Model YPC Two-Stage Steam-Fired Absorption ... - Usair-eng.com

Model YPC Two-Stage Steam-Fired Absorption ... - Usair-eng.com

Model YPC Two-Stage Steam-Fired Absorption ... - Usair-eng.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

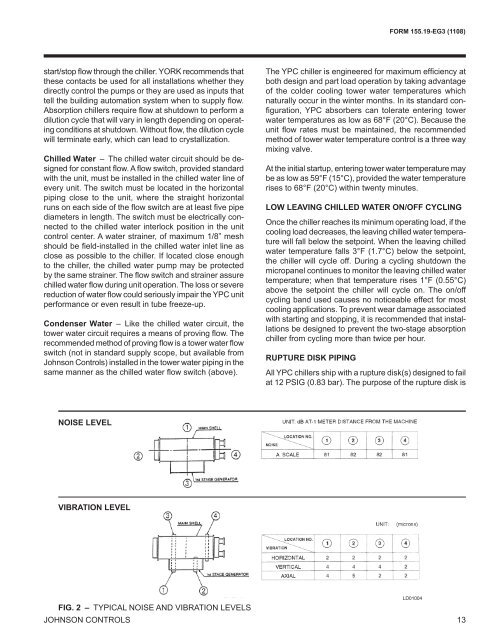

FORM 155.19-EG3 (1108)start/stop flow through the chiller. YORK re<strong>com</strong>mends thatthese contacts be used for all installations whether theydirectly control the pumps or they are used as inputs thattell the building automation system when to supply flow.<strong>Absorption</strong> chillers require flow at shutdown to perform adilution cycle that will vary in l<strong>eng</strong>th depending on operatingconditions at shutdown. Without flow, the dilution cyclewill terminate early, which can lead to crystallization.Chilled Water – The chilled water circuit should be designedfor constant flow. A flow switch, provided standardwith the unit, must be installed in the chilled water line ofevery unit. The switch must be located in the horizontalpiping close to the unit, where the straight horizontalruns on each side of the flow switch are at least five pipediameters in l<strong>eng</strong>th. The switch must be electrically connectedto the chilled water interlock position in the unitcontrol center. A water strainer, of maximum 1/8” meshshould be field-installed in the chilled water inlet line asclose as possible to the chiller. If located close enoughto the chiller, the chilled water pump may be protectedby the same strainer. The flow switch and strainer assurechilled water flow during unit operation. The loss or severereduction of water flow could seriously impair the <strong>YPC</strong> unitperformance or even result in tube freeze-up.Condenser Water – Like the chilled water circuit, thetower water circuit requires a means of proving flow. There<strong>com</strong>mended method of proving flow is a tower water flowswitch (not in standard supply scope, but available fromJohnson Controls) installed in the tower water piping in thesame manner as the chilled water flow switch (above).The <strong>YPC</strong> chiller is <strong>eng</strong>ineered for maximum efficiency atboth design and part load operation by taking advantageof the colder cooling tower water temperatures whichnaturally occur in the winter months. In its standard configuration,<strong>YPC</strong> absorbers can tolerate entering towerwater temperatures as low as 68°F (20°C). Because theunit flow rates must be maintained, the re<strong>com</strong>mendedmethod of tower water temperature control is a three waymixing valve.At the initial startup, entering tower water temperature maybe as low as 59°F (15°C), provided the water temperaturerises to 68°F (20°C) within twenty minutes.LOW LEAVING CHILLED WATER ON/OFF CYCLINGOnce the chiller reaches its minimum operating load, if thecooling load decreases, the leaving chilled water temperaturewill fall below the setpoint. When the leaving chilledwater temperature falls 3°F (1.7°C) below the setpoint,the chiller will cycle off. During a cycling shutdown themicropanel continues to monitor the leaving chilled watertemperature; when that temperature rises 1°F (0.55°C)above the setpoint the chiller will cycle on. The on/offcycling band used causes no noticeable effect for mostcooling applications. To prevent wear damage associatedwith starting and stopping, it is re<strong>com</strong>mended that installationsbe designed to prevent the two-stage absorptionchiller from cycling more than twice per hour.RUPTURE DISK PIPINGAll <strong>YPC</strong> chillers ship with a rupture disk(s) designed to failat 12 PSIG (0.83 bar). The purpose of the rupture disk isNOISE LEVELVIBRATION LEVELFIG. 2 – TYPICAL NOISE AND VIBRATION LEVELSJOHNSON CONTROLSLD0100413