You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

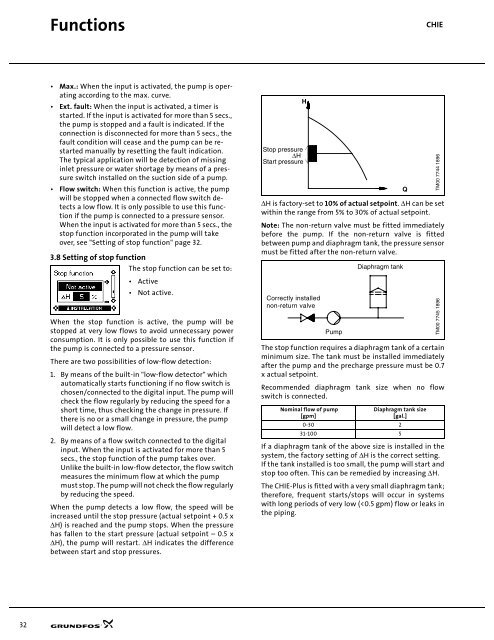

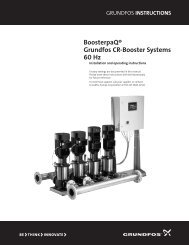

Functions<strong>CHI</strong>E• Max.: When the input is activated, the pump is operatingaccording to the max. curve.• Ext. fault: When the input is activated, a timer isstarted. If the input is activated for more than 5 secs.,the pump is stopped and a fault is indicated. If theconnection is disconnected for more than 5 secs., thefault condition will cease and the pump can be restartedmanually by resetting the fault indication.The typical application will be detection of missinginlet pressure or water shortage by means of a pressureswitch installed on the suction side of a pump.• Flow switch: When this function is active, the pumpwill be stopped when a connected flow switch detectsa low flow. It is only possible to use this functionif the pump is connected to a pressure sensor.When the input is activated for more than 5 secs., thestop function incorporated in the pump will takeover, see "Setting of stop function" page 32.3.8 Setting of stop functionThe stop function can be set to:• Active• Not active.When the stop function is active, the pump will bestopped at very low flows to avoid unnecessary powerconsumption. It is only possible to use this function ifthe pump is connected to a pressure sensor.There are two possibilities of low-flow detection:1. By means of the built-in "low-flow detector" whichautomatically starts functioning if no flow switch ischosen/connected to the digital input. The pump willcheck the flow regularly by reducing the speed for ashort time, thus checking the change in pressure. Ifthere is no or a small change in pressure, the pumpwill detect a low flow.2. By means of a flow switch connected to the digitalinput. When the input is activated for more than 5secs., the stop function of the pump takes over.Unlike the built-in low-flow detector, the flow switchmeasures the minimum flow at which the pumpmust stop. The pump will not check the flow regularlyby reducing the speed.When the pump detects a low flow, the speed will beincreased until the stop pressure (actual setpoint + 0.5 x∆H) is reached and the pump stops. When the pressurehas fallen to the start pressure (actual setpoint – 0.5 x∆H), the pump will restart. ∆H indicates the differencebetween start and stop pressures.HStop pressure∆HStart pressure∆H is factory-set to 10% of actual setpoint. ∆H can be setwithin the range from 5% to 30% of actual setpoint.Note: The non-return valve must be fitted immediatelybefore the pump. If the non-return valve is fittedbetween pump and diaphragm tank, the pressure sensormust be fitted after the non-return valve.Correctly installednon-return valve<strong>Pump</strong>The stop function requires a diaphragm tank of a certainminimum size. The tank must be installed immediatelyafter the pump and the precharge pressure must be 0.7x actual setpoint.Recommended diaphragm tank size when no flowswitch is connected.Nominal flow of pump[gpm]Diaphragm tankDiaphragm tank size[gal.]0-30 231-100 5If a diaphragm tank of the above size is installed in thesystem, the factory setting of ∆H is the correct setting.If the tank installed is too small, the pump will start andstop too often. This can be remedied by increasing ∆H.The <strong>CHI</strong>E-Plus is fitted with a very small diaphragm tank;therefore, frequent starts/stops will occur in systemswith long periods of very low (