You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

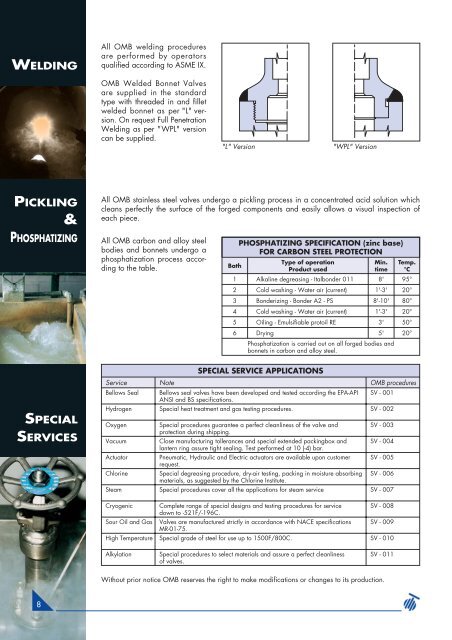

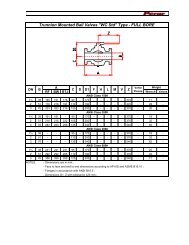

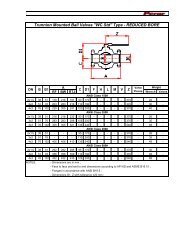

WELDINGAll <strong>OMB</strong> welding proceduresare performed by operatorsqualified according to ASME IX.<strong>OMB</strong> Welded Bonnet Valvesare supplied in the standardtype with threaded in and filletwelded bonnet as per "L" version.On request Full PenetrationWelding as per "WPL" versioncan be supplied."L" Version"WPL" VersionPICKLING&All <strong>OMB</strong> stainless steel valves undergo a pickling process in a concentrated acid solution whichcleans perfectly the surface of the forged components and easily allows a visual inspection ofeach piece.PHOSPHATIZINGAll <strong>OMB</strong> carbon and alloy steelbodies and bonnets undergo aphosphatization process accordingto the table.Bath123456PHOSPHATIZING SPECIFICATION (zinc base)FOR CARBON STEEL PROTECTIONType of operationProduct usedAlkaline degreasing - Italbonder 011Cold washing - Water air (current)Bonderizing - Bonder A2 - PSCold washing - Water air (current)Oiling - Emulsifiable protoil REDryingMin.time8'1'-3'8'-10'1'-3'3'5'Phosphatization is carried out on all forged bodies andbonnets in carbon and alloy steel.Temp.°C95°20°80°20°50°20°SPECIALSERVICESSPECIAL SERVICE APPLICATIONSService Note<strong>OMB</strong> proceduresBellows Seal Bellows seal valves have been developed and tested according the EPA-API SV - 001ANSI and BS specifications.Hydrogen Special heat treatment and gas testing procedures. SV - 002Oxygen Special procedures guarantee a perfect cleanliness of the valve and SV - 003protection during shipping.Vacuum Close manufacturing tollerances and special extended packingbox and SV - 004lantern ring assure tight sealing. Test performed at 10 (-4) bar.Actuator Pneumatic, Hydraulic and Electric actuators are available upon customer SV - 005request.Chlorine Special degreasing procedure, dry-air testing, packing in moisture absorbing SV - 006materials, as suggested by the Chlorine Institute.Steam Special procedures cover all the applications for steam service SV - 007Cryogenic Complete range of special designs and testing procedures for service SV - 008down to -521F/-196C.Sour Oil and Gas Valves are manufactured strictly in accordance with NACE specifications SV - 009MR-01-75.High Temperature Special grade of steel for use up to 1500F/800C. SV - 010Alkylation Special procedures to select materials and assure a perfect cleanliness SV - 011of valves.Without prior notice <strong>OMB</strong> reserves the right to make modifications or changes to its production.8