Installation Manual - Unical Lattner Condensing Hot Water Boilers

Installation Manual - Unical Lattner Condensing Hot Water Boilers

Installation Manual - Unical Lattner Condensing Hot Water Boilers

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

®LATTNER<strong>Condensing</strong> gas boilerALKON 90Notice:- This manual is avaible in the English and Frenchlanguage- In the Commonwealth of Massachusetts this boiler mustbe installed by a licensed Plumber or Gas Fitter.00333991 - 1 st edition - 06/2012INSTALLATIONAND SERVICINGMANUAL

2This unit is ready for operation with gas A (natural), you can make the transformation to workwith gas E and (propane HD) using proper kit provided by LATTNERCONTENTSWarning:Any operation on the unit must be performed by authorized personnel.Warning: this manual contains instructions to be used exclusively by the installer and/or a competent personin accordance with the current laws in force.The end user MUST not make any alterations to the boiler.Failure to follow the instructions indicated in this manual, which is supplied with the boiler, could cause injuryto persons, animals or damage to property. LATTNER shall not be held liable for any injury and/or damage.1 GENERAL INFORMATION................................................................................................................................................................................ 31.1 Symbols used in this guide .......................................................................................................................................................................... 31.2 Correct use of the appliance ....................................................................................................................................................................... 31.3 <strong>Water</strong> treatment ............................................................................................................................................................................................ 31.4 Information to be passed over to the person in charge of the appliance ................................................................................................. 41.5 Safety warnings ............................................................................................................................................................................................ 51.6 Data badge .................................................................................................................................................................................................... 51.7 The following instruction ............................................................................................................................................................................... 61.8 Tools, materials and additional equipment .................................................................................................................................................. 71.9 Disposal ........................................................................................................................................................................................................ 71.10General warnings ......................................................................................................................................................................................... 72 TECHNICAL FEATURES AND DIMENSIONS................................................................................................................................................. 82.1 Technical features ........................................................................................................................................................................................ 82.2 Dimensions ................................................................................................................................................................................................... 92.3 Main components ....................................................................................................................................................................................... 102.4 Boiler water circuit ...................................................................................................................................................................................... 112.5 Performances data ..................................................................................................................................................................................... 123 INSTRUCTIONS FOR THE INSTALLER ........................................................................................................................................................ 133.1 General warnings ...................................................................................................................................................................................... 133.2 Code and standard approvals .................................................................................................................................................................. 143.3 Packaging .................................................................................................................................................................................................. 143.4 Minimum clearance for servicing ............................................................................................................................................................. 173.5 Boiler location in a boiler house ................................................................................................................................................................ 173.6 Connections ............................................................................................................................................................................................... 183.7 <strong>Installation</strong> on existing heating systems .................................................................................................................................................. 183.8 Gas connection ......................................................................................................................................................................................... 193.9 Connection return and flow system pipes ............................................................................................................................................... 203.10 Determination of primary boiler pump or boiler pump system.......................................................................................................... 213.11 Pressure relief valve drain pipe ................................................................................................................................................................ 223.12 Working pressure...................................................................................................................................................................................... 223.13 Connecting the expansion vessel in a single boiler system .................................................................................................................. 223.14 <strong>Condensing</strong> drain ...................................................................................................................................................................................... 233.15 <strong>Water</strong> treatment ......................................................................................................................................................................................... 243.16 Combustion air and ventilation openings ................................................................................................................................................. 253.17 <strong>Installation</strong> of the exhaust and air intake system .................................................................................................................................... 263.18 Room air system for installation using indorr combustion air ................................................................................................................ 273.19 Electrical connection ................................................................................................................................................................................. 29Regulation in force .................................................................................................................................................................................... 29Mains electrical connection 120V - 60 Hz ............................................................................................................................................... 29Room thermostat and / or E8 heating controller connection .................................................................................................................. 30Connection of the additional safety device .............................................................................................................................................. 303.20 Wiring diagrams ......................................................................................................................................................................................... 313.21 Ladder diagrams ....................................................................................................................................................................................... 323.22 Starting up .................................................................................................................................................................................................. 333.23 Filling the system ....................................................................................................................................................................................... 333.24 Initial lighting ............................................................................................................................................................................................... 35Preliminary checks ................................................................................................................................................................................... 35Ignition and switching off ........................................................................................................................................................................... 35Information to be supplied to the user ..................................................................................................................................................... 353.25 Testing ignition safety shut off device ...................................................................................................................................................... 363.26 Burner adjustment ..................................................................................................................................................................................... 373.27 Programming of the operational parameters ........................................................................................................................................... 393.28 Variation of input range for high altitude ................................................................................................................................................... 414 SERVICING SCHEDULE .................................................................................................................................................................................. 414.1 Instructions for inspection and servicing .................................................................................................................................................. 41Table of the resistance values in function of the heating and domestic sensor temperature ............................................................... 424.2 Periodic examination of venting system ................................................................................................................................................... 424.3 Proper procedure for cleaning flue gas .................................................................................................................................................... 424.4 Proper procedure for cleaning the burner ................................................................................................................................................ 424.5 Visual inspection of the flame .................................................................................................................................................................... 434.6 Proper reassembly and resealing of the air intake system .................................................................................................................... 434.7 Verification and cleaning of the condensate evacuation siphon .............................................................................................................. 444.8 Sealing gasket between distributor and boiler body ................................................................................................................................445 FAULT FINDING ................................................................................................................................................................................................ 455.1 Error codes .................................................................................................................................................................................................. 465.2 Request of maintenance ............................................................................................................................................................................. 476. SPARE PARTS .................................................................................................................................................................................................. 48

General Information1 GENERAL INFORMATION1.1 - SYMBOLS USED IN THIS GUIDEWhen reading this guide particular care has to be given to the parts marked with the followings symbols:DANGERINDICATES AN IMMINENTLY HAZAR-DOUS SITUATION, WHICH IF NOTAVOIDED, WILL RESULT IN DEATHOR SERIOUS INJURY.WARNINGINDICATES A POTENTIALLY HAZAR-DOUS SITUATION, WHICH IF NOT AVO-IDED, COULD RESULT IN DEATH ORSERIOUS INJURY.CAUTIONINDICATES A POTENTIAL HAZAR-DOUS SITUATION, WHICH IF NOTAVOIDED, MAY RESULT IN MINOROR MODERATE INJURY.CAUTIONRISK OF ELECTRIC SHOCK. INDICA-TES PRESENCE OF HAZARDS DUETO ELECTRIC SHOCK.NOTICEINDICATES SPECIAL ISTRUCTIONS ONINSTALLATION, OPERATION ORMAINTENANCE THAT ARE IMPORTANTBUT NOT RELATED TO PERSONALINJURY OR PROPERTY DAMAGE.WARNING!If you do not follow these instructions exactly, a fire or explosion may result causing propertydamage, personal injury or loss of life.- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.- WHAT TO DO IF YOU SMELL GAS- Do NOT try to light any appliance- Do NOT touch any electrical switch.- Do NOT use any phone in your building.- Immediately call your gas supplier from a neighbor’sphone.Follow the gas supplier’s instructions.- If you cannot reach your gas supplier, call the fire dep.1.2 - CORRECT USE OF THE APPLIANCEThe ALKON appliance has been designed utilizing today’s heating technology and in compliance with thecurrent safety regulations.However, following an improper use, dangers could arise for the safety and lifeof the user or of other people, or damage could be caused to the appliance or other objects.The applianceis designed to be used in pumped hot water central heating systems. Any other use of this appliance will beconsidered improper. LATTNER declines any responsibility for any damages or injuries caused by animproper use; in this case the risk is completely at the user’s responsibility.In order to use the applianceaccording to the scopes it was designed for it is essential to carefully follow the instructions indicated inthis guide.1.3 - WATER TREATMENT• The hardness of the mains water supply conditions the frequency with which the heat exchanger is cleaned.• In hard water areas where the main water can exceed 15°f total hardness, a scale reducing device isrecommended. The choice of this device has to be made taking into consideration the characteristics ofthe water.• In order to improve the resistance to lime scale it is recommended to adjust the domestic hot water temperatureas near as possible to the one you really require.• We recommend you to check the state of cleanliness of the domestic hot water heat exchanger at the end ofthe first year and subsequently, on the basis of the lime scale found, this period can be extended to two years.3

General Information1.4 - INFORMATION TO BE HANDED OVER TO THE USERGo through the information in this manual with the owner/operator and make sure that he or she is familairwith all necessary operating instructions, in particular:• Hand over these instructions to the end user, together with any other literature regarding this appliance,placed inside the envelope contained in the packaging. The user has to keep these documents in a safeplace in order to always have them at hand for future reference.• Inform the user on the importance of air vents and of the flue outlet system, stressing the fact that is absolutelyforbidden to make any alterations to the boiler.• Inform the user how to check the system’s water pressure as well as informing him how to restore the correctpressure.• Explain the function of time and temperature controls, thermostats, heating controls and radiators, to ensurethe greatest possible fuel economy.• Remind the user that it is obligatory to carry out a comprehensive service annually and a combustion analysisevery two years (in compliance with the national law).• If the appliance is sold or transferred to another owner or if the present user moves home and leaves theappliance installed, ensure yourself that the manual always follows the appliance so that it can be consultedby the new owner and/or installer.Failure to follow the instructions indicated in this guide, which is supplied with the boiler, could cause injuryto persons, animals or damage to property. The manufacturer shall not be held liable for any such injury and/or damage.1.5 - SAFETY WARNINGSWARNING!The device should not be used by people with reduced physical, mental and sensory, experience andknowledge. These people must be well-informed and supervised during the work. Children must besupervised so they do not play with the appliance.WARNING!The installation, adjustment, and servicing of this appliance must be carried out by a competent person andinstalled in accordance with the current standards and regulations. Failure to correctly install this appliancecould cause injury to persons, animals or damage to property. The manufacturer shall not be held liable forany injury and/or damage.DANGER!Servicing or repairs of the appliance must be carried out by LATTNER authorised service technicians; LATTNERrecommends drawing up a service contract. Bad or irregular servicing could compromise the safe operationof the appliance, and could cause injury to persons, animals or damage to property for which LATTNER shallnot be held liable.WARNING!Modifications to parts connected to the applianceDo not carry out any modifications to the following parts:- the boiler- to the gas, air, water supply pipes and electrical current- to the flue pipe, safety relief valve and its drainage pipe- to the constructive components which influence the appliance’s safe operationWARNING!When tightening or loosening the screw pipe connections, use only adequate fork spanners.The improper use and/or the use of inadequate equipment can cause damages (for example water or gasleakages).4WARNING!Indications for appliances operating with propane gasEnsure yourself that before installing the appliance the gas tank has been purged.For a correct purging of the tank contact the liquid gas supplier or a competent person who has been legallyauthorized.If the tank has not been correctly purged problems could occur during ignition.If this occurs contact the liquid gas tank’s supplier.

General InformationDANGERSmell of gasIf you smell gas follow these safety indications:- Do not turn on or off electrical switches- Do no smoke- Do not use the telephone- Close the main gas tap- Open all windows and doors where the gas leakage has occurred- Inform the gas society or a company specialized in installing and servicing heating systemsDANGERExplosive and easily inflammable substancesDo not use or leave explosive or easily inflammable material (as for example: petrol, paint, paper) in the roomwhere the appliance has been installed.1.6 DATA BADGEA sample Data Plate for a Alkon Boiler is shown in figurebelow.®LATTNERA sample DataPackaging for a Alkon Boiler is shown in figurebelow.LATTNER5

General Information1.7 - THE FOLLOWING INSTRUCTION MUSTBE FOLLOWED6- The boiler must only be used for its designated purpose,as described in the <strong>Installation</strong> Instructions.- Each unit is fitted with a data plate. Consult the details onthis plate to verify whether the boiler is compliant with itsintended location, e.g.: gas type, power source and ventingclassification.- Only use the boiler with the accessories and spare partslisted.- Other combinations, accessories and consumables mustonly be used if they are specifically designed for the intendedapplication and do not affect the system performanceand the safety requirements.- Maintenance and repairs must only performed by trainedprofessionals.- <strong>Installation</strong> of a condensing gas boiler must be reported tothe relevant gas utility company and have it approved.- You are only allowed to operate the condensing gas boilerwith the vent system that has been specifically designedand approved for this type of boiler.- Please note that local permission for the vent system andthe condensate water connection to the public sewer systemmay be required.You must also respect:- The local building codes stipulating the installation rules.- The local building codes concerning the air intake andoutlet systems and the chimney connection.- The regulations for the power supply connection.- The technical rules laid down by the gas utility companyconcerning the connection of the gas connection to thelocal gas mains.- The instructions and standards concerning the safety equipmentfor the water/space heating system.- The <strong>Installation</strong> Instructions for building heating systems.- The boiler must be located in an area where leakage ofthe boiler or connections will not result in damage to thearea adjacent to the boiler or to lower floors of the structure.When such locations cannot be avoided, it is recommendedthat a suitable drain pan be installed under theboiler.- The boiler must be installed in such way that the all componentsare protected from water (dripping, spraying, rainetc.) during boiler operation and service.- The boiler must not be installed on or against carpeting.- Do not restrict or seal any air intake or outlet openings.- If you find any defects, you must inform the owner of thesystem of the defect and the associated hazard in writing.DANGER.Gas is flammable and may cause an explosion.Beware if you smell gas: there may be an explosionhazard!If the information in these instructions is not followed exactly,a fire or explosion may result causing property damage,personal injury or death.- Do not store or use gasoline or other flammable vaporsand liquids in the vicinity of this or any other appliance.WARNINGWHAT TO DO IF YOU SMELL GAS- Do NOT try to light any appliance.- Do NOT touch any electrical switch.- Do NOT use any phone in your building.- Immediately call your gas supplier from aneighbor’s phone. Follow the gas supplier’s instructions.- If you cannot reach your gas supllier, call thefire department.WARNINGShould overheating occur or the gas supplyfail to shut off, do not turn off or disconnectthe electrical supply to the pump. Instead,shut off the gas supply at a location externalto the boiler.Unsuitable heating system water can cause the formation ofscale or sludge, which affects system efficiency. It can alsocause corrosion and reduce life of the heatexchanger.- You must follow guidelines for boiler waterquality.- Thoroughly flush the system prior to filling.- Follow the LATTNER cleaning instructions.- Never use water that has been treated by a reverseosmosis, D.I., or distilled water to soften the water to fillthe heating system.- Do not use inhibitors or other additives unless approvedby LATTNER for that purpose!- When frost protection of the heating system is desired,only use LATTNER-approved antifreezes. The allowedmaximum concentration is 50%.- When using oxygen-permeable pipes, e. g. for underfloor heating systems, you must separate the systemfrom the boiler using plate heat exchangers.- Valve off boiler while flushing system, do not introduceany system cleaner into the boiler loop. Flush systemthoroughly to remove all system cleaner before fillingboiler.Approved antifreeze (max. concentration 50%):• Rhomar RhoGard Mutli-Metal (AL safe)• Noble Noburst ALApproved system cleaner:• Noble Noburst Hydronic System Cleaner• Fernox F3 Cleaner• Rhomar Hydro-Solv 9100The system cleaners from NoBurst, Rhomar, andFernox are not to be used in the boiler. The boilermust be closed off (valved off) from the rest of thesystem or not connected while the cleaners arein the system. The system should then be drainedand then thoroughly flushed with clean waterto remove all the system cleaner.Approved inhibitors:• Rhomar Pro-tek 922• Noble Noburst AL inhibitor

General Information1.8 - TOOLS, MATERIALS ANDADDITIONAL EQUIPMENTFor the installation and maintenance of the boiler youwill need:- Standard tools for space heating, gas and water fitting- Digital manometer that is capable of reading both positiveand negative pressures- Combustion analyzer- Digital multimeter- pH digital meter- Metric Allen wrenches- Metric socket wrenchesIn addition, a handtruck with a fastening belt is useful.1.9 - DISPOSAL- Dispose of the boiler packaging in an environmentallysound manner.- Dispose of components of the heating system (e.g. boileror control device), that must be replaced in an environmentallyresponsible manner.Operating Limits of the boiler:Max. boiler temperature: 176 °F (80 °C)Max Allowable Working Temperature ASME: 200 °FMax. Allowable Working Pressure ASME: 92 psi1.10 - GENERAL WARNINGSThis instruction manual is an integral and indispensablepart of the product and must be retained by the person incharge of the appliance.Do not obstruct the intake/outlet terminal ducts.In the event of failure and/or faulty functioning of the appliance,switch off the boiler. Do not attempt to make any repairs:contact qualified technicians.Any repairs must be carried out by LATTNER authorizedtechnicians and using only original spare parts. Nonobservanceof the above requirement may jeopardize thesafety of the appliance.To guarantee the efficiency and correct functioning of theappliance it is indispensable to have the boiler servicedannually by a qualified person.If the boiler remains unused for long periods, ensure that anydangerous parts are rendered innocuous.Before putting again into service an appliance which has beenunused for a certain time, proceed to rinse the domestic hotwater circuit, making the water flowing for the time necessaryto draw the full content of the domestic circuit.If the appliance is sold or transferred to another owner or ifthe present user moves home and leaves the applianceinstalled, ensure yourself that the manual always follows theappliance so that it can be consulted by the new owner and/or installer.Only original accessories must be used for all appliancessupplied with optionals or kits (including electrical ones).This appliance must be used only for the purposes for whichit has been expressively designed. Any other use shall beconsidered incorrect and therefore dangerous.Please read carefully the instructions contained in this manualas they provide important indications regarding the safeinstallation, use and servicing of this appliance.Keep this manual in a safe place for future reference.The installation and servicing must be carried out inaccordance with the regulations in force according to themanufacturer’s instructions and by legally competentauthorized persons.The installations for the domestic hot water productionMUST be build, in their entirety, with materials (taps, pipes,fittings, etc.) approved for drinkable water.By a competent person, we imply a person who has a specifictechnical qualification in the field of components for centralheating systems for domestic use, domestic hot waterproduction and servicing. The person must have thequalifications foreseen by the current laws in force.Bad or irregular servicing could compromise the safeoperation of the appliance, and could cause injury to persons,animals or damage to property. The manufacturer shall notbe held liable for any such injury and/or damage.Before carrying out any cleaning or servicing turn off theelectrical supply to the boiler by means of the ON/OFF switchand/or by means of the appropriate shutdown devices.7

Technical features and dimensions2TECHNICAL FEATURESAND DIMENSIONS2.1 - TECHNICAL FEATURESThe ALKON 90 boiler is a low water content thermal elementabout 2,64 gal (10 l), with a built-in premix gas burner, forheating only.It is mainly used as element for the modular boilers in cascade(max 4 boilers).PECULIAR CHARACTERISTICS:1) modular structure to tall integration.2) mainly for outdoor installation3) prearranged for quick installation ‘’ Plug and Play ‘’ alsoin cascade of up to 4 modules.4) modulation ratio of the single module5) control for every single module, with display anddiagnosticThese boilers have an input head power of:341,000 Btu (99,94 kW), These boilers are designed for useon gas category IV.The ALKON boiler is supplied complete with all the safetyand control devices in accordance with all the currentregulations and its technical and functional features complywith the regulations prescribed by:ANSI Z21.13 / CSA 4.9 - Gas-fired low pressuresteam and hot water boilersDESCRIPTION OF COMPONENTS AND FEATURES• Aluminium heat exchanger/condenser;• Premixed combustion group working at constant air-gasratio• Electronic ignition;• Safety limit thermostat;• Safety high limit thermostat;• Flow temperature sensor;• Return temperature sensor;• Automatic air vent;• Control panel with electrical protection• Flame modulation in function of the absorbed power;• Pump overrun function;• Pump• eBUS connection• E8 regulator (optional)• BCM (optional)• ON/OFF switch• Temperature adjustment in heating mode between86 ÷176 °F (30 and 80°C)• Smoke pressure switchOPTIONAL KITS:• Kit of manifold for additional safety devices• Krömschröder controller E8/Expansion modules andmodulating thermostats• Mixing bottle Kit• Chimney for single, battery or cascade mounting• Kit of blind flanges and hydraulic manifolds.Warningfor Outdoor installation is necessary• Electrical resistor kit for condensatesiphon• Electrical resistor kit on Flow and Returnmanifolds• Kit esternal top.8

2.2 - DIMENSIONSTechnical features and dimensions3.7’’(94 mm)3.9’’(100 mm)18’’(456 mm)12.8’’(324 mm)6.2’’(158 mm)11.6’’(295 mm)48.4’’(1238 mm)4.6’’(118 mm)23.9’’(607 mm)4,7’’(119 mm)20.2”(513 mm)R CH system return DN 80M CH flow system DN 80G Gas Inlet DN 50Sc Outlet condensate drain siphon Ø 325.3’’(134 mm)9.9’’(251 mm)11.2’’(284 mm)16.9’’(430 mm)9

Technical features and dimensions2.3 - MAIN COMPONENTSFLUE OUTLET PIPEØ100 mm (3,94“)AIR VENTVALVEMANUAL VENTVALVEFLAMEDETECTIONELECTRODEH.L.THERMOSTAT(Overheatexchangerprotection)MODULATINGFANGASVALVEIGNITIONELECTRODEH.L.THERMOSTATFLOWTEMPERATURESENSORMIN. WATERPRESSURESWITCHALUMINIUM HEATEXCHANGER/CONDENSERCONDENSATESENSOR NIVEAUBOILER DRAINCOCKCONDENSATEDRAIN3 WAY VALVE(FLOW)RETURNTEMPERATURESENSORFLOWMANIFOLDDN 80SAFETYVALVEGASMANIFOLDDN 50PUMPRETURNMANIFOLDDN 802 WAY VALVE(flow stop)RETURN10

2.4 - BOILER WATER CIRCUIT DIAGRAMTechnical features and dimensions109191181276134 514183171512RM206040 8020 1000 12021G161 Return gate valve2 Pump3 Flow gate valve (the way to the siphonis open in order to drain theboiler)4 CH flow temperature sensor5 CH return temperature sensor6 Pressure switch against lack ofwater7 HL thermostat8 HL thermostat(Overheat exchanger protection)9 <strong>Manual</strong> air vent10 Air vent valve11 Heat exchanger12 Fan13 Premix14 Condensate niveau sensor15 Gas valve16 Gas ball valve17 Condensate drain siphon18 Smoke pressure switch19 Flue Outlet20 Safety valve supplied21 Pressure gauge (optional)MGRC.H flowGas supplyC.H. return11

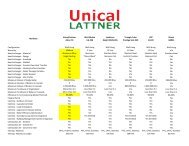

Technical features and dimensions2.5 - PERFORMANCE DATAFor information regarding the adjustment of: INJECTORS - BURNER PRESSURES – DIAPHRAGMS – OUTPUTS – GAS CONSUMPTIONS please refer to theparagraph ADAPTMENT TO THE USE OF OTHER GASES.ALKON 90Minimum heat inputNominal heat input (low)(*) Nominal heat input (high) (reduction for Altitude)Nominal heat output (HT)Minimum heat output (HT)Efficiency at full load (100%)Efficiency at min loadNominal heat output in condensing modeMinimum heat output in condensing modeEfficiency at nominal load in condensing modeEfficiency at min load in condensing modeCombustion efficiency at nominal loadCombustion efficiency at min loadStand-by lossesFlue gas temperature (Flue gas temp - room temp)Air excess λCondensate production max[Btu/hr (kW)][Btu/hr (kW)][Btu/hr (kW)][Btu/hr (kW)][Btu/hr (kW)][%][%][Btu/hr (kW)][Btu/hr (kW)][%][%][%][%][%][°F (°C)][%][lb/hr (kg/hr)]83,300341,000307,000298,60072,00087.5586.44298,60072,00093.6698.397.998.40.90101.325.5030.36(24,41)(99,94)(89,97)(87,51)(21,10)(87,51)(21,10)(38,5)(13,8)Boiler categoryMinimum water flow rate in CH circuit Δt 36 °F (20 °C)Min. pressure in CH circuitMax. pressure in CH circuitMin. dynamic gas pressure (natural gas)<strong>Water</strong> content in primary circuitMaximum operating temperatureMinimum operating temperature[gal/min (l/min)][psi (kPa)][psi (kPa)][in wc (kPa)][gal (L)][°F (°C)][°F (°C)]IV4.07.3923.5117686(15,12)(50)(634)(0,87)(3,9)(80)(30)Electrical supply[V-Hz]120 - 60Net weightGross weight[lb (kg)][lb (kg)]298312(135)(141,5)Max dynamic gas pressure A (natural)Nominal dynamic gas pressure A (natural)Min. dynamic gas pressure A (natural)[in wc (kPa)][in wc (kPa)][in wc (kPa)]10.57.03.5(2.61)(1.74)(0.87)Max dynamic gas pressure E (Propan HD)Nominal dynamic gas pressure E (Propan HD)Min. dynamic gas pressure E (Propan HD)[in wc (kPa)][in wc (kPa)][in wc (kPa)]13.011.08.0(3.23)(2.74)(1.99)(*) For adjustments, refer to section 3.26 and 3.2712

3INSTRUCTIONS FORTHE INSTALLERInstructions for the installer3.1 - GENERAL WARNINGSWARNING!This boiler has to be destined for the use forwhich it has been expressively designed for.Any other use shall be considered improperand therefore dangerous.This boiler is designed to heat water at atemperature inferior to boiling point at anatmospheric pressure.WARNING!These appliances are exclusively designedto be installed inside adequate boiler rooms.Therefore these appliances must not beinstalled and operated externally. An outdoorinstallation could cause malfunctioning andcould be dangerous. For externalinstallations, it is recommended to useappliances which are specifically designedand predisposed for this purpose.Before installing the boiler the following pointshave to be carried out by a competent engineer:a) The whole system should be thoroughlyflushed in order to remove any residual dirt orgrime which could compromise the correctboiler operation.b) Check that the boiler has been preset foroperating with the gas type available.This is verifiable via the indication on thepackaging and on the data badge;c) Check that the chimney/flue pipe has anadequate draught,does not have anyconstrictions, and that no other appliance’s flueoutlets have been fitted, unless the chimneyis serving more than one heating appliance,according to the specific standards andregulations in force.The connection between the boiler andchimney/flue outlet can be made only after thisverification has been carried out.WARNING!In rooms where there is the presence ofaggressive vapours or dust the appliancemust operate independently from the airpresent in the boiler’s location room!WARNING!The appliance must be installed by a qualifiedengineer, who complies to the technicalprofessionalrequirements, who, under his ownresponsibility, guarantees the compliance ofthe standards according to the latestregulations.WARNING!The appliance must be positioned so that atleast the minimum operational and servicingclearances are provided.The boiler must be connected to a heating system which iscompatible to its performance and output.Before boiler installation, complete all of thefollowing instructions:The installation must conform to the requirements of theauthority having jurisdiction or, in the absence of suchrequirements, to one of the following:- United States - <strong>Installation</strong> must conform to the requirementsof the National Fuel Gas Code, ANSI Z223.1/NFPA 54.- Canada - <strong>Installation</strong> must conform to the requirements ofCAN/CSA-B149.1 - Natural Gas and Propane <strong>Installation</strong>CodeWhere required by the authority having jurisdiction, theinstallation must conform to the Standard ASME CSD-1Controls and Safety Devices for Automatically Fired <strong>Boilers</strong>NOTES:- Installers must follow local regulations with respect toinstallation of Carbon Monoxide (CO) Detectors. Also, followthe maintenance recommendations in this manual.- FOR MASSACHUSETTS INSTALLATIONS: The boiler mustbe installed by a plumber or gas fitter licensed within theCommonwealth of Massachusetts.13

Instructions for the installer3.2 - CODE AND STANDARDSAPPROVALSALKON 90 has been reviewed for compliance with theapplicable sections of the following NorthAmerican Standards:ANSI Z21.13/CSA 4.9 - Gas-fired low pressuresteam and hot water boilersASME SECTION IV: ASME Boiler and Pressure VesselCode with addenda, Section IV: Rules for Construction ofHeating <strong>Boilers</strong>BTS - 2000 TESTING STANDARD METHOD TODETERMINE EFFICIENCY OFCOMMERCIAL SPACE HEATING BOILERSSCAQMD RULE 1146.2. EMISSIONS OF OXIDES OFNITROGEN FROM LARGE WATER HEATERS AND SMALLBOILERS AND PROCESS HEATERSCSD-1: CONTROLS AND SAFETY DEVICES FORAUTOMATICALLY FIRED BOILERS3.3 - PACKAGINGThe ALKON 90 boiler is supplied fully assembled in a strongcardboard box.After having unpacked the boiler check that it isintact and undamaged.CAUTIONKeep the packaging material (cardboard box,plastic bags, polyester protection etc.) out ofthe reach of children as they can bedangerous.LATTNER refuses all liability for injury topersons, animals or damage to propertyderiving from not having respected the abovementioned recommendations.56.3”1430 mmIn the packaging, in addition to the boiler, you can also findthe following contents:- Tecnical documetation set- Battery cover fixing kit (bag with notice - screws and verticalplates - cover plates)- Key and lock + pin kits- Connection kit drain pipe 3,9“ (100 mm)- Siphon connection kit (pipe pp)21.5”545 mm26.4”670 mmACAUTIONThe boiler may be damaged when not securedproperly.- Only transport the boiler using appropriate transportationequipment, such as a handtruck with a fastening belt orspecial equipment for maneuvering steps.- When shipping the boiler must be secured on the transportationequipment to prevent it from falling off.- Protect all parts against impacts if they are to be transported.- Follow the transportation markings on the packaging.• Packaged boilers must always be lifted and carried by twopeople, or you must use a handtruck or special equipmentfor transport.AEnvelope with adjustable feet, lock and key(placed on the pallet, inside the boiler).Remove screws ‘’A’’ to remove the boiler frompallet.14

Instructions for the installer- Remove the packaging materials.- Do not tear the packaging.- Take note of the necessary space around the boiler forinstallation of venting system, pipework and servicing. Seedrawing in section 3.4Mounting of the adjustable feetThe location of the boiler can be determined by using thedraw on page 16. Remember to account for the spacing of theplumbing kit.- Drill the necessary holes- Install the mounting bracket to the wall using the suppliedmounting materialsCAUTIONLifting and carrying precautions.To avoid personal injury please follow theserecommendations:- Always move the boiler with 2 people oruse special equipment.- When move the boiler, bend the knees, andkeep the back straight and feet apart.- Do not lift and twist at the same time.- Lift and carry the boiler close to the body.- Wear protective clothing and gloves to protectfrom any sharp edges.- Dispose the packaging materials.Before positioning the boiler, screw down theadjustable feet supplied with the boiler.Mounting of the lockerThe casing front panel is hinged on the R.H.side. The hinges ‘’A’’ are factory fitted on theR.H. side of the frame. For the introduction ofthe cocker remove the precut disk ‘’B’’ witha screwdriver and fit the cocker as shown inthe figure.AIn case the casing front panel needs to be hinged on theL.H. side, deplace the hinges ‘’A’’ from R.H. to L.H. side; thenremove the precut disk ‘’C’’ from the front panel and fit thelocker as shown in the figure.INTERNALSIDE OF THECASINGBEXTERNALSIDE OF THECASINGCBA15

Instructions for the installer3.4 - MINIMUM CLARANCE FORSERVICING12’’300 mm24’’610 mm24’’610 mmObserve minimum distance of the boilerTOP of the boiler: 24’’ (600 mm)FRONT of the boiler: 12” + 24” = 36” (900 mm)RIGHT side: 12’’ (300 mm)LEFTside: 12’’ (300 mm)BACK of the boiler: 12’ (300 mm)Maintain an installation clearance from combustible constructionfrom hot water piping of at least 1" (25 mm).Operatingspace11.6’’(281 mm)24’’(600 mm)12’’300 mm12’’300 mm3.5 - LOCATION OF BOILER INSIDE ABOILER ROOMThe boiler must be installed in accordance with the directionsindicated in the most recent Standards and legislationsregarding boiler rooms, installation of heating and hot watersystems, boiler ventilation, chimney’s capable of dischargingthe products of combustion of condensing boilers and anyother applicable requirement.The boiler will be placed on a flat and sufficiently strong basement,,with dimensions not smaller than the ones of the boiler.After installation the boiler will result perfectly horizontal andvery stable ( in order to reduce vibrations and noise).<strong>Installation</strong>When choosing the installation place, the following itemshave to be considered:- To grant an easy access to the boiler components in orderto facilitate the ordinary and extraordinary service operations.- The floor should not be of flammable material.- If the floor is flammable an insulation material, with thecapacity to withstand to the fire for at least 120 min shouldbe placed between the boiler and the floor and will protrudeboiler basement of 19’’ (0,5 m) all around.16

Instructions for the installer• Do not store or use gasoline or other flammable vaporsand liquids in the vicinity of this or any other appliance.• Never use or store any chlorinated detergents or halogenatedhydrocarbons (e.g. in spraycans, solvents and detergents,paints, adhesives) in proximity of the boiler.• The boiler must be installed in such a way that it is protectedfrom water (dripping, spraying, rain, etc.) duringoperation and service (circulator replacement, condensatetrap, control replacement, etc.)• This boiler is intended for indoor installation only• For outdoor installation see Warning for Outdoor installationat page 8.Products to avoid present in boiler roomand/or around combustion air intakeSpray cans containing chloro-/fluorcarbonsAmmonium and/or ammonium solutionsPermanent wave solutionsChlorinated waxes and/or cleanersSwimming pool chemicals based on chlorineCalcium chloride used for thawingSodium chloride used for water softeningRefrigerant leaksPaint or varnish removersHydrochloric acid/muriatic acidCements and gluesAntistatic fabric softeners used in clothes dryersChlorine-type bleaches, detergents, and cleaning solventsfound in household laundry roomsAdhesives used to fasten building products andother similar productsAreas likely to have contaminantsDry cleaning/laundry areas and establishmentsSwimming poolsMetal fabrication plantsBeauty shopsRefrigeration repair shopsPhoto processing plantsAuto body shopsPlastic manufacturing plantsFurniture refinishing areas and establishmentsNew building constructionRemodeling areasGarages with workshops17

Instructions for the installer3.6 - CONNECTIONSM = CH system flow 3’’ - DN 80R = CH system return 3’’ - DN 80G = Gas Supply 2’’ - DN 50S = Condensate Drain 1.25’’ - 32mm3.7 - INSTALLATION ON EXISTINGHEATING SYSTEMS- The circulation pump’s output, the head and flow directionare suitable.- The gas feeding supply pipe and the eventual tank areconstructed according to the regulations in force.- The expansion vessels assure the total absorption of thedilatation of the fluid contained in the system.- The system has been cleaned of impurities and lime scale.18’’(456 mm)12.74’’(324 mm)6.21’’(158 mm)GMSR11.6’’(295 mm)Boiler system flushing(Not Boiler heat exchanger)When replacing an existing boiler the heatingsystem should be flushed with the old boiler inplace before the new boiler is added to the system.If the old boiler has already been removed a bypassmust be piped in when the new boiler is installed in orderto facilitate the flushing of the system.The boiler must be valved off from the system, while thesystem is flushed.No system cleaner should ever enter the boiler heatexchanger because of its caustic nature it could damagethe heat exchanger.When the appliance is installed on existing systems, ensureyourself that:5,3’’134 mm)9.9’’(251 mm)11.2’’(284 mm)16.9’’(430 mm)- The flue outlet pipe is suitable for condensing boilers, forthe temperature of the products of combustion, calculatedand manufactured according to the regulations in force. Itmust be installed as much as possible in a straight line,tested for soundness, insulated and must not have anyocclusions or restrictions.Kit of blind flanges- The flue outlet pipe has a connection for the discharge ofcondensate.- The boiler room has a suitable outlet for the discharge ofcondensate produce by the boiler.- The electrical system has been fitted in compliance to thespecific norms and the work has been carried out by acompetent person.18

Instructions for the installer3.8 - GAS CONNECTIONDANGERThe gas connection must be carried out by aregistered engineer who will have to respectand comply to the regulations in force and tothe requirements indicated by the local gassupplier. An incorrect installation couldcause injury to persons, animals or damageto property. The manufacturer shall not beheld liable for any injury and/or damage.WARNINGLATTNER wall mounted boilers are built to runon Natural Gas or Propane Gas.The gas type the boiler is suitable for isindicated on the packaging label and on thedata plate boiler.First check the identification plate on the boilerfor the suitable gas type.DANGERDo not use the boiler for another type of gasthan indicated on the identification plate of theboiler. This will cause improper functioning andcan damage the boiler.Natural gas: refer to chapter 3.8.1Propane gas: refer to chapter 3.8.2The gas supply connection must comply with localregulations or, if such regulations do not exist,with the National Fuel Gas Code, ANSI Z223.1/NFPA 54.For Canada, the gas connection must comply withlocal regulations or, if such regulations do not exist,with the CAN/CSA-B149.1-05 - Natural Gas andPropane <strong>Installation</strong> CodeBefore installing the boiler it is recommended tothoroughly clean all the supply piping in order toremove any eventual residual grime which couldcompromise the boilers correct functioning.As a safety measure against gas leaks,LATTNER recommends installing a surveillanceand protective system made up of a gas leakagedetector combined with an on-off selenoid valveon the gas supply line.DANGERAlways check the safety of the gas pipe systemby means of a bubble test using leak-searchspray.The boiler and its individual shut off valve mustbe disconnected from the gas supply piping systemduring any pressure testing of that systemat test pressures in excess of 1/2 PSI (3.5kPa).3.8.1 - GAS CONNECTION WITH NATURAL GASPipe sizing for natural gas- Contact gas supplier to size the gas supply line and meter.Gas pipingThe connection to the boiler must include a suitable methodof disconnection and a gas control valve must be installedadjacent to the boiler for isolation purposes. The nominal inletworking gas pressure measured at the boiler should be 7"W.C. (18 mbar) for Natural gas (Gas A).Maximum pressure with no flow (lockup) or with the boilerrunning is 10.5 inches W.C. Minimum pressure with the gasflowing (verify during boiler startup) is 4.0 inches W.C.3.8.2 - GAS CONNECTION WITH PROPANE GASPipe sizing for propane gas- Contact gas supplier to size pipes, tanks, and 100% lockupgas pressure regulator.Propane Supply Pressure Requirements- Adjust propane supply regulator provided by the gas supplierfor 13 inches W.C. maximum pressure.- Pressure required at gas valve inlet pressure port:- Maximum 13 inches W.C. with no flow (lockup) or withboiler running.- Minimum 8 inches W.C. with gas flowing (verify duringboiler startup).Ensure that the high gas pressure regulator is installed atleast 6 to 10 feet upstream of the boiler.Gas piping- Use a gas shut off valve compatible with propane gases.- A sediment trap must be provide upstream of the gas controls.The connection to the boiler must include a suitable methodof disconnection.The nominal inlet working gas pressure measured at the boilershould be 11" W.C. (27 mbar) for Natural gas (Gas E).A gas control valve must be installed adjacent to the boiler forisolation purposes. The nominal inlet working gas pressuremeasured at the boiler should be 11 inch W.C. (27 mbar) forPropane gas (Gas E).The boiler must be isolated from the gas supplypiping system by closing its individual manualshutoff valve during any pressure testing of thegas supply piping system at test pressures equalto or less than 1/2 PSI (3.5 kPa).19

Instructions for the installer3.9 - FLOW AND RETURN PIPE CONNECTIONSNOTICEWhen using plastic pipes, observe the supplier’sinstructions especially those referring to recommendedjointing techniques and the notes relatingto the heating system water.NOTICETo prevent contamination in the heating systemwe recommend you integrate a dirt filter in thereturn pipe, near the boiler. In an old system it isa requirement to install a dirt filter. Also installshutoff valves to enable filter cleaning immediatelyupstream and down stream of the dirt filter(scale cartridge or y-strainer).When determining the size of the CH circuit pipes it isessential to bear in mind the pressure losses induced by anyof the system’s components and by the configuration of thesame system.WARNING!Ensure yourself that the system’s piping is notused as the earth clamps for the electrical ortelephonic system. They are absolutelyunsuitable for this use. In a short time this couldcause serious damage to the piping, boilerand radiators.NOTICEThe pipe to be connected to the boiler must becleaned before connecting in order to preventdirt from entering and damaging the boiler.WARNING!IT IS ABSOLUTELY FORBIDDEN TO FIT ON-OFFVALVES ON THE GENERATOR TO THE FOREOF THE SAFTEY DEVICESThe route of the piping has to be conceived taking all thenecessary precautions in order to avoid air locks and tofacilitate the continuous purging of the system.- Connect CH flow pipe to the Supply connection makingsure it is not under stress. Use a supply pipe with a minimumdiameter of 3’’ (80 mm)- Connect the return pipe with a fiat rubber seal installed tothe Return connection making sure it is not under stress.Use a return pipe with a minimum diameter of 3’’ (80 mm).WARNING!Before installing the boiler we recommendthat the system is flushed out with a suitableproduct, in order to eliminate any metallictooling or welding residues, oil and grimewhich could reach the boiler and affect theproper running of the boiler.20

Instructions for the installer3.10 - DETERMINATION OF PRIMARY BOILER PUMP OR BOILER SYSTEM PUMPThe boiler pump must have a delivery head which can ensurethe water flow rate as shown in the diagram “<strong>Water</strong> pressurelosses”.The following table gives an indication of the pump’s flow ratein function of the Δt of the primary circuit if the installation hasa mixing headerSize of the pumpsIf determined by the installeror technical engineers mustbe sized according to thedata of boiler and system.Power supply in btu (kW)Max flow ratedemanded in gal/h (l/h) ΔT 27°F (15°C)Max flow ratedemanded in gal/h (l/h) ΔT 36°F (20°C)ALKON 90298,600(87,51)13261097In case of fixed raet pump isrecommended to choose acirculator with flow rate andhead at about 2/3 of thecharacteristic curve.The Δt between supply andreturn boiler should never beless than 27 °F (15 K).PRESSURE AVAIBLE TO THE SYSTEMPressure losses in wcQ: water flow rate gal/hNOTE: The use of a mixing header fitted between the boiler circuit and the system circuit is always advisable.It becomes INDISPENSABLE if the system requires flow rates superior to the maximum permitted boiler flowrates, which is to say lower than 27 °F (15 K).21

Instructions for the installer3.11 - PRESSURE RELIEF VALVE DRAINPIPEWARNING!Please remember that it is forbidden tointerpose, between the boiler and thepressure relief valve, any type of cutting-offdevice. Moreover it is recommended to usecutting-off valves which do not exceed themaximum allowable operating pressure.WARNING!In correspondence to the heating pressurerelief valve foresee the installation of adischarge pipe with a funnel and a siphonwhich lead to an adequate drainage. Thedrainage has to be controllable by sight.If this precaution is not made, an eventualintervention of the pressure relief valve couldcause injury to persons, animals or damageto property. The manufacturer shall not beheld liable for any injury and/or damage.3.13 - CONNECTING THE EXPANSIONVESSEL IN A SINGLE BOILERSYSTEMCAUTIONDamage to the installation due to faultypressure relief valve.- The expansion vessel must be of sufficient capacity.- Connect the expansion tank to the boiler return.If a check valve is available: connect the expansion vesselto the CH side of the check valve in the return circuitNOTICEThe expansion tank is NOT a part of the deliveryand should be sourced locally. Please refer tothe expansion tank manufacturer for further information.Fill expansion tank to a minimum of 14.5 psi.3.14 - UNDERFLOOR HEATING SYSTEM(PLASTIC PIPES)NOTICEWhen using oxygen-permeable pipes, e. g. for floor heatingsystems, you must separate the system using plate heatexchangers.No recourse can be made to the terms of the warranty in theevent of failure to observe the regulations pertaining to plasticunderfloor heating pipes.This relief valve comply with the standard forRelief Valves and Automatic Gas ShutoffDevices for <strong>Hot</strong> <strong>Water</strong> Supply Systems ANSIZ21.22b-01(R08)/CSA 4.4b-01(R08)and/or the standard Temperature, Pressure,Temperature and Pressure Relief Valves andVacuum Relief Valves CAN1-4.4-M803.12 - WORKING PRESSUREThe boiler’s maximum allowable working pressure is set at92 psa (634 kPa); whilst the minimum pressure is prechargedto 7,3 psa (50 kPa).22

3.14 - CONDENSATE DRAINDuring the combustion process the boiler producescondensate which, through the “A” pipe, flows into the siphon.The condensate which forms inside the boiler has to be routedinto an adequate drain by means of the pipe “B”.DANGER!Before commissioning the appliance fill thesiphon and check the correct drainage of thecondensate.If the appliance is used with the condensatedrain siphon empty there could be danger ofintoxication resulting from the escape of fluegasses.NOTICEThe condensate must be drained from the boilerin accordance with local, state or federal rulesand regulations.Instructions for the installerNOTICEUse materials approved by the authority havingjurisdiction. in the absence of such authority, PVCand CPVC pipe must comply with ASTM D1785,F441 or D2665. Cement and primer must complywith ASTM D2564 or F493.For Canada, use ULC certified PVC or CPVCpipe, fittings and cement.CFillingpipeThe connection between the appliance and the sewage systemmust be carried out in compliance with the specific referencestandards, and in particular:- prevent the end user utilizing the condensate produced;- a siphon must be fitted (supplied with the boiler);- there must be no bottlenecks;- the connection must be made just under the bottom part ofthe boiler;- it must be installed so as to avoid freezing of the liquidwhen the boiler is operating and prevent the eventual pressurizationof the sewage system;- consent the correct downflow of the appliance’s liquid discharges;- it must be made with materials which are resistant to condensate- if the condensate outlet of the boiler is lower than the drain,a condensate pump must be used.- The condensate produced by the boiler has a pH valuebetween 3 and 4.- Install a neutralization unit if required by the local code.WARNINGBefore putting the boiler into operation fill the condensatetrap with 1.27 cups / 300 ml of water. If the boiler will be installedin a high temperature installation such as baseboard witha supply temperature of 160°F or above, fill the condensatetrap with vegetable oil instead of water.NOTEPeriodic cleaning of the condensatedisposal system must becarried out.BACondensateoutlet,pipe toconnect to thesewagesystwmBoilercondensateinlet23

Instructions for the installer3.15 - WATER TREATMENTThe chemical/physical features of the heating system’s waterare fundamental for the boiler’s correct operation and safety.Among the inconvenients caused by the bad quality of thefeeding water, the most frequent and the most serious is theincrustation of the boiler thermal exchange surfaces.Less frequent, but also serious, is the hydraulic circuitsurfaces.It is ascertained that the boiler incrustations, due to their lowthermal conductivity, highly reduce the thermal exchange, evenif with a thickness of some millimetres and provoque a verydangerous localised overheating.We suggest to make the water treatment of the heating circuitin the following cases:a) When the hardness of the water is higher than 9 grains(15°f);b) For C.H. installations with large water content;c) Renewal of the water system due to uncontrolled leakages;d) Subsequent refilling of the system due to maintenanceworks on the installation;e) Presence of different metals in the hydraulic circuit.The scope of this treatment is finalized for eliminating orsubstantially reducing the following problems:- lime scale deposit- corrosion sludge- deposits- microbiological growths (moulds, bacteria etc.)An appropriate treatment of the supply water will preventthe above stated problems and will maintain the correctoperation and efficiency of the generator in time.For this purpose it will be necessary to fix the followingchemical-physical characteristics of the water:PH include between 6,5 and 8Hardness 6 ÷ 9 grains (9 ÷ 15 fr)<strong>Water</strong> hardnessWhen there is a water hardness of more than 6 to 9 grainshardness a water softener must be installed.SedimentIf there is sediment in your domestic water supply sedimentfilter or other suitable device should be used to remove it.THE INSTALLATION MUST BE FORESEEN ON THE RETURNPIPE OF THE PRIMARY CIRCUIT DOWNSTREAM OF THECIRCULATING PUMP.WARNING!All necessary precautions must be taken forpreventing the formation and localization ofoxygen in the system’s water. For this reason,ensure yourself that the plastic piping used inunderfloor heating systems is impermeableto oxygen.If any anti-freeze solutions are used ensure that they arecompatible with aluminium and any other boilercomponents and materials.WARNING!Any damage caused to the boiler due to theformation of lime scale or by corrosive waterwill not be covered by the warranty.WARNINGAppropriate steps must be taken to ensurethe indirect tank water heater does not becomeplugged by scale caused by hard wateror sediment.If the indirect tank water heater becomesplugged by either scaling from hard water ofsediment it is not the responsibility of LATT-NER.24

Instructions for the installer3.16 - COMBUSTION AIR AND VENTILATIONOPENINGSProvisions for combustion and ventiiation air must be madein accordance with section 5.3, Air for Combustion and Ventilation,of the National Flue Gas Code, ANSI Z223.1/NFPA 54,or Sections 7.2, 7.3 or 7.4 of CAN/CGA B149, installationCodes, or appiicabie provisions of the local building codes.CAUTIONBOILER DAMAGE AND OPERATIONALFAILURESDue to insufficient or improper openings for combustionairand/or ventiiation of the boiler room.Provisions for combustion air and ventiiation arealways required,regardiess whether the combustion air istaken fromthe outside (sealed combustion) or inside (roomair for combustion).Insufficient ventilation of the boiler room can leadto high airtemperatures. This can result in boiler damage.All Air from inside the Building (room air)The closet shall be provided with two permanent openingscommunicating directly with an additional room(s). The totalinput of all gas utilization equipment installed in the combinedspace shall be considered in making this determination.Each opening shall have a minimum free area of 1 squareinch per 1,000 Btu per hour of total input rating of all gasutilization equipment in the confined space, but no less than100 square inches. One opening shall commence within 12inches (305 mm) of the top, and one opening shall commencewithin 12 inches (305 mm) of the bottom of the enclosure.The minimum dimension of air openings shall be not lessthan 4 inches (101 .6 mm).- Make sure that intake and exhaust openingsare sufficiently sized and no reduction or closureof openings takes place.- When the problem is not resolved, do not operatethe boiler.- Please note these restrictions and its dangersto the operator of the boiler.WARNINGBOILER DAMAGE !Due to contaminated air.- Boiler must be clear and free from combustiblematerials, gasoline and other flammable vaporsand liquids, and corrosive liquids and vapors.Never use chiorine and hydrocarbon containingchemicals (such as spray chemicals, solution andcleaning agents, paints, giues etc) in the vicinityof the boiler.- Do not store and use these chemicals in theboiler room.- Avoid excessive dust formation and buildup.NOTICEWhen one expects contaminated combustion air(near swimmingpools, chemical cleaning operations andhair salons),sealed combustion operation is recommended.DANGERFire danger due to flammable materials or liquids.- Do not store flammable materials and liquids inthe immediate vicinity of the boiler.25

Instructions for the installer3.17 - INSTALLATION OF THE EXHAUSTAND AIR INTAKE SYSTEMNOTICEConsult local and state codes pertaining to specialbuildingcode and fire department requirements. Adhereto nationalcode requirements.12’’ (305 mm)minimumEXHAUST12’’ (305 mm)minimumNOTICEObserve the listed maximum lengths of vent systemwhich are boiler model dependent.The maximumpermissible lenghts are listed at page 26- 2912’’ (305 mm)minimumINTAKE12’’ (305 mm)minimum12’’ (305 mm)minimumMinimum clearance of 4 ft (1.22m) horizontally from, and in nocase above or below, unless a 4 ft (1.22 m) horizontal distanceis maintained, from electric meters, gas meters, regulatorsand relief equipment.The minimum distance from adjacent public walkways, adjacentbuildings, openable windows and building openings shallnot be less than those values specified in the National FuelGas Code, ANSI Z223.1 / NFPA 54 and / or the Natural Gasand Propane <strong>Installation</strong> Code, CAN/CSA B149.1Do not extend exposed vent pipe outside the building beyondrecommended distance. Condensate could freeze and blockvent pipe.Vent should terminate at least 3 ft (915 mm) away from adjacentwalls, inside corners and 5 ft (1525 mm) below roof overhang(see figure).it is not recommended to terminate vent above any door orwindow, condensate can freeze causing ice formations.Do not use chimney as a raceway if another boiler or fireplace is vented into or through chimney.NOTICETerminals should be positioned as to avoid productsof combustion entering openings into buildingsor other vents.NOTICETerminals should be positioned as to avoid productsof combustion entering openings into buildingsor other vents.NOTICEMaintain 12” of clearance above the highest anticipatedsnow level or grade or, whichever is greater.Please refer to your local codes for the snowlevel in your area.NOTICEThe whole route of the vent system must be installedupwards, never downwards,completely nor partly.NOTICEThe terminal should be located where dispersalof combustion products is not impeded and withdue regard for the damage or discolouration thatmight occur to building products in the vicinity(see above figure).In certain weather conditions condensation mayalso accumulate on the outside of the air inletpipe. Such conditions must be considered andwhere necessary insulation of the inlet pipe maybe required.In cold and/or humid weather water vapor maycondense on leaving the vent terminal. The effectof such ‘water condensation’ must be considered.The terminal must be located in a place not likelyto cause a nuisance.26

Instructions for the installerThe flue system must be installed inaccordance with the local and nationalStandards.Use only original LATTNER flue outlet systems, which areprovided from the follow manufacturer:TABLE FLUE OUTLET SYSTEM3.18 - ROOM AIR SYSTEMFOR INSTALLATION USING INDOORCOMBUSTION AIRBoiler designed to be connected to an open flue which willterminate vertically through the roof. The combustion air iswithdrawn directly from the room where the boiler is installed.ItemDecriptionVentingpipe3.28 ftManufacturerSTABILEMaterialStainlessSteelCode LATTNER00362448WARNING: for this type of connection the room must complywith the same installation regulations valid for openchimney boilers.The chimney must comply to the current regulations.Ventingpipe1.62 ftSTABILEStainlessSteel00362449Elbow 90°STABILEStainlessSteel00362450Elbow 45°STABILEStainlessSteel00362451HorizontalFlue terminalVerticalFlueTerminalGROPPALLISTABILEAlluminiumStainlessSteel0036149300362452When using indoor air, LATTNER strongly recommends theuse of an indoor air filter.This boiler requires adequate combustion air for ventilationand dilution of flue gases.Failure to provide adequate combustion air can result in unitfailure, fire, explosion, serious bodily injury or death.Use the following methods to ensure adequate combustionair is available for correct and safe operation of this boiler.Damages caused by installation errors and for nonobservanceof the instructions given by the manufacturerwill invalidate all the supplier’s contractual or extracontractual responsibilities.If the boiler has to be replaced ALWAYS replace the flueoutlet system.The boiler has been tested and approved with the terminalsdistributed by <strong>Lattner</strong> that comply the requirements of ANSIZ21.13 / CSA 4.9 for the following flue configurations.Important: Combustion air must be free of corrosive chemicals.Do not provide combustion air from corrosive environments.Appliance failure due to corrosive air is not covered bywarranty.Combustion air must be free of acid forming chemical such assulfur, fluorine and chlorine. These chemicals have been foundto cause rapid damage and decay and can become toxic whenused as combustion air in gas appliances. Such chemicalscan be found in, but not limited to bleach, ammonia, cat litter,aerosol sprays, cleaning solvents, varnish, paint and air fresheners.Do not store these products or similar products in thevicinity of this boiler.Flue outlet systems must be purchasedfrom the dealer of products LATTNER.27

Instructions for the installerFLUE OUTLETS Ø 3.94‘‘ (100 mm)Preliminary operations:Fit the smoke evacuation (A) pipe Ø 3.94‘‘ (100mm), suppliedin the package (into the boiler), as shown in thepicture.Fix the screw B.L min = 39.7‘‘ (1 m)L max = 1181‘‘ (30 m)LABLATTENTION!For boiler have horizontal runs sloping upwardsnot less than 1/4 in / ft (21 mm / m) from the boilerto the vent terminal.L min = 39.7‘‘ (1 m)L max = 1181‘‘ (30 m)28

3.19 - ELECTRICAL CONNECTIONSRegulations in forceThe electrical connections to the boiler must be made in accordancewith all applicablelocal codes and the latest revision of the NFPA 70: NationalElectrical Code<strong>Installation</strong>s should also conform with C22.1 - Canadianelectrical code, part I (21st edition), safety standard for electricalinstallations if installed in Canada.CAUTIONThe boiler must be electrically grounded in accordancewith local codes, or in absence of localcodes, with the National Electrical Code,NFPA 70: National Electrical Code C22.1 - Canadianelectrical code, part I (21st edition), safetystandard for electrical installationsThe gas, D.H.W. and the CH system pipes cannotbe used as ground plates.Ensure that the above safety electrical requirements subsist;in case of doubt, ask for a professionally qualified technicianto check the appliance’s electrical system.LATTNER refuses responsibility for any damages arising fromfailure to earth the boiler correctly.It is necessary that a qualified technician verifies that theelectrical system is adequate to the appliance’s maximumabsorbed power, indicated on the data plate, verifying inparticular that the section of the system’s cables is suitableto the appliance’s maximum absorbed power.CAUTIONFor the appliance’s general electrical supply theuse of adaptors, multiple sockets and/orextension cords is strictly forbidden.The use of any power supplied equipmentimplies the observance of several fundamentalrules, such as:- Do not touch the appliance with any wet part of your bodyand/or barefooted;- Do not pull the supply cables- Do not expose the boiler to sunlight, rain, etc., unless it isexplicitly foreseen;- Do not permit children or inexpert people to use theappliance.CAUTIONExternal connection board connectionsWARNINGDanger of fatal accident due to electric shock.120 VAC connections may be present on theexternal connection board when power is suppliedto the boiler.- No changes may be made to the wiring of theboiler.- All connections should be designed in accordance with the applicable regulations.- Label all wires prior to disconnection whenservicing controls. Wiring errors can cause improper and dangerous operation.- Verify proper operation after operation servicing.Instructions for the installerMains electrical supply connection120 V - 60 HzPower supply cordThe boiler is provided complete with a mains supply cable118‘‘ (3 m) long and with a cross section area of 3 x 16 AWGThe electric connections of the boiler are shown in the sectionnamed “ACTUAL WIRING DIAGRAM” (paragraph 3.19)WARNING!We remind you that upstream of the electricalconnection, it will be necessary to foresee aservice relay (NOT SUPPLIED) which, whenthe additional electrical safety devices (ifany) intervene, shuts down the electricalsupply to the on-off fuel valve fitted on thegas supply circuit, but not to the boiler so asto guarantee the running of the pump andpermit the boiler to cool down.DANGER!The electrical connections must be carriedout only by a qualified engineer.Before carrying out the connections or anyother operation on the electrical parts,always switch off and disconnect theelectricity supply and ensure yourself that itcannot be accidentally turned on.It is necessary to fit a double pole switch on theelectrical supply line, having a contact separationin both poles, in an easy accessible position inorder to make quick and safe the servicingoperations.29

Instructions for the installerRoom thermostat and/or E8 heating controller connectionDANGER!Switch off and disconnect the electricitysupply before carrying out any operations onthe electrical parts.RoomthermostatE8 heatingcontroller- Gain access to the Y1 terminal board- For the Room thermostat connection 1 and 2and connect them to the thermostat’s cables.- For the Heating Controller connection use theconnecting terminals 3 and 4.Connection of the additional safety devicesCAUTION!Switch off and disconnect the electricitysupply before carrying out any operationson the electrical parts.For the connection remove the existing jumper.BLUEBLUEBLUEA hot water boiler installed above radiationlevel or as required by the Autority havingjurisdiction, must be provided with a low watercutoff devices either as a part of the boiler or atthe time of boiler installation.CDS - 1Prearrangement for theconnection of theadditional safety devicesBLACKTLTSC30

Instructions for the installer3.20 - FUNCTIONAL FLOW WIRING DIAGRAMDKE. ACCE. RIV.IGMDVPPFSRSRRSSTLTFTSCTR.ACCVGVM= Minimum water pressure switch= Ignition electrode= Detection electrode= Power switch On-Off= Motor 3 way valve (optional)= Pump= Smoke Pressostat= CH sensor= CH return sensor= DHW sensor (optional)= Limit thermostat= Smoke thermostat (only pre-arrangement)= High limit thermostat exchanger= Ignition transformer= Gas valve= Modulating fan detection/adjustmentCSD - 1Prearrangement for theconnection of theadditional safety devicesVMRIL./REG.542BLACK (-)BROWN (PWM)BLUE (TACHO)ORANGE +ALIM.230V1 2BROWN (L1)BLUE (N)3VGBLUEBROWNYEL/GREENBLUE - NBROWN - LYEL/GREENTR. ACCE. ACCTAE8YELL/GREENBROWNBLUEBLUEBROWNNBROWNLIGHTBLUEBROWNLIGHTBLUEL1RED120 V - 60 HzE. RIV.BLUEBROWNYELL/GREENPFIGBLUEBLUEDKPBROWN(no)WHITE (c)SRR SRPF1 (NC) BROWN3 ( C ) WHITEBLUEBLUESLCDS-1BLACKTFTLTSC31

Instructions for the installer3.21 - GENERAL LADDER DIAGRAMSRRSRPFCDS-1TLDKSL (**)A4-2A3-6A3-5 A3-4A3-3 A4-6 A4-5 A4-4 A4-5A4-1A2-3 A2-1A4-4A4-3DISPLAY8 8 8RIBBON CABLELIGA3AC/DCIGNA8 - 1A8 - 2CPURODFs1FLAMEGRL 4A8 - 2A8 - 1RL 3A1 - 4A1 - 3A1 - 2A1 - 1A9 - 2FA9 - 1RL 1A9 - 6P(*)A9 - 5120 VACRL 2A6 - 6 A6 - 515 kVSPARKCAUTIONHIGH VOLTAGE SPARK LEADATTENTION AUTE TENSION CÂBLE D’ALLUMAGE32

3.22 - STARTING UP: Filling and de-aeratingthe boiler and installationCAUTIONObserve the following rules of safety:- All work on the unit must take place in adry environment.- LATTNERunits may never be in operationwithout their housing, except in connectionwith maintenance or adjustments.- Never allow electrical or electroniccomponents to come into contact withwater.NOTICECarry out the following tasks in connectionwith maintenance, etc. to an already installedunit:- Shut down all programs- Close the gas shut off valveInstructions for the installer- Shut off the power at the main power switch- Close the service valves (supply and return)NOTICETake note of the following when maintenanceor adjustments are needed:- The unit must be able to function during theseactivities; for this reason, the unit’s supplyvoltage, gas pressure and water pressuremust be maintained. Ensure that this is not asource of potential danger during theseactivities.WARNINGFollowing maintenance or other activities;always check the installation of allparts through which gas flows (with bubbletest using leak-search spray).3.23 - FILLING THE SYSTEMWARNING!Do not mix the CH system’s water with antifreezeor anti-corrosion solutions using wrongconcentrations! It could cause damage to thewashers and could provoke noise duringnormal boiler operation.LATTNER refuses all liability for injury topersons, animals or damage to propertyderiving from not having respected the abovementioned recommendations.Before filling the heating system, the complete system, includingall zones, must be thoroughly cleaned and flushed toremove sediment.Flush until clean water runs free of sediment. LATTNER suggestsusing an approved system cleaner to flush the system,but not the boiler. Always use LATTNER approved antifreezes.See the list at page 7.Never use reverse osmosis, D.I., or distilled water for fillingthe heating system.WARNING!Do not use petroleum-based cleaning or sealingcompounds in the boiler system. Damageof seals and gaskets in boiler and system couldoccur, resulting in substantial property damage.The central heating installation needs to befilled with potable water.Use only potable water or approved glycol forfilling the heating system.When the water hardness of the filling waterexceeds > 8 gpg the water has to be treateduntil below the maximum value of 8 gpgThe pH value of the installation water must bebetween 6.5 and 8.5. Check the pH value usingproper equipment or by having the water analyzedby a water treatment company.If pH differs from above, contact LATTNER engineering forfurther assistance.Failure to adhere to the water quality requirements will resultin a void of warranty.Once all the connections are made, it is possible to fill thecircuit.This operation has to be performed very carefully, by observingthe following steps (boiler in Off position):- open the radiator bleeds and make ascertain the goodoperation of the automatic air vent fitted in the boiler.- open progressively the filling valve and make sure theautomatic air vent, in the system, work properly.- close the bleeders of the radiators when water starts tocome out.- control via manometer (Optional) that the water pressurehas reached a minimum value of 11,6/14,5 psi (0,8/1) bar- close the filling valve and bleed again all the radiators.- inspect for the soundness all the hydraulic connections.- after the commissioning of the boiler and the reaching ofthe normal operation temperature, switch off the operationof the boiler and the pump and repeate the bleed operation.- let the installation cool down and, if necessary, add waterin order to reach the minimum presure of 11,6/14,5 psi(0,8/1) barFor the filling of the system it is necessary tofit a filling valve on the C.H. return.The boiler is equipped with its own drain cock,whose position is shown in the figure of page11. This cock never has to be used for the drainof the system, because all the dirtiness of theinstallation could accumulate in the boiler, compromisingits operation. For that reason the installationmust be equipped with own drain cock,correctly sized according to the installation watercontent.33

34Instructions for the installer