G:\Government\Document Files\Handbook ... - Granta Design

G:\Government\Document Files\Handbook ... - Granta Design

G:\Government\Document Files\Handbook ... - Granta Design

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

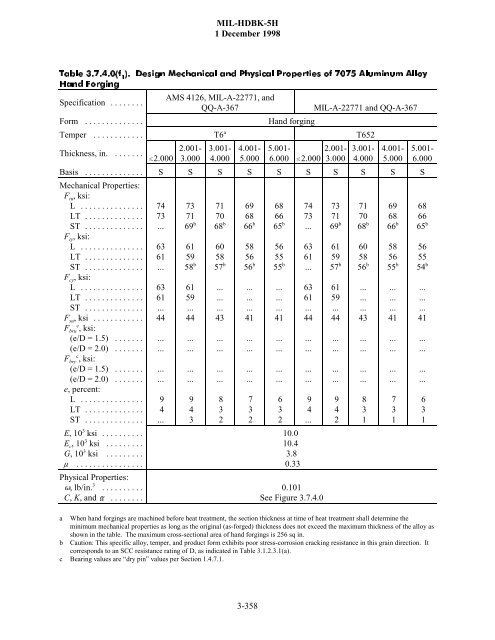

MIL-HDBK-5H1 December 1998 ! " " ,! +Specification ........AMS 4126, MIL-A-22771, andQQ-A-367MIL-A-22771 and QQ-A-367Form ..............Hand forgingTemper ............ T6 a T6522.001- 3.001- 4.001- 5.001- 2.001- 3.001- 4.001- 5.001-Thickness, in. .......2.000 3.000 4.000 5.000 6.000 2.000 3.000 4.000 5.000 6.000Basis .............. S S S S S S S S S SMechanical Properties:F tu , ksi:L ...............LT ..............ST ..............F ty , ksi:L ...............LT ..............ST ..............F cy , ksi:L ...............LT ..............ST ..............F su , ksi ............F bruc , ksi:(e/D = 1.5) .......(e/D = 2.0) .......F bryc , ksi:(e/D = 1.5) .......(e/D = 2.0) .......e, percent:L ...............LT ..............ST ..............E, 10 3 ksi ..........E c , 10 3 ksi .........G, 10 3 ksi .........µ ................Physical Properties:, lb/in. 3 ..........C, K, and ........7473...6361...6361...44............94...737169 b615958 b6159...44............943717068 b605857 b.........43............832696866 b585656 b.........41............732686665 b565555 b.........41............63210.010.43.80.337473...6361...6361...44............94...0.101See Figure 3.7.4.0a When hand forgings are machined before heat treatment, the section thickness at time of heat treatment shall determine theminimum mechanical properties as long as the original (as-forged) thickness does not exceed the maximum thickness of the alloy asshown in the table. The maximum cross-sectional area of hand forgings is 256 sq in.b Caution: This specific alloy, temper, and product form exhibits poor stress-corrosion cracking resistance in this grain direction. Itcorresponds to an SCC resistance rating of D, as indicated in Table 3.1.2.3.1(a).c Bearing values are “dry pin” values per Section 1.4.7.1.737169 b615957 b6159...44............942717068 b605856 b.........43............831696866 b585655 b.........41............731686665 b565554 b.........41............6313-358