III Interferometer: pr<strong>in</strong>ciple and use of <strong>in</strong>terferometry, optical flat and <strong>in</strong>terferometers, laser<strong>in</strong>terferometers. Measurement of screw threads and gears.Surface texture: quantitative evaluation of surface roughness and its measurement.Suggested Text Books & References:1. Beckwith Thomas G., Mechanical Measurements, Narosa Publish<strong>in</strong>g House, N. Delhi.2. Doeble<strong>in</strong> E.O., “Measurement Systems, Application Design”, McGraw Hill, 19903. Kumar D.S. “Mechanical Measurements and Control”, Metropolitan, N.Delhi.4. Hume K.J., “<strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Metrology”, Mac Donaldd & Co. 1963.5. Gupta, I.C., “<strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Metrology”, Dhanpat Rai & Sons, New Delhi, 1994.6. Sirohi, “Mechanical Measurement”, New Age Publishers7. Ja<strong>in</strong>, R.K., “<strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> Met5rology ” Khanna Publishers8. Ja<strong>in</strong> R.K., “Mechanical Measurement” Khanna PublishersKINEMATICS OF MACHINES0)Course Code ME-407 Credit 4(3-1-1. Introduction: L<strong>in</strong>ks, k<strong>in</strong>ematics pairs, l<strong>in</strong>kage mechanisms, <strong>in</strong>versions of slider crank cha<strong>in</strong> anddouble slider crank cha<strong>in</strong>, four bar l<strong>in</strong>kage, mechanisms compound cha<strong>in</strong>s <strong>in</strong> brief.2. Velocity and Acceleration I Mechanisms:Velocity of po<strong>in</strong>t <strong>in</strong> mech., relative velocity method,<strong>in</strong>stantaneous center method, Kennedy’s theorem acc-diagram, acc-centers, Correolis componentsacc., Kle<strong>in</strong>’s construction for slider crank and four bar mech. Analytical method for slider crankmech.3. Mechanism with Lower Parts.:Pantograph straight l<strong>in</strong>e motion mechanisms, Peucellier’sMechanism, hart’s straight l<strong>in</strong>e mech., Scort Rusel mech., analysis of hook’s jo<strong>in</strong>t, <strong>in</strong>troduction tothe analysis of complex mech., Davis and Ackermann steer<strong>in</strong>g gears.4. K<strong>in</strong>ematic Synthesis of Planner L<strong>in</strong>kages: L<strong>in</strong>kages, geometrical methods, 3 position synthesisof coupl<strong>in</strong>g rod, analytical method, fredenstem equation for functions generation.5. Cam s:Classification & term<strong>in</strong>ology law of gear<strong>in</strong>g, geometric & k<strong>in</strong>ematic characteristic of<strong>in</strong>volute, under cutt<strong>in</strong>g & <strong>in</strong>terference, gear tra<strong>in</strong>s (simple, compound & planetary)Books & reference:1. Theory of Mach<strong>in</strong>es Thomas Bevan2. Theory of Mach<strong>in</strong>es and Mechanisms-Shigley.3. Theory of Mach<strong>in</strong>es and Mechanisms – Ghosh and Mullick4. Theory of Mach<strong>in</strong>es & mechanism – Dukhipati.INDUSTRIAL ENGINEERINGCourse Code ME-411Credit4(3-1-0)1. Productivity: Introduction, def<strong>in</strong>ition, measurement, productivity <strong>in</strong>dex, ways to improveproductivity.2. Work study: Mean<strong>in</strong>g and benefits of work study, time and motion study Micromotion studyP.M.T.S. man mach<strong>in</strong>e Diagram flow chart. Motion economy, Method study, work measurement,work sampl<strong>in</strong>g standard time.3. Job Evaluation & Merit Rat<strong>in</strong>g: Job analysis, job description job simplification and job evaluationmethods & description, merit rat<strong>in</strong>g, wage <strong>in</strong>centive plans.4. Plant layout and Materials Handl<strong>in</strong>g: Plant location type of layout, pr<strong>in</strong>ciples of facility layoutpr<strong>in</strong>ciples of material handl<strong>in</strong>g, Material handl<strong>in</strong>g empts.

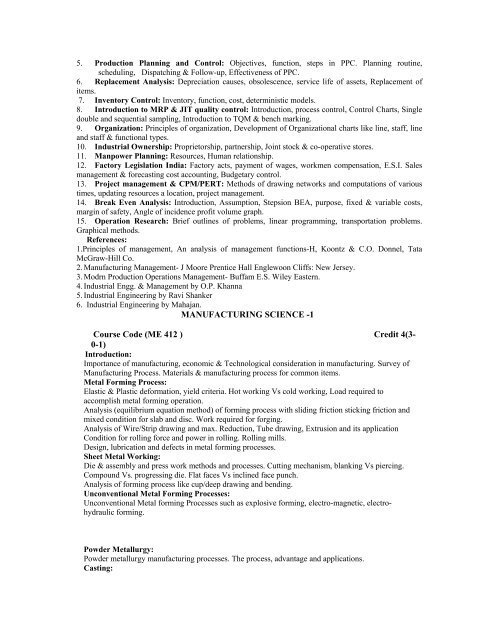

5. <strong>Production</strong> Plann<strong>in</strong>g and Control: Objectives, function, steps <strong>in</strong> PPC. Plann<strong>in</strong>g rout<strong>in</strong>e,sch<strong>edu</strong>l<strong>in</strong>g, Dispatch<strong>in</strong>g & Follow-up, Effectiveness of PPC.6. Replacement Analysis: Depreciation causes, obsolescence, service life of assets, Replacement ofitems.7. Inventory Control: Inventory, function, cost, determ<strong>in</strong>istic models.8. Introduction to MRP & JIT quality control: Introduction, process control, Control Charts, S<strong>in</strong>gledouble and sequential sampl<strong>in</strong>g, Introduction to TQM & bench mark<strong>in</strong>g.9. Organization: Pr<strong>in</strong>ciples of organization, Development of Organizational charts like l<strong>in</strong>e, staff, l<strong>in</strong>eand staff & functional types.10. <strong>Industrial</strong> Ownership: Proprietorship, partnership, Jo<strong>in</strong>t stock & co-operative stores.11. Manpower Plann<strong>in</strong>g: Resources, Human relationship.12. Factory Legislation India: Factory acts, payment of wages, workmen compensation, E.S.I. Salesmanagement & forecast<strong>in</strong>g cost account<strong>in</strong>g, Budgetary control.13. Project management & CPM/PERT: Methods of draw<strong>in</strong>g networks and computations of varioustimes, updat<strong>in</strong>g resources a location, project management.14. Break Even Analysis: Introduction, Assumption, Stepsion BEA, purpose, fixed & variable costs,marg<strong>in</strong> of safety, Angle of <strong>in</strong>cidence profit volume graph.15. Operation Research: Brief outl<strong>in</strong>es of problems, l<strong>in</strong>ear programm<strong>in</strong>g, transportation problems.Graphical methods.References:1.Pr<strong>in</strong>ciples of management, An analysis of management functions-H, Koontz & C.O. Donnel, TataMcGraw-Hill Co.2. Manufactur<strong>in</strong>g Management- J Moore Prentice Hall Englewoon Cliffs: New Jersey.3. Modrn <strong>Production</strong> Operations Management- Buffam E.S. Wiley Eastern.4. <strong>Industrial</strong> Engg. & Management by O.P. Khanna5. <strong>Industrial</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> by Ravi Shanker6. <strong>Industrial</strong> <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong> by Mahajan.MANUFACTURING SCIENCE -1Course Code (ME 412 ) Credit 4(3-0-1)Introduction:Importance of manufactur<strong>in</strong>g, economic & <strong>Tech</strong>nological consideration <strong>in</strong> manufactur<strong>in</strong>g. Survey ofManufactur<strong>in</strong>g Process. Materials & manufactur<strong>in</strong>g process for common items.Metal Form<strong>in</strong>g Process:Elastic & Plastic deformation, yield criteria. Hot work<strong>in</strong>g Vs cold work<strong>in</strong>g, Load required toaccomplish metal form<strong>in</strong>g operation.Analysis (equilibrium equation method) of form<strong>in</strong>g process with slid<strong>in</strong>g friction stick<strong>in</strong>g friction andmixed condition for slab and disc. Work required for forg<strong>in</strong>g.Analysis of Wire/Strip draw<strong>in</strong>g and max. R<strong>edu</strong>ction, Tube draw<strong>in</strong>g, Extrusion and its applicationCondition for roll<strong>in</strong>g force and power <strong>in</strong> roll<strong>in</strong>g. Roll<strong>in</strong>g mills.Design, lubrication and defects <strong>in</strong> metal form<strong>in</strong>g processes.Sheet Metal Work<strong>in</strong>g:Die & assembly and press work methods and processes. Cutt<strong>in</strong>g mechanism, blank<strong>in</strong>g Vs pierc<strong>in</strong>g.Compound Vs. progress<strong>in</strong>g die. Flat faces Vs <strong>in</strong>cl<strong>in</strong>ed face punch.Analysis of form<strong>in</strong>g process like cup/deep draw<strong>in</strong>g and bend<strong>in</strong>g.Unconventional Metal Form<strong>in</strong>g Processes:Unconventional Metal form<strong>in</strong>g Processes such as explosive form<strong>in</strong>g, electro-magnetic, electrohydraulicform<strong>in</strong>g.Powder Metallurgy:Powder metallurgy manufactur<strong>in</strong>g processes. The process, advantage and applications.Cast<strong>in</strong>g:

- Page 1 and 2: B. Tech. Production & IndustrialEng

- Page 3 and 4: 6 ME 516 Energy Management 3‐1‐

- Page 5 and 6: Sin, orign of sin, manifestation of

- Page 7 and 8: Center of gravity, centroids of lin

- Page 9 and 10: 2. To determine the Ferrous content

- Page 11 and 12: 6. Study of Scientific and General

- Page 13 and 14: 6. X-Rays: Origin of X-rays, Contin

- Page 15 and 16: 11. Write C program to demonstrate

- Page 17 and 18: Steam Turbines: Classification, imp

- Page 19 and 20: Theories of Failure:Various theorie

- Page 21 and 22: Environment Protection act.Air (Pre

- Page 23: Transformers:Construction, EMF equa

- Page 27 and 28: Interpolation:Introduction, Errors

- Page 29 and 30: Note-1. Students may be advised to

- Page 31 and 32: Mental blocks, Removal blocks, Idea

- Page 33 and 34: Carburetion and gasoline Injection:

- Page 35 and 36: With initial review teaching of Aut

- Page 37 and 38: 2. Conventional energy resources an

- Page 39 and 40: Array, matrix, string, structure, c

- Page 41 and 42: Generals requirements, Road, tyre a

- Page 43 and 44: INTRODUCTION : Past , Present and f

- Page 45 and 46: Study of the design aspects. Fluid

- Page 47: MECHANICAL VIBRATIONCourse Code ME-