 90 °C(during installation) – 5 °C up <strong>to</strong> + 50 °C(under short circuit) max. + 250 °CMinimum bending radius: 10 × cable diameterTechnical dataFlame propagation:*(Test temperature: + 60 °C; test duration 4 h. Tensile strength and elongation atbreak: at least 60 % <strong>of</strong> <strong>the</strong> values before aging)

www.leoni-communication-infrastructure.com<strong>Power</strong> and Control Cables45Electrical Properties at 20 °CLConduc<strong>to</strong>r resistance: according <strong>to</strong> IEC 60228Test voltage U rms(core : core):3500 VTest voltage U rms(core : armour):3500 VNominal voltage U o/ U:600/1000 VHighest system voltage U m: max. 1200 V(for 3-phase systems)Geometrical dataSize RT <strong>of</strong> insulation RT <strong>of</strong> inner sheathDia. over inner Dia. <strong>of</strong> armoursheath 1wireRT <strong>of</strong> outer sheath Outer dia. Weightnom. nom. approx. nom. nom. approx. approx.1,5 mm² (mm) (mm) (mm) (mm) (mm) (mm) (kg/km)2 × 1.5 RM 0.70 0.8 7.7 0.9 1.8 13.1 2953 × 1.5 RM 0.70 0.8 8.3 0.9 1.8 13.7 3284 × 1.5 RM 0.70 0.8 9.0 0.9 1.8 14.4 3655 × 1.5 RM 0.70 0.8 9.8 0.9 1.8 15.2 4002.5 mm²2 × 2.5 RM 0.70 0.8 8.5 0.9 1.8 13.9 3393 × 2.5 RM 0.70 0.8 9.1 0.9 1.8 14.5 3764 × 2.5 RM 0.70 0.8 10.0 0.9 1.8 15.4 4295 × 2.5 RM 0.70 0.8 11.0 0.9 1.8 16.4 480RT = Radial Thickness2X = XLPE InsulationH = LSZH inner and outer sheathR = Steel round wire armouring

46 <strong>Power</strong> and Control Cableswww.leoni-communication-infrastructure.com<strong>Power</strong> and Control Cable2XHRHX, Multi-Pair, 600/1000 V, IEC 60502-1AdvantagesHalogen free and flame retardantUV resistantOil resistantMechanical protection via steel round wireElectron-beam cross-linkedApplicationFor electricity supply and control in public networks and industrialplants or public buildings, where people are potentiallyendangered in case <strong>of</strong> fire. Recommended for indoor andoutdoor installation, in dry and wet locations. For direct burial.ConstructionConduc<strong>to</strong>r: plain annealed copper wire, circular stranded(RM), according <strong>to</strong> IEC 60228Insulation: cross-linked polyethylene XLPEColour code:2-core: blue / brown3-core: brown / black / grey4-core: blue / brown / black / grey5-core: blue / brown / black / grey / black(o<strong>the</strong>r colours on request)Laying up: cores twisted in layers (if necessary with fillingelement(s))Wrapping: at least 1 layer <strong>of</strong> plastic tapeInner sheath: low smoke zero halogen flame retardantcompound LSZH, blackArmour: galvanised round steel wiresOuter sheath: cross linked low smoke zero halogen flameretardant compound LSZH, blackFlame propagation:Test on single cable IEC 60332-1-2Test on bunched cables IEC 60332-3-24 (Cat.C)Smoke density: IEC 61034-1 and 2Limiting Oxygen Index (LOI): ASTM D 2863 (min. 30 %)Flammability temperature (FT): ISO 4589-3 ann. A(min. + 250 °C)Amount <strong>of</strong> halogen acid gas: IEC 60754-1 (0 %)Degree <strong>of</strong> acidity <strong>of</strong> gases: IEC 60754-2 (pH > 4.3,C < 10µS/mm)Oil resistance: IEC 60092-359 (SHF-2)Sunlight resistance: UL 1581 Section 1200Temperatur range:(during operation) – 30 °C up <strong>to</strong> + 90 °C(during installation) – 5 °C up <strong>to</strong> + 50 °C(under short circuit) max. + 250 °CMinimum bending radius: 10 × cable diameterTechnical data

www.leoni-communication-infrastructure.com<strong>Power</strong> and Control Cables47Electrical Properties at 20 °CConduc<strong>to</strong>r resistance: according <strong>to</strong> IEC 60228Test voltage U rms(core : core):Test voltage U rms(core : armour):Nominal voltage U o/ U:3500 V3500 V600/1000 VHighest system voltage U m: max. 1200 V(for 3-phase systems)Geometrical dataSize RT <strong>of</strong> insulation RT <strong>of</strong> inner sheathDia. over innersheath 1Dia. <strong>of</strong> armourwireRT <strong>of</strong> outer sheath Outer dia. Weightnom. nom. approx. nom. nom. approx. approx.1,5 mm² (mm) (mm) (mm) (mm) (mm) (mm) (kg/km)2 × 1.5 RM 0.70 0.8 7.7 0.9 1.8 13.1 2953 × 1.5 RM 0.70 0.8 8.3 0.9 1.8 13.7 3284 × 1.5 RM 0.70 0.8 9.0 0.9 1.8 14.4 3655 × 1.5 RM 0.70 0.8 9.8 0.9 1.8 15.2 4002.5 mm²2 × 2.5 RM 0.70 0.8 8.5 0.9 1.8 13.9 3393 × 2.5 RM 0.70 0.8 9.1 0.9 1.8 14.5 3764 × 2.5 RM 0.70 0.8 10.0 0.9 1.8 15.4 4295 × 2.5 RM 0.70 0.8 11.0 0.9 1.8 16.4 480RT = Radial Thickness2X = XLPE InsulationH = LSZH inner and outer sheathR = Steel round wire armouringHX = cross-linked LSZH Outer sheath

48 <strong>Solar</strong>-Hybrid-Cableswww.leoni-communication-infrastructure.com<strong>Solar</strong>-Hybrid-Cable RS 485SK-v2XHX, 3 × 1,5 RM + 1 × 2 × AWG 18/7 PiMF 120 ΩAdvantagesHalogen freeFlame retardantUV resistantOil resistantElectron-beam cross-linkedApplicationFor <strong>energy</strong> supply and data transmission for heliostats.Recommended for indoor and outdoor installation, in dry andwet locations.ConstructionEnergy supply: (3 × 1,5 RM)Conduc<strong>to</strong>r: tinned copper, circular stranded (RM),size: 1,5 mm² (conduc<strong>to</strong>r class 2 acc. <strong>to</strong> IEC 60228)Insulation: cross-linked polyethyleneColour code: back, grey, brownLaying up: cores <strong>to</strong> tripleWrapping: at least 1 layer <strong>of</strong> plastic tape, overlappedData transmission: (1 × 2 × AWG 18/7)Conduc<strong>to</strong>r: tinned copper, stranded, size AWG 18/7 (~0,9 mm²)Insulation: cross-linked polyethyleneColour code: white / blueLaying up: cores <strong>to</strong> pairWrapping: at least 1 layer <strong>of</strong> plastic tape, overlappedPair screen: 1 layer <strong>of</strong> aluminium-bonded polyester tape overtinned copper drain wire, 7-strandsCable coreLaying up: screened data pair with <strong>energy</strong> supply elements <strong>to</strong>cable coreWrapping: at least 1 layer <strong>of</strong> plastic tape, overlappedOuter sheath: cross-linked low smoke zero halogen flameretardant compound LSZH, blackTechnical dataFlame propagation:Test on single cable IEC 60332-1-2Test on bunched cables IEC 60332-3-24 (Cat.C)Smoke density: IEC 61034-2 (L.T. > 60 %)Limiting Oxygen Index (LOI): ASTM D 2863 (min. 30 %)Amount <strong>of</strong> halogen acid gas: IEC 60754-1 (0 %)Degree <strong>of</strong> acidity <strong>of</strong> gases: IEC 60754-2 (pH > 4.3,C < 10µS/mm)Oil resistance: IEC 60092-359 (SHF 2)Sunlight resistance: UL 1581 Section 1200Temperatur range:(during operation) – 30 °C bis + 90 °C(during installation) – 5 °C bis + 50 °C(under short circuit) max. + 250 °CMinimum bending radius: 7.5 × cable diameter

www.leoni-communication-infrastructure.com<strong>Solar</strong>-Hybrid-Cables49Electrical Properties at 20 °C (Paar AWG 18/7)Conduc<strong>to</strong>r resistance: max. 23,6 Ω/kmInsulation resistance: min. 5000 MΩ × kmMutual capacitance: nom. 42 nF/kmInductance: nom. 0,70 mH/kmImpedance at 1 MHz nom. 120 Ω ± 10 %Attenuation at 1 MHz nom. 11 dB/kmTest voltage U rms(core : core):1500 VTest voltage U rms(core : screen):1500 VOperating voltage: max. 600 VGeometrical data (pair AWG 18/7)No. <strong>of</strong> pairsCore diameterapprox.AWG 18/7(mm)1 3.2Geometrical data (complete cable)RT <strong>of</strong> outer sheath Overall diameter Weightnom. approx. approx.(mm) (mm) kg/km1.2 15.0 210RT = Radial ThicknessSK- = Hybrid cabel2X = XLPE InsulationHX = cross-linked LSZH Outer sheathPiMF = Pair in Metal Foil

50 Optical Fiber Cableswww.leoni-communication-infrastructure.comOptical Fiber CableKL-A-DQ(ZN)BHSWAH, IEC 60794-3AdvantagesHalogen free and UV resistantDry-coreWith rodent protectionArmouredApplicationDry-core, watertight outdoor cable with LSZH sheath. For MAN(city networks) and LAN (campus/backbone), suitable for splicingtechnique. For indoor and outdoor installation in cable trays,in raceways. For direct burial applications.ConstructionOptical fiber: Multimode fibres G50/125 according <strong>to</strong>IEC 60793-2-10. Category OM2e according <strong>to</strong> EN 50173.Fiber colour code: according <strong>to</strong> DIN VDE 0888. Colours: red,green, blue, yellow, white, grey, brown, violet, turquoise,black, orange, pinkBuffer tube: central, loose buffer tube, filled with thixotropiccompound. Colour code: green.Structure: conduc<strong>to</strong>rs longitudinally stranded (with fillingelement(s) if necessary)Filling material: waterblocking <strong>of</strong> cable core by waterswellableelementsWrapping: at least 1 layer <strong>of</strong> plastic tape, overlappedStrain baring elements: glass yarns as strain baring elementsInner sheath: low smoke zero halogen flame retardantcompound LSZH, blackArmour: galvanised round steel wiresOuter sheath: low smoke zero halogen flame retardantcompound LSZH, blackTechnical dataFlame propagation:Test on single cable IEC 60332-1-2Test on bunched cables IEC 60332-3-24 (Cat.C)Smoke density: IEC 61034-2 (L.T. > 60 %)Limiting Oxygen Index (LOI): ASTM D 2863 (min. 30 %)Flammability temperature (FT): ISO 4589-3 ann. A(min. + 250 °)Amount <strong>of</strong> halogen acid gas: IEC 60754-1 (0 %)Degree<strong>of</strong> acidity <strong>of</strong> gases: IEC 60754-2 (pH > 4.3,C < 10µS/mm)Tensile test: IEC 60794-1-2-E1 (1750 N)Crush test: IEC 60794-1-2-E3 (1500 N/10 cm)Impact test: IEC 60794-1-2-E4 (1.5 Nm)Watertightness test: IEC 60794-1-2-F5b (3 m, 24 h)Oil resistance: ICEA S-73-532*Sunlight resistance: UL 1581 Section 1200Temperature range:(during operation) – 25 °C bis + 70 °C(during installation) – 5 °C bis + 50 °C(during s<strong>to</strong>rage) – 40 °C bis + 70C °CMinimum bending radius:(during installation) 20 × cable diameter(installed)15 × cable diameter*(Test temperature: + 60 °C; test duration 4 h. Tensile strength and elongation atbreak: at least 60 % <strong>of</strong> <strong>the</strong> values before aging)

www.leoni-communication-infrastructure.comOptical Fiber Cables51Optical Properties at 20 °COptical attenuation at 850 nm: max. 2,5 dB/kmOptical attenuation at 1300 nm: max. 0,7 dB/kmCladding diameter: µm 125 ± 1Coating diameter: µm 245 ± 5Coating non-circularity: max. 1 %Modefield diameter (1310 nm): 9,2 ± 0,4 µmBandwith (850 nm):Bandwith (1300 nm):1200 MHz × km1200 MHz × kmGeometrical dataNumber <strong>of</strong> cores inelementsRT <strong>of</strong> inner sheathDia. over innersheath 1Dia. <strong>of</strong> armour wire RT <strong>of</strong> outer sheath Outer dia. Weightnom. ca. nom. nom. ca. ca.(mm) (mm) (mm) (mm) (mm) (kg/km)6 1.0 7.1 0.9 1.3 11.5 2368 1.0 7.1 0.9 1.3 11.5 23612 1.0 7.1 0.9 1.3 11.5 236RT = Radial ThicknessKL- = Fiber cabelA- = External cableD = Filled loose tubeQ = Dry cable (swelling elements)(ZN)B = Glass yarnsH = LSZH inner and outer sheathSWA = Steel round wire armouring

52 Optical Fiber Cableswww.leoni-communication-infrastructure.comOptical Fiber CableKL-AT-V(ZN)HSWAH, IEC 60794-3AdvantagesHalogen freeCompact wire and dividing elementsUV resistantOil resistantMechanical protection via steel round wireApplicationDry-core, watertight outdoor cable with LSZH sheath. For MAN(city networks) and LAN (campus/backbone), suitable for splicingtechnique. For indoor and outdoor installation in cable trays,in raceways. For direct burial applications.ConstructionOptical fiber: Hard Clad Silica fiber 200/2320 (HCS).Fiber colour code: naturalBuffer tube: semi tight buffer tube. Colour code: natural.Element sheath: aramid yarns as strain baring elements, lowsmoke zero halogen flame retardant compund LSHZ, yellowInner sheath: low smoke zero halogen flame retardantcompound LSZH, blackArmour: galvanised round steel wiresOuter sheath: low smoke zero halogen flame retardantcompound LSZH, blackTechnical dataFlame propagation:Test on single core IEC 60332-1-2Test on bunched cablesIEC 60332-3-24 (Cat.C)Smoke density: IEC 61034-2 (L.T. > 60 %)Limiting Oxygen Index (LOI): ASTM D 2863 (min. 30 %)Flammability temperature (FT): ISO 4589-3 ann. A(min. + 250 °)Amount <strong>of</strong> halogen acid gas: IEC 60754-1 (0 %)Degree <strong>of</strong> acidity <strong>of</strong> gases: IEC 60754-2 (pH > 4.3,C < 10µS/mm)Tensile test: IEC 60794-1-2-E1 (1750 N)Crush test: IEC 60794-1-2-E3 (1500 N/10 cm)Watertightness test: IEC 60794-1-2-F5b (up <strong>to</strong> inner sheath)Oil resistance: ICEA S-73-532*Sunlight resistance: UL 1581 Section 1200Temperatur range:(during operation) – 20 °C bis + 70 °C(during installation) – 5 °C bis + 50 °C(during s<strong>to</strong>rage) – 20 °C bis + 70C °CMinimum bending radius:(during installation)(installed)20 × cable diameter15 × cable diameter*(Test temperature: + 60 °C; test duration 4 h. Tensile strength and elongation atbreak: at least 60 % <strong>of</strong> <strong>the</strong> values before aging)

www.leoni-communication-infrastructure.comOptical Fiber Cables53Optical Properties at 20 °COptical attenuation at 650 nm: max. 10 dB/kmOptical attenuation at 850 nm: max. 8,0 dB/kmCladding diameter: 200 µmCoating diameter: 230 µmCoating non-circularity: max. 1 %Bandwith (650 nm): min. 17 MHz × kmBandwith (850 nm):20 MHz × kmNumerical aperture: 0,37Geometrical dataNumber <strong>of</strong> cores inelementsDia. breakout element Dia. <strong>of</strong> armour wire RT <strong>of</strong> outer sheath RT <strong>of</strong> outer sheath Outer dia.ca. nom. nom. ca.(mm) (mm) (mm) (mm) (mm)2 × 1 2.1 9.4 0.9 1.4 14.0RT = Radial ThicknessKL- = Optical fibre cableAT- = Distribution cableV = Virtual fixed wire(ZN) = Aramid yarnsH = LSZH inner and outer sheathSWA = Steel round wire armouring

54 CAN Fieldbus Cableswww.leoni-communication-infrastructure.comCAN Fieldbus CableFB-v2XCeHX PiMF 120 ΩAdvantagesHalogen freeFlame retardantUV resistantElectron-beam cross-linkedApplicationFor transmission <strong>of</strong> CAN (Control Area Network) bus signals orcomputer signals with RS 485 or RS 422 interface, for locationswhere people are potentially endangered in case <strong>of</strong> fire. Notallowed for direct connection <strong>to</strong> low impendance source, e.g.<strong>the</strong> public mains electricity supply. Recommended for indoorand outdoor installation, in dry and wet locations. Not for directburial.ConstructionConduc<strong>to</strong>r: tinned annealed copper wire, stranded,size AWG 24Insulation: cross-linked polyethylene XLPEOuter sheath: cross-linked low smoke zero halogen flameretardant compound LSZH, blackColour code: white / blue, white / orange, white / green,white /brownIndividual screen: plastic coated aluminium tape, metallicsurface outside, in contact with collective screenLaying up: cores twisted <strong>to</strong> pairs, screened pairs twisted <strong>to</strong>cable core; (if necessary with filling element(s))Collective screen: tinned copper wire braid, opt. coverageapprox. 80 %Outer sheath: cross linked low smoke zero halogen flameretardant compound LSZH, blackTechnical dataFlame propagationTest on single cable IEC 60332-1-2Test on bunched cableIEC 60332-3-24 (Cat.C)Smoke density: IEC 61034-2 (L.T. > 60 %)Limiting Oxygen Index (LOI): ASTM D 2863 (min. 30 %)Flammability temperature (FT): ISO 4589-3 ann. A(min. + 250 °)Amount <strong>of</strong> halogen acid gas: IEC 60754-1 (0 %)Degree <strong>of</strong> acidity <strong>of</strong> gases: IEC 60754-2 (pH > 4.3,C < 10µS/mm)Oil resistance: ICEA S-73-532Sunlight resistance: UL 1581 Section 1200Temperature range(during operation) – 30 °C up <strong>to</strong> + 90 °C(during installation) – 5 °C up <strong>to</strong> + 50 °CMinimum bending radius: 7.5 × cable diameter

56 Technic & Supportwww.leoni-communication-infrastructure.comDesign options/Construction details(according <strong>to</strong> EN 50288-7)Multi-Element Metallic Cables for Analogue and Digital Communication and Control SystemsConduc<strong>to</strong>r■■Copper, plain or tinned■■■■Conduc<strong>to</strong>r sizes: 0.5 mm² up <strong>to</strong> 2.5 mm²Conduc<strong>to</strong>r shape: solid, stranded or flexibleInsulation■■■■PVC, PE (solid and foam), XLPE, PP(solid and foam), zero halogen,flame-retardant compoundsAdditional materials under preparationCabling elementsCores, pairs, triples, quads■■Individual screen■■■■■■Plastic laminated metal foilwith drain wirePlain or coated metal braidCombination <strong>of</strong> a braid and a foilAssembling■■■■Directly or in units in concentric layersWith or without moisture barrierMoisture barriers■ ■ Dry ➔ swellable tapes, and/or cords,■■swellable powderWet ➔ petrojelly filling compoundDesign OptionsScreening <strong>of</strong>cabling elementsTypeOptionsConduc<strong>to</strong>rInsulationTwisting<strong>of</strong> pairs, triplesand quadsAssembling <strong>of</strong>cabling elements+ / 0 moisturebarriersScreening<strong>of</strong> cable elementassemblyMulticoretypesConstruction DetailsReference StandardsConduc<strong>to</strong>r■■According <strong>to</strong> EN 60228, class 1, 2 or 5■■Max. conduc<strong>to</strong>r resistancefor multi-element cables (beside cores):Standard value + 2 %Insulation■■Acc. <strong>to</strong> EN 50290-2-21, 23, 25, 26 a. 29■■Concentricity <strong>of</strong> insulation: min. 75 %■■Min. insulation thickness depending onvoltage rating and conduc<strong>to</strong>r sizeCabling elements■■■■Max. length <strong>of</strong> lay:up <strong>to</strong> 1.5 mm² ≤ 100 mm2.5 mm² ≤ 150 mmIdentification: numbered cores or tapesor acc. <strong>to</strong> IEC 60189-2 or IEC 60708-1Individual screen■■Overlapping <strong>of</strong> <strong>the</strong> foil: min. 20 %■■Filling fac<strong>to</strong>r <strong>of</strong> <strong>the</strong> braid 0.6 and 0.3resp. when combined with a foilAssembling■■Wrappings <strong>of</strong> non hygroscopic tapesinterstitial fillers, where neccessaryMoisture barriers■■Petrojelly according <strong>to</strong> EN 50290-2-29Overall screen■■Overlapping <strong>of</strong> <strong>the</strong> foil min. 20 %■■Filling fac<strong>to</strong>r <strong>of</strong> <strong>the</strong> braid > 0.6 and > 0.3■■resp. when combined with a foilOne or both side laminated aluminum tapelongitudinally overlapped, bonded <strong>to</strong> <strong>the</strong> innersurface <strong>of</strong> an extruded sheath, thickness <strong>of</strong> alum.tape: min. 0.15 mm without coating

www.leoni-communication-infrastructure.comTechnic & Support57Overall screen■■■■■■■■Plastic laminated metal foil with drainwirePlain or coated metal braidCombination <strong>of</strong> a braid and a foilLaminated sheathInner sheath■■PVC, PE, zero halogen, flame-retardantcompounds■■Additional materials under preparationChemical and/or environmentalprotectiona) Lead sheath orb) Multi layer sheath■■Laminated HDPE sheath andan additional polyamid coveringBedding■■■■Extruded layer <strong>of</strong> PVC, PE or zero halogen,flame retardant compounds orHelically applied tape(s)Armour■■■■■■Single layer <strong>of</strong> round steel wires (SWA)Single or double layer <strong>of</strong> steelor brass tapes (B)Metal braid (Q)Outer sheath■■■■PVC, PE, or zero halogenflame-retardant compoundsAdditional materials under preparationVoltage rating 300 V or 500 VInner sheathArmouringOuter sheathLead sheathBeddingMultilayersheathInner sheath■■According <strong>to</strong> EN 50290-2-22 and 27■■■■Optional under lead sheathThickness: 0.04 x D + 0.7 mm (min. 0.8 mm)(D = Diameter under inner sheath)Bedding■■According <strong>to</strong> EN 50290-2-22, 24 and 27■■Thickness: depending on diameterunder bedding; min.1.0 mmArmour■■■■■■SWA: acc. <strong>to</strong> EN 10257-1; min. dia. 0.9 mmB: min. thickness: 0.2 mm a. 0.075 mm resp.Q: Filling fac<strong>to</strong>r:min. 0.57, wire dia. min. 0.3. mma) Lead sheath■■According <strong>to</strong> EN 50307■■Thickness: 0.03 x D + 0.7 mm (min. 0.8 mm)(D = Diameter under lead sheath)b) Multi layer sheath■■Thickness <strong>of</strong> polyamid covering: min. 0.3Outer sheath■■According <strong>to</strong> EN 50290-2-22, 24 and 27■■■■Thickness for unarmoured types:0.04 x D + 0.7 mm (min. 0.8 mm)Thickness for armoured types:0.028 x D + 1.1 mm (min. 1.3 mm)(D = diameter under outer sheath)

58 Pho<strong>to</strong>voltaic <strong>Power</strong> Cableswww.leoni-communication-infrastructure.comBETAflam ® <strong>Solar</strong> 125 RV flex FRNCPho<strong>to</strong>voltaic <strong>Power</strong> Cables, halgen free, flame retardantAdvantagesUV-, ozon- and hydrolysis resistantHigh temperature resistant, <strong>the</strong> materials do not melt or flowVery long service life > 25 years at 90 °CCompatible <strong>to</strong> all popular connec<strong>to</strong>rsFlexible and space saving InstallationApplicationDouble insulated, electron-beam cross-linked cables for Pho<strong>to</strong>voltaicpower applications. With reduced diameter an integratedjacket.ConstructionConduc<strong>to</strong>r: Tinned fine copper strands, according <strong>to</strong> VDE0295 / IEC 60228, class 5Insulation: XLPO, flame retardant, halogen free,electron-beam cross-linkedJacket: XLPO, flame retardant, halogen free,electron-beam cross-linked, UV and ozone resistantJacket colour: BlackBending radius: 4 × occasionally moved > 5 × >10 mm fixed installation > 5 × occasionally moved > 7 × Material properties / StandardsFire performance: IEC 60332-1Smoke emission: IEC 61034; EN 50268-2Low fire load: DIN 51900Approvals: TÜV 2 PfG 1169 02.2007 PV1-FApplication standards: UNE 21123; UNE 20.460-5-52,UTE C 32-502Technical specificationNominal voltage: U 0/U = 600 / 1000 V AC, 1000 / 1800 V DCTest voltage: 6500 V, 50 Hz, 5 min.Temperature rating:– 40 °C up <strong>to</strong> + 125 °C– 40 °F up <strong>to</strong> + 257 °FAmbient temperature: > 25 years (TÜV)– 40 °C up <strong>to</strong> + 90 °C– 40 °F up <strong>to</strong> + 194 °FMax. short circuit temperature: 280 °C, + 536 °F

www.leoni-communication-infrastructure.comPho<strong>to</strong>voltaic <strong>Power</strong> Cables59Dimensions, WeightsConstruction Part no.Conduc<strong>to</strong>rconstructionLeiter Dia. Outer Dia. Resistance max. Weight Fire loadn × mm² n × mm mm mm mΩ/m kg / km kWh/m1 × 2.5 304467 45 × 0.25 2.05 4.5 8.21 41 0.0731 × 4 304468 52 × 0.30 2.55 5 5.09 57 0.0881 × 6 304469 78 × 0.30 3.1 5.6 3.39 77 0.1041 × 10 304471 75 × 0.40 4.1 6.7 1.95 119 0.1321× 16 304472 119 × 0.40 5.5 9.7 1.24 217 0.2951 × 25 304474 182 × 0.40 6.6 11.2 0.79 313 0.3981 × 35 304475 259 × 0.40 7.7 12.3 0.56 415 0.4541 × 50 304476 380 × 0.40 9.9 14.9 0.39 594 0.604Order Units on s<strong>to</strong>ckConstruction Part no. Part no. Part no. Part no.n × mm² 24 × 500 m 18 × 500 m 18 × 1000 m 8 × 1000 m1 × 4 304468V1 304468V2 1 × 6 304469V2 304469V31 × 10 304471V2 Fur<strong>the</strong>r packaging units upon request.Bold printed part no. = s<strong>to</strong>ck item.Fur<strong>the</strong>r designs upon request.