You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

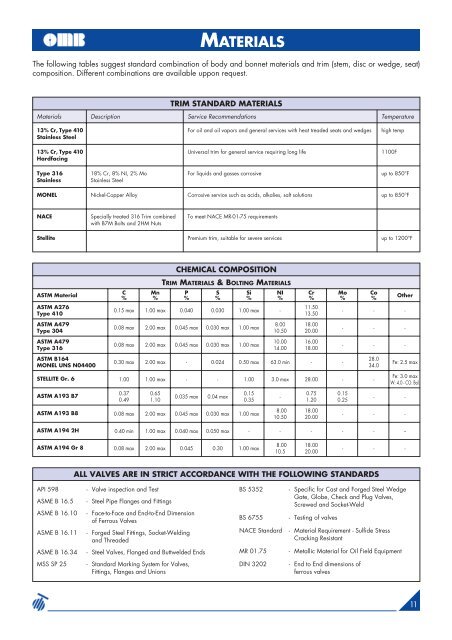

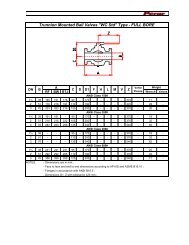

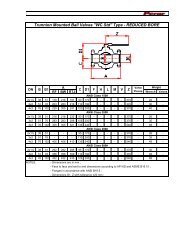

VALVE MATERIALS SPECIALISTSThe following tables suggest standard combination of body and bonnet materials and trim (stem, disc or wedge, seat)composition. Different combinations are available uppon request.TRIM STANDARD MATERIALSMaterialsDescriptionService RecommendationsTemperature13% Cr, Type 410 For oil and oil vapors and general services with heat treaded seats and wedges high tempStainless <strong>Steel</strong>13% Cr, Type 410 Universal trim for general service requiring long life 1100FHardfacingType 316 18% Cr, 8% NI, 2% Mo For liquids and gasses corrosive up to 850°FStainlessStainless <strong>Steel</strong>MONEL Nickel-Copper Alloy Corrosive service such as acids, alkalies, salt solutions up to 850°FNACE Specially treated 316 Trim combined To meet NACE MR-01-75 requirementswith B7M Bolts and 2HM NutsStellite Premium trim, suitable for severe services up to 1200°FCHEMICAL COMPOSITIONTRIM MATERIALS & BOLTING MATERIALSASTM MaterialC Mn P S Si NI Cr Mo Co% % % % % % % % %OtherASTM A27611.500.15 max 1.00 max 0.040 0.030 1.00 max -- - -Type 410 13.50ASTM A4798.00 18.000.08 max 2.00 max 0.045 max 0.030 max 1.00 maxType 304 10.50 20.00ASTM A47910.00 16.000.08 max 2.00 max 0.045 max 0.030 max 1.00 maxType 316 14.00 18.00- - -- - -ASTM B16428.00.30 max 2.00 max - 0.024 0.50 max 63.0 min - -MONEL UNS N04400 34.0STELLITE Gr. 6 1.00 1.00 max - - 1.00 3.0 max 28.00 - -Fe: 2.5 maxFe: 3.0 maxW: 4.0 - CO: Bal.ASTM A193 B70.37 0.650.150.75 0.150.035 max 0.04 max-0.49 1.10 0.35 1.20 0.25- -ASTM A193 B8 0.08 max 2.00 max 0.045 max 0.030 max 1.00 max8.00 18.0010.50 20.00- - -ASTM A194 2H 0.40 min 1.00 max 0.040 max 0.050 max - - - - - --ASTM A194 Gr 8 0.08 max 2.00 max 0.045 0.30 1.00 max8.00 18.0010.5 20.00- - -ALL VALVES ARE IN STRICT ACCORDANCE WITH THE FOLLOWING STANDARDSAPI 598ASME B 16.5ASME B 16.10ASME B 16.11- Valve inspection and Test- <strong>Steel</strong> Pipe Flanges and Fittings- Face-to-Face and End-to-End Dimensionof Ferrous Valves- <strong>Forged</strong> <strong>Steel</strong> Fittings, Socket-Weldingand ThreadedBS 5352BS 6755NACE Standard- Specific for Cast and <strong>Forged</strong> <strong>Steel</strong> WedgeGate, Globe, Check and Plug Valves,Screwed and Socket-Weld- Testing of valves- Material Requirement - Sulfide StressCracking ResistantASME B 16.34- <strong>Steel</strong> Valves, Flanged and Buttwelded EndsMR 01.75- Metallic Material for Oil Field EquipmentMSS SP 25- Standard Marking System for Valves,Fittings, Flanges and UnionsDIN 3202- End to End dimensions offerrous valves11