SUPER STAR-CLEAR SPECIFICATIONS - Pool Plaza

SUPER STAR-CLEAR SPECIFICATIONS - Pool Plaza

SUPER STAR-CLEAR SPECIFICATIONS - Pool Plaza

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

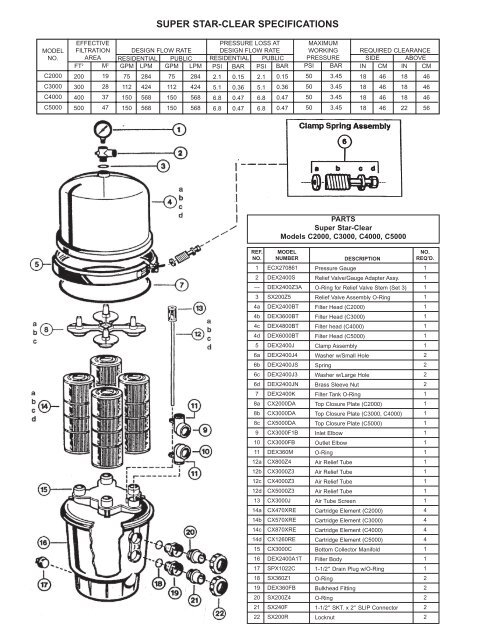

<strong>SUPER</strong> <strong>STAR</strong>-<strong>CLEAR</strong> <strong>SPECIFICATIONS</strong>MODELNO.C2000C3000C4000C5000EFFECTIVEFILTRATIONAREAFT 2 M 2200 19300 28400 37500 47DESIGN FLOW RATERESIDENTIAL PUBLICGPM75112150150LPM284424568568GPM75112150150LPM284424568568PRESSURE LOSS ATDESIGN FLOW RATERESIDENTIAL PUBLICPSI2.15.16.86.8BAR0.150.360.470.47PSI2.15.16.86.8BAR0.150.360.470.47MAXIMUMWORKINGPRESSUREPSI BAR50 3.4550 3.4550 3.4550 3.45REQUIRED <strong>CLEAR</strong>ANCESIDE ABOVEIN18181818CM46464646IN18181822CM46464656PARTSSuper Star-ClearModels C2000, C3000, C4000, C5000REF.NO.12---34a4b4c4d56a6b6c6d78a8b8c9101112a12b12c12d1314a14b14c14d1516171819202122MODELNUMBERECX270861DEX2400SDEX2400Z3ASX200Z5DEX2400BTDEX3600BTDEX4800BTDEX6000BTDEX2400JDEX2400J4DEX2400JSDEX2400J3DEX2400JNDEX2400KCX2000DACX3000DACX5000DACX3000F1BCX3000FBDEX360MCX800Z4CX3000Z3CX4000Z3CX5000Z3CX3000JCX470XRECX570XRECX870XRECX1260RECX3000CDEX2400A1TSPX1022CSX360Z1DEX360FBSX200Z4SX240FSX200RDESCRIPTIONPressure GaugeRelief Valve/Gauge Adapter Assy.O-Ring for Relief Valve Stem (Set 3)Relief Valve Assembly O-RingFilter Head (C2000)Filter Head (C3000)Filter head (C4000)Filter Head (C5000)Clamp AssemblyWasher w/Small HoleSpringWasher w/Large HoleBrass Sleeve NutFilter Tank O-RingTop Closure Plate (C2000)Top Closure Plate (C3000, C4000)Top Closure Plate (C5000)Inlet ElbowOutlet ElbowO-RingAir Relief TubeAir Relief TubeAir Relief TubeAir Relief TubeAir Tube ScreenCartridge Element (C2000)Cartridge Element (C3000)Cartridge Element (C4000)Cartridge Element (C5000)Bottom Collector ManifoldFilter Body1-1/2” Drain Plug w/O-RingO-RingBulkhead FittingO-Ring1-1/2” SKT. x 2” SLIP ConnectorLocknutNO.REQ’D.1111111112222111111111111444411122222

OWNER’S GUIDEISC2000-98MODELS C2000, C3000, C4000, C5000Hayward Super Star-Clear filters are high performance swimming pool filters with filtration ratings to 9000gallons (34 KL) per hour. Manufactured from durable, corrosion-proof materials, they are designed forcontinuous or intermittent operation, for installation above or below the pool water line, for fresh or salt waterswimming pools or spas. Star-Clear filters utilize multiple reusable, reinforced polyester filter cartridgeelements to provide a high degree of water clarity and long filter cycles with absolute minimum care.PUMP SELECTION AND LOCATIONTo power your filter, select a continuous duty pump designedfor swimming pool or spa service.It is important to first determine where your pump and filter willbe located. If above the water line, a self-priming pump mustbe used. Self-priming pumps (such as Hayward Super Pump ® ,Super II or Max-Flo) have the ability to lift water from alower level and prime automatically.Select a pump with an average output range suitable for the filter'scapacity. Other considerations are operation of hydrotherapyfittings, automatic cleaners, etc. Your dealer will help youselect the proper size pump for your system.3.4.5.6.7.8.9.Connect the pool suction plumbing between the skimmer,pool outlet, etc., and the pump.Install the pool return plumbing.If pressure gauge is not installed, apply Teflon tape to thegauge threads, and carefully screw the gauge into thegauge adapter assembly.A filter drain plug is furnished with each filter and is all thatis needed for complete filter draining. A manual air ventvalve is furnished to aid in bleeding off unwanted air whenstarting the filter. The auto air relief provides air removalduring operation.All electrical connections should be made in accordancewith local codes.Check for joint leaks before operating.Refer to pump instruction booklet for pump information.FILTER LOCATION1. Since plumbing fittings offer a resistance to water flow,position the filter as close to the swimming pool as practical.Keep the number of fittings to a minimum. Select awell-drained area, one that will not flood when it rains.2. The filter should be placed on a level concrete slab, veryfirm ground, or equivalent, as recommended by your pooldealer. Allow a top clearance for cartridge removal of 18”(457 mm) for C2000, C3000 and C4000, 22” (559 mm) forC5000. Be sure filter, pump, drain and pressure gauge areaccessible for convenient operation.3. Position filter so the tank can drain by gravity.4. If practical, place pump and filter in the shade to shield itfrom continuous, direct heat from the sun.PLUMBING1. Use 1-1/2” or 2” piping. Connections are 1-1/2” socket(solvent weld) or 2” male slip. We suggest unions beprovided for easy servicing.2. Refer to the diagram for typical installation. Ball valves arerecommended where needed. While all systems vary, themain consideration is to provide the desired control ofwater flow from the pool to the pump and filter and back tothe pool. When the filter is located below the water level,provide valves to prevent back flow of water to the filterduring cleaning and routine servicing.NOTE: ANSI/NSPI-4 Article V, standard for above-ground andon-ground pools, advises that components such as thefiltration system, pumps and heater be positioned so as toprevent their being used as a means of access to the pool byyoung children.BEFORE <strong>STAR</strong>TING THE FILTERSuperchlorinate the pool water by adding unstabilized granularor liquid chlorine. Stabilized forms of chlorine are recommendedfor normal daily use after the initial clean up of the water.Follow chemical manufacturer’s recommendations forsuperchlorination and daily use.31-3/4”(807 mm)36-1/2”(927 mm)42-1/2”(1080 mm)48-1/2”(1232 mm)C2000C3000C4000C5000

IMPORTANT SAFETY INSTRUCTIONS.READ AND FOLLOW ALL INSTRUCTIONS.When installing and using this equipment, basic safety precautionsmust always be followed. This filter operates under high pressure.Failure to follow instructions may result in serious injury.••••REMOVE CLAMP TAPE. DO NOT LEAVE TAPE EXPOSED TO SUN.MAKE SURE CLAMP IS LOCATED AND CENTERED PROPERLYOVER THE FILTER FLANGE.BOTH SIDES OF THE CLAMP MUST BE TIGHTENED FIRMLY ANDEVENLY UNTIL SPRING COILS TOUCH EACH OTHER (SEEILLUSTRATION BELOW).FINAL SPACE BETWEEN BOTH CLAMP HALVES SHOULD BEEQUAL.CAUTION: All suction and discharge valves must be open when startingthe system. Failure to do so could result in severe personal injury and/orproperty damage.The following clamp spring assembly, which includes a spring, twowashers (small and large hole) and a sleeve nut, provides avisual means of ensuring that the clamp is tight.<strong>STAR</strong>TING THE FILTERBE SURE CENTER CLAMP IS SECURE. Be sure filter drain plugis closed. Open Air Relief Valve at top of filter a few turns. Opensuction and return valves (when used). Stand clear of filter andprime and start the pump, following the manufacturer’sinstructions. Air trapped in the system will automatically vent to thepool and out the Air Relief Valve. Close Air Relief Valve when asteady stream of water emerges.FILTERINGFiltration starts as soon as flow is steady through the filter. As thefilter cartridge removes dirt from the pool water, the accumulateddirt causes a resistance to flow. As a result, the gauge pressurewill rise and the flow will decrease. When the pressure rises 7-10psi (.49-.69 Bar) above the starting pressure, or when flowdecreases below desired rate, clean or replace the filter cartridges.CLEAN/REPLACE CARTRIDGESRemoving Cartridge Elements1. Shut off the pump.2. If filter is located below water level, close valves (or block offsuction and discharge lines) to prevent backflow of water frompool.3. Unscrew and remove drain plug and allow water to drain fromfilter. Close drain plug. (Note: To assist draining process,open air vent a few turns.)4. Disassembly:5.a.b.Using a 9/16” wrench, alternately loosen both clampsleeve nuts. Remove one clamp sleeve nut assembly(spring, two washers and sleeve nut) and carefully removeclamp.To remove Filter Head, tap it on the side to break seal atcenter of tank OR insert a blunt screwdriver into one of thenotches located behind Connector Fittings, or 90˚ to the leftof the Connector Fittings, and twist to lift filter headslightly. DO NOT grasp gauge assembly when removingfilter head—breakage will result.To Remove Cartridges:a. Lift off top closure plate.b. Remove cartridges from bottom collector manifold by usinga slight rocking motion and lifting up.c. Clean cartridge. (see Cleaning Cartridges)1.2.3.4.DEX2400J4Washer w/Small HoleDEX2400JSSpringDEX2400J3Washer w/Large HoleDEX2400JNBrass Sleeve NutReinstalling Cartridges1. Flush and drain any dirt or debris from the bottom of the filtertank.2. Carefully replace cartridges over hubs on bottom manifold.Place top closure plate securely into top of cartridges.3. Clean and lightly lubricate Tank O-ring and carefully placeover Filter Body lip.4. Clean Filter Head flange sealing surface, and place over TankO-ring, pressing down firmly and evenly to seat the FilterHead in place.5. Replace Clamp Assembly. Make sure clamp is located andcentered properly over the filter flange. If Clamp is tight, tapClamp with rubber mallet or block of wood to help seat it.Insert threaded stud through retainer and secure with ClampSpring Assembly (be sure to position small and large holewashers properly—see illustration in IMPORTANT SAFETYINSTRUCTIONS).In some cases it may be necessary to use the two-part filterclamp to assist in assembling the filter cover to the filter base.With one nut, spring and washer assembly already removed,loosen the remaining clamp nut to maximize clamp opening. IfClamp is tight, tap Clamp with rubber mallet or block of woodto help seat it as you are tightening nuts. If the two (2) clampsprings (DE2400JS) are temporarily removed in order to fullyextend the clamp bolts, the clamp springs and washers MUSTbe reassembled as shown in the CLAMP SPRING ASSEMBLYdiagram in IMPORTANT SAFETY INSTRUCTIONS.Tighten sleeve nuts alternately to secure Clamp firmly andevenly to form a good seal (be sure spring coils touch eachother and final space between Clamp halves is even—seeillustration in IMPORTANT SAFETY INSTRUCTIONS).6. Install Drain Plug, open pool suction and return valves andproceed as in <strong>STAR</strong>TING THE FILTER.Cleaning CartridgesThe cartridge filter element can be cleaned by pressure washinginside and out with a garden hose. (The cartridge is easier toclean when dry.) After hosing the cartridge, for best results, allowcartridge to dry and carefully brush pleated surface areas toremove fine particles.Algae, suntan oil and body oils can form a coating on the cartridgepleats which may not be thoroughly removed by hosing. To removesuch materials, soak the cartridge in a solution of filter elementcleaner (various brands are available at pool dealer). Followmanufacturer’s directions for use and allow an hour for soaking.Hose thoroughly before reinstalling the filter.If calcium or mineral deposits are excessive, the cartridge may berestored to “like new” condition by soaking in muriatic acid. Usecommercially available 20% muriatic acid added to water in 1 to 1ratio. Use a plastic container and take extreme care when handlingcleaning agents as they can be harmful to eyes, skin and clothing.After cleaning, flush with water.A spare cartridge filter element is an excellent investment. Itprovides convenience and ensures that your filter will always beready to operate at peak efficiency.Hayward cartridges are specifically designed and engineered foruse in Star-Clear filters. For best results, use only genuineHayward Star-Clear cartridges in your filter. Order Model No.CX470XRE, CX570XRE, CX870XRE or CX1260RE from yourdealer. The Hayward name is your guarantee of quality.VACUUMINGVacuuming can be performed directly into the filter wheneverneeded. Clean cartridges after vacuuming, if required.

WINTERIZINGIn areas where sub-freezing temperatures can be expected,the filter should be drained and/or removed from its operatinglocation and stored indoors. Remove and clean cartridges.Reinstall cartridges in filter tank.SERVICE AND REPAIRSConsult your local authorized Hayward dealer or servicecenter. No returns may be made directly to the factory withoutthe expressed written authorization of Hayward <strong>Pool</strong> Products,Inc.ALGAE CONTROLAlgae is a form of plant life which can vary in size from a fewthousandths of an inch to the size of a small tree. Of the manyforms of algae, those most frequently found in swimming poolwater are microscopic in size and green in color.Algae readily grows in sunlight and can, under favorableconditions quickly overgrow a swimming pool turning itcompletely green in just a few hours. On the other hand,swimming pool water can be unfavorable to algae growthsimply by maintaining a chlorine level of at least 1.0 ppm in thewater at all times. The chlorine level should be checked at leastonce a day using a suitable test kit.If an algae condition develops and the pool water “blooms”green, superchlorination of the pool will be necessary to clearit. Add unstabilized granular chlorine, or liquid chlorine. Followchemical manufacturer’s recommendation for superchlorination.The algae will quickly become inactive and can then beremoved by the filter. Live algae, on the other hand, multipliesso fast that the filter cannot keep up with its growth rate.When correctly used, commercial algaecides are effectiveagainst algae, though algaecides should be used inconjunction with, and not as a substitute for, regularchlorination or superchlorination.Maintaining a chlorine level of at least 1.0 ppm in the pool waterat all times is the most effective way to prevent algae growth inswimming pools.PLEASE REALIZE . . .Pure, clear swimming pool water is a combination of twofactors—adequate filtration and proper water chemistrybalance. One without the other will not give the clean, clearwater you desire.Your filter system is designed for continuous operation.However, this is not necessary for most swimming pools. Youcan determine your filter operation schedule based on yourpool size and usage. Be sure to operate your filtration systemlong enough each day to obtain at least one complete turnoverof your pool water.To properly sanitize your pool, maintain a free chlorine level of1 to 3 ppm and a pH range of 7.2 and 7.6. Insufficient chlorineor an out of balance pH level will permit algae and bacteria togrow in your pool and make it difficult for your filter to properlyclean the pool water.POOL CHEMISTRY GUIDELINESpHSUGGESTED POOL CHEMISTRY LEVELS7.2 to 7.6ACTION REQUIRED TO CORRECT POOL CHEMISTRYTO RAISETO LOWERAdd Soda AshAdd Muriatic Acid or Sodium BisulphateTOTAL ALKALINITY100 to 130 ppmAdd Sodium BicarbonateAdd Muriatic AcidCHLORINE (UNSTABILIZED)0.3 to 1.0 ppmAdd Chlorine ChemicalNo action—chlorine will naturally dissipateCHLORINE (STABILIZED)1.0 to 3.0 ppmAdd Chlorine ChemicalNo action—chlorine will naturally dissipateCHLORINE STABILIZER(Cyanuric Acid)40 to 70 ppmAdd StabilizerDilution—partially drain & refill pool with waterthat has not been treated with Cyanuric Acid.Rev: 11/98©1998 Hayward