B. Tech. Production & Industrial Engineering - Shiats.edu.in

B. Tech. Production & Industrial Engineering - Shiats.edu.in

B. Tech. Production & Industrial Engineering - Shiats.edu.in

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

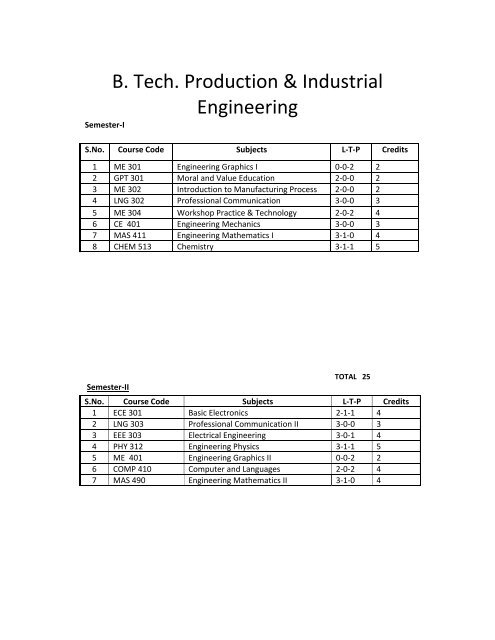

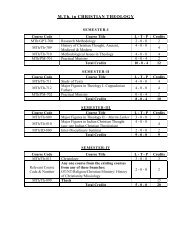

B. <strong>Tech</strong>. <strong>Production</strong> & <strong>Industrial</strong><strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong>Semester‐IS.No. Course Code Subjects L‐T‐P Credits1 ME 301 <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Graphics I 0‐0‐2 22 GPT 301 Moral and Value Education 2‐0‐0 23 ME 302 Introduction to Manufactur<strong>in</strong>g Process 2‐0‐0 24 LNG 302 Professional Communication 3‐0‐0 35 ME 304 Workshop Practice & <strong>Tech</strong>nology 2‐0‐2 46 CE 401 <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mechanics 3‐0‐0 37 MAS 411 <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mathematics I 3‐1‐0 48 CHEM 513 Chemistry 3‐1‐1 5Semester‐IITOTAL 25S.No. Course Code Subjects L‐T‐P Credits1 ECE 301 Basic Electronics 2‐1‐1 42 LNG 303 Professional Communication II 3‐0‐0 33 EEE 303 Electrical <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> 3‐0‐1 44 PHY 312 <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Physics 3‐1‐1 55 ME 401 <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Graphics II 0‐0‐2 26 COMP 410 Computer and Languages 2‐0‐2 47 MAS 490 <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mathematics II 3‐1‐0 4

Semester‐IIITOTAL 26S.No. Course Code Subjects L‐T‐P Credits1 ME 403 Mach<strong>in</strong>e Draw<strong>in</strong>g and Computer Aided 0‐0‐2 2Draft<strong>in</strong>g2 ME 404 Applied Thermodynamics 3‐1‐1 53 CE 406 Fluid Mechanics 3‐0‐1 44 CE 408 Strength of Materials 3‐0‐0 35 ME 410 Material Science and Test<strong>in</strong>g 3‐0‐1 46 SES 415 Environmental Studies 2‐0‐0 27 COMP 510 Foundation of Information <strong>Tech</strong>nology 2‐1‐2 58 MAS 590 <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mathematics III 3‐1‐0 4TOTAL 29Semester‐IVS.No. Course Code Subjects L‐T‐P Credits1 EEE 404 Electrical Mach<strong>in</strong>es 3‐0‐1 42 ME 405 Measurement and Metrology 2‐1‐1 43 ME 407 K<strong>in</strong>ematics of Mach<strong>in</strong>es 3‐1‐0 44 ME 411 <strong>Industrial</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> 3‐1‐0 45 ME 412 Manufactur<strong>in</strong>g Science I 3‐0‐1 46 ME 416 Management Information System 3‐0‐0 37 MAS 491 Computer Based Numerical &Statistical 2‐0‐1 3<strong>Tech</strong>niquesTOTAL 26Semester‐VS.No. Course Code Subjects L‐T‐P Credits1 BAM 315 Elements of Economics and Pr<strong>in</strong>ciples of 3‐1‐0 4Management Science2 ME 409 Mach<strong>in</strong>e Design I 2‐0‐2 43 ME 503 Heat and Mass Transfer 3‐0‐1 44 ME 504 Dynamic of Mach<strong>in</strong>es 3‐0‐1 45 ME 506 Product Development and Design 2‐1‐0 36 ME 507 Manufactur<strong>in</strong>g Science II 3‐0‐1 47 ME 508 IC Eng<strong>in</strong>e 3‐1‐0 4TOTAL 27Semester‐VIS.No. Course Code Subjects L‐T‐P Credits1 ME 501 Tool Design 3‐0‐1 42 ME 505 Mach<strong>in</strong>e Design II 3‐0‐1 43 ME 509 Project Management 2‐1‐0 34 EEE 509 Automatic Controls 2‐1‐0 35 ME 510 Quality <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> 3‐0‐1 4

6 ME 516 Energy Management 3‐1‐0 47 ME 580 Sem<strong>in</strong>ar I 0‐0‐2 28 CE 516 Fluid Mach<strong>in</strong>ery 2‐1‐1 4TOTAL 28Note: Four Weeks Practical summer tra<strong>in</strong><strong>in</strong>g‐2 after VI Semester (to be evaluated <strong>in</strong> VIISemester)Semester‐VIIS.No. Course Code Subjects L‐T‐P Credits1 ME 518 Design aga<strong>in</strong>st Fatigue and Failure 3‐1‐0 42 ME 601 Computer Aided Design 3‐0‐2 53 ME 602 Computer aided Manufactur<strong>in</strong>g 3‐0‐2 54 ME 603 Automobile <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> 2‐1‐1 45 ME 604 <strong>Industrial</strong> Tra<strong>in</strong><strong>in</strong>g 0‐0‐1 16 ME 680 Sem<strong>in</strong>ar II 0‐0‐2 27 ME 699a Project 0‐0‐2 2Semester‐VIIITOTAL 23S.No. Course Code Subjects L‐T‐P Credits1 ME 606 Mechanical System Design 3‐1‐0 42 ME 665‐679 Electives ‐1 3‐0‐0 33 ME 665‐679 Electives ‐2 3‐0‐0 34 ME 665‐679 Electives ‐3 3‐0‐0 35 ME 699b Project (Execution and Report ) 0‐0‐6 6TOTAL 19

SyllabusENGINEERING GRAPHICS ICourse Code ME‐301 CREDIT : 2 (0-0-2)1. Introduction: Graphics as a tool to communicate ideas, eng<strong>in</strong>eer<strong>in</strong>g draw<strong>in</strong>g <strong>in</strong>struments andits uses. Letter<strong>in</strong>g and dimension<strong>in</strong>g, scales, layouts of draw<strong>in</strong>g sheets Construction ofgeometrical figures like pentagon and hexagon.2. Orthographic Projection: Pr<strong>in</strong>ciples of orthographic projections, Pr<strong>in</strong>cipal and auxiliaryplanes, First and Third angle projections. Projection of po<strong>in</strong>ts. Pictorial view.Projection ofl<strong>in</strong>es parallel to both the planes. Parallel to one and <strong>in</strong>cl<strong>in</strong>ed to other, Incl<strong>in</strong>ed to both theplanes. Application to practical problems. Projection of solid <strong>in</strong> simple position, Axis or slantedge <strong>in</strong>cl<strong>in</strong>ed to one and parallel to other Plane, Solids ly<strong>in</strong>g on a face or generator on a plane.Section<strong>in</strong>g of solids ly<strong>in</strong>g <strong>in</strong> various positions, True shape of the section.Development oflateral surfaces, sheet metal draw<strong>in</strong>g.3. Isometric Projection: Pr<strong>in</strong>ciples of isometric projection, Isometric projection us<strong>in</strong>g box andoffset methods.References:1. Bhatt N.D.: Elementary <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Draw<strong>in</strong>g, Charothar Publish<strong>in</strong>g.2. Laxmi Narayan V & Vaish W.: A Text Book of Practical Geometry on GeometricalDraw<strong>in</strong>g.MORAL AND VALUE EDUCATIONCourse Code GPT-301 CREDIT : 2 (2-0-0)My country and my people, the many Indians, be<strong>in</strong>g and becom<strong>in</strong>g an Indian, nationalism and<strong>in</strong>ternationalism.Some life issues- love, sex and marriage, men and money-value of time, mean<strong>in</strong>g of work,human communication, human suffer<strong>in</strong>g, addiction, ecology, women’s issues.Understand<strong>in</strong>g one’s neighbour, neibhourhood groups: their structure and functions,Patterns of social <strong>in</strong>teraction of group dynamics.Preparation for a career, choice of vocation, motivation for study and research. The present<strong>edu</strong>cational system: curriculum and syllabus, teach<strong>in</strong>g methods, exam<strong>in</strong>ation and workexperience.Def<strong>in</strong>ition of value <strong>edu</strong>cation, moral and ethics, laws and morale based on ten commandmentsand two great commandments.Discovery of self, self-awareness, growth of <strong>in</strong>tellect- man’s spiritual nature emotions, will,respect, the rights of life, liberty, property, truth and reputation.

S<strong>in</strong>, orign of s<strong>in</strong>, manifestation of s<strong>in</strong>, the results of s<strong>in</strong>, the remedy of s<strong>in</strong>, s<strong>in</strong> as an act, S<strong>in</strong> asa state, s<strong>in</strong> as a nature.Conscience- as def<strong>in</strong>ed <strong>in</strong> oxford dictionary and W<strong>in</strong>ston dictionary. Types of consciousness(such as Evil, convicted, purged, pure, weak, good, void of offence).INTRODUCTION TO MANUFACTURING PROCESSCourse Code ME-302 CREDIT : 2 (2-0-0)1. Introduction to eng<strong>in</strong>eer<strong>in</strong>g materials- Metals & alloys- composition-properties and uses2. Manufactur<strong>in</strong>g Process – Classification, mechanization, Automation , Inter-changeability,computers <strong>in</strong> manufactur<strong>in</strong>g ,CAD,CAM,CIM,MRP, GT3. Metal Form<strong>in</strong>g- Brief <strong>in</strong>troduction to press work<strong>in</strong>g, cast<strong>in</strong>g, plastic process<strong>in</strong>g ,Smithyoperations.4. Mach<strong>in</strong>e Tools-Introduction to lathe mach<strong>in</strong>es , Drill<strong>in</strong>g, Shaper, Slotter, Planer , Bor<strong>in</strong>gmach<strong>in</strong>es.5. Mach<strong>in</strong>e Operation-Turn<strong>in</strong>g, Thread<strong>in</strong>g, Bor<strong>in</strong>g, Drill<strong>in</strong>g.6. Plastic Process<strong>in</strong>gPROFESSIONAL COMUNICATION ICourse Code LNG-302 CREDIT : 3(3-0-0)1. Study of selected Literacy Texts.I.Collection of short essays.II.Collection of short stories.2. Test<strong>in</strong>g Written Comprehension Ability.: Comprehension Passages of 500 words MultipleChoice Questions.3. Composition & Grammar.4.Report Writ<strong>in</strong>g: Characteristics of Bus<strong>in</strong>ess Reports. Structure of reports: Front Matter, Ma<strong>in</strong>Body, and Back Matter Style of Reports: Def<strong>in</strong>ition, the Scientific Attitude, Readability ofReports, Choice of Words and Phrases, Construction and length of sentences, Constructionand length of Paragraphs. The l<strong>in</strong>eout or break up of a format report Blank Form Report,Frogen Report, Memoranda Form Report, Periodic Report, Miscellaneous Report.5. Speech Drills:Us<strong>in</strong>g the language laboratory to develop Speak<strong>in</strong>g Communication Skills.(i) Word Accent: <strong>Production</strong> of correct accentual patterns <strong>in</strong>volv<strong>in</strong>g two and three syllabiwords.(j) Rhythm: Stress-tone rhythm <strong>in</strong> sentences.(k) Intonation: Ris<strong>in</strong>g Tone and Talk<strong>in</strong>g Tone Ear Tra<strong>in</strong><strong>in</strong>g and <strong>Production</strong> Tests.References:1. Close R.A.: A University Grammar of English Workbook.

Longman, London, 1998.2. Jones, Daniel: English Pronounc<strong>in</strong>g Dictionary, ELBS, and London, 1999.3. Sharma S.D: A Textbook of Spoken and Written English, Vikas, 1994.4. Alvarez, Joseph A.: The Elements of <strong>Tech</strong>nical Writ<strong>in</strong>g, New York: Harcourt, 1998.5. 5.Bansal, R.K.: Spoken English For India, Orient Longman, 1993.WORKSHOP PRACTICE AND TECHNOLOGYCourse Code ME-304 CREDIT : 4(2-0-2)I. Introduction to tools- Description , applications of tools used <strong>in</strong> different shops2. Carpentry- Classification of tools-mark<strong>in</strong>g and measur<strong>in</strong>g-hold<strong>in</strong>g and support<strong>in</strong>gplann<strong>in</strong>g-cutt<strong>in</strong>g-bor<strong>in</strong>g –strik<strong>in</strong>g-miscellaneous-etc.3. Fitt<strong>in</strong>g shop-Mark<strong>in</strong>g & measur<strong>in</strong>g, hold<strong>in</strong>g, cutt<strong>in</strong>g tools etc4. Smithy- hold<strong>in</strong>g and support<strong>in</strong>g tools, cutt<strong>in</strong>g tools , strik<strong>in</strong>g tools5. Sheet metal1.Weld<strong>in</strong>gII Properties of metals- Strength, elasticity , plasticity, Malleability , hardness, brittleness etc.III.Timber- Introduction-selection of timbers-season<strong>in</strong>g of timbers – timber defectsIV.Brief <strong>in</strong>troduction to jo<strong>in</strong><strong>in</strong>g process-Nuts& bolts-Screw- Screws-rivets & rivet<strong>in</strong>g- weld<strong>in</strong>gelectricarc-gas weld<strong>in</strong>g- TIG-MIG weld<strong>in</strong>g –threadsV.Extrusion-Classification-process geometry- Geometrical relationship- analysis of extrusionstresses-load – power – maximum r<strong>edu</strong>ction possible-work<strong>in</strong>g and application of <strong>in</strong>directextrusion- hydrostatic extrusion- defects <strong>in</strong> extruded parts.VI . Forg<strong>in</strong>g – classification- strip sand disc forg<strong>in</strong>g- Process geometry-geometrical relationship-Analysis - defects <strong>in</strong> forged products .VII. Roll<strong>in</strong>g – classification-process geometry-geometrical relationship analysis-roll<strong>in</strong>g pressure &roll<strong>in</strong>g separat<strong>in</strong>g force.2)ENGINEERING MECHANICSCourse Code CE-401 CREDIT : 4 (2-0-1. force and equilibriumBasic concepts, force, moment and couple, pr<strong>in</strong>ciple of transmissibility, verigonon’s theorem,resultant of force systems, concurrent and non-concurrent coplanar forces, funicular polygon, andfree body diagram.1. TrussesPlane structures, various methods of analysis of trusses, method of jo<strong>in</strong>ts, method of sections andgraphical method.2. Moment of <strong>in</strong>ertia

Center of gravity, centroids of l<strong>in</strong>e, area, volume and composite Bodies, area moment of <strong>in</strong>ertiaand mass moment of <strong>in</strong>ertia for plane figures and bodies <strong>in</strong>clud<strong>in</strong>g composite bodies, productmoment of <strong>in</strong>ertia, parallel axis theorem, pr<strong>in</strong>cipal moment of <strong>in</strong>ertia.3. FrictionIntroduction, dry friction, co-efficient of static friction, friction cone, screw jack and beltfriction.4. BeamsBend<strong>in</strong>g moment and shear force diagrams for statically determ<strong>in</strong>ate beams.5. K<strong>in</strong>ematics of Rigid BodiesPlane motion, absolute motion, relative motion, translat<strong>in</strong>g axes and rotat<strong>in</strong>g axes.6. K<strong>in</strong>etics of Rigid BodiesPlane motion, force Mass and Acceleration, Work and energy, Impulse and momentum,pr<strong>in</strong>ciples of energy conservation, Pr<strong>in</strong>ciple of virtual work, D’AleMbert’s pr<strong>in</strong>cipal anddynamic equilibrium.References:1. Beer F.p and Johnston F.R: mechanics for eng<strong>in</strong>eers, McGraw hill.2. Meriam, J.L: Statistics, John Wiley.3. Meriam, J.L: Dynamics, John Wiley.4. Shames I.H: <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mechanics, Prentice Hall of India.5. Dayaratnam, P: Statistics, Tata Mc Graw Hill.6. Timeshenko, S.and Ypung D: <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mechanics, Mc Graw Hill.ENGINEERING MATHEMATICS - ICourse Code MAS-411 CREDIT : 4 (3-1-0)1. Matrices :Elementary row and column transformations, L<strong>in</strong>ear dependence, Rank ofmatrix, Consistency of system of l<strong>in</strong>ear equations and solution of l<strong>in</strong>ear equations,Characteristic equation, and Caley-Hamilton theorem, Eigen values and eigen vectors,Diagonalisation, Complex and unitary matrices.2. Differential Calculus-I:Leibnitz theorem, Partial differentiation, Euler’s theorem,Asymptotes, Curve trac<strong>in</strong>g, Change of Variables, expansion of functions of one andseveral variables. Cyl<strong>in</strong>drical and spherical coord<strong>in</strong>ate systems3. Differential Calculus-II:Jacobian, Approximation of errors, Extrema of function ofseveral variables, Lagrange’s method of multipliers (simple applications).4. Multiple <strong>in</strong>tegrals:Double and triple <strong>in</strong>tegrals, change of order, change of variables,Gamma & Beta functions,application to area, volume, Disrichlet’s <strong>in</strong>tegral and itsapplications.5. Vector Calculus:Po<strong>in</strong>t functions, Gradient, divergence and curl of a vector and theirphysical <strong>in</strong>terpretations, l<strong>in</strong>e, surface & volume <strong>in</strong>tegrals, Gauss divergence theorem andGreens & Stokes theorem.References:1. Shanti Narayan: A Text Book of matrices, S.Chand & Co.2. Thomas/F<strong>in</strong>ney: Calculus and Analytic Geometry, Narosa Pub. House.3. J. N. Kapur: Mathematical Statistis, S. Chand &Co.4. C. Prasad: Mathematics for Eng<strong>in</strong>eers, Prasad Mudranalaya.5. B.S. Grewal: Higher <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mathematics, Khanna Publishers.6. Jaggi & Mathur : Advanced <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mathematics, Khanna Publishers.7. Piskunov, N.: Differential & Integral Calculus, Moscow Peace Pub.

8. H.K. Das, <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mathematics.9. Vijai Shankar Verma & Sanjeev Kumar, <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mathematics.10. Rakesh Dubey, <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> MathematicsCHEMISTRYCourse Code CHEM-513 CREDIT : 5 (3-1-1)1. General Chemistry:Advanced Theory of Chemical Bond<strong>in</strong>g: Valence bond and molecularorbital theory. Structure of NH 3 , H 2 O, SO 3 , PCl 5 , XeO 2 molecules. Theories of bond<strong>in</strong>g <strong>in</strong>metals and semiconductors,n-type and p-type semi-conductors, Imperfections <strong>in</strong> materials.Born-Haber cycle, Bragg’s conditions.2. Physical Chemistry:Equilibrium on Reactivity: Bronsted and Lewis Acids, pH, pka, pkbScale, Buffer solution. Stereochemistry of organic compounds, Co-ord<strong>in</strong>ation chemistry,Nomenclature, Valence Bond and crystal field theory.Chemical K<strong>in</strong>etics & Catalysis: Rate law, Order of reactions, Parallel and reversiblereactions, Catalysis, Homogeneous and heterogeneous catalysis, Characteristics ofcatalytic reaction, Catalytic promoters and poi-sons, Auto catalysis and negativecatalysis, Intermediate compound formation theory and absorption theory.3. Environment Chemistry:Atmospheric Chemistry & Air Pollution: Environment andEcology, Environmental segments, Structure and composition of atmosphere, RadiationBalance of Earth and Green House Effect, Formation and depletion of Ozone layer,Chemical and photochemical reactions of various species <strong>in</strong> atmosphere, Air pollution –sources, reactions and s<strong>in</strong>ks for pollutants, Acid ra<strong>in</strong>s and Smog formation. Pollutioncontrol methods.Corrosion and Lubrication: Introduction, causes of corrosion, Theories of corrosion,Factors <strong>in</strong>fluenc<strong>in</strong>g Corrosion, Corrosion <strong>in</strong>hibitors, passivity, Types of corrosion,Protection from corrosion and protective coat<strong>in</strong>gs. Theory, Classification and mechanismof Lubrication.4. Applied Chemistry:Water and Waste Water Chemistry: Introduction, Hardness ofwater, characteristics imparted by impurities, Analysis of contam<strong>in</strong>ants, Treatment ofWater by Zeolite, L-S process, Boiler feed water, Waste water treatment.5. Chemistry of <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Materials:Fuels & Combustion: Classification of fuels, Nonconventional Energy, Biogas, Biomass and solar energy. Calorific value- gross and net,characteristics of good fuel, Determ<strong>in</strong>ation of calorific value, Solid fuels, Analysis of coal,Liquid fuels.Instrumentation: IR, UV, NMR, MASS AND ASS.6. <strong>Industrial</strong> Chemistry:Polymer Chemistry: Classification of Polymers, Includ<strong>in</strong>gBiopolymers condensation and addition polymers and their applications. <strong>Industrial</strong>Application and mechanism of chemical reaction, Beckman, Hoffman, Reimer Tiemann,Cunnizzaro, Diels Alder and Skraup synthesis.References:1. Puri and Sharma/Pr<strong>in</strong>ciples of Physical Chemistry.2. Manas Chandra/Atomic Structure and Chemical Bond.3. Bahl and Tuli /<strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Chemistry.4. Ja<strong>in</strong> and Ja<strong>in</strong>/A Text-Book of <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Chemistry5. S.S Dara/Environmental Chemistry and Pollution Control.6. S.S Dara /Environmental Chemistry.7. A.K De/Environmental Chemistry.LIST OF EXPERIMENTS (ANY TEN):1. To determ<strong>in</strong>e the percentage of available chlor<strong>in</strong>e <strong>in</strong> the supplied sample of Bleach<strong>in</strong>gpowder.

2. To determ<strong>in</strong>e the Ferrous content <strong>in</strong> the supplied sample of iron ore by titrimetric analysisaga<strong>in</strong>st standard K Cr solution us<strong>in</strong>g K, Fe(CN) g as external <strong>in</strong>dicator.3. To determ<strong>in</strong>e the chloride content <strong>in</strong> supplied water sample us<strong>in</strong>g Mohr’s method.4. To determ<strong>in</strong>e the constituents and amount of alkal<strong>in</strong>ity of the supplied water sample.5. To determ<strong>in</strong>e the Temporary and Permanent hardness of water sample by Coplexometry.6. To f<strong>in</strong>d the Chemical Oxygen Demand of a waste water sample us<strong>in</strong>g Potassium dichromate.7. To determ<strong>in</strong>e iron concentration <strong>in</strong> the sample of water by spectrophotometric method.8. To f<strong>in</strong>d out the Velocity constant for the <strong>in</strong>version of cane sugar <strong>in</strong> acidic medium and toshow that <strong>in</strong>version follows the first order k<strong>in</strong>etics.9. To determ<strong>in</strong>e the Molecular weight of a polystyrene sample by us<strong>in</strong>g Viscometer method.10. To determ<strong>in</strong>e pH of a solution us<strong>in</strong>g a pH-meter and titration of such a solution pHmetrically.11. To determ<strong>in</strong>e the calorific value of a fuel sample by us<strong>in</strong>g a Bomb Calorimeter.12. Analysis of a coal sample by proximate analysis method.References:1. Vogel’s Qualitative Chemical Analysis: Ed. By Jaffery Bassette et. al. (ELBS).2. Applied Chemistry- Theory and Practice, 2 nd Ed. By Virmani and Narula (New AgeInternational Pub.).3. Experiments <strong>in</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Chemistry, Ed. By Masood Alam (Maktaba Jamia Limited).BASIC ELECTRONICS1-1)Course Code ECE-301 CREDIT : 4 (2-1. Energy Bands <strong>in</strong> Solids: Energy band theory of solids, Concept of forbidden gap, Insulators,Metals and Semiconductors.2. Transport Phenomenon <strong>in</strong> Semiconductors: Mobility and conductivity, electrons and holes <strong>in</strong>an <strong>in</strong>tr<strong>in</strong>sic semiconductor, Donor and acceptor impurities, Fermi level, carrier densities <strong>in</strong>semiconductor, electrical properties of semiconductor, Hall effect, Diffusion.3. Junction Diode:P-N junction, depletion layer, V-I characteristics, diode resistance,capacitance, switch<strong>in</strong>g time, diode application as a rectifier (half wave and full wave), diodecircuits (clipper, clamper, voltage multipliers) Breakdown mechanism, Zener & Avalanche,breakdown characteristics, Zener diode and its applications.4. Bi-junction Transistor:Bipolar junction Transistor, CE, CB and CC configuration,characteristic curves (cut off, active and saturation region), Requirement of bias<strong>in</strong>g, bias<strong>in</strong>g typesand bias<strong>in</strong>g analysis, stability.5. Transistor as an Amplifier:Graphical analysis of CE amplifier, concept of voltage ga<strong>in</strong>,current ga<strong>in</strong> and power ga<strong>in</strong>, h-parameter (low frequency), computation of A v , R I , R o andapproximate formulae.6. Operational Amplifiers:Concepts of ideal op-amp, <strong>in</strong>vert<strong>in</strong>g, non-<strong>in</strong>vert<strong>in</strong>g and unity ga<strong>in</strong>amplifiers, adders, difference amplifiers. , Integrators.

7. Switch<strong>in</strong>g Theory & Logic Gates: Number systems, conversion of bases, Boolean algebra,Logic Gates, concept of universal gate, canonical forms, and m<strong>in</strong>imization us<strong>in</strong>g K-map.8. Electronic Instruments: Multimeter, CRO and its Applications.References:1. Boylestad & Nashelsky/Electronic Devices & Circuits/ PHI.2. Morris Mano/Digital Computer Design/ PHI.3. Milliman, J. Halkias/Integrated Electronics/TMH.4. Malv<strong>in</strong>o & Leach/Digital Pr<strong>in</strong>ciples & Application/List of Experiments:1. Study of Diode characteristics.2. Study of Common Base Transistor characteristics.3. Study of Common Emitter Transistor characteristics.4. Study of Half Wave Rectifier with effect of Capacitor and also calculate the ripple factor.5. Study of Full- Wave Rectifier with effect of Capacitor and also calculate the ripple factor.6. Study of Various Logic Gates.7. Study of Clipp<strong>in</strong>g and clamp<strong>in</strong>g Circuits.8. Study of C.R.O., Function generator, Multimeter.PROFESSIONAL COMMUNICATION IICourse Code LNG-303 CREDIT : 3 (3-0-0)1. <strong>Tech</strong>nical Written Communication(a) Nature, orig<strong>in</strong> and development of technical written communication.(b) Salient Features.(c) Difference between technical writ<strong>in</strong>g and general writ<strong>in</strong>g.2. Pre-requisites of Scientific and <strong>Tech</strong>nical Communication(a) Fragment sentences.(b) Parallel comparisons.(c) Elements of a series.(d) Squ<strong>in</strong>t<strong>in</strong>g construction and split <strong>in</strong>f<strong>in</strong>itive.(e) Modifiers, connectives, antecedents and clause subord<strong>in</strong>ation.(f) Dangl<strong>in</strong>g participles and gerunds.(g) Ellipsis.(h) Coherence, Unity, Chronological method, spatial method, <strong>in</strong>ductive method, l<strong>in</strong>earmethod, d<strong>edu</strong>ctive method, <strong>in</strong>terrupted method.3. Bus<strong>in</strong>ess Correspondence(a) General pr<strong>in</strong>ciples of bus<strong>in</strong>ess correspondence.(b) Ramifications of bus<strong>in</strong>ess letters.(c) Letters giv<strong>in</strong>g <strong>in</strong>structions, <strong>in</strong>quiries and answers to enquiries, compla<strong>in</strong>ts andadjustments, letters urg<strong>in</strong>g action, employment letters, application and resumes.4. Proposal Writ<strong>in</strong>g(a) Proposal: Def<strong>in</strong>itions and k<strong>in</strong>ds.(b) Division of format proposals (front matter, title page, summary/ abstract, Table ofcontents etc.)(c) Statement of request, body- statement of problem, background, scope, methodology,Advantages and disadvantages.5. Writ<strong>in</strong>g Scientific and Semi-technical Articles(a) Source material, topic sentence, literature review.(b) Tables, figures, footnotes, bibliography.

6. Study of Scientific and General Texts.(A). Prescribed text books for detailed study Arora, V.N (et. al.), Improve your writ<strong>in</strong>g (Delhi: Oxford University Press, 1981.2 Lesson No. 1.2, 1.6, 2.4, 3.5, 4.1, 4.3, 5.1, 5.4, 6.2.(B). For extended Read<strong>in</strong>g (any one of the follow<strong>in</strong>g) Orwell George, N<strong>in</strong>eteen Eighty Four (New York: Pengu<strong>in</strong>, 1984)2 Hem<strong>in</strong>gway, Ernest, The old man and the Sea, (Oxford: 1990)7.Listen<strong>in</strong>gComprehension(a).Ear-tra<strong>in</strong><strong>in</strong>g.(b). Uses of latest scientific techniques (AVR Comprehension tra<strong>in</strong>er,SRA Comprehension tra<strong>in</strong>er, SRA Comprehension Accelerator, AVR ComprehensionReteometer.)8.Read<strong>in</strong>gComprehension.(a) Scann<strong>in</strong>g method.(b) Skimm<strong>in</strong>g method.9. Phonetic Transcription10. Stresses and Intonation.References1. Sherman, Theodore A. (et al) Modern <strong>Tech</strong>nical Writ<strong>in</strong>g, New Jersey, Prentice Hall, 1991.2. Legget, Glenn (et al) Essentials of grammar and composition, Macmillan, Delhi 1994.3. Strunk, Jr. William (et al), The elements of style, Macmillan, 1987.4. Sharma, S.D A Text Book of Scientific and <strong>Tech</strong>nical Writ<strong>in</strong>g, Vikas, Delhi, 1990.ELECTRICAL ENGINEERINGCourse Code EEE-303 CREDIT : 4 (3-0-1)1. S<strong>in</strong>usoidal Steady State Circuit Analysis:Voltage, Current, S<strong>in</strong>usoidal & Phasorrepresentation.1-Phase A.C. Circuit-behavior of resistance, Inductance and Capacitance andtheir comb<strong>in</strong>ations, impedance, concept of power, power factor, series & parallel resonancebandwidthand quality factor.2. Network Theory:Introduction to basic physical laws, Network theory: Superposition,Theven<strong>in</strong>, Norton, Maximum Power transfer theorems, Star-delta transformation, Circuit theoryConcepts: Mesh and Nodal analysis.3. Three Phase Supply:Star/delta connections, l<strong>in</strong>e and phase voltage/current relations, Threephasepower and its measurement.4. Basic Instruments:Instruments for measurement of voltage, Current, power and energy:Construction, pr<strong>in</strong>ciple and application.5. Magnetic Circuit and Transformer:Magnetic circuit concept, theory and work<strong>in</strong>g pr<strong>in</strong>cipleof s<strong>in</strong>gle-phase transformer.6. Rotat<strong>in</strong>g Mach<strong>in</strong>es:Pr<strong>in</strong>ciples of energy conversion, Basic concepts of rotat<strong>in</strong>g mach<strong>in</strong>es,DC mach<strong>in</strong>es, Different types and their characteristics & applications. Elementary idea ofoperation of synchronous and <strong>in</strong>duction mach<strong>in</strong>es. S<strong>in</strong>gle-phase <strong>in</strong>duction & stepper motors,Applications.7. Power Systems:Introduction, Elements, L<strong>in</strong>e diagram, Supply systems, Power factorimprovement.Reference:1. V. Del Toro/ Pr<strong>in</strong>ciples of Electrical <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong>/ PHI.2. W.H Hayt & J.E Kennedy/ <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Circuit Analysis/ McGraw Hill.

3. I.J Nagrath/ Basic Electrical <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong>/ Tata McGraw Hill.4. A.E Fitzgerald/ Electronic Instruments & Measurement <strong>Tech</strong>niques/ PHI.5. Higg<strong>in</strong>botham L.Grabel/Basic Electrical <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong>/ McGraw Hill.LIST OF PRACTICALSA m<strong>in</strong>imum of 10 experiments from the follow<strong>in</strong>g:1. Verification of Theven<strong>in</strong>’s Theorem.2. Verification of Superposition Theorem.3. Verification of Norton’s Theorem4. Verification of Kirchoff’s Law.5. To measure the value of impedance and power factor <strong>in</strong> RLC series A.C. circuit.6. To measure the value of impedance and power factor <strong>in</strong> RLC parallel A.C.circuit.7. To study resonance by frequency variation <strong>in</strong> series RLC circuit.8. To calibrate the given energy meter with the help of a standard wattmeter.9. To f<strong>in</strong>d the relation between l<strong>in</strong>e current and phase current and l<strong>in</strong>e voltage and phase voltage<strong>in</strong> Star – Delta connections.10. To perform open circuit and short circuit test and draw the equivalent circuit of a s<strong>in</strong>glephasetransformer.11. To measure three phase power by two-wattmeter method.12. To draw the magnetiz<strong>in</strong>g characteristic of a s<strong>in</strong>gle-phase transformer.Additional experiments may be added based on contents of syllabi.ENGINEERING PHYSICSCourse Code PHY-312 CREDIT :5 (3-1-1)1. Special Theory of Relativity:Michelson Morley experiment, Inertial frames of reference,Postulates of special theory of relativity, Lorentz transformation equation of space and time,length contraction, time dilaton, addition of velocities, variation of mass with velocity, massenergyequivalence.2. Optics :Interference: Coherent sources, Conditions of <strong>in</strong>terference, Fresnel’s bi-prismexperiment, displacement of fr<strong>in</strong>ges, <strong>in</strong>terference <strong>in</strong> th<strong>in</strong> films, wedge shaped film,Newton’s r<strong>in</strong>gs.Diffraction: S<strong>in</strong>gle slit and double slit diffraction, diffraction grat<strong>in</strong>g, Reyleigh’s criterion oflimit of resolution, resolv<strong>in</strong>g power of telescope, microscope and grat<strong>in</strong>g.Polarization: Polarization of light, Pictorial representation of polarized light, Brewster’s law,Malus law, Phenomena of double refraction, Geometry of calcite crystal, Optical activity,Specific rotation, Polarimeter.3. Fields: Scalar and vector fields, Gradient of a scalar field, divergence and curl of a vector field,l<strong>in</strong>e <strong>in</strong>tegral, conservative vector field, Gauss’ Divergence theorem, Stoke’s theorem.4. Electrostatics: Gauss’ law and its applications, Poisson and Laplace equations. Maxwell’sequations, Basic Concepts of Electromagnetic waves and its solution <strong>in</strong> free space.5. Magnetic Properties of Materials:Para, dia, ferro, antiferro and ferro-magnetic materials,hysteresis, Methods of plott<strong>in</strong>g hysteresis curve of a ferro-magnetic material and their uses,magnetic circuits.

6. X-Rays: Orig<strong>in</strong> of X-rays, Cont<strong>in</strong>uous and characteristic X-Ray spectra, Moseley’s law,Absorption of X-rays, Diffraction of X-rays, Bragg’s law, Bragg’s spectrometer, Practicalapplication of X-rays, Compton effect.7. Quantum Theory:Wave particle duality, De Broglie concept of matter waves, Davisson andGermer experiment, Heissenberg’s uncerta<strong>in</strong>ty pr<strong>in</strong>ciple, Schrod<strong>in</strong>ger wave equation and itsapplications.8. LaserSpontaneous and stimulated emission of radiation, E<strong>in</strong>ste<strong>in</strong>’s coefficients, Ma<strong>in</strong> components of alaser, types of lasers and their applications.References:1. Arthur Beiser: Concepts Of Modern Physics, TMH.2. Subramanyam & Brij Lal: A Text Book of Optics, S. Chand & Co.3. K.K. Tiwari: Electricity & Magnetism, S. Chand & Co.4. Brij Lal & Subramanyam: Electricity & Magnetism.5. Wehr, Richardo & Adair: Physics of the Atom.List Of Experiments (Any Ten)1. To determ<strong>in</strong>e the wavelength of monochromatic light by Newton’s r<strong>in</strong>g.2. To determ<strong>in</strong>e the wavelength of monochromatic light with the help of Fresnel’s biprism.3. To determ<strong>in</strong>e the focal length of two lenses by nodal slide and locate the position of card<strong>in</strong>al po<strong>in</strong>ts.4. To determ<strong>in</strong>e the specific rotation of cane sugar solution us<strong>in</strong>g half shade polarimeter.5. To determ<strong>in</strong>e the wavelength of spectral l<strong>in</strong>es us<strong>in</strong>g plane transmission grat<strong>in</strong>g.6.To determ<strong>in</strong>e the specific resistance of the material of given wire us<strong>in</strong>g Carey Foster’sbridge.7. To determ<strong>in</strong>e the variation of magnetic field along the axis of a current carry<strong>in</strong>g coil andthen to estimate the radius of the coil.8. To verify Stefan’s Law by electrical method.9. To calibrate the given ammeter and voltmeter.10. To study the Hall Effect and determ<strong>in</strong>e Hall coefficient, carrier density and mobility of agiven semiconductor material us<strong>in</strong>g Hall Effect set up.11. To determ<strong>in</strong>e the energy band gap of a given semiconductor material.12. To determ<strong>in</strong>e E.C.E of copper us<strong>in</strong>g Tangent or Helmholtz galvanometer.13. To draw hysteresis curve of a given sample of ferromagnetic material and from this todeterm<strong>in</strong>e magnetic susceptibility and permeability of the given specimen.14. To determ<strong>in</strong>e the ballistic constant of a ballistic galvanometer.15. To determ<strong>in</strong>e the viscosity of a liquid.16. To determ<strong>in</strong>e refractive <strong>in</strong>dex of the material of prism us<strong>in</strong>g spectrometer.ENGINEERING GRAPHICS IICourse Code ME-401CREDIT:2(0-0-2)1. Introduction: Graphic language, Classification of draw<strong>in</strong>gs, Pr<strong>in</strong>ciples of draw<strong>in</strong>g: IS codesfor Mach<strong>in</strong>e draw<strong>in</strong>g, L<strong>in</strong>es, Sections, Dimension<strong>in</strong>g, Standard abbreviation.2. Orthographic Projections: Pr<strong>in</strong>ciples of first and third angle projections, draw<strong>in</strong>g andsketch<strong>in</strong>g of mach<strong>in</strong>e elements <strong>in</strong> orthographic projections, spac<strong>in</strong>g of views.3. Screwed (Threaded) Fasteners: Introduction, Screw thread nomenclature, Forms of threads,Thread series, Thread designation. Representation of threads, Bolted jo<strong>in</strong>ts, Lock<strong>in</strong>garrangements for nuts, Foundation bolts.4. Keys and Cotters: Keys, Cotter jo<strong>in</strong>ts.5. Shaft Coupl<strong>in</strong>gs: Introduction, Rigid and flexible coupl<strong>in</strong>g.

6. Riveted Jo<strong>in</strong>ts: Introduction, Rivets and rivet<strong>in</strong>g, Rivet heads, Classification of rivetedjo<strong>in</strong>ts.7. Assembly Draw<strong>in</strong>g: Introduction, Eng<strong>in</strong>e parts, Stuff<strong>in</strong>g box etc.8. Free Hand Sketch<strong>in</strong>g:Need for free hand sketch<strong>in</strong>g, Free hand sketch<strong>in</strong>g of some threadedfasteners and simple mach<strong>in</strong>e components.References:1. N. Siddeshwar, P. Kannaiah, V.V.S Shastri: Mach<strong>in</strong>e Draw<strong>in</strong>g, TMH, New Delhi.2. K.L Narayana, P. Kannaiah, K. VenkatReddy: Mach<strong>in</strong>e Draw<strong>in</strong>g, New Age InternationalPublications, 2 nd edition.3. <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> draw<strong>in</strong>g practice for schools and colleges, SP 46-1998(BIS).COMPUTER AND LANGUAGESCourse Code COM-410 CREDIT : 4(2-0-2)1 Computer hardware components and their functions2 Basic operat<strong>in</strong>g system concepts3 MS-DOS and gett<strong>in</strong>g to know DOS commands4 Familiariz<strong>in</strong>g with WINDOWS environment5 Gett<strong>in</strong>g started with UNIX6 Files and Directories and their use <strong>in</strong> different Operat<strong>in</strong>g System Environments7 Gett<strong>in</strong>g to know different editors like edit & vi8 Introduction to Internet9 Gett<strong>in</strong>g familiar with Web Browsers like Netscape Navigator & Internet Explorer10 Send<strong>in</strong>g & receiv<strong>in</strong>g mail over Internet11 Introduction to PINE and /or ELM12 Need of programm<strong>in</strong>g languages.13 Language translators.14 Introduction to “C” language15 Data types operators and expressions.16 Conditional & loop<strong>in</strong>g statements.17 Function & Arrays.18 Introduction to Po<strong>in</strong>ters & Structures.References:1. DOS the complete reference by Kris Jamsa, Tata- McGraw Hill Publication.2. UNIX POWER TOOLS by J.Peek Tim O’reilly & M. Locekides, BPB Publication.3. The ‘C’ Programm<strong>in</strong>g Language by B.W Kernighan & D.M Ritchie, Prentice Hall of India.4. Us<strong>in</strong>g LINUX- Latest Edition by Jade Tackett & David Ganter, Prentice Hall of India.LIST OF PRACTICALS1. Basic Internal and External DOS Commands.2. Write a simple batch program.3. Giv<strong>in</strong>g exposure to W<strong>in</strong>dows environment.4. File and program management <strong>in</strong> w<strong>in</strong>dows.5. Practice of basic UNIX commands.6. Write simple shell script.7. Introduction to word process<strong>in</strong>g.8. Exposure to advance feature supported by some editors.9. Net Surf<strong>in</strong>g.10. Creation and check<strong>in</strong>g of E-mail account.

11. Write C program to demonstrate each of the follow<strong>in</strong>g:1 Conditional statements.2 Loop<strong>in</strong>g statements.3 User def<strong>in</strong>ed functions.4 Arrays.5 Po<strong>in</strong>ters and structures.12. Familiariz<strong>in</strong>g mail account us<strong>in</strong>g PINE, delet<strong>in</strong>g, creat<strong>in</strong>g folder/mail-messages, add<strong>in</strong>gsignature, creat<strong>in</strong>g director of addresses.ENGINEERING MATHEMATICS IICourse Code MAS-490 CREDIT : 4 (3-1-0)1. Differential Equations:Ord<strong>in</strong>ary differential equations of first order, exact differentialequations, L<strong>in</strong>ear differential equations of 1st order with constant coefficients,Complementary functions and particular <strong>in</strong>tegrals, Simultaneous l<strong>in</strong>ear differentialequations, Solution of second order differential equation by chang<strong>in</strong>g dependent and<strong>in</strong>dependent variables, Method of variation of parameters, Applications to eng<strong>in</strong>eer<strong>in</strong>gproblems(without derivation).2. Series Solution & Special Functions:Series solutions of ODE of 2nd order with variablecoefficients with special emphasis to the differential of legendre and Bessel.Legendre’s polynomials, bessel’s functions and their properties.3. LaplaceTransform:Laplace transform, Existence theorem, Laplace transform derivativesand <strong>in</strong>tegrals, Inverse Laplace transform, Unit-step function, Dirac Delta function,Laplace transform of periodic functions, convolution theorem Applications to solvesimple l<strong>in</strong>ear and simultaneous differential equations.4. Fourier Series And Partial Differential Equations :Periodic functions,Trignometricseries, Fourier series of functions with period 2n, Eulers formulae, functions hav<strong>in</strong>garbitrary period, even and odd functions, change of <strong>in</strong>terval, half range s<strong>in</strong>e and cos<strong>in</strong>eseries.Introdution to partial differtial equations, l<strong>in</strong>ear partial differential equation with constantcoefficients of 2nd order and their classifications, parabolic, elliptic & hyperbolic withillustrative examples.5. Application of Partial Differential EquationsMethod of separation of variables for solv<strong>in</strong>g partial differential equation, Waveequation up to two dimension, Laplace equation <strong>in</strong> two dimension, Heat conductionequations up to two dimension, Equation of transmission L<strong>in</strong>es.References:1. E. Kreyszig: Advanced <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mathematics, Wiley Eastern Ltd.2. B.S Grewal: Higher <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mathematics, Khanna Publishers.3. Jaggi & Mathur: Advanced <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Mathematics, Khanna Publishers.

4. C. Prasad: Advanced Mathematics for Eng<strong>in</strong>eers, Prasad Mudranalaya.MACHINE DRAWING & COMPUTER AIDED DRAFTING LABCourse Code ME-403 CREDIT : 2 (0-0-2)Review (1 Class)Orthographic projection, miss<strong>in</strong>g l<strong>in</strong>es, <strong>in</strong>terpretation of views and section<strong>in</strong>g.Part and Assembly Draw<strong>in</strong>g (2 Classes):Introduction, assemblies draw<strong>in</strong>g of stuff<strong>in</strong>g box, steam eng<strong>in</strong>e cross head, air valves, lathetailstock, gate valve, screw jack, connect<strong>in</strong>g rods, spark plug, tool post, safety valves etc. Draw<strong>in</strong>gexercise.Specification of Materials:<strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> materials, code designation of steels, copper and alum<strong>in</strong>um and its alloys.Limits, Tolerance and fits: (1 Class)Introduction, Limit systems, tolerance fits, draw<strong>in</strong>gs and exercises.Surface Roughness:Introduction, surface roughness, mach<strong>in</strong><strong>in</strong>g symbols, <strong>in</strong>dication of surfaceroughness, draw<strong>in</strong>g exercises.<strong>Production</strong> Draw<strong>in</strong>g:Introduction to develop<strong>in</strong>g and read<strong>in</strong>g or production draw<strong>in</strong>g of simplemach<strong>in</strong>e elements like helical gear, bevel gear, flange, p<strong>in</strong>ion shaft, connect<strong>in</strong>g rot, crankshaft,belt pulley, piston details etc. Idea about tool draw<strong>in</strong>g.Computer Aided Draft<strong>in</strong>g:Introduction, <strong>in</strong>put, output devices, <strong>in</strong>troduction to draft<strong>in</strong>g softwarelike Auto CAD, basic commands and development of simple 2D and 3D draw<strong>in</strong>gs.References:1. Mach<strong>in</strong>e Draw<strong>in</strong>g by Narayana, et.all, New Age.2. <strong>Production</strong> Draw<strong>in</strong>g by Narayana, et.all. New Age.3. Auto CAD 14 for <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Draw<strong>in</strong>g by P. Nageswara Rao, TMH.APPLIED THERMODYNAMICSCourse Code ME-404 CREDIT : 5 (3-1-1)Review of Thermodynamics: Brief review of basic laws of thermodynamics, Helmholtz & Gibb’sfunction, Mathematical conditions for exact deferential. The Maxwell Relations, Clapeyron Equation, Joule– Thompson coefficient curve, Availability & Irreversibility.Steam Boilers: Brief review of properties of steam, use of steam table and Mollier chart, Steamgenerators- classifications, work<strong>in</strong>g of fire-tube and water tube boilers, boiler mount<strong>in</strong>gs & accessories, Airpreheater, Feed water heater, Superheater, Boiler efficiency, Equivalent evaporation, Heat balance. Boilerdraught.Steam Eng<strong>in</strong>es:Rank<strong>in</strong>e and modified Rank<strong>in</strong>e cycles, Work<strong>in</strong>g of eng<strong>in</strong>e <strong>in</strong>dicator diagram.Nozzle: Flow through nozzle, variation of velocity, area and specific volume, Nozzle efficiency, Criticalcondition.

Steam Turb<strong>in</strong>es: Classification, impulse and reaction turb<strong>in</strong>es, Compound<strong>in</strong>g, Velocity diagram,workdone, Reaction, Efficiency, Bleed<strong>in</strong>g, Comparison with steam eng<strong>in</strong>es, Reheat factor, Govern<strong>in</strong>g ofturb<strong>in</strong>es, Velocity diagram, Work done, Efficiencies of reaction and impulse turb<strong>in</strong>es.IC Eng<strong>in</strong>es: Classification, Constraction details. Application of four stroke and two stroke eng<strong>in</strong>es,Review of Otto, diesel and Dual cycles, Work done, Efficiencies, Indicator diagram, Valve tim<strong>in</strong>g diagram.EfficienciesGas Turb<strong>in</strong>es: Review of Bryaton cycle, Thermal ref<strong>in</strong>ement of a gas turb<strong>in</strong>e cycle, Comparison with ICEng<strong>in</strong>e and steam turb<strong>in</strong>e.Refrigeration and Heat Pump Cycles: Def<strong>in</strong>ition, Types, Carnot refrigerat<strong>in</strong>g cycle, Bell Coleman cycle. Unit ofrefrigeration. Description of simple vapour compression and vapour absorption systems. Introduction to aircondition<strong>in</strong>g.Compressors: Reciprocat<strong>in</strong>g compressor, Construction details and work<strong>in</strong>g pr<strong>in</strong>ciple, Efficiency, Power<strong>in</strong>put, Intercool<strong>in</strong>g , Work<strong>in</strong>g pr<strong>in</strong>ciple of centrifugal and axial flow compressor, Power <strong>in</strong>put calculation.Reference:1. Heat <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> by V.P. Vasandani & D. S. Kumar Publisher Metropolition Book Co. (P)Ltd.2. Thermal Engg. By P.L. Blallaney, Khanna Publishers.3. Theory of Steam Turb<strong>in</strong>e by W. J. Kearton4. Applied Thermodynamics by R. Yadav 6 th edn, CPH, Allahabad.5. Thermal Engg., By R. K. Rajput, Laxmi Publication.6. Turb<strong>in</strong>e Compressors & Fans by S. M. Yahya, HMT7. Thermal Engg. By S .K. kulshrestha, Vicars, Pub. House Ltd.8. Fundamental of Engg. Thermodynamics by R. Yadav 7 th edn, CPH, Allahabad9. Engg. Thermodynamics by Nag10. Engg. Thermodynamics by C .P. AroraFLUID MECHANICSCourse Code CE-406 CREDIT : 4 (3-0-1)I. Introduction: Fluids and cont<strong>in</strong>uum Physical properties of fluids, ideal and real fluids, Newtonian andNon-Newtorian fluids, measurement of surface tension.II. K<strong>in</strong>ematics of Fluid flow:Steady and unsteady, uniform and nonuniform, lam<strong>in</strong>ar and turbulent flows,one, two and three dimensional flows, streaml<strong>in</strong>es, streak l<strong>in</strong>es and path l<strong>in</strong>es, cont<strong>in</strong>uity equation,rotation and circulation, elementary explanation of stream function and velocity potential, graphical andexperimental methods of draw<strong>in</strong>g flow nets.III. Fluid Statics: Pressure-density-height relationship, manometers, pressure on plane and curved surfacescenter of pressure, buoyancy stability of immersed and float<strong>in</strong>g bodies, fluid masses subjected touniform accelerations, measurement of pressure.IV. Dynamics of fluid flow:Euler’s equation of motion along a streaml<strong>in</strong>e and its <strong>in</strong>tegration, Bernoulli’sequation and its applications-Pitot tube, flow through orifices, mouthpieces, nozzles, notches & weirs,sluice gates under free and submerged flow conditions, Aeration of nappe, cavitation, free and forcevortex momentum equation and its application of energy and momentum equations, flow measurements,determ<strong>in</strong>ation of Cd, Cc, and Cv, energy loss.V. Dimensional Analysis and Hydraulic Similitude: Dimensional analysis, Buck<strong>in</strong>gham’s Theorem,important dimensionless numbers and their significance, geometric, K<strong>in</strong>ematic and dynamicsimilarity, model studies.VI. Lam<strong>in</strong>ar and Turbulent flow through pipes, stoke’s law, flow between parallel plates, flowthrough porous media, fluidisation, measurement of viscosity, transition form lam<strong>in</strong>ar to turbulentflwo, turbulent flow, equation for turbulent flow, eddy viscosity, mix<strong>in</strong>g length concept andvelocity distribution <strong>in</strong> turbulent flow, Hot-wire anemometer and LDA.

VII. Boundary Layer Analysis:Boundary layer thicknesses boundary layer over a flat plate,lam<strong>in</strong>ar boundary layer, application of momentum equation, turbulent boundary layer, lam<strong>in</strong>ar sublayer,smooth and rough boundaries, atmospheric boundary layer, local and average frictioncoefficient, separation and its control, measurement of shear.VIII. Pipe flow:Nature of turbulent flow <strong>in</strong> pipes, equation for velocity distribution over smoothand rough surfaces, resistance coefficient and its variation, flow <strong>in</strong> sudden expansion, contraction,diffusers, bends, valves and siphons, concept of equivalent length, branched pipes, pipes <strong>in</strong> seriesand parallel, simple networks.IX. Flow past Submerged Bodies:Drag and lift, drag on a sphere, cyl<strong>in</strong>der and disc, lift, Magnuseffect and circulation.X. Compressibility Effects <strong>in</strong> pipe Flow:Transmission of pressure waves <strong>in</strong> rigid and elasticpipes, water hammer, analysis of simple surge tank exclud<strong>in</strong>g friction.References:1. Som & Biswas: Introduction of fluid mechanics & Mach<strong>in</strong>es, TMH.2. S.K. Agrawal: Fluid Mechanics & Mach<strong>in</strong>ery, TMH3. Garde, R.J. and A.G. Mirajgaoker, “<strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Fluid Mechanics” (<strong>in</strong>clud<strong>in</strong>g HydraulicMach<strong>in</strong>es), Second Ed. Nemchand & Bros, Roorkee, 19834. Garde, R.J. “Fluid Mechanics through Problems”, Wiley Eastern Limited, New Delhi, 19895. Hunter Rouse, “Elementary Mechanics of Fluids”, John Wiley & Sons, Omc. 19466. L.H. Shames, “Mechanics of Fluids”, McGraw Hill, Int. Student, Education.7. Fluid Mechanics by Jagdish Lal8. Vijay Gupta and S.K. Gupta, “Fluid Mechanics and its Applications”, Villey Eastern Ltd.9. Fluid Mechanics by Modi & Seth.FLUID MECHANICS LAB1. To determ<strong>in</strong>e experimentally the metacentric height of ship model.2. To verify the momentum equation experimentally.3. To determ<strong>in</strong>e the coefficient of discharge of an orifice (or a mouth piece) of a given shape. Also todeterm<strong>in</strong>e the coefficient of velocity and the coefficient of contraction of the orifice (or the mouthpiece)4. To plot the flow net for a given model us<strong>in</strong>g the concept of electrical analogy.5. To measure surface tension of a liquid.6. To calibrate an orifice meter and study the variation of the coefficient of discharge with theReynolds number.7. To verify Darcy’s law and to f<strong>in</strong>e out the coefficient of permeability of the given medium.8. To study the transition from lam<strong>in</strong>ar to turbulent flow and to determ<strong>in</strong>e the lower criticalReynolds number.9. To study the velocity distribution <strong>in</strong> a pipe and also to compute the discharge by <strong>in</strong>tegrat<strong>in</strong>g thevelocity profile.10. To study the variation of friction factor, “f” for turbulent flow <strong>in</strong> smooth and rough commercialpipes.11. To determ<strong>in</strong>e the loss coefficients for the pipe fitt<strong>in</strong>gs.12. To study the flow behavior <strong>in</strong> a pipe bend and to calibrate the pipe bend for deschargemeasurement.13. To study the boundary layer velocity profile and to determ<strong>in</strong>e boundary layer thickness anddisplacement thickness. Also to determ<strong>in</strong>e the exponent <strong>in</strong> the power law of velocity distribution.STRENGTH OF MATERIALS0)Course Code CE-408 CREDIT : 3 (3-0-Introduction: Brief review, concept of stress, stra<strong>in</strong>, ductility, toughness, elastic constants,hardness, brittleness, tension, compression, shear, Brief review of Mohr’s circle for compoundstresses & for pr<strong>in</strong>cipal stresses.

Theories of Failure:Various theories of failure and its comparison.Review of Bend<strong>in</strong>g and Torsion:Brief review of bend<strong>in</strong>g of beams and shear force & bend<strong>in</strong>gmoment diagram. Review of torsion of circular shaft and comb<strong>in</strong>ed bend<strong>in</strong>g & torsion. Shear<strong>in</strong>gstresses <strong>in</strong> beams section.Deflection of Beams: Deflection of beams, Integration method, Macaulay’s method, Area momentmethod, Unit load method.Columns and Struts: Theory of columns & Struts, Eulers and Rank<strong>in</strong>e formulae.Th<strong>in</strong> Cyl<strong>in</strong>ders: Theory of th<strong>in</strong> cyl<strong>in</strong>ders subjected to pressure. Expression for hoop stress andlongitud<strong>in</strong>al stress. Design of th<strong>in</strong> cyl<strong>in</strong>ders.Thick Cyl<strong>in</strong>ders and Spherical Shells:Stresses and stra<strong>in</strong> <strong>in</strong> thick shells/cyl<strong>in</strong>der subjected topressures. Compound cyl<strong>in</strong>ders press fits on solid shaft.Fracture, Fatique and Creep:Stress concentration, Grifith’s formula. Fatigue load<strong>in</strong>g, endurancelimit, Creep.References:1. Strength of Materials by Ryder2. Strength of Materials by S<strong>in</strong>ger3. Strength of Materials by Oimoshenko4. Engg. Mechanics of Solids by Popov5. Mechanics of Materials by Bear Johnson6. Strength of Materials by R.K. Rajput7. Strength of Materials by Ramamrutham & Nara<strong>in</strong>.MATERIAL SCIENCE & TESTINGCourse Code ME-410 CREDIT :4(3-0-1)In troduction: Historical perspective, importance of materials, Brief review of modern & atomicconcepts <strong>in</strong> Physics and Chemistry. Atomic models, Periodic table, Chemical bond<strong>in</strong>gs.Crystallography and Imperfections: Concept of unit cell space lattice, Bravais lattices, commoncrystal structures, Atomic pack<strong>in</strong>g factor and density. Miller <strong>in</strong>dices. X-ray crystallography techniques.Imperfections, Defects & Dislocations <strong>in</strong> solids.Mechanical Properties and Test<strong>in</strong>g: Stress stra<strong>in</strong> diagram, Ductile & brittle material, Stress VsStrength. Toughness, Hardness, Fracture, Fatigue and Creep. Test<strong>in</strong>g such as Strength test<strong>in</strong>gs,Hardness test<strong>in</strong>g, Impact test<strong>in</strong>gs, Fatigue Test<strong>in</strong>g Creep test<strong>in</strong>g, Non-destructive test<strong>in</strong>g (NDT)Microstructural Exam: Microscope pr<strong>in</strong>ciple and methods. Preparation of samples and microstructureexam and gra<strong>in</strong> size determ<strong>in</strong>ation. Comparative study of microstructure of various metals & alloyssuch as Mild steel, CI, Brass.Phase Diagram and Equilibrium Diagram: Unitary and B<strong>in</strong>ary diagrams, Phase rules, Types ofequilibrium diagrams: Solid solution type, eutectic type and comb<strong>in</strong>ation type. Iron-carbon equilibriumdiagram.Ferrous Materials: Iron and steel manufacture, furnaces. Various types of carbon steels alloy steelsand cast irons, its properties and uses.Heat Treatment: Various types of heat treatment such as Anneal<strong>in</strong>g, Normaliz<strong>in</strong>g Quench<strong>in</strong>g,Temper<strong>in</strong>g and case harden<strong>in</strong>g. Time Temperature Transformation (TTT) diagrams.Non-Ferrous metals and alloys:Non-ferrous metals such as Cu, Al, Zn, Cr, Ni, etc. and itsapplications. Various type Brass, Bronze, bear<strong>in</strong>g materials, its properties and uses. Alum<strong>in</strong>um alloyssuch as Duralum<strong>in</strong>. Other advanced materials/alloys.Magnetic Properties: Concept of magnetism-Dia, para, ferro Hysteresis. Soft and har magneticstorages.Electric Properties: Energy ban concept of conductor, <strong>in</strong>sulator and semiconductor. Intr<strong>in</strong>sic &extr<strong>in</strong>sic semi-conductors, P-n junction and transistors. Basic devices and its application. Superconductivity and its applications. Messier effect. Type I & II Superconductors. High TeSuperconductors.

Ceramics: Structure types and properties and applications of ceramics. Mechanical/Electricalbehaviour and process<strong>in</strong>g of plastic.Plastics: Various types of polymers/plastics and its applications. Mechanical behaviors andprocess<strong>in</strong>g of plastics. Future of plastics.Other Materials: Brief description of other material such as concrete, wood, glass etc. and its uses.Performance of materials <strong>in</strong> Service: Brief theoretical consideration of fracture, Fatigue, Creep andCorrosion and its control.References:1. W.D. Callister, Jr.-Material Science & <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Addition Wesly Publish<strong>in</strong>g Co.2. Van Vlash- Elements of Material Science & <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> John Wiley & Sons.3. V. Raghvan- Material Science, Prentice Hall of India4. Narual- Material Science, TMH5. Srivastava, Sr<strong>in</strong>ivasan – Science of Materials <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Newage.MATERIAL SCIENCE AND TESTING LABA. Material Science Lab Experiments: (at least 5 of the follow<strong>in</strong>g)1. Mak<strong>in</strong>g a plastic mould for small metallic specimen.2. Specimen preparation for micro structural exam<strong>in</strong>ation – cutt<strong>in</strong>g, gr<strong>in</strong>d<strong>in</strong>g, polish<strong>in</strong>g, etch<strong>in</strong>g.ENVIRONMENTAL STUDIES-1Course Code SES-415 CREDIT 2(2 – 0 - 0)1: The Multidiscipl<strong>in</strong>ary Nature of Environmental Studies.Def<strong>in</strong>ition, Scope and Importance.(i) Ecosystems.Concept of an Ecosystem.Structure and function of an Ecosystem.Producers,consumers and decomposers.Energy flow <strong>in</strong> he ecosystem.Ecological successsion.Food cha<strong>in</strong>s,food webs and ecological pyramids.Introduction,types,Characteristics features,structures and function of the follow<strong>in</strong>g ecosystem:(a) Forest Ecosystem.(b) Grassland Ecosystem.(c) Desert Ecosystem.(d) Aquatic Ecosystem (Ponds,streams,lakes,rivers,oceans,estuaries).(ii) Social Issues and the EnvironmentFrom unsusta<strong>in</strong>able to susta<strong>in</strong>able development.Urban problems related to energy.Water conservation, ra<strong>in</strong> water harvest<strong>in</strong>g, water shed management.Resettlement and rehabilitation of people; its problems and concerns case studies.Environmental ethics: Issues and possible solutions.Climate change, global warm<strong>in</strong>g, acid ra<strong>in</strong>, ozone layer depletion, nuclear accidents andholocaust,Case studiesWasteland reclamation.Consumerism and waste products.

Environment Protection act.Air (Prevention and Control of Pollution) ActVisit to local polluted site-Urban/Rural/<strong>in</strong>dustrial/Agricultural.Study of Common plants, <strong>in</strong>sects, birds.Study of simple ecosystems-ponds, river. Hillslopes etc(Field work equal to 5 lecture hours).Issues <strong>in</strong>volved <strong>in</strong> enforcement of environmental legislation; public awareness.FOUNDATIONS OF INFORMATION TECHNOLOGYCourse Code COMP-510 CREDIT :5 (2-1-2)Fundamental Concept of InformationInformation Concept and Process<strong>in</strong>g: Def<strong>in</strong>ition of Information, Need of Information, Quality ofInformation, Value of Information, Concept of Information, Entropy Category and Level of <strong>in</strong>formation<strong>in</strong> Bus<strong>in</strong>ess Organization, Data concepts and Data Process<strong>in</strong>g, Data Representation.Information Representation: Information Contents, Introduction to <strong>in</strong>formation representation <strong>in</strong>Digital Media, Text, Images, Graphics, Animation, Audio, Video, Elementary concepts <strong>in</strong> <strong>in</strong>formationPreservence, Data compression, Huffman Cod<strong>in</strong>g, Shannon Pr<strong>in</strong>ciples, Adaptive Compression, LZWCod<strong>in</strong>g, Images Compression, Introduction to Jpeg, Mpeg, Mheg.Compute Programm<strong>in</strong>gComputer Appreciation: Def<strong>in</strong>ition of Electronic computer, History, Generations, Characteristic andapplication of computers, classification of computers, RAM/ROM, Computer Hardware, CPU, Various I/ODevices, Peripherals, Storage Media, Software Def<strong>in</strong>ition.Programm<strong>in</strong>g Language Classification & Program Methodology: Computer Languages, Generations ofLanguages, Introduction to 4 GLS, Software Development Methodology, Life Cycles, Software Cod<strong>in</strong>g,Test<strong>in</strong>g, Ma<strong>in</strong>tenance, Industry Standards, Introduction to ISO, SEI-CMM Standards for IT Industry.Digital Devices and basic Network Concepts: Digital Fundamentals: Various Codes, Decimal, B<strong>in</strong>ary, HexDecimal Conversion, Float<strong>in</strong>g Numbers, Gates, Flip Flops, M<strong>in</strong>imization adder, Multiplexers.Computer Networks and Communication: Need For Data Transmission Over Distances, Types of DataTransmission, Media for Data Transmission, Network<strong>in</strong>g of Computers-Introduction of Lan and WAN,Network Topologies, basic Concepts <strong>in</strong> Computer Networks, Client-Server Architecture, Introduction toAdvanced Communication <strong>Tech</strong>niques, ISDN, ATM, Token Based Protocol, CSMA/CD, MobileCommunication.Internet and Web <strong>Tech</strong>nologiesInternet & World Wide Web: Hypertext Markup Language, DHJML, WWW, Gopher, FTP, Telnet, WebBrowsers, Net Surf<strong>in</strong>g Search Eng<strong>in</strong>es, E-mail, Basic concepts <strong>in</strong> E-Commerce, EDI, Electronic Payments,Digital Signatures, Network, Security, Fireball.Web <strong>Tech</strong>nologies: Elementary Concepts <strong>in</strong>, Object Oriented Programm<strong>in</strong>g, Corba, Com/Dcom, WirelessApplication Protocol, ASP Script<strong>in</strong>g, HTML, Java, Java Applets, WAP, WML, JSP, EJB, XML.Advanced Concepts <strong>in</strong> Information <strong>Tech</strong>nology:IT Industry Trends, Careers and Applications <strong>in</strong> India: Scientific, Bus<strong>in</strong>ess, Educational andenterta<strong>in</strong>ment applications, Industry Automation, Weather forecast<strong>in</strong>g awareness of ongo<strong>in</strong>g IT projects <strong>in</strong>India, NICNET ernet, Application of IT to E Commerce, Electronic Governance, Multimedia, Enterta<strong>in</strong>ment.Suggested Text Books & References:1. Curt<strong>in</strong>, “Information <strong>Tech</strong>nology: Break<strong>in</strong>g News”, Tm + 12. Raja Raman, V. “Introduction to Computers”3. Bajpai, Kushwaha & Yadav, “Intrduction to Computer & C Programm<strong>in</strong>g”, New Age.4. Nelson, “Data Compression”, BPB5. Bharohoke, “Fundamentals of Information <strong>Tech</strong>nology”, Excel6. Peter Nortans “Introduction to Computers”, TM +17. Leon & Leon “Fundamental of Information <strong>Tech</strong>nology”, Vikas Publish<strong>in</strong>g House

8. Kanter, “manag<strong>in</strong>g Information System”9. Lehngart, “Internet 101”, Addision Wesley10. Cistems “Internet, An Introduction”, Tata McGray Hill.IT LABWrite Programs <strong>in</strong> C for the follow<strong>in</strong>g.1. Conversion of B<strong>in</strong>ary to Hexadecimal, Decimal to BCD and vice versa2. LOGIC Design<strong>in</strong>g of gates and flip flops.3. For M<strong>in</strong>imization methods4. Introduction to <strong>in</strong>formation representation <strong>in</strong> digi8tal media text, Images, Graphics, Animations,Audio, Video.5. Dataflow diagram for generation of Prime Numbers6. Demonstrate Different Lan TopologiesWorld Wide Web,File Transfer Protocol,Goffer,Telenet,Web browsers, Search eng<strong>in</strong>e ,Email SitesCreate your own email address us<strong>in</strong>g any of the eng<strong>in</strong>es Ex. ID @ eng<strong>in</strong>e.com7.Institutions may add 4 more experiments as per the availability of expertise available with them.ENGINEERING MATHEMATICS-IIICourse Code MAS –590 Credit (3-1-0) 41. Ord<strong>in</strong>ary Y. Differential Difference Equations: ODE of 2 nd order with constant coefficientsboth homogeneous and non- homogeneous Types with applications to electrical and mechanicalsystems. Difference equations and their Solutions by z transform. Series solutions of ODE of 2 ndorders with variable Coefficients with special emphasis to the differential equations ofLegendre, Bessel and Chebyshev. Legendre’s polynomials, Chabyshev polynomials andBessel’s functions and Their properties.2. Integral Transforms: Fourier transform and <strong>in</strong>tegral Hanker transforms and Hilberttransforms and their Properties, some simple applications. Partial Differential Equations:L<strong>in</strong>ear PDE with constant coefficients of 2 nd order and their classifications, PDE of Parabolic,elliptic and hyperbolic type with illustrative examples. Separation of variables Method forsolv<strong>in</strong>g PDE. Such as two dimensional heat equations, wave equations and Laplace equations.3. Functions of a Complex variable: Analytic (functions, Gauchy- Riemam equations, harmonicfunctions l<strong>in</strong>e <strong>in</strong>tegral <strong>in</strong> the Complex plane, caucry’s Integral theorem cauchy’s <strong>in</strong>tegralformula derivatives of analytic Functions, Liouvilles Theorem, fundamental theorem of Algebrarepresentation of a Function py power series, Taylor’s series and Laurent’s Series, poles,S<strong>in</strong>gularities and Zeros. Residue theorem, evaluation of <strong>in</strong>tegrals us<strong>in</strong>g. Residue theorem.Conformal” Mapp<strong>in</strong>g, l<strong>in</strong>ear fractional transformations, special l<strong>in</strong>ear fractional transformations.Reference:Kreyszig, E. (1993): Advanced Engg. Mathematics 7 th Edition, John Willey & sons <strong>in</strong>c.Paopoulis: Signal Analysis 3 rd Edition (1988) Me Graw Hill .ELECTRICAL MACHINESCourse Code EEE-404 Credit 4(3-0-1)D.C. Mach<strong>in</strong>es:Constructional features and pr<strong>in</strong>ciples of operation of shunt, series and compoundgenerators and motors <strong>in</strong>clud<strong>in</strong>g EMF equation and armature reaction, Performance characteristicsof generators and motors, start<strong>in</strong>g, Speed control and brak<strong>in</strong>g of motors. Two Quadrant and FourQuadrant operation of motors, choice of DC motors for different applications, Losses and efficiency.

Transformers:Construction, EMF equation, Pr<strong>in</strong>ciple of operation, Phasor diagram on no-load,dffect of load, equivalent circuit, Voltage regulation, Losses and efficiency, Tests on transformers,Prediction of efficiency and regulation, Autotransformers, Instrument transformers, Three phasetransformers.Induction Motors:Rotat<strong>in</strong>g magnetic fields, pr<strong>in</strong>ciple of operation, Equivalent circuit, Torque-slipcharacteristic, Starters foe cage and wound rotor type <strong>in</strong>duction motors, Speed control and brak<strong>in</strong>g,S<strong>in</strong>gle Phase <strong>in</strong>duction motors and methods of start<strong>in</strong>g.Synchronous Mach<strong>in</strong>es:Construction, EMF equation, Effect of pitch and distribution, Armaturereaction and determ<strong>in</strong>ation of regulation of synchronous generators, Pr<strong>in</strong>ciple of motor operation,effect of excitation on l<strong>in</strong>e currents (V-curves), methods of synchronization, typical applications ofAC motors <strong>in</strong> <strong>in</strong>dustries.Reference:1. Hughes Edward, Electrical <strong>Tech</strong>nology, Addision Wesley Longman Ltd.2. Nagrath I.J. & Kothari D.P., Electrical Mach<strong>in</strong>es, TMH3. Cotton H., Advanced Electrical <strong>Tech</strong>nology, Wheeler & Co.4. Fitzgerald, K<strong>in</strong>gsley. Kusko, Dumas-Electrical Mach<strong>in</strong>es TMH5. Kosow L.L., electrical Mach<strong>in</strong>ery and Transformers, PHI6. Parker Smith, Electrical <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Problems, CBS.Course Code (ME-405MEASUREMENT & METROLOGYCredit4(2-1-1)1. Mechanical MeasurementsIntroduction: Introduction to Measurement and Measur<strong>in</strong>g <strong>in</strong>struments, Generalized Measur<strong>in</strong>gsystem and functional elements, units of Measurement, static and dynamic performancecharacteristics of Measurement devices, calibration, concept of error, sources of error, statisticalanalysis of errors.Sensors and Transducers: Types of Sensors, types of transducers and their characteristics.Time and Transducers: Counters, Stroboscope, frequency measurement by direct comparisonMeasurement of pressure: Gravitational, direct act<strong>in</strong>g, elastic and <strong>in</strong>direct type pressuretransducers. Measurement of very low pressures.Measurements of Force and Torque: Different types of load cells elastic transducers, Pneumatic& Hydraulic systems.Temperature Measurement: By thermometers, bimetallic, thermocouples, thermostats andpyrometers. Vibration and Noise MeasurementSeismic <strong>in</strong>struments, vibration pick ups and decibel meters, vibrometers accelerometers.Data Acquisition system: Introduction to data acquisition systems, s<strong>in</strong>gle and multi-channelsystem, microprocessors and PC based data acquisition systems. Input-output devices.Signal Transmission and Process<strong>in</strong>g: Devices and Systems.METROLOGYII. Metrology and Inspection: Standards of l<strong>in</strong>ear measurement, l<strong>in</strong>e and end standards. Limit, fitsand tolerances. Interchangeability and standardization.L<strong>in</strong>ear and angular measurements devices and systems.Limit gauges classification, Taylor’s Pr<strong>in</strong>ciple of Gauge Design.Measurement of geometric forms like straightness, flatness, roundness and circularity.Tool makers microscope, profile project autocollimator.

III Interferometer: pr<strong>in</strong>ciple and use of <strong>in</strong>terferometry, optical flat and <strong>in</strong>terferometers, laser<strong>in</strong>terferometers. Measurement of screw threads and gears.Surface texture: quantitative evaluation of surface roughness and its measurement.Suggested Text Books & References:1. Beckwith Thomas G., Mechanical Measurements, Narosa Publish<strong>in</strong>g House, N. Delhi.2. Doeble<strong>in</strong> E.O., “Measurement Systems, Application Design”, McGraw Hill, 19903. Kumar D.S. “Mechanical Measurements and Control”, Metropolitan, N.Delhi.4. Hume K.J., “<strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Metrology”, Mac Donaldd & Co. 1963.5. Gupta, I.C., “<strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Metrology”, Dhanpat Rai & Sons, New Delhi, 1994.6. Sirohi, “Mechanical Measurement”, New Age Publishers7. Ja<strong>in</strong>, R.K., “<strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Met5rology ” Khanna Publishers8. Ja<strong>in</strong> R.K., “Mechanical Measurement” Khanna PublishersKINEMATICS OF MACHINES0)Course Code ME-407 Credit 4(3-1-1. Introduction: L<strong>in</strong>ks, k<strong>in</strong>ematics pairs, l<strong>in</strong>kage mechanisms, <strong>in</strong>versions of slider crank cha<strong>in</strong> anddouble slider crank cha<strong>in</strong>, four bar l<strong>in</strong>kage, mechanisms compound cha<strong>in</strong>s <strong>in</strong> brief.2. Velocity and Acceleration I Mechanisms:Velocity of po<strong>in</strong>t <strong>in</strong> mech., relative velocity method,<strong>in</strong>stantaneous center method, Kennedy’s theorem acc-diagram, acc-centers, Correolis componentsacc., Kle<strong>in</strong>’s construction for slider crank and four bar mech. Analytical method for slider crankmech.3. Mechanism with Lower Parts.:Pantograph straight l<strong>in</strong>e motion mechanisms, Peucellier’sMechanism, hart’s straight l<strong>in</strong>e mech., Scort Rusel mech., analysis of hook’s jo<strong>in</strong>t, <strong>in</strong>troduction tothe analysis of complex mech., Davis and Ackermann steer<strong>in</strong>g gears.4. K<strong>in</strong>ematic Synthesis of Planner L<strong>in</strong>kages: L<strong>in</strong>kages, geometrical methods, 3 position synthesisof coupl<strong>in</strong>g rod, analytical method, fredenstem equation for functions generation.5. Cam s:Classification & term<strong>in</strong>ology law of gear<strong>in</strong>g, geometric & k<strong>in</strong>ematic characteristic of<strong>in</strong>volute, under cutt<strong>in</strong>g & <strong>in</strong>terference, gear tra<strong>in</strong>s (simple, compound & planetary)Books & reference:1. Theory of Mach<strong>in</strong>es Thomas Bevan2. Theory of Mach<strong>in</strong>es and Mechanisms-Shigley.3. Theory of Mach<strong>in</strong>es and Mechanisms – Ghosh and Mullick4. Theory of Mach<strong>in</strong>es & mechanism – Dukhipati.INDUSTRIAL ENGINEERINGCourse Code ME-411Credit4(3-1-0)1. Productivity: Introduction, def<strong>in</strong>ition, measurement, productivity <strong>in</strong>dex, ways to improveproductivity.2. Work study: Mean<strong>in</strong>g and benefits of work study, time and motion study Micromotion studyP.M.T.S. man mach<strong>in</strong>e Diagram flow chart. Motion economy, Method study, work measurement,work sampl<strong>in</strong>g standard time.3. Job Evaluation & Merit Rat<strong>in</strong>g: Job analysis, job description job simplification and job evaluationmethods & description, merit rat<strong>in</strong>g, wage <strong>in</strong>centive plans.4. Plant layout and Materials Handl<strong>in</strong>g: Plant location type of layout, pr<strong>in</strong>ciples of facility layoutpr<strong>in</strong>ciples of material handl<strong>in</strong>g, Material handl<strong>in</strong>g empts.