Installation Instructions - Carrier

Installation Instructions - Carrier

Installation Instructions - Carrier

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

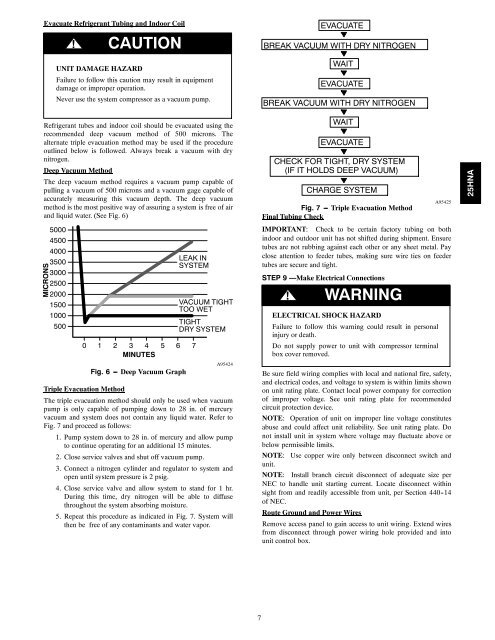

Evacuate Refrigerant Tubing and Indoor Coil!CAUTIONUNIT DAMAGE HAZARDFailure to follow this caution may result in equipmentdamage or improper operation.Never use the system compressor as a vacuum pump.Refrigerant tubes and indoor coil should be evacuated using therecommended deep vacuum method of 500 microns. Thealternate triple evacuation method may be used if the procedureoutlined below is followed. Always break a vacuum with drynitrogen.Deep Vacuum MethodThe deep vacuum method requires a vacuum pump capable ofpulling a vacuum of 500 microns and a vacuum gage capable ofaccurately measuring this vacuum depth. The deep vacuummethod is the most positive way of assuring a system is free of airand liquid water. (See Fig. 6)MICRONS500045004000350030002500200015001000500LEAK INSYSTEM0 1 2 3 4 5 6 7MINUTESTriple Evacuation MethodFig. 6 --- Deep Vacuum GraphVACUUM TIGHTTOO WETTIGHTDRY SYSTEMA95424A95424The triple evacuation method should only be used when vacuumpump is only capable of pumping down to 28 in. of mercuryvacuum and system does not contain any liquid water. Refer toFig. 7 and proceed as follows:1. Pump system down to 28 in. of mercury and allow pumpto continue operating for an additional 15 minutes.2. Close service valves and shut off vacuum pump.3. Connect a nitrogen cylinder and regulator to system andopen until system pressure is 2 psig.4. Close service valve and allow system to stand for 1 hr.During this time, dry nitrogen will be able to diffusethroughout the system absorbing moisture.5. Repeat this procedure as indicated in Fig. 7. System willthen be free of any contaminants and water vapor.EVACUATEBREAK VACUUM WITH DRY NITROGENWAITEVACUATEBREAK VACUUM WITH DRY NITROGENWAITEVACUATECHECK FOR TIGHT, DRY SYSTEM(IF IT HOLDS DEEP VACUUM)CHARGE SYSTEMFig. 7 --- Triple Evacuation MethodFinal Tubing CheckA95425IMPORTANT: Check to be certain factory tubing on bothindoor and outdoor unit has not shifted during shipment. Ensuretubes are not rubbing against each other or any sheet metal. Payclose attention to feeder tubes, making sure wire ties on feedertubes are secure and tight.STEP 9 —Make Electrical Connections! WARNINGELECTRICAL SHOCK HAZARDFailure to follow this warning could result in personalinjury or death.Do not supply power to unit with compressor terminalbox cover removed.Be sure field wiring complies with local and national fire, safety,and electrical codes, and voltage to system is within limits shownon unit rating plate. Contact local power company for correctionof improper voltage. See unit rating plate for recommendedcircuit protection device.NOTE: Operation of unit on improper line voltage constitutesabuse and could affect unit reliability. See unit rating plate. Donot install unit in system where voltage may fluctuate above orbelow permissible limits.NOTE: Use copper wire only between disconnect switch andunit.NOTE: Install branch circuit disconnect of adequate size perNEC to handle unit starting current. Locate disconnect withinsight from and readily accessible from unit, per Section 440 -14of NEC.Route Ground and Power WiresRemove access panel to gain access to unit wiring. Extend wiresfrom disconnect through power wiring hole provided and intounit control box.25HNA7