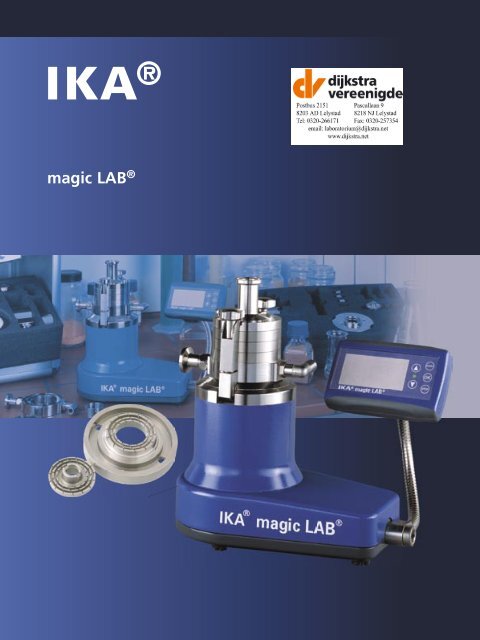

IKA® magic LAB

IKA® magic LAB

IKA® magic LAB

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Smooth change-over fromlaboratory to production plantModule CMSIKA ® <strong>magic</strong> <strong>LAB</strong> ®Micro-Plant:IKA ®Powder / granule incorporationinto liquids, batch operation forenrichment processwith exchangeable modules(UTL/DR/MK/MKO)5Basic module:ULTRA-TURRAX ® : UTLsingle stage dispersing/mixing inline61ModuleULTRA-TURRAX ® UTC7dispersing/mixing inbatch operation5

IKA ® <strong>magic</strong> <strong>LAB</strong> ®Module Colloid Mill / Cone Mill (MK/MKO)MustardInletclamp ¾”FunctionalityOperating unitIndication of theoperating data:ModuleSpeedTorqueTemperatureTimerTooth pasteOutletclamp ½”Heating/coolingconnectionSpicesCough mixtureSiliconeWhen is a mill used?For wet or fine milling of hard and granular raw materials,and for the production of finest emulsions and pastes.The MK-module (Colloid Mill)consists of two cones with different flowchannels on their surfaces. The cones can beshifted one against the other to a minimumdistance, thus changing flow and friction.By adjusting the milling gap you can thendetermin the particle size.The MKO-module (Cone Mill)Spice pasteTool kit MK / MKO1is working according to the same principle asthe MK-module. Neverthless, the outlet areaof its cones has a non-abrasive, rough andfine pored surface. This results in an enlargedfriction surface that enables to produce evenfiner suspensions at reduced flow. Furthertechnical details are the same as for moduleMK.Alumina5 524 31 mixing chamber, complete2 rotor3 distance sleeve4 locking nut5 clampMedicines8

IKA ® <strong>magic</strong> <strong>LAB</strong> ®Module for batch powder incorporation (CMS)IKA ®InletsolidsInletliquidsOutletmixtureFunctionalityOperating unitIndication of theoperating data:ModuleSpeedTorqueTemperatureTimerAluminaCarbopolSpice saucesCalcium carbonateBatch-wise "solid/liquid"mixing• For dust- and agglomeration freeincorporation and fast mixing of powdersinto liquids• Especially suited for enrichment of liquidsby powders in a recirculation processPolymeresTool kit CMS• Solids content up to 65%• The machines produces a vacuum at thesolids inlet, thus enabling the suction ofpowders directly from a funnel13Colour paste754 6271 inlet housing2 generator3 mixing chamber4 locking nut5 distance sleeve6 sealing flange7 clampAcrylic resinPectine9

IKA ® <strong>magic</strong> <strong>LAB</strong> ®Module for continuous powder incorporation (MHD)SolidsInletliquidsAluminaCarbopolOutletmixtureFunctionalityOperating unitIndication of theoperating data:ModuleSpeedTorqueTemperatureTimerHeating/coolingconnectionCaoutchoucDextrineColour pasteSpice mixturePectineLewatite10Tool kit MHD2149 957638Continuous "solid/liquid"mixingThis module serves for continuousproduction of dispersions. Besidesfast wettening of the solids and theavoidance of agglomerations it alsohomogenizes and disperses, resultingin a ready mixed product in only onepass. The mixing relation is controlledby volumetric or gravimetric dosingdevices. Solids contents up to approx.80% and viscosities up to approx.50 Pas will be possible.1 inlet socket2 mixing chamber3 pump housing4 generator 2P5 injection unit6 feeding screw7 mixing tool8 distance sleeve9 clamp

IKA ® <strong>magic</strong> <strong>LAB</strong> ®Transportbox mit integriertem Stativ Micro-Plant with <strong>magic</strong> <strong>LAB</strong> ®IKA ®MedicinesPolymeresExchangeablemodules:UTL/DR/MK/MKOMedical spraysCough mixtureA small plant with enormousflexibilty for the determinationof process parameters for alarge scale-up.SaucesIt serves for:• Development of formulations and determination of the process• Determination of many process parameters like speed,shear frequency, temperature, pressure, time, necessary energy,and many more• Determination of the optimum mixing and dispersing moduleWC-gelCosmetic creamsWorking volume (funnel):up to 1500 mlProduct temperature: up to 90°CProcess pressure:2.5 barPossible modules:UTL/DR/MK/MKOKetchup11

IKA ® <strong>magic</strong> <strong>LAB</strong> ®Module ULTRA-TURRAX ® (UTC)CleanserIndicationof theoperatingdataDo the change from inlineto batch deviceTurn the <strong>magic</strong> <strong>LAB</strong> ® upside down, give itan UTC tool kit and you can start makingthe preparation in a beaker glass.Beaker glass sizes up to 1.5 l,special generators on requestDetergentBoss headR 271<strong>magic</strong> <strong>LAB</strong> ®Liquid soapStandThe lashing strap RH5 with bosshead R270 saves the beaker glassfrom turning or moving aside.Module UTCSpice pasteShower gelTool kit UTCDispersing in batch operation• Especially for smallest quantities beforeswitching over to an inline systemDressings12• For estimation of the necessary shear force• For quick determination of rheologicalchanges such as structure, viscosity, etc.Washing agents53451 flange2 tool UTC - S25N3 distance sleeve4 coupling5 clampSoftener12

IKA ® <strong>magic</strong> <strong>LAB</strong> ®Transport box with roller carrier/standIKA ®KetchupPolymeresTechnical greasesTooth pasteSiliconeTransport boxThe IKA ® <strong>magic</strong> <strong>LAB</strong> ® is stored in a practicaltransport box. The different modules areplaced in clear drawers with premouldedinserts. The drive unit itself can be taken outfrom the side. The electric plug-in connectionsto the <strong>magic</strong> <strong>LAB</strong> ® as well as to thepower supply are mounted on the back sideof the box.For transport purposes the box is fixed ontoa roller carrier with telescopic lever. Thislever can be adjusted in height and servesat the same time as stand for fixing of the<strong>magic</strong> <strong>LAB</strong> ® with module UTC (see oppositepage).Dimensions of the box:(L x H x W) approx. 300 x 460 x 400 mm.MedicinesMedical spraysLipstick13

IKA ® <strong>magic</strong> <strong>LAB</strong> ®Operation and information centreOperation andinformation centreThe info centre of the <strong>magic</strong> <strong>LAB</strong> ® offers a lotof functions, but is nevertheless designed ina very clear and operator friendly way. It onlyneeds a few manipulations and adjustmentsand the <strong>magic</strong> <strong>LAB</strong> ® is ready for operation.First the operation and information centre isconnected to the <strong>magic</strong> <strong>LAB</strong> ® by means of aconnection cable. The mains unit can eitherremain in the transport box or be placedseparately. As soon as it is connected to thepower supply, a green lamp is lighted in theinfo centre and the starting screen appears.Via the push-buttons with arrow you canthen choose the module of the <strong>magic</strong> <strong>LAB</strong> ®and the respective speed range.It is as easy setting the nominal and actualvalues. Moreover the requested languagecan be chosen (Geman, English, French,Spanish and Italian). The possibility of datatransfer to a PC is planned for the future.14

IKA ® <strong>magic</strong> <strong>LAB</strong> ®Technical dataIKA ®l/h12010080604020<strong>magic</strong> <strong>LAB</strong> ®10 20 30 x 10 3 (min -1 )Drive:Motor power:Speed range:Process data:900 Wup to 30.000 rpmProduct temperature: up to 90°C(continuous duty)up to 120°C(30% duty cycle)Process pressure:Batch size (UTC):Flow capacity (DR):Materials:up to 2.5 barup to 120 l/hup to 1.5 lall parts in contact withthe product made ofstainless steel AISI 316LHere you may choose the suitable size of your later production machine.Please ask for our catalogue "IKA ® Process Technology"Machine size/50/40/30/20/10052000/0410 20 30 70 125 (x 10 3 l/h)2000/042000/05 2000/102000/202000/302000/402000/5015

DIN EN ISO 9001Reg. Nr.-20602-01<strong>magic</strong> <strong>LAB</strong> ® 05/06-esubject to technical changes