OmniScan® iX - Tecsud

OmniScan® iX - Tecsud

OmniScan® iX - Tecsud

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

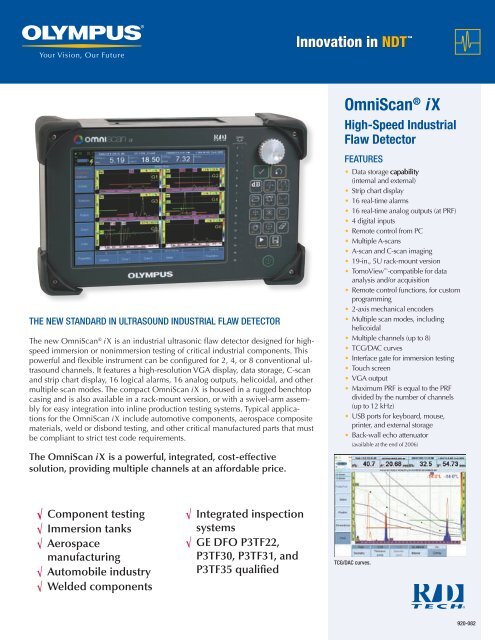

OmniScan ® i XHigh-Speed IndustrialFlaw DetectorThe New Standard in Ultrasound industrial Flaw detectorThe new OmniScan ® <strong>iX</strong> is an industrial ultrasonic flaw detector designed for highspeedimmersion or nonimmersion testing of critical industrial components. Thispowerful and flexible instrument can be configured for 2, 4, or 8 conventional ultrasoundchannels. It features a high-resolution VGA display, data storage, C-scanand strip chart display, 16 logical alarms, 16 analog outputs, helicoidal, and othermultiple scan modes. The compact OmniScan <strong>iX</strong> is housed in a rugged benchtopcasing and is also available in a rack-mount version, or with a swivel-arm assemblyfor easy integration into inline production testing systems. Typical applicationsfor the OmniScan <strong>iX</strong> include automotive components, aerospace compositematerials, weld or disbond testing, and other critical manufactured parts that mustbe compliant to strict test code requirements.The OmniScan <strong>iX</strong> is a powerful, integrated, cost-effectivesolution, providing multiple channels at an affordable price.FEATURES• Data storage capability(internal and external)• Strip chart display• 16 real-time alarms• 16 real-time analog outputs (at PRF)• 4 digital inputs• Remote control from PC• Multiple A-scans• A-scan and C-scan imaging• 19-in., 5U rack-mount version• TomoView -compatible for dataanalysis and/or acquisition• Remote control functions, for customprogramming• 2-axis mechanical encoders• Multiple scan modes, includinghelicoidal• Multiple channels (up to 8)• TCG/DAC curves• Interface gate for immersion testing• Touch screen• VGA output• Maximum PRF is equal to the PRFdivided by the number of channels(up to 12 kHz)• USB ports for keyboard, mouse,printer, and external storage• Back-wall echo attenuator(available at the end of 2006)√ Component testing√ Immersion tanks√ Aerospacemanufacturing√ Automobile industry√ Welded components√ Integrated inspectionsystems√ GE DFO P3TF22,P3TF30, P3TF31, andP3TF35 qualifiedTCG/DAC curves.920-082

OmniScan i X Benefits and FeaturesComplete Integrated Solution• Automatic gate synchronizes from previous gate for higher dynamicrange of thickness.• A‐scan data storage and C-scan postprocessing capabilities• Interface gate for surface following synchronization of measurementgate and/or TCG/DAC curves• Either positive or negative gate on RF signal (independent for eachgate)• 16 alarms completely configurable on single-gate events or multiplegateevents, filter for n occurrences from one or multiple channels• Customizable color palette for amplitude and thickness C-scan• 60 Hz A-scan refresh rate with overlays of envelope and peak insidethe gateRear view showing the numerous connectors enabling easy integration.• Affordable price• Rugged construction for industrial environment with rack-mount option• Remote control functions, for custom programming from PC• TomoView -compatible for data analysis and/or acquisition• Optional data library to access A‐scan and/or C-Scan on PC, for customprocessingSoftware FeaturesFull-featured C‐scan.Strip chart view.• Each channel can have unique setups for multizone inspection.• Surface following interface gate• Built-in strip chart display and data storage• Multiple A-scans• A-scan and C-scan imaging• TCG curves• Multiple scan modes, including helicoidal• Back-wall echo attenuator (available at the end of 2006)• Monitoring of amplitude, peak position, crossing-level position, andthickness on each gateHardware Features• Data storage (internal and external)• Multichannel configuration (up to 8 channels)• PRF up to 12 kHz / number of channels• Analog and alarm output compatibility with older systems• 16 real-time fully programmable alarms• 16 real-time analog outputs (at PRF)• 4 digital inputs to remotely control the machine• 2-axis mechanical encoders (option)• 2‐axis mechanical encoder with data acquisition synchronization onmechanical movementChannel ConfigurationThe OmniScan <strong>iX</strong> can be configured for pulse-echo, pitchand-catch,or sequence firing.CH1CH2CH3Pulse-echo configuration.CH4CH5CH6CH1CH7CH2CH8CH3CH4Pitch-and-catch configuration.CH5CH6CH7CH8

Component TestingComponent testing is typically performed under an assembly-line environment.The OmniScan ® <strong>iX</strong> is used to accept or reject (go-no-go testing) thousands of partsa day. Multichannel instrument configurations lend themselves very well to assembly-lineapplications, which are aimed at detecting flaws within the various zonesof a part—not just under one particular area with one transducer. 16 alarm outputson the OmniScan <strong>iX</strong> allow the tracking of a particular zone and monitoring thezone that is giving the alarm conditions.Weld and Flaw Inspection in Tubular GoodsTubular flaw detection can be configured using multiple channels, as necessary, toachieve 100% inspection of critical defects. Inspections often require the ability tointerrogate for ID and OD notches and internal flaws or delaminations.Often 5 pulse-echo channels are required: 2 transducers diametrically opposedfor axial-flaw detection; 2 transducers diametrically opposed for transverse flawdetection; and one 0-degree probe for thickness- or laminar-flaw indications.Additional channels could be required for oblique angles.Billet InspectionThe ease of integration, channel flexibility, and the ability to invoke more advancedfunctionality makes the OmniScan <strong>iX</strong> an ideal instrument or centerpiecefor a newly integrated system or a well-suited replacement of an existing ultrasonicsystem.Plate InspectionUltrasonic equipment for plate and sheet inspection often requires multichannelcapacity for faster inspection speed and coverage. Typically, large elementtransducers are used to detect flaws faster. The detected flaws are then sized usinga spherically focused transducer. The OmniScan <strong>iX</strong> offers a conventional UTinstrument replacement option for those not quite ready to adopt a phased arrayapproach.Engine-Disc InspectionCritical inspection of turbine engine discs requires a very sensitive ultrasonic flawdetector capable of detecting small defects in difficult nickel-based metals. Suchinstruments must be able to operate at high gains, with extremely low noise onboth the A-scan display as well as the analog output. The OmniScan <strong>iX</strong> meets thesevery demanding requirements. Additional OmniScan <strong>iX</strong> features such as strip-chartrecorder, C-scan display, and back-echo attenuator make this a very versatile instrument.The OmniScan <strong>iX</strong> can easily drop into existing, older test stations, then latertransfer to a full functional station to perform on-board mapping/C-scan.The OmniScan <strong>iX</strong>has been qualified by GE Aircraft Engines and added to the DFOas follows:• P3TF22 Longitudinal Immersion Ultrasonic Inspection of Forgings to Flat Bottom HoleSensitivities• P3TF30 High Sensitivity Ultrasonic Inspection of Forged Fine Grain Powder Alloy• P3TF31 Ultrasonic Immersion Inspection of Powder Metallurgy Extruded Bars and Billets• P3TF35 Side Drill Hole Ultrasonic Inspection

OmniScan ® <strong>iX</strong> SpecificationsBenchtop versionRack-mount versionWeightDisplayOverall dimensions (W × H × D)375 mm × 238 mm × 185 mm (14.75 in. × 9.4 in. × 7.3 in.)485 mm × 222 mm × 190 mm (19 in. × 8.7 in. × 7.5 in.)6.5 kg (14.3 lb)800 × 600 10.4 in. TFT color LCDConnectors BNC (2, 4, or 8)Pulser/ReceiverNumber of pulsers/receivers 2, 4, or 8PulserPulse output 50 V, 100 V, 200 V, 300 V ±10%Pulse widthFall timePulse shapeOutput impedanceReceiver gain rangeAdjustable from 30 ns to 1000 ns ±10%, resolution of 2.5 nsLess than 7 nsNegative square waveLess than 7 ΩReceiver0–100 dB, by steps of 0.1 dBMaximum input signal 20 V p-p (screen at 128%)Minimum sensibility 200 µV p-p (screen at 128%)Noise referred to input 160 µV p-p (26 µV RMS) (128%)Input impedanceInput filter(100% bandwidth)Bandwidth of the systemRectifierModeSmoothing50 ΩNumber of points 16TCG rangeMaximum gain slopeA-scan acquisition rateMaximum pulsing rateCentered at 1 MHz (1.5 MHz), centered at 2 MHz (2.25 MHz), centeredat 5 MHz (4 MHz), centered at 10 MHz (12 MHz), centered at 15 MHz,centered at 20 MHz, 0.25–2.5 MHz, 2–25 MHz BB0.25–35 MHz (–3 dB)Positive, negative, full unrectifiedPE (pulse-echo), PC (pitch-and-catch), TT (through-transmission).In PC mode, the maximum number of pulsers equals the number ofchannels divided by 2.DigitalUp to 40 dB20 dB/µsReal-time averaging 2, 4, 8, 16QuantitySynchronizationA-scan recording (TOFD)TCGData acquisition6000 A-scans/s(PRF/N, where N = number of channels) (512-point A-scan)12 kHz (C-scan + Alarm mode). Up to 6 kHz with full A-scan recordingData processingGates3: I (synchro), A and B (measure)I, A, B referenced on main bang, B referenced on gate I or A (postsynchronization)Data storage6000 A-scans/s (512-point A-scan) (3 MB/s transfer rate)C-scan type data recording12,000 (A1, A2, A3, T1, T2, T3) (3 gates); 12 kHz (lower frequency forcorrosion mapping)Storage Internal 8 GB Microdrive ®Refresh rateModesOn timeOn encoderNumber of alarmsConditionsSignalAnalog outputs (at full PRF)Digital inputsData visualization60 HzA-scan, B-scan, C-scan, strip charts, multiple A-scans, and TOFDData synchronization1 Hz–12 kHzOn 1 or 2 axes divided by 1 to 65,536 stepsOutputs and inputs16 (programmable, hold time and delay, filters for n occurrences)Any logical combination of gatesAmplitude or time of flight of gate A or B16 (0 V to +5 V) (programmable for each gate)4 programmable DINOmniScan <strong>iX</strong> OptionsHardware OptionsOMNI-IX-A-RACK1: OmniScan <strong>iX</strong> rackmountbracket optionThe OmniScan i X is also available as a 19-in., 5U rack-mountversion for easier integration into production environments.OMNI-IX-A-ACC1: OmniScan <strong>iX</strong> accessorykit includes the following:• 1 external keyboard,• 1 optical mouse,• 1 storage USB keyOMNI-IX-A-SWIV: OmniScan <strong>iX</strong> swivelarmassemblyOMNI-IX-A-SCASE: OmniScan <strong>iX</strong> hardcarrying caseSoftware OptionsOMNI-IX-SO-ENC1: OmniScan <strong>iX</strong> softwareoption to activate two encoderinputs on the instrumentOMNI-IX-SO-BEA*: OmniScan <strong>iX</strong> softwareoption to activate back wall echoattenuator on the instrument(available the end of 2006) Standard Inclusions• OmniScan <strong>iX</strong> instrument• Ethernet ® cable• OmniScan software• Users User’s manual• NDT Remote Control SoftwareLibrary 2.0OmniScan_<strong>iX</strong>_EN_0609 • Printed in Canada • Copyright © 2005–2006 by Olympus NDT. All Rights Reserved.All specifications are subject to change without notice.Olympus and the Olympus logo are registered trademarks of Olympus Corporation.R/D Tech, the R/D Tech logo, OmniScan, and the OmniScan logo are registered trademarks, and “Innovation in NDT” and TomoView are trademarksof Olympus NDT Corporation in Canada, the United States, and/or other countries.Other company or product names mentioned in this document may be trademarks or registered trademarks of their respective owners.Olympus NDT505, boul. du Parc-TechnologiqueQuébec (Québec) G1P 4S9Canadardtech@olympusndt.comwww.olympusNDT.com