B. Tech. Production & Industrial Engineering - Shiats.edu.in

B. Tech. Production & Industrial Engineering - Shiats.edu.in

B. Tech. Production & Industrial Engineering - Shiats.edu.in

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

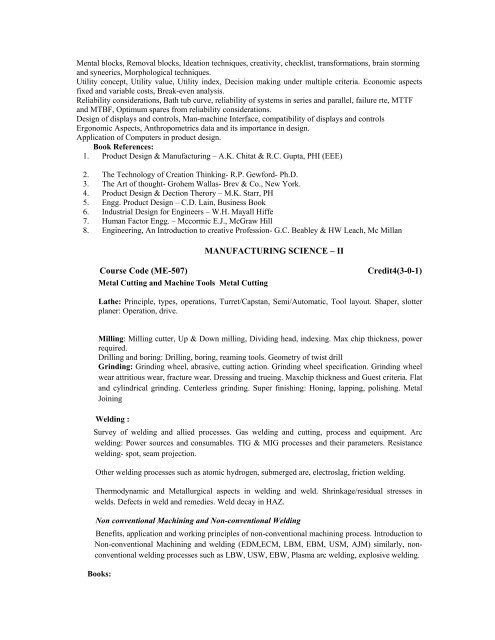

Mental blocks, Removal blocks, Ideation techniques, creativity, checklist, transformations, bra<strong>in</strong> storm<strong>in</strong>gand syneerics, Morphological techniques.Utility concept, Utility value, Utility <strong>in</strong>dex, Decision mak<strong>in</strong>g under multiple criteria. Economic aspectsfixed and variable costs, Break-even analysis.Reliability considerations, Bath tub curve, reliability of systems <strong>in</strong> series and parallel, failure rte, MTTFand MTBF, Optimum spares from reliability considerations.Design of displays and controls, Man-mach<strong>in</strong>e Interface, compatibility of displays and controlsErgonomic Aspects, Anthropometrics data and its importance <strong>in</strong> design.Application of Computers <strong>in</strong> product design.Book References:1. Product Design & Manufactur<strong>in</strong>g – A.K. Chitat & R.C. Gupta, PHI (EEE)2. The <strong>Tech</strong>nology of Creation Th<strong>in</strong>k<strong>in</strong>g- R.P. Gewford- Ph.D.3. The Art of thought- Grohem Wallas- Brev & Co., New York.4. Product Design & Dection Therory – M.K. Starr, PH5. Engg. Product Design – C.D. La<strong>in</strong>, Bus<strong>in</strong>ess Book6. <strong>Industrial</strong> Design for Eng<strong>in</strong>eers – W.H. Mayall Hiffe7. Human Factor Engg. – Mccormic E.J., McGraw Hill8. <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong>, An Introduction to creative Profession- G.C. Beabley & HW Leach, Mc MillanMANUFACTURING SCIENCE – IICourse Code (ME-507)Metal Cutt<strong>in</strong>g and Mach<strong>in</strong>e Tools Metal Cutt<strong>in</strong>gCredit4(3-0-1)Lathe: Pr<strong>in</strong>ciple, types, operations, Turret/Capstan, Semi/Automatic, Tool layout. Shaper, slotterplaner: Operation, drive.Mill<strong>in</strong>g: Mill<strong>in</strong>g cutter, Up & Down mill<strong>in</strong>g, Divid<strong>in</strong>g head, <strong>in</strong>dex<strong>in</strong>g. Max chip thickness, powerrequired.Drill<strong>in</strong>g and bor<strong>in</strong>g: Drill<strong>in</strong>g, bor<strong>in</strong>g, ream<strong>in</strong>g tools. Geometry of twist drillGr<strong>in</strong>d<strong>in</strong>g: Gr<strong>in</strong>d<strong>in</strong>g wheel, abrasive, cutt<strong>in</strong>g action. Gr<strong>in</strong>d<strong>in</strong>g wheel specification. Gr<strong>in</strong>d<strong>in</strong>g wheelwear attritious wear, fracture wear. Dress<strong>in</strong>g and true<strong>in</strong>g. Maxchip thickness and Guest criteria. Flatand cyl<strong>in</strong>drical gr<strong>in</strong>d<strong>in</strong>g. Centerless gr<strong>in</strong>d<strong>in</strong>g. Super f<strong>in</strong>ish<strong>in</strong>g: Hon<strong>in</strong>g, lapp<strong>in</strong>g, polish<strong>in</strong>g. MetalJo<strong>in</strong><strong>in</strong>gWeld<strong>in</strong>g :Survey of weld<strong>in</strong>g and allied processes. Gas weld<strong>in</strong>g and cutt<strong>in</strong>g, process and equipment. Arcweld<strong>in</strong>g: Power sources and consumables. TIG & MIG processes and their parameters. Resistanceweld<strong>in</strong>g- spot, seam projection.Other weld<strong>in</strong>g processes such as atomic hydrogen, submerged are, electroslag, friction weld<strong>in</strong>g.Thermodynamic and Metallurgical aspects <strong>in</strong> weld<strong>in</strong>g and weld. Shr<strong>in</strong>kage/residual stresses <strong>in</strong>welds. Defects <strong>in</strong> weld and remedies. Weld decay <strong>in</strong> HAZ.Non conventional Mach<strong>in</strong><strong>in</strong>g and Non-conventional Weld<strong>in</strong>gBenefits, application and work<strong>in</strong>g pr<strong>in</strong>ciples of non-conventional mach<strong>in</strong><strong>in</strong>g process. Introduction toNon-conventional Mach<strong>in</strong><strong>in</strong>g and weld<strong>in</strong>g (EDM,ECM, LBM, EBM, USM, AJM) similarly, nonconventionalweld<strong>in</strong>g processes such as LBW, USW, EBW, Plasma arc weld<strong>in</strong>g, explosive weld<strong>in</strong>g.Books: