Brochure - Unical Lattner Condensing Hot Water Boilers

Brochure - Unical Lattner Condensing Hot Water Boilers

Brochure - Unical Lattner Condensing Hot Water Boilers

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ALKON 50 -70

Flexible output,maximum seasonalefficiencyMODELLO ALKON 50max/minnominal heatoutputcondensingconventionalefficiency class (Directive 92/42)kWkW49,3-10,347,2-9,1ALKON 7068,5-10,365,5-9,1Farewell bad seasonsALKON 50 and ALKON 70 are powerful,condensing, compact (depth 26,6 mm)and friendly use gas boilers.To develop these products <strong>Unical</strong> hasadopted the new heating generatorconcept: “Power Optimized Boiler”.It is a well known fact that heating systemsare subjected to heavy variations of heatdemand.ALKON 50 and ALKON 70, thanks to theirelevated modulating rate, guaranteemaximum fuel saving and the maximumrespect of the environment in every typeof usage, because it represents the besttechnology available today.Heat where it is neededTo complete a boiler house with ALKON,26.6 cm are sufficient and able to containup to 70 kW of avant-garde technologyin the condensation field.Very high seasonal efficiency, very lowpolluting emissions and an advancedregulation control make of ALKON 50and ALKON 70 perfect heating machines.And with all the available accessories itis the ideal solution to renew old boilerhouses and to exploit at the maximumreduced spaces.

The details of ALKONALKON in briefEFFICENCY CLASS (directive CE 92/42).Seasonal efficiency up to 108%.CLASS 5 Low NOx (EN 483), thanks to the pre-mixburner with gas-air ratio control which offers a constantCO 2 content for the whole modulation range.Aluminium (Al/Si/Mg) heat exchanger/condenser.Dimensions: height 93 cm, width 61,5 andonly 26,6 in depth.Very high modulation ratio:. 1:7 for ALKON 70. 1:5 for ALKON 50Integral standard interface for modulating heatingcontrollers with protocol communication (bus-data).Coupling with a modulating pump(supplied as standard for ALKON 70)And moreover, in order to create a specific system whichcan satisfy any type of heating system, <strong>Unical</strong> offers specialoptional accessories:• PUMPS (with constant or modulating flow rate)• HEATING CONTROLLERS• MIXING HEADERS• ADDITIONAL SAFETY DEVICES KIT• ARRANGEMENT FORMULTIPLE BOILER INSTALLATION.thickness26,6Ultra compact aluminium heatexchanger-condenser (Al/Si/Mg)Combustion always under control(modulating fan)Ultra flat: only 26,6 cm in depthE8 heating controller forcontrolling complex heatingsystems and cascade applicationsyearsguaranteeThanks to its particulartechnical configuration,synonymous of quality andsafety, the ALKON boiler’sheat exchanger is suppliedwith a 5 year guarantee.CASKADupto 8 unitsBoiler operation assured evenwith low gas pressures (13 mbar)Quick and easy to serviceAdditional guarantee

High quality ...SEALED PRE-MIXEDMODULATING FANSPECIAL METAL FIBREBURNERFLAME DETECTION ELECTRODEIGNITION ELECTRODEFLUE OUTLETSMOKES SAMPLING POINTCHIMNEYCONDENSATE DRAINALMINIUM HEAT EXCHANGER(AI/Si/Mg)OVERHEATINGTHERMOSTAT

... point by pointAluminium heartApplying the same technology used inthe motorcar industry, the ALKON’s 50motor is a cast aluminium/silicon andmagnesium heat exchanger/condenser.Its major features are the lightweightand compact design: weighing only10 kg and measuring 12 cm in depth,47 cm high and 43 cm wide. The verysevere final tests (according tothe Standard EN 303-1, with a pressureof 26 bar) brilliantly passed, testifythe high quality of this casting.The technology (<strong>Unical</strong> patent),already experimented on the rangeof high and average output MODULEXboilers, has permitted the constructionof a compact heat exchanger which,as well as favouring an elevated heattransfer, also consents self-cleaningof the flue side.Thus, the following benefitsare guaranteed:• Long lasting performance, thanksto the absence of lime scale.• Extremely easy servicingMoreover, thanks to the 100% wetsurfaces in the heat exchanger,a maximum lifespan and reliabilityis ensured, thanks to the optimumcirculation which neveroverburdens it.Blue flameThe combustion system is sited ina special sealed box, placed abovethe heat exchanger, composedby a modulating fan, gas valve, gas/airmixer, ignition device, flame controland a special ‘metal fibre” burner whichproduces the so-called “blue flame”pre-mixed combustion, with a CO 2emission equal to 9% at minimumand maximum output.Silent performanceThanks to the pre-mixed modulatingfan’s low operating pressure, capableof developing a soft flame, the ALKONboiler ensures quiet operation.Low NOx microflameThe microflames which develop internallyundergo a very quick cooling downprocess with a subsequent reductionof the volumetric thermal load.Class 5 Low NOxIn the ALKON boiler, the particular blueflame pre-mixed combustion,with an equivalent flame temperature,transmits greater energy than thatobtained with traditional combustion.Thanks to the practically total oxidizationof the molecules of natural gas, the verylow polluting emissions producedpromote the ALKON boiler intothe selective Class 5 Low NOx category(EN 483). Moreover, the absenceof turbulences ensures absolutesafe operation.Optimum long flue lengthsThe pre-mixed combustion, thanks tothe available manometric head,guarantees flue outlet systems upto 30metres long with a diameter of 80 mm.Efficiency (%)110109108106104102100989694High resistance and long lifeThe physical unalterability of theburner’s metal fibre construction limitsthe mechanical and thermal stresses,ensuring long life. Servicing is facilitatedthanks to the reduced use ofcomponents and ease of access.Exceptional modulation ratioThe prerogative for obtaining a highseasonal efficiency is to be ableto dispose of a “flexible” boiler.To be able to modulate down toan output of only 8,8 kW means thatthe boiler is able to adjust itself to therequired output to meetthe system’s minimum loads, withoutmaking the burner fire/turn offexcessively, dispersing energy uselessly.This same flexibility guarantees areserve of energy, which is alwaysready to satisfy extreme requirements,such as a great demand of immediateheat output.CasingThe casing is in steel plates, paintedwith epoxy-polyester powders andinternally insulated with reflectingpolyethylene materials 5 mm thick.EFFICIENCY DEPENDING ON THE HEATING LOAD20 25 30 35 40 45 50 55 60 65 70Return temperature (C°)30% part load100% full load

Money saving ...Operating efficiency levelsupto and over 108% !The condensing technology has the primaryscope of drastically reducing latent heat(contained in water vapour), which is lostthrough the flue system, thereby exploitingto the utmost the energy containedin the gas burned and giving the condensingboiler an exceptionally high levelof operating efficiency, impossible to reachwith conventional boilers.The ALKON’s 50 heat exchanger/condenserhas been designed so that the system’sreturning cold water passes throughits terminal part: the contact of the fluegases with this cold surface causestheir transition from the vapour phaseto the liquid phase (condensate),with the subsequent release of heat tothe C.H. system water.This process therefore enables the boilerto recover nearly 1 kW per m 3 of gas burned,which normally, with traditional combustion,would be lost to the environmentwith the flue gasses.Combustion/condensation phenomenonALKON<strong>Condensing</strong> boilerCONVENTIONALBOILERUSEABLECONDENSING HEAT+12%- 2 % - 1 %100% 112% 110% 109%UNUSEABLECONDENSING HEATFlue sidelossesFlue sidelossesRadiatonlossRadiatonloss- 7 % - 1 %100% 100% 93% 92%FUEL SAVINGThe energy efficiency indicated is the “Net calorific value”Thus the ALKON 50's and ALKON 70'suseful efficiency reaches 109%!Seasonal efficiency, which is stronglyinfluenced by the heating load factor,which is to say, by the variations of usageaccording to the climatic conditionsand the type of heating system, alwaysmaintains itself at very high levels, placingthis boiler at the top of today’s technology.

... with condensationMathematicalintelligenceAs evidenced in the diagram, with the samehours of boiler operation, if you comparea conventional boiler with an ALKON boiler,you can see that the efficiency of this lastboiler is proportionally the opposite to theheat input requested by the heating system,always maintaining itself greater then avery efficient conventional boiler.Infact, the ALKON can supply a 10% higherefficiency rate compared to a conventionalboiler. Moreover, during the milder season,at the minimum load, the differential infavour of the ALKON reaches upto 19 %.CONVENTIONAL BOILERALKONEfficiency (%)10910210092,590802 3 4 7812 1211 11 1110 10 109 8 87685 45332OTT. NOV. DIC. GEN. FEB. MAR.Months ( daily hours of boiler operation )

The control panelInnovative functionssimple to useThe ALKON is a versatile boiler.Particular care has been givento the flexibility of the controls.The control panel is equipped withan alphanumerical display with 6 preselectionkeys, which enable the userto view the following information:1. Boiler operation•Boiler status; flow and returntemperature•Error code2. User’s parameters•Working temperature setting•On/off central heating3. Service parameters•Maximum working temperature setting•Thermostat•Pump overrun time•Fan ignition speed4. Data readout•Global flow and return temperatureBut the possibilities do not finish here.Infact, using the dedicated E8 heatingcontroller, the control and commandfunctions are reinforced and extended tothe sequence control of multiple boilerinstallations and remote management* ofevery possible configuration.Temperature increase keyReset key/Error code displayDHW set keyCentral heating adjustment keyTemperature decrease keyCH selection key:Stand-by/Central heatingDisplay

ALKON’s brainE8, the intelligent heating controllerThe application and connection of the dedicated E8heating controller, permits a decisive qualitative leap inboiler management depending of the applied loads.The E8, as well as becoming the window of dialoguewith the boiler, thanks to its features, permits the completemanagement of the C.H. system, exploiting the maximummodulating output and the maximum obtainablecondensation.Function E8Self-adaptionThrough the elaboration of data transmittedby the room sensor, this function adjuststhe boiler output to the building’scharacteristics, ensuring a constant monitoringof the indoor temperature on the basisof the variation of the outdoor temperature,keeping in consideration the building’s thermalinertia and the contribution of “free” heat(solar radiation, internal heat sources etc).Boiler heating OptimizationThe heating controller, on the basis ofthe timer/heating programme set by the user,once the system’s characteristics have beenevaluated, will activate the function forautomatically bringing forward the start ofheating so as to ensure that the set temperatureis reached at the time requested by the user.Fast set temperatureThis is obtained by calculating the optimumignition start-up time. This calculationcan be carried out taking into considerationthe outdoor temperature or the roomtemperature.Overheating protectionThe boiler’s safety temperature is controlledvia the pumps overrun time in order to getrid of any thermal inertia.Multiple zone controlWith the same heating control you can control2 independent circuits with differentcharacteristics, though having ensuredall the described functions, includingthe deep sliding temperature function.Programme settingThe heating programmes can be set dailyor weekly, with more than one On-Off firingtimes or temperature reductions duringthe arch of the day.Domestichot waterproductionThere are manyprogrammeswhich controlthe domestichot waterproduction.You canchoose from the maximum of comfort tothe maximum fuel saving. In order to permitthe storage cylinder to supply hot water rapidly,the heating controller brings the boiler’stemperature to the maximum set value.AntilegionEvery 20 heating starts-up or once a week, onSaturday at 01:00 hrs, the storage tank is heatedup to 60°C. This function will eliminate anyeventual bacterium which have formed in theDHW.Frost protection modeThe frost protection operation mode preventsthe C.H. heating from freezing by automaticallyswitching heating operation on. In the frostprotection mode, the room temperature for allthe heating circuits is set to 5°C and the storagetank sensor frost protection is activated whenthe temperature drops below 10°C.Optimisation of DHW(loading pump)The DHW loading pump is switched on onlyif the boiler temperature exceeds by 5K thestorage tank temperature. It is deactivated whenthe boiler temperature drops below the storagetank temperature or if the storage tanktemperature is higher than the nominaltemperature.Slope offset (heating slope distance)The boiler temperature that is required for amixed circuit is calculated byadding to the calculatedtemperature setting for theheating circuit temperaturethe heating curve distance.The heating curve distancecompensates for sensortolerances and heat loss upto the mixer.Number of burnerignitionsBurner run hoursMixing valve opening timeBased on the characteristics of theservomotorAnd more:• Management of up to 15 mixed circuitscontrolled by the outdoor sensor (refer toaccessories).• Integration with renewable energy sourcesas for example: solar systems and/or solid fuelboilers.• 0-10 volt signal: the great flexibility of the E8also permits the boiler set point to be controlledby an external control signal. This will enable,having at disposal an even more complex system,to exploit all the heating control’s functions.• Remote controls*: via appropriate software,this function enables the reduction of systemmanagement, remote indication of boiler run,thereby avoiding unnecessary inspection visits.* available in the near future

The modulating pumpALKON 70MODULATION PUMP(standard supply)3500 ÷ 1000 l/hMAX Output 70 kW∆t 16°CMIN Output 10 kW∆t 9°CCONSTANT WATERFLOW RATE (optional)3000 l/hMAX Output 50 kW∆t 14°CMIN Output 10 kW∆t 3°CALKON 50MODULATION PUMP(optional)3000 ÷ 900 l/hMAX Output 50 kW∆t 14°CMIN Output 10 kW∆t 10°CWith the modulating pump the ∆t (refer to table) between the flowand return is maintained at a high level and subsequentlythe boiler will operate in condensing condition for a longer time.It is a well know fact that the system’sperformance, or rather, the energy supplyis conditioned by the temperature differencebetween the flow and return (∆t).Well then, it is not sufficient to modulatethe generator’s power, above all withcondensing boilers. In order to improve theboiler efficiency it is necessary to maintainthe return temperature as low as possible.Therefore, the ALKON's electronics, incombination with the heating controller, whenthe supplied output decreases, reduces thenumber of revolutions of the pumpand therefore the hourly water flow rate,maintaining the ∆t (temperature difference)practically constant.ALKON 70 is delivered, as standard, withmodulating pump.For ALKON 50 the pump is optional andit is possible to make a choice betweenthe modulating or fixed flow rate pump,thus allowing the highest installationflexibility.ALKON heating system designThe ALKON condensing boiler permitsmany types of solutions for every system.A typical layout can be seen below: theALKON is a rapid generator withLAYOUT OF 2 DIRECT/MIXED AND DHW PRODUCTION HEATING ZONESa low water content, which faithfully followsthe variations of the heating loadwith maximum fuel saving.Provision for a pump will have to be madeon the basis of the circuit’s characteristicsand therefore, interface the boiler’s variousheating loads via the mixing header.ReturnFlowE8heating controllerAdditionalSafety Devices KitMixingheaderDHW CircuitHeating CircuitIts various and very important tasks are:To make independent the connected circuits.To act as “separator” so as to permitthe separation and collection of the sludgeof the system.To vent automatically the air contained inthe circuits.If a DHW storage tank is foreseen, a loadingpump must be fitted.The zones or various C.H. systems,for example in a block of flats with severalapartments, can be controlled by the E8heating controller.Filter

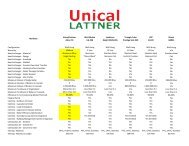

Dimensions and technical dataA107S78125179266Legend:R - Heating system returnM - Heating system flowG - Gas inletSc - Condensate siphon drain outlet(aluminium body)Scf - Condensate drain(coming from the flue outlet pipe)VIEW FROM ABOVE135930SVR M GScScf7826661585 110 110 132 100 78VIEW FROM BELOWMODELALKON 50 ALKON 70OutputNominal/Minimum heat OUTPUT IN CONDENSING MODEkWNominal/Minimum heat OUTPUTkWHEAT INPUTkWEfficiencyEFFICIENCY CATEGORY (Directive CEE 92/42)Efficiency at full load (100%) / Required efficiency (100%)%Efficiency at 30% part load / Required efficiency at part load (30%)%Efficiency at nominal load (100%) / Required efficiency (100%) IN CONDENSING MODE %Efficiency at 30% part load / Required efficiency (30%) IN CONDENSING MODE%Efficiency at the min. modulating output in condensing mode (9,1 kW)%Combustion efficiency at nominal load (100%) / part load%Stand-by losses (min-max)%CombustionCO2 (min/max input)%CO at 0% of 02 (min)mg/kWhNOx (value according to EN 297/A3 and EN 483)mg/kWhPRODUZIONE DI CONDENSAkg/hNOx classAppliance’s family gas categoryCentral HeatingMin/Max operating temp. in CH mode°CMin/Max pressure in CH circuitbarMin. water flow rate in CH circuit (∆t 20°C)l/minWeightNet weightkgElectrical supplyMaximum absorbed power * (with modulating pump)WElectrical supply / power consumptionV/HzElectrical protectionIP49,3 / 10,347,2 / 9,148,5 / 9,397,3 / 96,3106,2 / 94,0101,6 / 92,7109 / 97,910997,8 / 98,43,47 / 0,58919,733,97,85II2H3P30 / 850,5-65,45077 (172)*230 / 50X4D68,5 / 10,365,5 / 9,167,5 / 9,697 / 96,6105,8 / 94,4101,5 / 92,8109 / 97,910998,4 / 98,23,47 / 0,35919,734,6810,875II2H3P30 / 850,5-67,650290230 /50X4DNote: Room temperature = 20°C

Range of components ...192736845The new vision of the modernheating system is no longersatisfied with just the boiler!Therefore, <strong>Unical</strong> placesat your disposal a richcatalogue of componentswhich facilitate the system’slayout and enable you to obtainthe maximum result fromthe technology employedand the heating system design.MODULATINGPUMPStandard supply formod. ALKON 70MODULATINGPUMPOptional for mod.ALKON 50cod. 00361320CONSTANT FLOWRATE PUMPOptional for mod.ALKON 50cod. 00361321RANGE OF MODELSWall mounted, condensing boiler ALKON 50, equipped for Nat. gas cod. 41010012 pos. 1Wall mounted, condensing boiler ALKON 50, equipped for LPG cod. 41010028Wall mounted, condensing boiler ALKON 70, equipped for Nat. gas cod. 41010098Wall mounted, condensing boiler ALKON 70, equipped for LPG cod. 41010099OPTIONS8 heating controller kit cod. 00361332 pos. 2omplete with:Outdoor sensor, flow sensor, boiler sensor,D.H.W. Storage tank sensor, connecting terminals.1 supporting frame cod. 00361366 pos. 3Collector kits cod. 00361314 pos. 4composed of:Ballstop valves 1 1/4” (2x), Flow collector, Return collector, Return pipe connection,Flow pipe connection, Flow return pipe header connection,Safety valve 6 bar, Closed expansion vessel 1 l for boiler.Kit flange cieche cod. 00361450 pos. 5Mixing header kit (maximum flow rate 6 m 3 /h) cod. 00361333 pos. 6Modulating pump (optional for. ALKON 50) cod. 00361320 pos. 7Constant flow rate pump (optional for ALKON 50) cod. 00361321Additional zone control BM8 cod. 00361358(digital timer with outdoor sensor for connection to CAN-BUS 4 wires)E8 holder WAG, for wall mounting installation cod. 00361359Electrical harness for D.H.W. storage thank, if any (ALKON 50) cod. 00361668Electrical harness for D.H.W. storage thank, if any (ALKON 70) cod. 00361736ADDITIONAL SAFETY DEVICES KITADDITIONAL SAFETY DEVICES COLLECTOR KIT code: 00361313 pos. 8ADDITIONAL SAFETY DEVICES KIT code: 00361316 pos. 9composed of: 3-way cock 1/2”, pressure gauge R 3/8, R 1/2 bulb holders (2x),100°C H.L. thermostat, 5 bar safety max pressure switch, thermometer, shock absorber for pressure gauge.Note: The C.H. system expansion vessel and the relevant safety valve (pressure relief) are not supplied becausetheir setting depend on the maximun working pressure and water content of the installation.The gas feeding pipes are not supplied.

... and the accessoriesDHW STORAGE - PRODUCTION CYLINDERSDHW heater-storage cylinder with coil heat exchanger.SANICAL 300SANICAL 400SANICAL 500SANICAL 750SANICAL 1000code: BSE0040code: BSE0050code: BSE0060code: BSE0070code: BSE0080Flue outletsCONFIGURATION FLUE OUTLET KITOriginal flue pipes are available to complete the flueing system.Coaxial elbow 90° ø 80/ø M/F LR code: 00361200Flue outlet terminal code: KIT5770CTerminal grille ø 80 code: 00310012Extension ø 80 L 1000 mmcode: KIT5750CExtension ø 80 L 500 mmcode: KIT5760CAir inlet terminal ø 80code: KIT5780CSANICAL 300only mod. ALKON 50max = 7 mmin = 1 m - LKIT5820C00361216L00361255m00310012L min = 1 m - L max = 30 m0036120000361200KIT5770CL min = 1 m - L max = 30KIT5790C0036120000310012KIT5750CKIT5760CL min = 1 m (0,5 asp. + 0,5 scarico)L max = 30 m (15 asp. + 15 scarico)00361200KIT5770C00361200KIT5780CCONCENTRIC VERTICAL FLUE Ø 80/125 mmTipo C3300360357L min = 1 m - L max = 5m0036125600361255CONVENTIONAL FLUE OUTLET Ø 80 mmTipo B23TWIN FLUE Ø 80 mmTipo C53BALANCED FLUE Ø 80/125 mmTipo C13

CASKADIntegrationand perfect compatibilityALKON multiplies itself!The flexible E8 heating controller viathe e-Bus connection system permitsthe management, with only two wires,of up to 8 ALKON units.Subdivided in two banks of 4 boilerseach, they can supply a total outputof up to 560 kW (with 8 ALKON 70)and up to 400 kW (with 8 ALKON50), with a subsequent flexibility ofuse. Suitable hydraulic connectionkits, approved flue outlet systems,easy to mount frames and all theADDITIONAL SAFETY DEVICES inorder to present the system approvedby <strong>Unical</strong>, permits the fast installationof the complete circuit with a mixingheader, suitably dimensioned for thedesigned output. This gives you theadvantage of having at disposal,where space is very reduced, highefficiency modules, guaranteeing:Recovery and restoration of oldheating plantsBetter efficiency levels thanks tothe excellent modulation ratiowhich reduces the output in allthe boilers, proportionally to theoutput required and shuts themdown in sequence.

CASKAD with n° 4 ALKON unitsin a multiple boiler installation.Reliable operation under everycondition thanks to output sharing.The versatility of combinationswhich the ALKON CASKAD modularsystem offers, is practically endless.In this case you can choose an ALKONas the “master” boiler who,via the E8 heating controller, “controls”the subsequent ALKON “slave” boilers,who are also equipped with a pump.Choosing from the accessories available, themultiple arrangement of boilers will beconstructed on the basis of the C.H. system’srequirements.Each boiler can be fitted with a single flueoutlet configuration which, then, conveys theflue gases into a sole collector.The above applications are approved andcertified according to the existing Standards.

CASKADincreases output and efficiencyEfficiency (%)109108106104ALKON EFFICIENCYThe ALKON offers flexibleoperation and highoperating efficienciesWe have seen that the individualALKON boiler has an approved efficiencywhich, when the output reduces, increasesprogressively from 102 to 109% (incondensing mode).10210 15 20 25 30 35 40 45 5055 60 65 70Output (kW)This is possible because to the heatexchanger increases its efficiency, andflue temperature decreases, when theinput is reduced.Output sharing with 4 x 50kW modules in cascadeRequested output 200 kW50 kW 50 kW 50 kW 50 kWRequested output100 kW25 kW 25 kW 25 kW 25 kWIn order to increase the total operatingefficiency of the ALKON CASKAD,the E8 heating controller maintainsthe major number of ALKON unitsin the multiple boiler installation, firing atthe lowest possible rate (as shown in thebesides examples).Using this method the heating systemwill always operate at the maximumpossible efficiency, independentlyfrom the rate supplied.Total efficiencyη = 102Total efficiencyη = 106Always with the same operation principle,when the heating load slowly reduceitself, the output of each module will alsobe controlled and proportionally reduced.Requested output40 kW10 kW 10 kW 10 kW 10 kWRequested output30 kW10 kW 10 kW 10 kW OFFAs the minimum rate of each moduleis 10 kW, if the required load is inferiorto the total minimum output of the singleunits (n° units x 10 kW), only the ALKONboilers, needed to reach the requestedoutput at the maximum efficiency level,will be fired and the other units will beshut down.Total efficiencyη = 109Total efficiencyη = 109Moreover, in order to ensure an equaldaily rotation of each module, every24 hours each unit will be fired alternately,so as to ensure that each one operatesfor the same number of hours.

Accessories:neutralizing kitsOptionalacid condensateneutralizing kitThe condensate water produced duringcombustion reacts with NOx formingacid molecules (pH value = 4,5).It could become necessary to neutralizethese substances before their dischargein the drainage system water.In order to respect the ecosystem <strong>Unical</strong>proposes the NH condensate neutralizers.KIT NH 500– for boiler outputs upto 500 kW (code 00361551):the neutralization occurs accordingto the principal of the passage of acidiccondensate through the granularneutralizing material.The passage takes place from the bottomto the upper direction.FLOW RATEBOILER OUTPUTDELIVERY HEADFLUID TEMPERATURESTAGNATION POINT HEIGHTNEUTRALIZING SUBSTANCEDURATION OF NORMAL CONDENSATEl/hkW°CmmKIT NH 500UP TO 70UP TO 500-5-4090GENO® - Neutralit -Hz12 months (1500 operating hrs)KIT NH 1000up to140up to10004 m a 140 l/h5-4090GENO® - Neutralit -Hz12 months (1500 operating hrs)Kit NH 1000 – for boiler outputs upto 1000 kW (code 00361136): in the NH1000 system the condensate is convergedthrough a zone filled up by a granularneutralizing material, in which an integratedfilter layer can also be found.When evacuating this zone the neutralizedcondensate reaches a level controllerpump, also operating as an hoisting system,which pumps it towards the drain outlet.This system is able to treat up to 140 l/hof condensate, for boiler outputs up to1000 kW and it is approved by the Germanbody DVGW.CONDENSATE/AMBIENT WATER TEMPERATUREDIMENSIONS (lengthxwidthxheight)INLET/OUTLET CONNECTIONINLET/OUTLET HEIGHTHEIGHT TOO FULL OR 2° OUTLET TUBEELECTRICAL CONNECTIONABSORBED ELECTRICAL OUTPUTABSORBED ELECTRICAL SUPPLYPROTECTION GRADE°CmmmmWA5 - 60476x300x185DN 1550/90-----5 - 40640 x 400 x 270DN 20/DN 1050150230V/50Hz450,33IP 54CONDENSATE NEUTRALIZERSKIT NH 500 (boiler output up to 500 kW) code: 00361551KIT NH 1000 (boiler output up to 1000 kW) code: 00361136Neutralizer salts refill – Refill 8: code: 00361138Neutralizer salts refill – Refill 25: code: 00361139

CASKAD ...Installation of 2 ALKON boilers in a multipleboiler installation216 1078541193CONFIGURATION1 - ALKON 50 natural gas Cod. 41010012- ALKON 50 LPG Cod. 41010028or:- ALKON 70 natural gas Cod. 41010098- ALKON 70 LPG Cod. 410100992 - E8 heating controller Cod. 003613323 - Supporting frame for 2 units Cod. 003613634 - ALKON collectors kit Cod. 003613145 - Additional Safety Device Kitstub pipe 50-200 kW Cod. 003613136 - Additional Safety Device Kit Cod. 003613167 - Hydraulic separator kit up to 180 kW Cod. 003614998 - Separator connection kit up to 180 kW Cod. 003614149 - Flue outlet kit 2 ALKON units Cod. 0036136110 - Modulating pump (optional for Alkon 50) Cod. 00361320- Fixed rate pump (optional for Alkon 50) Cod. 0036132111 - Blind flange kit Cod. 00361450ADDITIONAL FLUE OUTLET ACCESSORIES45° elbow DN 160 Cod. 0026243087° elbow DN 160 Cod. 00262431Extension DN 160 L = 250 Cod. 00262432Extension DN 160 L = 500 Cod. 00262433Extension DN 160 L = 1000 Cod. 00262434Extension DN 160 L = 2000 Cod. 00262435Inspection pipe DN 160 Cod. 00262438Smoke thermostat kit* Cod. 00361451CONTROLS ACCESSORIESWAG holder kitfor wall mounting installation Cod. 00361359BM8 remote control kit Cod. 00361358Installation of 3 ALKON boilers in a multipleboiler installation726 10859143a9a113COMPOSIZIONE1 - ALKON 50 natural gas Cod. 41010012- ALKON 50 LPG Cod. 41010028oppure:- ALKON 70 natural gas Cod. 41010098- ALKON 70 LPG Cod. 410100992 - E8 heating controller Cod. 003613323 - Supporting frame for 2 units Cod. 003613633a - Expansion frame for 1 unit Cod. 003613654 - ALKON collectors kit Cod. 003613145 - Additional Safety Devices Kitstub pipe 50-200 kW Cod. 003613136 - Additional Safety Devices Kit Cod. 003613167 - Hydraulic separator kitup to 180 kW (per mod. Alkon 50) Cod. 00361499up to 450 kW (per mod. Alkon 70) Cod. 003615008 - Separator connection kitup to 180 kW (per mod. Alkon 50) Cod. 00361414up to 450 kW (per mod. Alkon 70) Cod. 003614159 - Flue outlet kit 2 ALKON units Cod. 003613619a - Expansion flue outlet kit 1 ALKON unit Cod. 0036136210 - Modulating pump (optional for Alkon 50) Cod. 00361320Fixed rate pump (optional for Alkon 50) Cod. 0036132111 - Blind flange kit Cod. 00361450ADDITIONAL FLUE OUTLET ACCESSORIES45° elbow DN 160 Cod. 0026243087° elbow DN 160 Cod. 00262431Extension DN 160 L = 250 Cod. 00262432Extension DN 160 L = 500 Cod. 00262433Extension DN 160 L = 1000 Cod. 00262434Extension DN 160 L = 2000 Cod. 00262435Inspection pipe DN 160 Cod. 00262438Smoke thermostat kit* Cod. 00361451CONTROLS ACCESSORIESWAG holder kitfor wall mounting installation Cod. 00361359BM8 remote control kit Cod. 00361358* Usable also on single boiler with PPS flue.

... the configurationsCOMPOSIZIONE1 - ALKON 50 natural gas Cod. 41010012- ALKON 50 LPG Cod. 41010028oppure:- ALKON 70 natural gas Cod. 41010098- ALKON 70 LPG Cod. 410100992 - E8 heating controller Cod. 003613323 - Supporting frame for 2 units Cod. 003613633a - Expansion frame for 1 unit Cod. 003613654 - ALKON collectors kit Cod. 003613145 - Additional Safety Devices Kitstub pipe 50-200 kW Cod. 003613136 - Additional Safety Devices Kit Cod. 003613167 - Hydraulic separator kitup to 450 kW Cod. 003615008 - Kit di collegamento separatoreup to 450 kW Cod. 003614159 - Flue outlet kit 2 ALKON units Cod. 003613619a - Expansion flue outlet kit 1 ALKON unit Cod. 0036136210 - Modulating pump (optional for Alkon 50) Cod. 00361320- Fixed rate pump (optional for Alkon 50) Cod. 0036132111 - Blind flange kit Cod. 00361450ADDITIONAL FLUE OUTLET ACCESSORIES45° elbow DN 160 Cod. 0026243087° elbow DN 160 Cod. 00262431Extension DN 160 L = 250 Cod. 00262432Extension DN 160 L = 500 Cod. 00262433Extension DN 160 L = 1000 Cod. 00262434Extension DN 160 L = 2000 Cod. 00262435Inspection pipe DN 160 Cod. 00262438Smoke thermostat kit* Cod. 00361451CONTROLS ACCESSORIESWAG holder kitfor wall mounting installation Cod. 00361359BM8 remote control kit Cod. 00361358Installation of 4 ALKON boilers in a multipleboiler installation26 10919a3a3a17 8549a3411Configuration of CASKAD 200 kW2585001000620173434.6469.6 765765765 765Note: The gas feed pipes are not supplied.If installing a heating system with outputs higher than 200 kW (with ALKON 50) AND 280 kW (with ALKON 70),please look at the user and servicing instructions manuals on www.unical.ag.505Ed. n° 2 - 11/2008 cod. 31919