Signals System and actuat<strong>in</strong>g devices; real time <strong>in</strong>terfac<strong>in</strong>g. Applications of? Mechatronics <strong>in</strong> Manufactur<strong>in</strong>gand Automation Case Studies.METAL FORMING1- Fundaments of Elasticity, Plasticity and Viscoplastcity, Stress and stra<strong>in</strong> <strong>in</strong>variant?Elesticity- State?? of stress and stra<strong>in</strong>, stress-stra<strong>in</strong> relations,? stra<strong>in</strong>-displacement relations.Plasticity and Viscoplasticity: Yeld?? criterian, effective stress and stra<strong>in</strong>, state of plastic stra<strong>in</strong>,Plastic stra<strong>in</strong> rate, Flow rule, Effective stra<strong>in</strong> rate, plastic anisotropy and viscoplasticity(determ<strong>in</strong>ation of load and power) concept of solid and flow formulations.?2- Analysiz of Deformation Processes us<strong>in</strong>g SSM, UBM & SLMPla<strong>in</strong> stra<strong>in</strong> Problems: Draw<strong>in</strong>g and Extrusion of sheet, Roll<strong>in</strong>g and forg<strong>in</strong>g of strips.Axisymmetric?? Problems: Draw<strong>in</strong>g and Extrusion of bar and tube, forg<strong>in</strong>g of solid and Hallowdisc.Sheet metal problems: Axisymmetric deep draw<strong>in</strong>g and stretch<strong>in</strong>g.ENERGY CONSERVATIONCourse Code ME-674 CREDIT : 3(3-0-0)1.Introduction: The energy crisis and options: the energy conservation option, energy <strong>in</strong>tensity ofdeveloped and develop<strong>in</strong>g economies, energy audit<strong>in</strong>g ? basic requirements, scope and purpose,process energy and gross energy requirements.2.Efficient energy conversion: efficient combustion, waste as a fuel, comb<strong>in</strong>ed cycles for efficientpower generation, comb<strong>in</strong>ed heat and power plants, comb<strong>in</strong>ed cool<strong>in</strong>g and power plants.3. Energy recovery: <strong>in</strong>sulation: <strong>in</strong>sulat<strong>in</strong>g materials, economic thickness of <strong>in</strong>sulation; heat recoveryheat exchangers: recuperative heat exchangers, run-around coil systems, regenerative heat exchangers;heat pumps; and heat-pipes.4. Process <strong>in</strong>tegration: basic concepts of p<strong>in</strong>ch technology, stream networks, significance of the p<strong>in</strong>ch,design of energy recovery system.5. Energy conservation <strong>in</strong> build<strong>in</strong>gs: degree-days, steady state loads and comfort. Condition<strong>in</strong>g the airfor process requirements and human comfort, thermal performance monitor<strong>in</strong>g, efficient light<strong>in</strong>gsystems, solar passive features.6. Economics of energy sav<strong>in</strong>g schemes and case studies.REFERENCES(A) Energy efficiency? by Eastop and Croft, Longman Scientific and <strong>Tech</strong>nical, 1990(B) Manag<strong>in</strong>g energy <strong>in</strong> commerce and <strong>in</strong>dustry? by Gordon A Payne, Butterworths, 1984.CAD OF THERMAL SYSTEMSCourse Code ME-675 CREDIT : 3 (3-0-0)

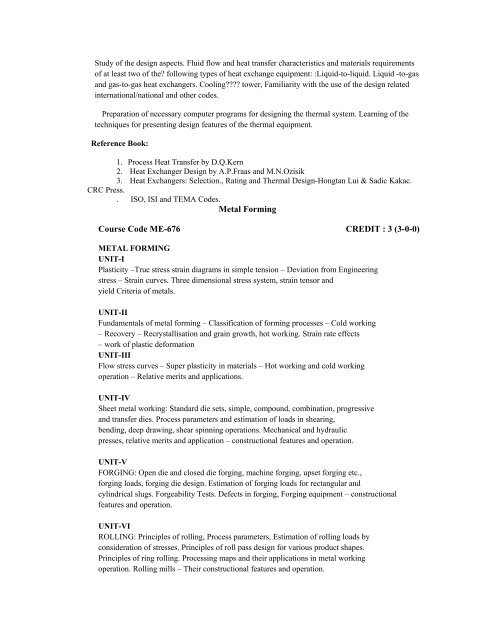

Study of the design aspects. Fluid flow and heat transfer characteristics and materials requirementsof at least two of the? follow<strong>in</strong>g types of heat exchange equipment: :Liquid-to-liquid. Liquid -to-gasand gas-to-gas heat exchangers. Cool<strong>in</strong>g???? tower, Familiarity with the use of the design related<strong>in</strong>ternational/national and other codes.Preparation of necessary computer programs for design<strong>in</strong>g the thermal system. Learn<strong>in</strong>g of thetechniques for present<strong>in</strong>g design features of the thermal equipment.Reference Book:1. Process Heat Transfer by D.Q.Kern2. Heat Exchanger Design by A.P.Fraas and M.N.Ozisik3. Heat Exchangers: Selection., Rat<strong>in</strong>g and Thermal Design-Hongtan Lui & Sadic Kakac.CRC Press.. ISO, ISI and TEMA Codes.Metal Form<strong>in</strong>gCourse Code ME-676 CREDIT : 3 (3-0-0)METAL FORMINGUNIT-IPlasticity –True stress stra<strong>in</strong> diagrams <strong>in</strong> simple tension – Deviation from <strong>Eng<strong>in</strong>eer<strong>in</strong>g</strong>stress – Stra<strong>in</strong> curves. Three dimensional stress system, stra<strong>in</strong> tensor andyield Criteria of metals.UNIT-IIFundamentals of metal form<strong>in</strong>g – Classification of form<strong>in</strong>g processes – Cold work<strong>in</strong>g– Recovery – Recrystallisation and gra<strong>in</strong> growth, hot work<strong>in</strong>g. Stra<strong>in</strong> rate effects– work of plastic deformationUNIT-IIIFlow stress curves – Super plasticity <strong>in</strong> materials – Hot work<strong>in</strong>g and cold work<strong>in</strong>goperation – Relative merits and applications.UNIT-IVSheet metal work<strong>in</strong>g: Standard die sets, simple, compound, comb<strong>in</strong>ation, progressiveand transfer dies. Process parameters and estimation of loads <strong>in</strong> shear<strong>in</strong>g,bend<strong>in</strong>g, deep draw<strong>in</strong>g, shear sp<strong>in</strong>n<strong>in</strong>g operations. Mechanical and hydraulicpresses, relative merits and application – constructional features and operation.UNIT-VFORGING: Open die and closed die forg<strong>in</strong>g, mach<strong>in</strong>e forg<strong>in</strong>g, upset forg<strong>in</strong>g etc.,forg<strong>in</strong>g loads, forg<strong>in</strong>g die design. Estimation of forg<strong>in</strong>g loads for rectangular andcyl<strong>in</strong>drical slugs. Forgeability Tests. Defects <strong>in</strong> forg<strong>in</strong>g, Forg<strong>in</strong>g equipment – constructionalfeatures and operation.UNIT-VIROLLING: Pr<strong>in</strong>ciples of roll<strong>in</strong>g, Process parameters, Estimation of roll<strong>in</strong>g loads byconsideration of stresses. Pr<strong>in</strong>ciples of roll pass design for various product shapes.Pr<strong>in</strong>ciples of r<strong>in</strong>g roll<strong>in</strong>g. Process<strong>in</strong>g maps and their applications <strong>in</strong> metal work<strong>in</strong>goperation. Roll<strong>in</strong>g mills – Their constructional features and operation.

- Page 1 and 2: B. Tech. Production & IndustrialEng

- Page 3 and 4: 6 ME 516 Energy Management 3‐1‐

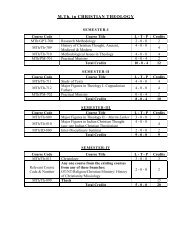

- Page 5 and 6: Sin, orign of sin, manifestation of

- Page 7 and 8: Center of gravity, centroids of lin

- Page 9 and 10: 2. To determine the Ferrous content

- Page 11 and 12: 6. Study of Scientific and General

- Page 13 and 14: 6. X-Rays: Origin of X-rays, Contin

- Page 15 and 16: 11. Write C program to demonstrate

- Page 17 and 18: Steam Turbines: Classification, imp

- Page 19 and 20: Theories of Failure:Various theorie

- Page 21 and 22: Environment Protection act.Air (Pre

- Page 23 and 24: Transformers:Construction, EMF equa

- Page 25 and 26: 5. Production Planning and Control:

- Page 27 and 28: Interpolation:Introduction, Errors

- Page 29 and 30: Note-1. Students may be advised to

- Page 31 and 32: Mental blocks, Removal blocks, Idea

- Page 33 and 34: Carburetion and gasoline Injection:

- Page 35 and 36: With initial review teaching of Aut

- Page 37 and 38: 2. Conventional energy resources an

- Page 39 and 40: Array, matrix, string, structure, c

- Page 41 and 42: Generals requirements, Road, tyre a

- Page 43: INTRODUCTION : Past , Present and f

- Page 47: MECHANICAL VIBRATIONCourse Code ME-