Brazilian Biofuels Programmes from the WEL Nexus Perspective

Brazilian Biofuels Programmes from the WEL Nexus Perspective

Brazilian Biofuels Programmes from the WEL Nexus Perspective

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

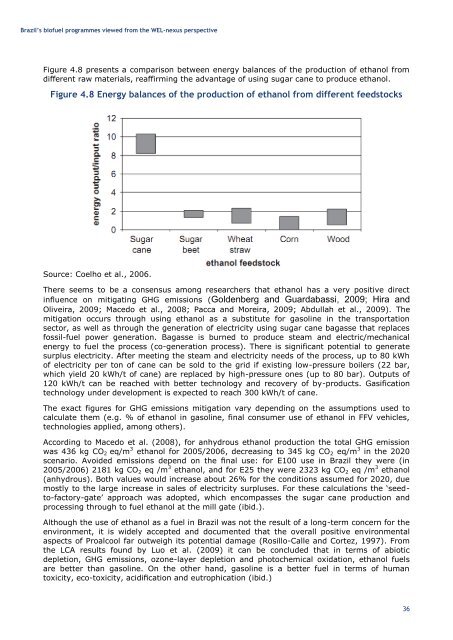

Brazil’s biofuel programmes viewed <strong>from</strong> <strong>the</strong> <strong>WEL</strong>-nexus perspectiveFigure 4.8 presents a comparison between energy balances of <strong>the</strong> production of ethanol <strong>from</strong>different raw materials, reaffirming <strong>the</strong> advantage of using sugar cane to produce ethanol.Figure 4.8 Energy balances of <strong>the</strong> production of ethanol <strong>from</strong> different feedstocksSource: Coelho et al., 2006.There seems to be a consensus among researchers that ethanol has a very positive directinfluence on mitigating GHG emissions (Goldenberg and Guardabassi, 2009; Hira andOliveira, 2009; Macedo et al., 2008; Pacca and Moreira, 2009; Abdullah et al., 2009). Themitigation occurs through using ethanol as a substitute for gasoline in <strong>the</strong> transportationsector, as well as through <strong>the</strong> generation of electricity using sugar cane bagasse that replacesfossil-fuel power generation. Bagasse is burned to produce steam and electric/mechanicalenergy to fuel <strong>the</strong> process (co-generation process). There is significant potential to generatesurplus electricity. After meeting <strong>the</strong> steam and electricity needs of <strong>the</strong> process, up to 80 kWhof electricity per ton of cane can be sold to <strong>the</strong> grid if existing low-pressure boilers (22 bar,which yield 20 kWh/t of cane) are replaced by high-pressure ones (up to 80 bar). Outputs of120 kWh/t can be reached with better technology and recovery of by-products. Gasificationtechnology under development is expected to reach 300 kWh/t of cane.The exact figures for GHG emissions mitigation vary depending on <strong>the</strong> assumptions used tocalculate <strong>the</strong>m (e.g. % of ethanol in gasoline, final consumer use of ethanol in FFV vehicles,technologies applied, among o<strong>the</strong>rs).According to Macedo et al. (2008), for anhydrous ethanol production <strong>the</strong> total GHG emissionwas 436 kg CO 2 eq/m 3 ethanol for 2005/2006, decreasing to 345 kg CO 2 eq/m 3 in <strong>the</strong> 2020scenario. Avoided emissions depend on <strong>the</strong> final use: for E100 use in Brazil <strong>the</strong>y were (in2005/2006) 2181 kg CO 2 eq /m 3 ethanol, and for E25 <strong>the</strong>y were 2323 kg CO 2 eq /m 3 ethanol(anhydrous). Both values would increase about 26% for <strong>the</strong> conditions assumed for 2020, duemostly to <strong>the</strong> large increase in sales of electricity surpluses. For <strong>the</strong>se calculations <strong>the</strong> ‘seedto-factory-gate’approach was adopted, which encompasses <strong>the</strong> sugar cane production andprocessing through to fuel ethanol at <strong>the</strong> mill gate (ibid.).Although <strong>the</strong> use of ethanol as a fuel in Brazil was not <strong>the</strong> result of a long-term concern for <strong>the</strong>environment, it is widely accepted and documented that <strong>the</strong> overall positive environmentalaspects of Proalcool far outweigh its potential damage (Rosillo-Calle and Cortez, 1997). From<strong>the</strong> LCA results found by Luo et al. (2009) it can be concluded that in terms of abioticdepletion, GHG emissions, ozone-layer depletion and photochemical oxidation, ethanol fuelsare better than gasoline. On <strong>the</strong> o<strong>the</strong>r hand, gasoline is a better fuel in terms of humantoxicity, eco-toxicity, acidification and eutrophication (ibid.)36