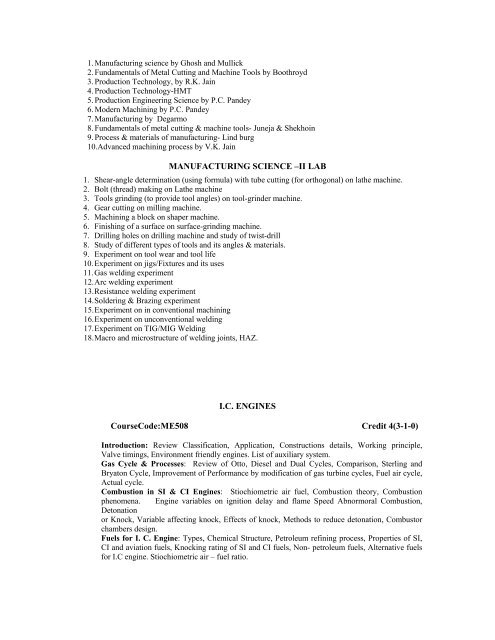

1. Manufactur<strong>in</strong>g science by Ghosh and Mullick2. Fundamentals of Metal Cutt<strong>in</strong>g and Mach<strong>in</strong>e Tools by Boothroyd3. <strong>Production</strong> <strong>Tech</strong>nology, by R.K. Ja<strong>in</strong>4. <strong>Production</strong> <strong>Tech</strong>nology-HMT5. <strong>Production</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Science by P.C. Pandey6. Modern Mach<strong>in</strong><strong>in</strong>g by P.C. Pandey7. Manufactur<strong>in</strong>g by Degarmo8. Fundamentals of metal cutt<strong>in</strong>g & mach<strong>in</strong>e tools- Juneja & Shekho<strong>in</strong>9. Process & materials of manufactur<strong>in</strong>g- L<strong>in</strong>d burg10.Advanced mach<strong>in</strong><strong>in</strong>g process by V.K. Ja<strong>in</strong>MANUFACTURING SCIENCE –II LAB1. Shear-angle determ<strong>in</strong>ation (us<strong>in</strong>g formula) with tube cutt<strong>in</strong>g (for orthogonal) on lathe mach<strong>in</strong>e.2. Bolt (thread) mak<strong>in</strong>g on Lathe mach<strong>in</strong>e3. Tools gr<strong>in</strong>d<strong>in</strong>g (to provide tool angles) on tool-gr<strong>in</strong>der mach<strong>in</strong>e.4. Gear cutt<strong>in</strong>g on mill<strong>in</strong>g mach<strong>in</strong>e.5. Mach<strong>in</strong><strong>in</strong>g a block on shaper mach<strong>in</strong>e.6. F<strong>in</strong>ish<strong>in</strong>g of a surface on surface-gr<strong>in</strong>d<strong>in</strong>g mach<strong>in</strong>e.7. Drill<strong>in</strong>g holes on drill<strong>in</strong>g mach<strong>in</strong>e and study of twist-drill8. Study of different types of tools and its angles & materials.9. Experiment on tool wear and tool life10. Experiment on jigs/Fixtures and its uses11. Gas weld<strong>in</strong>g experiment12. Arc weld<strong>in</strong>g experiment13. Resistance weld<strong>in</strong>g experiment14. Solder<strong>in</strong>g & Braz<strong>in</strong>g experiment15. Experiment on <strong>in</strong> conventional mach<strong>in</strong><strong>in</strong>g16. Experiment on unconventional weld<strong>in</strong>g17. Experiment on TIG/MIG Weld<strong>in</strong>g18. Macro and microstructure of weld<strong>in</strong>g jo<strong>in</strong>ts, HAZ.I.C. ENGINESCourseCode:ME508 Credit 4(3-1-0)Introduction: Review Classification, Application, Constructions details, Work<strong>in</strong>g pr<strong>in</strong>ciple,Valve tim<strong>in</strong>gs, Environment friendly eng<strong>in</strong>es. List of auxiliary system.Gas Cycle & Processes: Review of Otto, Diesel and Dual Cycles, Comparison, Sterl<strong>in</strong>g andBryaton Cycle, Improvement of Performance by modification of gas turb<strong>in</strong>e cycles, Fuel air cycle,Actual cycle.Combustion <strong>in</strong> SI & CI Eng<strong>in</strong>es: Stiochiometric air fuel, Combustion theory, Combustionphenomena. Eng<strong>in</strong>e variables on ignition delay and flame Speed Abnormoral Combustion,Detonationor Knock, Variable affect<strong>in</strong>g knock, Effects of knock, Methods to r<strong>edu</strong>ce detonation, Combustorchambers design.Fuels for I. C. Eng<strong>in</strong>e: Types, Chemical Structure, Petroleum ref<strong>in</strong><strong>in</strong>g process, Properties of SI,CI and aviation fuels, Knock<strong>in</strong>g rat<strong>in</strong>g of SI and CI fuels, Non- petroleum fuels, Alternative fuelsfor I.C eng<strong>in</strong>e. Stiochiometric air – fuel ratio.

Carburetion and gasol<strong>in</strong>e Injection: Intake and exhaust system, Eng<strong>in</strong>e air-fuel requirement,Simple carburetor, Complete carburetor and its elements, Types, Fuel pump, Fuel system, Multipo<strong>in</strong>tfuel <strong>in</strong>jection system. Govern<strong>in</strong>g of SI eng<strong>in</strong>es.C.I. Fuel Injection System: Requirements of <strong>in</strong>jection system, Types, Injection pump, Govern<strong>in</strong>g,Fuel <strong>in</strong>jector, Injector nozzle.Ignition System: Requirements, Types – Battery and Magneto ignition system, Spark plug, Contactbreaker, Dual angle, Fir<strong>in</strong>g order , Spark advance mechanism , Electronic ignition systemsEng<strong>in</strong>e Friction and Lubrication: Total eng<strong>in</strong>e friction, Factors affect<strong>in</strong>g eng<strong>in</strong>e friction,Lubrication, Mechanism of lubrication, Lubricants and their properties, Additives, Lubricationsystems.Eng<strong>in</strong>e Cool<strong>in</strong>g System: Necessity of cool<strong>in</strong>g, Heat transfer and energy balance, Parametersaffect<strong>in</strong>g eng<strong>in</strong>e heat transfer, Cool<strong>in</strong>g system.Supercharg<strong>in</strong>g : Objective, Methods, Turbocharger, performance.Two- stroke Eng<strong>in</strong>es: Classification, Scaveng<strong>in</strong>g processes, advantages and disadvantages,Performance.Measurement, Test<strong>in</strong>g & Performance: Performance parameters, Type of tests – speed fuel andair consumption, friction, Indicated and brake power, Performance characteristics, Heat balancesheet.Air Pollution and Control: Sources and classification, Effects of air pollution, Pollutants from I.C. eng<strong>in</strong>es, Mechanism of formation of pollutants, Particulate emissions, Exhaust gas treatment.References:1. I.C. eng<strong>in</strong>e Analysis and practice –E.F. obert2. A Course <strong>in</strong> <strong>in</strong>ternal combustion eng<strong>in</strong>es –M.L. Mathur & R.P. Sharma, Dhanpat, Rai & sons,New Delhi.3. Internal combustion eng<strong>in</strong>es- Maleev4. Heat Engg.-Vasandani & Kumar5. Internal Combustion Eng<strong>in</strong>e-Gill and Smith6. Internal combustion Eng<strong>in</strong>es and Air Pollution- R. Yadav, CPH, Allahabad7. I.C. Eng<strong>in</strong>es by V. Ganesam, TMH8. Internal combustion Eng<strong>in</strong>e- Heywood, Mc-Graw HillTOOL DESIGN1)Course Code (ME-501) Credit: 4(3-0-1.Broad classification of Tools‐cutt<strong>in</strong>g tools. Dies. Hold<strong>in</strong>g and measur<strong>in</strong>g tools2.Design of cutt<strong>in</strong>g tools : S<strong>in</strong>gle po<strong>in</strong>t and multipo<strong>in</strong>t cutt<strong>in</strong>g tools .S<strong>in</strong>gle po<strong>in</strong>t cutt<strong>in</strong>g tools : Classification. Nomenclature . geometry . design of s<strong>in</strong>gle po<strong>in</strong>t tools forShapers . planers . etc. Chip breakers and their design.Multipo<strong>in</strong>t Cutt<strong>in</strong>g Tools :Classification and specification. Nomenclature. Design of drills , mill<strong>in</strong>g cuttersBroaches, taps etc.Design of form tools : Flat and circular form tools, their design and application.3.Design of Dies : Classification of Dies , Design of Dies for bulk metal deformation , ‐ wire draw<strong>in</strong>g ,Extrusion, Forg<strong>in</strong>g and Roll<strong>in</strong>g . Design of Dies for sheet metal , Blank<strong>in</strong>g and Pierc<strong>in</strong>g . Bend<strong>in</strong>g andDeep draw<strong>in</strong>g . Design of Dies for Cast<strong>in</strong>g and Mould<strong>in</strong>g . Power Metallurgy die design .4 Design of Jigs and Fixtures : Classification of Jigs and Fixtures , Fundamental Pr<strong>in</strong>ciples of design of jigs andfixtures, Location and clamp<strong>in</strong>g <strong>in</strong> jigs and fixtures , Simple design of drill<strong>in</strong>g jigs, mill<strong>in</strong>g fixtures , etc.<strong>in</strong>dex<strong>in</strong>g jigs and fixtures .

- Page 1 and 2: B. Tech. Production & IndustrialEng

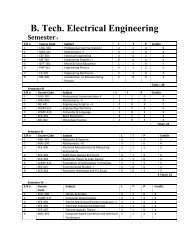

- Page 3 and 4: 6 ME 516 Energy Management 3‐1‐

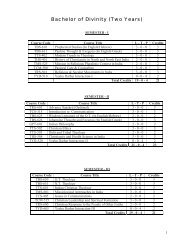

- Page 5 and 6: Sin, orign of sin, manifestation of

- Page 7 and 8: Center of gravity, centroids of lin

- Page 9 and 10: 2. To determine the Ferrous content

- Page 11 and 12: 6. Study of Scientific and General

- Page 13 and 14: 6. X-Rays: Origin of X-rays, Contin

- Page 15 and 16: 11. Write C program to demonstrate

- Page 17 and 18: Steam Turbines: Classification, imp

- Page 19 and 20: Theories of Failure:Various theorie

- Page 21 and 22: Environment Protection act.Air (Pre

- Page 23 and 24: Transformers:Construction, EMF equa

- Page 25 and 26: 5. Production Planning and Control:

- Page 27 and 28: Interpolation:Introduction, Errors

- Page 29 and 30: Note-1. Students may be advised to

- Page 31: Mental blocks, Removal blocks, Idea

- Page 35 and 36: With initial review teaching of Aut

- Page 37 and 38: 2. Conventional energy resources an

- Page 39 and 40: Array, matrix, string, structure, c

- Page 41 and 42: Generals requirements, Road, tyre a

- Page 43 and 44: INTRODUCTION : Past , Present and f

- Page 45 and 46: Study of the design aspects. Fluid

- Page 47: MECHANICAL VIBRATIONCourse Code ME-