Customised Solutions - Incledon

Customised Solutions - Incledon

Customised Solutions - Incledon

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

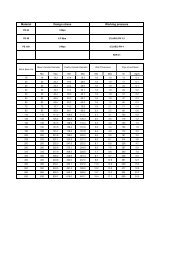

Difficult liquid applicationsWhen pumping dangerous and aggressive liquids, safety is all important. We provide solutions for aggressive and abrasiveliquids, hazardous and hardening liquids as well as flammable liquids.CR range• Chemical industries• Pharmaceutical industries• Petrochemical industries• Refineries• Distilling plants• Paint industries• MiningTemperature controlPumps used in applications involving temperature control are exposed to very low or very high temperatures as well as fluctuations.This extreme exposure stresses the materials due to thermal expansion or contraction.CR rangeCooling systems for:• Electronic data processing• Laser equipment• Medical equipment• Industrial cooling and freezing processesTemperature control systems for:• Casting and moulding tools• Oil processing• Chemical processesSituation Consequence SolutionSeepageAPPLICATION AREASSituation Consequence SolutionSeepageSecondary refrigerantsStandard pumps cannot handle very lowtemperaturesSpecial pump capable of handlingliquids down to -40°C16Abrasive liquids Excessive wear of shaft seal faces Use double shaft seal 14Thermal oilsVery high temperaturesSpecial shaft seal designed to handle oilup to 240°C15Toxic liquidsContamination of environment orpeopleUse MAGdrive or double shaft seal1415Viscous or dense liquidsHigh viscosity or liquid density causesmotor overloadOversize motor 13Flammable liquidsRisk of explosion or fireATEX approved motor and pump forexplosive environments12Temperature control Adapt pump performance CRE, speed controlled pumps 12Crystallising liquidsLeakage due to crystallisation betweenshaft seal facesDouble shaft seal(tandem or back-to-back)14Explosive environment Risk of explosion or fire ATEX approved motor and pump 12Aggressive liquidsCorroded pump metal parts or swollenrubberSpecial material e.g. titanium andresistant rubber1415Limited space for installationPump is too high and may not fit intoinstallation areaMGE high-speed motor solution orhorizontal design and bracket mounting1216Varying frequencies and voltagesaround the worldNeed for different frequencies andvoltagesChoose among our wide range of motorswith different frequencies and voltages12NBG/NKG range• Chemical industries• Petrochemical industries• Refineries• Distilling plants• Paint industries• MiningNBG/NKG rangeCooling systems for:• Electronic data processing• Laser equipment• Medical equipment• Industrial cooling and freezing processesTemperature control systems for:• Casting and moulding tools• Oil processing• Chemical processesSituation Consequence SolutionSeepageSituation Consequence SolutionSeepageAbrasive liquidsExcessive wear of shaft seal facesSecondary refrigerantsStandard pumps cannot handle very lowtemperaturesSpecial pump capable of handlingliquids down to -25°C2829Toxic liquidsContamination of environment or peopleThermal oilsShaft seal and rubbers destroyedSpecial shaft seal designed to handle oilup to 220°C2627Crystallising liquidsLeakage due to crystallisation betweenshaft seal facesUse double shaft seal(tandem or back-to-back)26Viscous or dense liquidsHigh viscosity or liquid density causesmotor overloadOversize motor 25Sticky liquidsDamage of shaft seal torque transmissionsystemTemperature controlPump performance must adaptUse NBGE/NKGE speed controlledpumps24Vacuum operationAir ingress in pump systemExplosive environment Risk of explosion or fire ATEX approved motor and pump 24Flammable liquidsRisk of explosion or fireATEX approved motor and pump forexplosive environments24Varying frequencies and voltagesaround the worldNeed for different frequencies andvoltagesChoose among our wide range of motorswith different frequencies and voltages25Aggressive liquidsCorroded pump metal parts or swollenrubberUse stainless steel pumps, resistantrubber and double shaft seal solution26276 7