Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

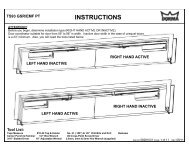

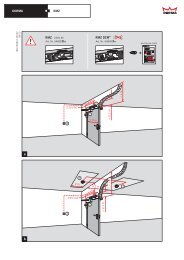

Special stacking arrangementsStacking at the wall in closed compartmentbehind pivoting end panelStacking in front of 90° wall with 90° angle sectionwithout closing pivoting end panelStacking panels of varying widthClosed wallStacking without stacking trackwith 4 panels (2 pivoting end panels/2 sliding panels)07/08 7

95°*<strong>HSW</strong> Supportand Guide ElementsStacking track calculationsStraight track rail with stacking position transverse to travel directiona = depending on pull handle depthor 75 mm where profile cylinderprovided at front-mounted slide boltb = 65 mm for <strong>HSW</strong>-G80 mm for <strong>HSW</strong>-R90 mm for <strong>HSW</strong>-ISO36100 100150T1T2 = T1–36a b bb 65* <strong>HSW</strong>-GPcannot be provided witha 95° branch92T3 = T4 – 92T4 = T1T3b b b baWidth of stacking trackB1 = Panel width – 120 mm - (0.087 x T1)92 B2 = B1 – 19265Straight track rail with stacking track parallel to direction of travel (135°)B1100 100B2 = B1 – 4141100100135°T1T2 = T1 – 41a = depending on pull handle depthb = 65 mm for <strong>HSW</strong>-G80 mm for <strong>HSW</strong>-R and <strong>HSW</strong>-GP90 mm for <strong>HSW</strong>-ISOB1 = Panel width – 130 mmT1 = T3 x 1.4148 07/08

90°Straight track rail with stacking position parallel to travel direction (90°) with up to 6 panels100 10036B1B2 = B1 – 1289295°** <strong>HSW</strong>-GPcannot be provided witha 95° branchT1B1 = Panel width – 130 mm – ( (T1 – 80) x 0.087 )a = depending on pull handle depth or 75 mm whereprofile cylinder provided at front-mounted slide boltb = 65 mm for <strong>HSW</strong>-G80 mm for <strong>HSW</strong>-R90 mm for <strong>HSW</strong>-ISO36T2 = T1 – 100T1130100T2 = T1 – 10080 b b b b a 130100100B1B2 = B1 – 1361005°80 b b b b b b a100Straight track rail with stacking position parallel to travel direction (90°) with more than 6 panelsB1 = Panel width – 130 mma = depending on pull handle depth or 75 mm whereprofile cylinder provided at front-mounted slide boltb = 65 mm for <strong>HSW</strong>-G80 mm for <strong>HSW</strong>-R and <strong>HSW</strong>-GP90 mm for <strong>HSW</strong>-ISO07/08 9

<strong>HSW</strong> Supportand Guide ElementsNiche parkingExtended application possibilitiesPracticalsystem design<strong>DORMA</strong>-Glas offers a furtherstacking variant for fullyglazed sliding walls, namelythe niche parking system.This has all the advantagesinherent in the <strong>HSW</strong>-Gdesign - such as individualconfiguration of the slidingfrontage without a floortrack, or incorporation of aspecial sliding or stationarypanel as a single or doubleaction leaf.This version is ideal wherethe stacked panels of the<strong>HSW</strong>-G may constitute anobstruction or would not bein keeping with the overallappearance of the store.The glass panels are thusparked in line within a nichecomprising a double wall ora wall and other parts of thestore fixtures and fittings. Inthis way, they do not disruptthe overall appearance ofthe interior.With large systems, the panelscan be stowed in parallelon two tracks instead of in asingle-track line.User-friendlyAs direct access to the panelsparked in the niche is notusually possible, a handcrank is used in order tomove the panels back to theentry point. From here theycan be pulled out manually,taken to the appropriateposition and then securedwith their face-mounted floorbolts.Convenient and safeFor added convenience wherethe system height exceeds3000 mm, an automaticpanel removal system is recommended.The individual panels arebrought out to the nicheentrance by means of apushbutton-operated motor,enabling them then to bepulled out and positionedmanually. The motor stops assoon as the pushbutton isreleased.PlanningIn the case of systems ofangular configuration, thecollision curve in the area ofthe angle has to be taken intoaccount during the planningphase, and this will havevarying radii depending onthe panel width. The internaldimension of the parkingpocket (i.e. the niche) variesdepending on the systemlayout and panel type (seepage 12). Together, the totalnumber of panels per trackshould not exceed an overallweight of 1000 kg.Electric drive actuationShop frontageApprox.panelwidthElectricdriveManualcrankNiche sideManual actuationManualcrankApprox.panelwidthCollision curve and crank areamust be kept free of structural anddecorative elements10 07/08

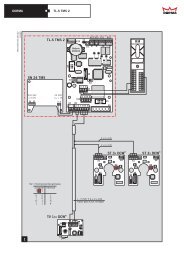

Actuation optionsElectric drive actuationManual actuation224567572Over-slungmotor146107522413213272 72 72 72Under-slungmotor1467513875156123Centre distance150 / 130 / 120 / 90Rail arrangementViews from aboveSingle-track, manualTwin-track, manual80500300Belt guide length50080Crank endDirection of travel to the leftCrank endDirection of travel to the rightSingle-track, electricElectricdriveTwin-track, electric60500Belt guide length300 560500Electricdrive6007/08 13

<strong>HSW</strong> Supportand Guide ElementsTrack RailsTrack rails and modulesStraight track rail50150 1505030075ø93672Stacking track railTrack rail at closed wall positionFlexible and stableHorizontal sliding walls canbe constructed in a widerange of differentconfigurations to suit the siteof installation, prevailingstructural conditions and theplanning concept.With <strong>DORMA</strong> <strong>HSW</strong> systems,a variety of designs can beimplemented with ease.Straight, segmented andcurved track rails can becombined to producevirtually any serpentineshape required. The trackrails in the form of hollowsections combine all thevirtues of light weight,stability and torsionalstiffness. And whencombined with the <strong>HSW</strong>substructure, installationbecomes even easier.Flexibility and stability meanthat even unusual systemconfigurations can beimplemented without problemto give maximumfunctional reliability.90° T-piece135° T-pieceLeftor right90° L-piece3636200404060 60 4040030 30400200408090°36ø9ø9Straight track railFor a straight-line systemconfiguration, a drill holeinterval of 300 mm in thetrack rail is sufficient, whilethe stacking area requires aninterval of 150 mm. Wherethe track assumes an angleof 161-179°, the track rail ismitred, while at anglesbetween 90 and 160°, a castcurve is incorporated. Thestandard modules availableare indicated in the adjacentillustrations.curved section corneredoutside 85°/90°36366036curved section corneredoutside 45°22.5°60ø94020090° angle left/right13613685°/90°13645°90°13614 07/08

Segmented track railWith the segmented trackrail, it is possible toimplement the <strong>DORMA</strong><strong>HSW</strong> as a polygonalpartition or frontage. In sodoing, it is essential to notethe following requirements:the panel width andsegment chord lengthmust be properlycoordinated;segment panels areprovided at the bottomwith locks or face-mountedfloor bolts and the endface profile covers areequipped with additionalbuffers for collisionprotection;it is important to ensurethat the opening sweep ofsingle action and doubleaction panels does notgive rise to collisions.Curved track railA curved track rail is alsoavailable where a curved<strong>DORMA</strong> <strong>HSW</strong> system configurationis required. Themost important technicalprerequisites for this are asfollows:Collision curveonly non-pivoting slidingpanels may be installed inthe curved track rail section;the track rail must bestraight in the parking orstacking area;no top locking element canbe installed;each panel is provided withtwo face-mounted floorbolts;a 100 mm straight tracksection 1 is necessary asthe transition from thecurved track rail to thestraight stacking track rail;blends from the curved configurationto a straight linecan be implemented usingstandard modules 2 ;the smallest curve radius is3500 mm (smaller radii onapplication) 3 ;the feasibility of ellipticsystem configurations mustbe considered on a case-bycasebasis – for this,drawings will be necessary;the start and end points ofthe curve are alwaysprovided with a 90° saw cut(radial saw cut).7275Curved track rail, bolteddouble shell construction5030030030020030021ø931R minof the neutral fibre= 3500 mmCountersunk screwDIN 7991M6x10. A207/08 15

<strong>HSW</strong> Bearing andLocating ElementsSubstructureThe SystemProblems and solutionsInstalling a horizontal slidingwall system invariablyrequires a certain set ofstructural conditions to beestablished. The system willneed to be precisely alignedvertically - usually subsequentto installation - aswell as being exactlyconfigured and securelylocated. Because <strong>DORMA</strong><strong>HSW</strong> systems do not usefloor-level supports and floortracks, the systemrequirements and all theirtechnical properties must betaken into account whendesigning the substructureand its incorporation withinthe ceiling. This often verycostly planning process isnormally undertaken by thefabricator as the installationcompany, and alongside thecalculations there are manyindividual structural andinstallation proceduresinvolved. The new <strong>DORMA</strong>substructure system is ofmodular construction and isdesigned to significantlyreduce on-site installationcost and time. This conceptalso offers the particularflexibility required toovercome structuralconstraints, such as thepresence of air conditioningshafts or pre-existingelectrical systems in theceiling.M10 threaded rodFixing plateMilled “U” recessPivoting angle bracketStandard squaresection tubesPivot fixingSubstructureprofileUpperbolting channelCentre channelLateralbolting channelLowerbolting channelTrack railSystem designThe <strong>DORMA</strong> substructureconsists primarily of thefollowing components:substructure profile withmodules for branching tothe stacking area, threadedrods for suspension of theprofile(s), and standardsquare section tubes withappropriate fixings andceiling brackets for bracingand stiffening theconstruction.16 07/08

Safety and flexibilityThe <strong>DORMA</strong> substructurehas been developed on thebasis of extensive practicalexperience of therequirements involved inthis kind of system.Consequently, the profileincorporates features thatgreatly facilitate installationand ensure that pre-existingstructural factors can beaccommodated withmaximum flexibility.Various bolting channels runthe whole length of theprofile, allowing bolts to beinserted easily at anylocation within the systemconfiguration. So there is noneed for pre-drilling andthread cutting in order tomount the track rails ontothe substructure.Bolted connections can bemade directly through thelower bolting channel. Theproblem of removingdrillings and filings from thetrack rails is thus also athing of the past.Bolting channels on bothsides of the profile can beused e.g. for fixing thebrackets needed forattaching the ceilingretention elements. Inaddition, centering grooveson all main profile surfacesfacilitate overhead drilling,e.g. for accessoryattachment. Weldingbrackets designed forbolting onto the profileprovide another option,allowing the <strong>DORMA</strong> systemto be utilised for additionalcustomer-specificapplications.The substructure profile issuspended from threadedrods. These are first placedin the U-recesses usingfixing plates that lock intothe upper bolting channel.Each pair of threaded rodsis regarded as constitutingone suspension point. Hereagain the system remainsexceptionally flexible: thestaggered U-recessespositioned at intervals of100 mm enhance the abilityof the system toaccommodate structuralconstraints. Depending onthe weight of the systemand the permitteddeflection, it is possible tospan a distance of up to2.10 m between twosuspension points.Standard flat steel bars canbe inserted in the centrechannel to further stiffenthe profile, particularly inthe area of the joints. Thismeans that just onesuspension point in thevicinity of the joint can beprovided instead of the two -one either side of the joint -that are usually needed. Soexisting buildinginstallations of all types canbe effectively bypassed.Once the substructure hasbeen installed, the <strong>HSW</strong>system is vertically alignedand fixed directly via thethreaded rods. Subsequentadjustments, e.g. after thebuilding has settled into itsfoundations, can also becarried out by the samemeans.The standard square sectiontubes offer extra safety,especially where the slidingpanels deviate from a straightline. Panel sway must beeffectively countered by thestructural design adopted atsuch locations. Diagonalstruts that counteract thepressure load stabilise thesystem in the area of thestacked panels. Thetelescopic square sectiontubes are connected asadditional bracing elements(struts) to the substructure bya pivot fixing. The struts arebolted to the ceiling usingthe appropriate anglebrackets.The forces (shownby arrows) that occurduring opening andclosing of the sliding wallsystem must be absorbedby appropriately locatedbracing elements.The modular design of the<strong>DORMA</strong> substructure isprecisely matched to themodules of the <strong>DORMA</strong> <strong>HSW</strong>track rail. The structuralelements can be mixed andmatched as desired with theresult that a small number ofcomponent types is sufficientto create a complex, flexiblesystem that conforms fully toall safety requirements.A drawing of the requiredsubstructure can berequested from <strong>DORMA</strong> tosupplement the <strong>HSW</strong> systemdrawing always supplied withthe quotation.07/08 17

<strong>HSW</strong> Bearing andLocating ElementsSubstructurePlanning detailsCalculating thesuspension intervalsMax. 2 mm deflectionbetween two suspension pointsWith a maximum load (panelweight) of 150 kg/m and apermitted deflection of thesubstructure with track rail of2 mm, the interval betweentwo suspension points mustbe no greater than 1.45 m.The table below shows othervalues for different loads.In order to prevent system sway, every second suspensionpoint must be reinforced by a strut. The substructureprofile ends (travel path and stacking area) should ideallybe directly connected to the masonry or to existingstructural members.Table for the calculation of the max. distance dimensionFFront60 kg/m75 kg/m90 kg/m105 kg/m120 kg/m135 kg/m150 kg/m160 kg/mAM max.AMF2050 mm1900 mm1750 mm1750 mm1600 mm1600 mm1450 mm1450 mmAMParking areaF = ForceAM = Distance dimensionForce example:The distance dimension of108.98 kg/m = 1710 mmIllustrative example of loadvalues<strong>HSW</strong>-G characteristic valuesFormula for calculating the:Glazing height= system height – 0.309 m= panel height – 0.193 mGlazing weightGlass 10 mm = 25.00 kg/m 2Glass 12 mm = 30.00 kg/m 2Door rail weightAluminium = 12.00 kg/mBrass = 14.50 kg/mStainl. steel = 13.25 kg/mExample system<strong>HSW</strong>-G system instainless steelSystem heightGlazing thickness3.50 m12 mmCalculationLoad= glazing weight x glazingheight + door track weight= 30 kg/m 2 x (3.50 m –0.309 m) + 13.25 kg/m= 30 kg/m 2 x 3.191 m +13.25 kg/m= 108.98 kg/m18 07/08

Stacking area designView from belowThe construction of thestacking area, assembledfrom substructure and trackrail modules, provides agood illustration of how thiswell-designed system can beutilised. The individualcomponents are coordinatedto ensure safe integration.Joints in the substructureare offset to those in thetrack rails so that individualjoints coincide withcontinuous material in allcases.Provided that the track railsare adequately bolted to thesubstructure, gaps of up to40 cm measured from onesuspension point to the nextare permitted in thesubstructure.Substructure Track rail Detachablesection90° branch moduleStrutView from below95° branchmoduleView from aboveJoint area reinforced using flat steel bars inserted inthe centre channelJoints reinforced by centralsteel bar only require onelocal suspension point.1 suspension point= 2 threaded rodsL-piece for95° branchStrut90° T-pieceSuspension points either side of joints not reinforced by central steel bar07/08 19

<strong>HSW</strong> Bearing andLocating ElementsSubstructureVariants of connection/DetailsUK-ProfileProfile connectionwith connection lugArt. No. 815.442.001.40Bending ofconnection lug on siteaccording to needWall connection with angeledconnection lugsArt. No. 815.442.001.4030.530,53050Direct connectionto ceilingWelding connectionto steel girderFlexible connectioto ceilingConnectionto steel constructionConnection oppartunitiesto existing bearing structurelike ceilings, balks, steelgirder by dint of adapter plateArt. No. 815.435.001.4020 07/08

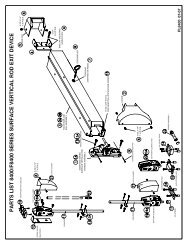

Component parts, accessoriesComponent parts1DFE1 Pivoting angle bracketArt. No. 815.437.001.402 Fixing plateArt. No. 815.434.001.403 Pivot fixingArt. No. 815.436.001.404 Adapter plateArt. No. 815.435.001.405 Basic substructure profile,stock length 6 mArt. No. 815.658.000.99Fixed lengthArt. No. 815.659.000.99AGDIN and standard parts byothers or on requestCSN = Company standard no.HA Threaded rod M10 x 1000CSN 800.01.470.3.30BGB Hex nut DIN 439-2 M10CSN 800.03.001.3.302CBIK3JC Washer ISO 7089-10CSN 800.04.009.3.30D Hex nut DIN 934-M6CSN 800.03.005.3.30E Hex socket screwDIN 933-M6x35CSN 800.01.337.3.304Adapter plate forneutral connectionF Telescopic strut top section,square section tube,galvanised steel 20x20x2CSN 800.16.025.4.325LG Drilling screw DIN 7504ST4 8x16CSN 800.01.286.3.30H Telescopic strut bottomsection, square section tube,galvanised steel 25x25x2CSN 800.16.026.4.32I Hex nut DIN 934-M6CSN 800.03.005.3.30J Hex socket screwDIN 933-M6x40CSN 800.01.319.3.3049100Stock length 6 m200100 100K Self-tapping screwISO 7049-St4.8 x 13-C-HCSN 800.01.493.3.30757217 +0.211 +0.20.5 AL Cheesehead screwfor fixing track rail tosubstructure profileDIN 912-M8x25CSN 800.01.018.3.3001/08 21

<strong>HSW</strong>/<strong>FSW</strong>Panel Types<strong>HSW</strong>-G / <strong>FSW</strong>-G /<strong>HSW</strong>-GP / <strong>HSW</strong>-GEPanel typesIn the case of the fullyglazed <strong>HSW</strong>-G system, thepanels create a continuous,transparent surface withoutany lateral framing.For a more sophisticated orintricate appearance, singlepointfixings (<strong>HSW</strong>-GP) arealso available.<strong>HSW</strong>-G /<strong>FSW</strong>-G,C,C plusFully glazed with door rails<strong>HSW</strong>-GPFully glazedwith single-pointfixings<strong>HSW</strong>-GE BOXesFully glazedwithpatch fittingsExample of an <strong>HSW</strong>-G systemFully glazed with door railsThis folding system withtop and bottom glazingrails coordinates perfectlywith the <strong>HSW</strong>-G variant.The <strong>FSW</strong>-G operates withouta separate stacking area,and instead folds togetherwithin the main frontage orpartition zone.Example of an <strong>FSW</strong>-G systemHinge-linked door rails<strong>HSW</strong>-G / <strong>FSW</strong>-G<strong>FSW</strong>-C/C plus<strong>HSW</strong>-GP<strong>HSW</strong>-GE BOXes22 07/08

<strong>HSW</strong>/<strong>FSW</strong>Panel Types<strong>HSW</strong>-R<strong>HSW</strong>-ISO<strong>HSW</strong>-RFullyframed<strong>HSW</strong>-ISOFully framedwith double glazingThe all-round framingprovided on the individualpanels of an <strong>HSW</strong>-R systemnot only offers high stabilitybut also an excellent barrierto keep out externalinfluences. The panels canbe constructed withlaminated or toughenedsafety glass as required.Example of an <strong>HSW</strong>-R systemFully framedor <strong>HSW</strong>-ISOFully framed with thermalbreakframe profiles07/08 23

<strong>HSW</strong>Panel Types<strong>HSW</strong>-G<strong>HSW</strong>-G panel types and functionsHorizontal sliding wallsFully glazed with glazing railstop and bottomWithin an <strong>HSW</strong>-G system,the individual panels can bedesigned to perform certainspecial functions. Theserange from simple slidingpanels to integrated doorswith a variety of door closers,or special panels for unusualinstallation situations. Andeach system can be assembledto suit individual requirements.Max. panel sizesand weightsSingleaction/doubleaction end panelNon-sliding.Single actionpanel with floorpivot and TS 73door closer.Double actionpanel with floorpivot or BTSfloor spring.Sliding panelFixed whenfrontage closed.Single actionsliding panelSingle actionsliding panelwith TS 92cam-actiondoor closer,operationalwhen frontageclosed.Double actionsliding panel *Double actionsliding panelwith BTSfloor spring,operationalwhen frontageclosed.Double actionsliding panel *With RTStransom doorcloser,operationalwhen frontageclosed.Max. system height4000 mm4000 mm3600 mm3000 mm 3600 mmMax. panel width1250 mm1250 mm 1250 mm950 mm 1250 mmMax. panel weight150 kg150 kg 100 kg 75 kg 100 kgThe individual panels can also be of differing widths.The largest width should not exceed max. 115% of the smallest width.* For these panel types please consider our notes on portal systems on page 89.24 07/08

<strong>HSW</strong>-G system designIrrespective of the function ofthe individual panels, an<strong>HSW</strong>-G system comprises thefollowing basic components:1 Installation-efficient<strong>DORMA</strong> substructure toaccommodate track railmounting requirements(optional)2 Track rail for bolting to thesubstructure.3 Carrier4 Suspension assembly and5 bearing profile for safe andeasy sliding of the panels.6 Top door rail and7 bottom door rail, bothcomprising base profileswith clip-on face and sidecovers.8 Toughened safety glassortoughened laminatedsafety glass (by others)Bottom door rail designsAll depicted combinations are also available asmirror arrangementsEnd-mounted pinbolt at wallEnd-mountedslide bolt72End-mounted pinbolt at wallFace-mountedslide bolt751End-mounted pinbolt at wallDeadlock2753Recess forend-mounted slide boltFace-mountedslide bolt25352.533±545Recess forend-mounted slide boltEnd-mountedslide bolt1006Recess forend-mounted slide boltDeadlock8DeadlockEnd-mountedslide bolt3210Face-mountedslide boltEnd-mountedslide bolt820Face-mountedslide boltFace-mountedslide bolt10077FloorsurfaceFace-mountedslide boltDeadlock07/08 25

<strong>HSW</strong>Panel Types<strong>HSW</strong>-GSingle action/double action end panelEnd panelNon-moving and alwaysequipped with a bottomdeadbolt with the option ofa top bolt or side-action deadlock.Can be designed as a doubleaction or single action leaf.Single action or double action end panel with floor pivot7533±535Pivotbearing1002.5Double action end panelAssembly types:Height of glazing= Total height –308 mm25204463End cover63Floor pivot with roundspindleBTS 84 for panels upto 100 kg, with optionalhold-open at 90° dooropening angleBTS 80 for panels up to150 kg with adjustablehold-open device710036.527Single action end panelwith stop-type coverstop and bottom.Assembly types:45196536Floor pivot with roundspindleAs above, but with<strong>DORMA</strong> TS 73 or TS 92overhead door closerBTS 84 for panels upto 100 kg, with optionalhold-open at 90° dooropening angleBTS 80 for panels up to150 kg with adjustablehold-open deviceDouble action end panel with floor springMounting dimensionsabcdBTS841084030651 - 58BTS80786034151-57ba463dc26 07/08

Single action end panel with TS 73 overhead door closer and additional locking device2224563193.5205 160140Single action end panel with TS 92 overhead door closer and additional locking device375Additionallocking deviseData and featuresTS 73 VTS 9272317max.1463145.5 199 140min. panel width 870 mm6Closing strength, variableNon-handedClosing strengthcontinously adjustableClosing speed variableby valve adjustmentLatching speed adjustmentCushioned stay limit, mechanicalWeightLengthOverall depthHeightSize EN 2-4via adjusting screwand arm hingevia arm1.8 kg233 mm42.50 mm60 mmSize EN 2-4via adjustingscrewvia valve1.9 kg281 mm47 mm65 mm07/08 27

<strong>HSW</strong>Panel Types<strong>HSW</strong>-GSliding panelSliding panelStationary when the frontageor partition is closed.75Track roller2.535Sliding panelThe sliding panels are themoving elements. Once intheir closed position, theyare locked down. Thecomponents available forthis are provided in thebottom door rail in the formof face-mounted slide bolts,end-mounted slide bolts,end pin bolts or deadlocks.2533±5100SlidingpanelEnd coverGlazing height= Total height – 308 mm201004Sliding panelEnd-mountedslide bolt7EccentricbushingBottom door railPanel width250 250Base profile with integralfunctional element(here: face-mounted slide bolt)Base profile withfunctional element(here: deadlock)28 07/08

<strong>HSW</strong>Panel Types<strong>HSW</strong>-GSingle action sliding panelSingle action sliding panelSwing panel with TS 92cam-action door closer foroperation as a single actiondoor when the frontage isclosed.75Track rollerSingle-action sliding panelwith <strong>DORMA</strong> TS 92 camactiondoor closerThis panel type is installedwhere doors only need to beopened in one direction.The pivoting sliding panelscan be fitted open inwardly oroutwardly. In both cases, thecam-action door closer is fixedto the inside face.Standard assemblytop: Pivot bearing, TS 92with slide channel,one locking devicebottom: Face-mounted slidebolt as pivot (releasedfor sliding function)and lockOptional equipmenttop: Second locking device(for reshuffle bypass)bottom: Optional second facemountedslide boltinstead of deadlockø10max. 2.513.543533±5TS 924100SlidingpanelPivotbearingSingle action sliding panelGlazing height= Total height – 308 mm2520Locking deviceø7 M67810015465Face-mounted slide bolt129Eccentricbushing7360 110Top pivot07/08 29

<strong>HSW</strong>Panel Types<strong>HSW</strong>-GDouble action sliding panelwith BTS floor springDouble action sliding panelPivoting panel with BTS floorspring for operation as a doubleaction door when thefrontage is closed.75Track roller4Double action sliding panelwith <strong>DORMA</strong> BTS floor springThe combination of doubleaction sliding panels with<strong>DORMA</strong> BTS floor springshas become a classic solution.These panels are generallyequipped with a bottom deadlockand top lockingdevice.Assembly types:• BTS 84´Z´ for double actionsliding panels with BTS at80 kg, with optional holdopenat 90° door openingangle.• BTS 80´Z´ for panels up to150 kg with adjustablehold-open device.The maximum weight for thedouble action sliding panelwith <strong>DORMA</strong> BTS floor springis 75 kg.For these panel types pleaseconsider our notes on portalsystems on page 89.Locking deviceø7 M681512973ø10max. 2.513.543533±5Pivot bearingGlazing height= Total height – 308 mm2520BTS 80´Z´ = 78BTS 84´Z´ = 1081001007SlidingpanelBTS 80 = 60BTS 84 = 40204Double action sliding panel65BTS 80´Z´ = 51-57BTS 84´Z´ = 51-58BTS 80 = 341BTS 84 = 30660 110Top pivot30 07/08

<strong>HSW</strong>Panel Types<strong>HSW</strong>-GDouble action sliding panelwith RTS transom door closerDouble action sliding panelPivoting panel with RTStransom door closer foroperation as a double actiondoor when the frontage isclosed.75Track roller3233±5RTS 8546RTS 85Double action sliding panelwith integral <strong>DORMA</strong> RTStransom door closerDouble action sliding panelswith <strong>DORMA</strong> RTS transomdoor closers (patenteddesign) are characterised bytheir exceptional ease ofinstallation and operation;an excellent alternative to thesolution with the BTS floorspring because the RTS doesnot require a large recess inthe floor. These panels aregenerally equipped witha bottom deadlock and toplocking device plus a bottomface-mounted slide boltoperating as the pivot bearing(released for the slidingfunction).The standard solution takesthe form of the RTS 85without hold-open, or asa special option, with a 90°hold-open.Glazing height= Total height – 312 mm2020Locking deviceM6ø781007563SlidingpanelDouble actionsliding panel4RTS insert65Face-mounted slide bolt129 73EccentricbushingFor these panel types pleaseconsider our notes on portalsystems on page 89.58ø7max. 2.514.5360 11007/08 31

<strong>HSW</strong>Panel Types<strong>HSW</strong>-GSpecial panelsSingle action doorSingle action panel, nonsliding,operatesindependently of the rest ofthe system.Top centreupper part7590° opening angleOffset pivoting end panel at wall214The single action door withoffset pivoting arm assemblycan be swung around 180°,so leaving the entireoperating zone free.A bottom deadlock securesthe closed leaf.Top centrelower partBottomdoor arm45457 33±5100100 352.52End cover180° opening angleOffset pivoting end panelat fixed screen4Pivoting end panelviews as seenfrom below180° opening angleOffset pivoting end panelat wall24Fixed side screenNon-moving side screen,independent of the rest ofthe system.75Fixed screenfixingarrangementThe fixed side screen is ofthe same basic design asthe sliding panels. And ifrequired, the fixings can bereplaced by a carrier systemto convert such a screeninto a sliding panel.Glazing height= Total height – 308 mm25207 33±5100100 352.5Slidingpanel465Fixed screenEnd coverEnd-mountedslide bolt withfixed pin32 07/08

Magnetic door holderPanel hingeRoller carrier251002.53533-575Magnetic door holderEnd-mounted slidebolt andpanel hinge42065Panel width4Panel widthMagnetic door holders top and bottom30<strong>FSW</strong>-C42<strong>FSW</strong>-C plus7230End-mounted slide boltPanel hingeFolding sliding panelHinged, with lock and slide bolt at the bottom, latchingbolts top and bottom for fixing the final folding panel to theslide panel.Max. panel sizes and weightsMax. panel width 2 x 1000 mmMax. system height 3000 mmMax. panel weight 2 x 70 kg6028 1507/08 33

<strong>HSW</strong>Panel Types<strong>HSW</strong>-GP<strong>HSW</strong>-GP panels and functionsFully glazed sliding walls withpoint-fixed track roller carriersengaging in standard track railThe characteristic featuresof <strong>HSW</strong>-GP systems are thesingle-point fixings of theglass panels in combinationwith a conventional track railprofile. The design, featuringa high-grade stainless steelfinish and the distinctiveflush-mounted attachments,coordinates perfectly withcontemporary architecture.Even curved glazing can besecurely held by this system.And this can also becombined with curved trackrail profiles to produceunique configurations.Max. panel sizesand weightsSingle/doubleaction end panelNon-sliding.With full-lengthpivot rod andoffset pivot.Single actionpanel with floorpivot, roundspindle and stop.Double actionpanel with floorpivot or BTSfloor spring.Sliding panelFixed whenfrontage closed.Single/doubleaction end panelNon-sliding.With centre pivottop and bottom.Single actionpanel with floorpivot, roundspindle and stop.Double actionpanel with floorpivot.Fixed screenNon-sliding.Fixed sidescreen withretaining pinsat the top andfixed screenstraps at thebottom.Max. system height3000 mm3000 mm3000 mm3000 mmMax. panel width1200 mm1200 mm1200 mm1200 mmMax. panel weight100 kg100 kg100 kg100 kgThe individual panels can also be of differing widths.The largest width should not exceed max. 115% of the smallest width.34 07/08

<strong>HSW</strong>-GP system designThe <strong>HSW</strong>-GP systemconsists of the followingbasic components:1 installation-efficient <strong>DORMA</strong>substructure to accommodatetrack rail mountingrequirements (optional).2 track rail for bolting tothe substructure.3 roller,4 suspension assembly,5 strap with single-point fixings,6 toughened safety glass or toughenedlaminated safety glass (by others),7 bottom strap with end-mounted pin,8 bottom strap with face-mounted slide bolt.Sliding panelwith bottom end-mounted pin72Sliding panelwith bottom face-mounted slide bolt72175752753119119429442944Inside114Inside5050751145675555Glazing height = Total height – 126 mmTotal height15.58.5395555Glazing height = Total height – 126 mmTotal height8Floorsurface64764707/08 35

<strong>HSW</strong>Panel Types<strong>HSW</strong>-GP<strong>HSW</strong>-GP panel types and glass drilling requirementsSingle/double action end panel with pivot rod71Glass drilling patternGlazing width6571Pivot pinPivot rod, shorttype with singlepointfixingsPull handle with single-pointfixings/Back-to-backpull handlesPivot rod connectingtubePivot rod, shorttype, with singlepointfixingsDeadlockBottombearing bush150Length of connecting tube= Glazing height – 535 mmGlass bore centres for pullhandle/back-to-back pullhandles1560 ±0.31040 ±0.3520 ±0.3min. 65 mm65Countersunk boresCountersunk boresØ 55for deadlock150 150Glazing height = Total height – 126 mm773865113Single/double action end panel50Glass drilling patternGlazing width4150Strap with singlepointfixings55Glass bore centres for pullhandle/back-to-back pullhandlesCountersunk bores55Pull handle/Back-tobackpull handlesPivot strap withfloor pivotDeadlock55644981560 ±0.31040 ±0.3520 ±0.3min. 65 mm65Countersunk boresØ 55for deadlock65416455Visible corner notchGlazing height = Total height – 126 mm36 07/08

Sliding panelFixed screen50Glass drilling pattern50Glazing41width4150Straps with single-pointfixingsStraps with single-pointfixings5555Countersunk bores55Bottom strapwithface-mountedslide boltFixed screen strap4141Glazing height = Total height – 126 mmBottom strapFixed screen strap555564Countersunk bores6455864418Visible corner notchesGlass boresand notches10/12Bores for pullhandle pairsBoresfor locksVisible corner notches,bottomCountersunkbores forsingle-pointfixings for thepull handlesand strapsØ 263-0.2Ø 32+0.290°Ø 2210/12Ø 5510/1267R7151567R7Special stopPivot rods(short type)with single-pointfixings and connectingtubePull handle with single-pointfixings±1562±15Bottom pivotforpivot rodsBack-to-back pull handles07/08 37

<strong>HSW</strong>Panel Types<strong>HSW</strong>-GE BOXes<strong>HSW</strong>-GE BOXes panels and functionsFully glazed sliding wallswith patch fittings2 4 4 4 2Box 1 Box 3 Box 5 Box 2There are six different boxesavailable for your in-house<strong>HSW</strong> system planning anddesign work. Aside from therequisite hardware and fittings,each box also containsthe necessary number ofeccentric bush-type keeps.The locks contained in the<strong>HSW</strong>-GE BOXes areequipped exclusively withdouble Europrofile cylindersso that no LH/RH handingdistinction needs to be madein the case of double-actionend panels.The bottom functional elementscan be installed oneither side of the panelsusing the different fittingsprovided. When designingstacking/parking areas,please ensure compliancewith the instructions providedin this technical brochure(available under WN No.800.51.024.6.32)on pages 46 and 47.Double actionend panelNon-sliding.Double actionpanel with floorpivot or BTSfloor spring.Sliding panelFixed whenfrontage closed.Sliding panelFixed whenfrontage closed.Fixed screenNon-sliding.Fixed sidescreen withretaining pinsat the top andat the bottom.Max. panel sizes and weightsMax. system height3000 mm3000 mm3000 mm3000 mmMax. panel width1100 mm1100 mm1100 mm1100 mmMax. panel weight80 kg80 kg80 kg80 kg38 07/08

<strong>HSW</strong>-GE BOX 1Double action end panel with floor point7233±55175263Double-action end panel,non-sliding. Equipped asstandard with a top pivotbearing, bottom verticalactionfloor lock for doubleEuroprofile cylinder, and bottompivot with round spindle.Suitable for RH and LHhanding.As an option, a BTS 84 floorspring may be used insteadof the bottom pivot.The BTS 84 is suitable forpanels weighing up to 100 kgand can be provided with orwithout a hold-open devicefor retention at a 90° dooropening angle.Fitting componentsBOX 163Fittings can be used onboth sides.Note changes in glasspreparation/drillingrequirements!2592 40Double action end panel optional with BTS floor spring6351732.5517For glass preparationsee page 4507/08 39

<strong>HSW</strong>Panel Types<strong>HSW</strong>-GE BOXes<strong>HSW</strong>-GE BOX 2Fixed screen with retaining pins7233±55175Non-sliding side screen,installed independently ofthe rest of the system.Equipped as standard withtwo fixed screen mountingsat the top and two verticalactionfloor locks for doubleEuroprofile cylinders at thebottom. The fixed screen isof the same visual design asthe sliding panels.If required, it can also beconverted into a sliding panelby replacing the fixed screenmountings with a rollercarrier.263Fitting componentsBOX 2517Fittings can be used onboth sides.Can also be used as a sliding panel by replacing the fixed screenmounting with a roller carrier.For glass preparationsee page 4540 07/08

<strong>HSW</strong>-GE BOX 3Sliding panel with lock7572The sliding panels are heldin position once the systemis closed. Equipped asstandard with a verticalactionfloor lock for a doubleEuroprofile cylinder, and akeeper for an end-mountedslide bolt.512Fitting componentsBOX 3Fittings can be used onboth sides.51733±563Next panel with bottom end-mounted slide-boltFor glass preparationsee page 4507/08 41

<strong>HSW</strong>Panel Types<strong>HSW</strong>-GE BOXes<strong>HSW</strong>-GE BOX 4Sliding panel with end-mounted slide bolt72The sliding panels are heldin position once the systemis closed. Equipped asstandard with a keeper foran end-mounted slide boltand with an end-mountedslide bolt.51754Fitting componentsBOX 4Fittings can be used onboth sides.51733±563Next panel with bottom end-mounted slide boltFor glass preparationsee page 4542 07/08

<strong>HSW</strong>-GE BOX 5Sliding panel with lock and end mounted slide bolt72The sliding panels are heldin position once the systemis closed. Equipped asstandard with a verticalactionfloor lock for a doubleEuroprofile cylinder, and anend-mounted slide bolt.51752Fitting componentsBOX 5Fittings can be used onboth sides.51733±563Next panel with end mounted slide bolt receiver for end fixed locking boltFor glass preparationsee page 4507/08 43

<strong>HSW</strong>Panel Types<strong>HSW</strong>-GE BOXes<strong>HSW</strong>-GE BOX 6Sliding panel with lock72The sliding panels are heldin position once the systemis closed. Always equippedwith two vertical-action floorlocks for double Europrofilecylinders.5175263Fitting componentsBOX 6Fittings can be used onboth sides.51733±5For glass preparationsee page 4544 07/08

<strong>HSW</strong>Panel Types<strong>HSW</strong>-GEGlass preparation<strong>HSW</strong>-GE Glass preparation BOX 1- 6Top glass panel preparation BOX 1- 6Glass width36R55R80Glass height = total height -115(Total height = top edge track to FFL)20Glass cut-out for:- top patch fittings GE 20 and GE 30- bottom patch fitting GE 10 for floor bearingDepending on versionBottom glass panel preparation BOX 1433716114868R10148Glass cut-out bottom for:- GE patch lock- end-mounted slide bolt- strike box for end-mounted slide boltGlass panel preparation bottom BOX 2 - 607/08 45

<strong>HSW</strong>Panel Types<strong>HSW</strong>-GE BOXesStacking trackdesign data<strong>HSW</strong>-GE BOXes 90° Standard stacking track- Stacking track depth is designed for a maximum of 10 panels (1 x pivoting end panel and 9 x sliding panels).- In its as-delivered condition, the stacking track width accommodates the maximum panel width (b = 1100 mm).- Adjustment to actual panel width is accomplished using track rail section B2. This track rail section is non-weldedin its as-delivered condition and is connected to the track rail modules by means of pins (L = 50 mm).Straight track rail with stacking position transverse to travel direction (90°)90086410010010065656510072B1 = panel width - 130B2 = B1 - 200B210090°100a800a = Depending on length of handle46 07/08

<strong>HSW</strong>-GE BOXes Standard stacking track parallel to direction of travel- The depth of the stacking track is designed for a maximum of 10 sliding panels.A pivoting end panel is also envisaged as a means of accessing the parking position.- In its as-delivered condition, the stacking track width accommodates the maximum panel width (b = 1100 mm).- Adjustment to actual panel width is accomplished using track rail section B2. This track rail section isnon-welded in its as-delivered condition and is connected to the track rail modules by means of pins (L = 50 mm).Straight track rail with stacking position parallel to travel direction100100B1 = panel width - 130200B2 = B1 - 100100B26565656513010065760 1008607207/08 47

<strong>FSW</strong>Panel Types<strong>FSW</strong>-G<strong>FSW</strong>-G panel types and functions<strong>FSW</strong> folding sliding walls asfully glazed partitions andfrontages, with door railstop and bottom, track rollerposition at the end of everysecond panel.Folding sliding walls are idealfor a straight-line systemconfiguration. Because thepanels of an <strong>FSW</strong> system arevisually compatible with the<strong>HSW</strong>-G panels, both systemtypes can use the same trackrail construction and can beeffectively combined within asingle frontage. Consequently,an <strong>FSW</strong> system can also becomplemented through theaddition of a free-standing<strong>HSW</strong> double action or singleaction end panel.An <strong>FSW</strong> system essentiallycontains the following hingedcomponents:1 <strong>FSW</strong> end assembly with1 or 3 folding panelsTwo counter-running systemscan be combined to createfrontages with 8 panels.End panelwith top pivotand bottomfloor pivot.53Folding panelwith carrier andlocking devicetop and bottom.1 4621 Track rail2 Folding panel3 Folding hinge4 Roller7Folding panelwith carrier andlocking devicetop and bottom.26End panelwith top pivotand floor pivot.5 <strong>FSW</strong> end panel6 Top locking device7 Bottom locking device5Max. panel sizes andweightsMax. system height 3000 mmMax. panel width 1000 mmMax. panel weight70 kg48 07/08

<strong>FSW</strong>-G system designThe <strong>FSW</strong>-G systemconsists of the followingbasic components:1 installation-efficient <strong>DORMA</strong>substructure to accommodatetrack rail mountingrequirements (optional).2 track rail for bolting to thesubstructure.3 top pivot,4 roller,5 top locking device,6 suspension assembly and7 carrier profile for safeand easy sliding of thepanels.8 folding hinge,9 top door rail and10 bottom door rail, bothcomprising base profileswith clip-on face and sidecovers.11 toughened safety glass ortoughened laminated safetyglass (by others),12 floor pivot,13 face-mounted slide boltEnd panelFolding panel72175234757892533±56535113210202.510081210137100Floorsurface388.5Door rails cut to size4.5507/08 49

<strong>FSW</strong>Panel Types<strong>FSW</strong>-G<strong>FSW</strong>-G assembly typesType 1 Type 2min. 120 mmType 1a 2 folding panels left (as drawn)Type 1b 2 folding panels right(mirror arrangement)Type 1c 4 folding panels (2 panels leftand 2 panels right)Type 2a 4 folding panels left (as drawn)Type 2b 4 folding panels right(mirror arrangement)Type 2c 8 folding panels(4 panels left and 4 panels right)min. 120 mmType 3Type 3a 6 folding panels as drawn(4 panels left and 2 panels right)Type 3b 6 folding panels, mirror arrangement(2 panels left and 4 panels right)50 07/08

<strong>HSW</strong> end panel(Access leaf)Type 4Type 4a 2 folding panels left and1 access leaf right (as drawn)Type 4b 2 folding panels right and1 access leaf left (mirror arrangement)min. 120 mmType 5a 4 folding panels left and1 access leaf right (as drawn)Type 5b 4 folding panels right and1 access leaf left (mirror arrangement)07/08 51

<strong>FSW</strong>Panel Types<strong>FSW</strong>-C<strong>FSW</strong>-C panels and functionsFolding sliding walls, fullyglazed, with door rails top andbottom, track roller position inthe panel centre.Large spans can beimplemented with the <strong>FSW</strong>-C.The number of panels persystem can be freely selectedbetween 3 and 8. Thanks tothe central suspension point,pairing is not necessary. Doublesystems with two counterrunningassemblies can alsobe installed.The panels are guided on asturdy track rail fixed to theceiling. An additional floortrack is not necessary, so thefloor covering can be laidwithout interruption.Folding sliding walls require ahalf-width base panel fittedwith pivot bearings, to whichthe folding panels are connected.In order tomaintain system symmetry,the final folding panelwithout a track roller is alsoof half-width design.Finalfoldingpanelwithlockingdevicestop andbottom.Folding panelwith carrier,locking devicestop and bottom.Folding panelwith carrier andlocking devicebottom.Folding panelwith carrier andlocking devicebottom.Basepanelwithfloorpivotandlockingdevicebottom.33148446The hinges exhibit a slightpivot offset. This ensuresthat the folded assembly isparticularly compact whileat the same time providingfor good stability.Max. panel sizes andweights234851 Track rail2 Final folding panel3 Folding hinge4 Locking device3455 Folding panel6 Base panel7 Floor pivot8 Roller7Max. system height 3000 mmMax. panel width 1000 mmWidth of the base panel= half panel width + 63 mmFor assembly options, see pages 44/45Max. panel weight70 kgNumber of panels 3 to 852 07/08

<strong>FSW</strong>-C system designThe <strong>FSW</strong>-C systemconsists of the followingbasic components:1 installation-efficient <strong>DORMA</strong>substructure to accommodatetrack rail mountingrequirements (optional).2 track rail for bolting to thesubstructure.3 roller,4 suspension assembly and5 carrier profile for safeand easy sliding of thepanels.6 top door rail and7 bottom door rail, bothcomprising base profileswith clip-on face and sidecovers.8 top latching bolt,9 toughened safety glassor toughened laminatedsafety glass (by others),10 bottom latching bolt.72175Folding panel/finalfolding panel withlatching bolts topand bottomBottom hinge2Glass panes3457533±535Latchingbolts top andbottomFacemountedslide bolt689710Floorsurface<strong>FSW</strong>-C42<strong>FSW</strong>-C plus72<strong>FSW</strong>-C42-C plus72321025201007 1002.535 353030End-mounted slide bolt,bottom20281507/08 53

<strong>FSW</strong>Panel Types<strong>FSW</strong>-C<strong>FSW</strong>-C assembly typesType C11 single action end panel(narrow)3 folding panels1 base panel (narrow)1/2 FB1/2 FB1/2 FB+ 634 4 4 4FBFBFB1/2 FBFB FB = Panel = Flügelbreite width+ 63Inside7442Inside42 mm between the door rails64 mm between the glass panesType C21 final folding panel(narrow)3 folding panels1 base panel (narrow)Inside7442Inside42 mm between the door rails64 mm between the glass panes54 07/08

Type C31 access leaf(final folding panel)2 folding panels1 base panel (narrow)1/2 FB4 4 4FB FBFB = Panel widthFB1/2 FB+ 63Inside7442Inside42 mm between the door rails64 mm between the glass panesType C3 double (counter-running) systemLeft:1 base panel (narrow)2 folding panels1 access leaf (final folding panel)Right:1 access leaf (final folding panel)2 folding panels1 base panel (narrow)744242 mm between the door rails64 mm between the glass panes07/08 55

<strong>FSW</strong>Panel Types<strong>FSW</strong>-C plus<strong>FSW</strong>-C plusAccess with convenience – theplus with the <strong>FSW</strong>-C.The <strong>FSW</strong>-C model offers thepossibility of using the finalfolding panel as an accessdoor when the frontage isclosed – with all theconvenience offered by the<strong>DORMA</strong> TS 93 G door closer.In this case, the specialbottom locking device andthe top clamp-mounted stopstabilise the first foldingpanel, while the top anglestop ensures that the closedfinal folding panel is in thecorrect position.The folding hinges connectingthe access leaf to the foldingpanel have a large pivot pointoffset in order to create roomfor the door closer and pullhandles. All the other foldingpanels are equipped with astandard folding hinge androller.Type Cp11 access leaf (final folding panelwith TS 93 G door closer)1 folding panel1 base panel (narrow)FBFB = Panel widthInside1/2 FB4 4FB1/2 FB+ 63Max. panel sizesand weightsMax. system height 3000 mm10472Max. panel width 1000 mmWidth of the base panel= half panel width + 63 mmMax. panel weight 70 kgNumber of panels 3 to 8Inside42 mm between the door rails64 mm between the glass panesType Cp1 double (counter-running) systemLeft:1 base panel (narrow)1 folding panel1 access leaf (final folding panelwith TS 93 G door closer)Right:1 access leaf (final folding panelwith TS 93 G door closer)1 folding panel1 base panel (narrow)10472inside42 mm between the door rails64 mm between the glass panes56 07/08

Type Cp21 access leaf (final folding panelwith TS 93 G)2 folding panels1 base panel (narrow)1/2 FB4FBFBFB = Panel width4 4FB1/2 FB+ 63Daten and featuresTS 93Closing strength/SizeClosing strength,variableClosing speed, variableSame specification forDIN-L and DIN-RLatching speedadjustmentCushioned stay limitadjustableFixing adjustableWeightLengthOverall depthHeightEN 2 - 5via adjustingscrewvia valvevia valve80° - 120°75° - 150°3,5 kg275 mm53 mm60 mmInsideInside42 mm between the door rails64 mm between the glass panes10472Type Cp2 double (counter-running) systemLeft:1 base panel (narrow)2 folding panels1 access leaf (final folding panelwith TS 93 G)Right:1 access leaf (final foldingpanel with TS 93 G)2 folding panels1 base panel (narrow)10472Inside42 mm between the door rails64 mm between the glass panes07/08 57

<strong>HSW</strong>Panel Types<strong>HSW</strong>-R<strong>HSW</strong>-R panel types and functionsHorizontal sliding walls,fully framed,for toughened safety glass,laminated safety glass ordouble glazingRobust profile frames withtop, bottom and side sealsfor elevated resistance tomechanical loading andprotection againstweathering, heat loss anddraughts. Available withtoughened safety glass, laminatedsafety glass, doubleglazing or special glazing;standard fixing profile for8 to 22 mm, other glazingthicknesses on application.Max. panel sizesand weightsSingle/doubleaction end panelNon-sliding.Single actionpanel with floorpivot and TS 73door closer.Double actionpanel with floorpivot or BTSfloor spring.Sliding panelFixed whenfrontage closed.Single actionsliding panelWith integratedconcealed doorcloser type ITS96, Size 3-6;operational whenfrontage closed.Minimal panelwidth 870 mm.Double actionsliding panel *With integratedconcealed doorcloser type ITS96, Size 3-6;operational whenfrontage closed.Minimal panelwidth 870 mm.Max. system height3000 mm3000 mm3000 mm3000 mmMax. panel width1100 mm1100 mm 1100 mm1100 mmMax. panel weight100 kg100 kg 100 kg 100 kgThe individual panels can also be of differing widths.The largest width should not exceed max. 115% of the smallest width.* For these panel types please consider our notes on portal systems on page 89.58 07/08

<strong>HSW</strong>-R system designIrrespective of the function ofthe individual panels, an<strong>HSW</strong>-R system comprises thefollowing components:721 Installation-efficient<strong>DORMA</strong> substructure toaccommodate track railmounting requirements(optional)2 Track rail for bolting to thesubstructure3 Carrier4 Suspension assembly5 Adapter frame6 Glazing frame profile,horizontal7 Glazing rail8 Glazing frame profile,vertical9 Toughened safety glass,laminated safety glass orsealed double glazing units(by others)10 Bottom rail757533±56050151912345678960750228151922 5087610Toughened safetyglassversionFFL07/08 59

<strong>HSW</strong>Panel Types<strong>HSW</strong>-RSingle/Double ActionEnd PanelsEnd panelNon-moving and alwaysequipped with bottomdeadbolt with the option of atop bolt or side action deadlock.Single action or doubleaction options.Single action or double action end panel with floor pivot755033±5Pivot bearing75863Double action end panelAssembly types:Floor pivot with roundspindleBTS 84 for panels upto 100 kg, with optionalhold-open at 90° dooropening angleBTS 80 for panelsof 100-150 kg, providedwith hold-open asstandardSingle action end panelwith stop plates at the topbolt.Assembly types:Floor pivot with round spindleAs above, but with<strong>DORMA</strong> TS 73 or TS 92overhead door closerBTS 84 for panels upto 100 kg, with optionalhold-open at 90° dooropening angleBTS 80 for panelsof 100-150 kg, providedwith hold-open asstandardHeight of glazing =Total height –329 mm50607Double action end panelwith floor springMounting dimensionsabcdBTS80786034151-57BTS841084030651-58b15 1584519a86336.56563d2736c60 07/08

Single action end panel with TS 73 overhead door closer and additional locking device and door stop2224563193.5205160140Single action end panel with TS 92 overhead door closer and additional locking device37563199145.5 89min. panel width 870 mmData and featuresClosing strength/sizeClosing strength,variableClosing speed adjustmentNon-handedLatching speed adjustmentCushioned stay limit adjustmentHold-open adjustmentWeightLengthOverall depthHeightTS 73 VEN 2-4via adjusting screwand arm hingevia valvevia arm75°-180°75°-160°1.8 kg233 mm42.50 mm60 mmTS 92EN 2-4via adjusting screwand arm hingevia valvevia arm80°-120°75°-150°1.9 kg281 mm47 mm65 mm3.5Additionallocking device50Ø7M6Ø1007/08 61

<strong>HSW</strong>Panel Types<strong>HSW</strong>-RSliding PanelsSliding panelFixed when partition isclosed.Sliding panelEngaging the panel in the strike plate75Slidingpanel67Sliding panel7533±5±5Ø 25 Ø 850Strike plateSliding panelsThe sliding panels are movingelements. Once in theirclosed position, they arelocked down.The components availablefor this are provided in thebottom rail in the form offace-mounted floor bolts ordeadlocks.Glazing height =Total height - 329 mm50608-101515Slidingpanel48Engaging the panel in eccentric bushingSliding panel±2.5min.30Eccentric bushingØ 25Ø 8Sliding panel to panel connectionsSealPanel widthGlass width =Panel width - 75 mm67Panel to wall connectionWall connection profilewithbrush profile51Sliding panel651Sliding panel51 516Sliding 10panelDouble actionsliding panelBrush profile6Abutmentwitharticulatedjoint90-170°Sliding panelBrush profileWallSliding panelSingle actionsliding panelSliding panelWall62 07/08

<strong>HSW</strong>Panel Types<strong>HSW</strong>-R Single ActionSliding PanelsSingle action sliding panelSingle action sliding panelwith integrated ITS 96,size 3-6 concealed doorcloser for operation as singleaction door when the frontageis closed.75Track rollerTop pivot75Single actionsliding panelSingle action sliding panelwith integrated<strong>DORMA</strong> ITS 96concealed door closer,size 3-6This panel type is used wherepassdoors only need to beopened in one direction.The single action sliding panelcan be configured for eitherinward or outward opening.8-10151560 50min.3050633±5Glass height =Total height - 329 mm±2.5Face-mountedfloor boltEccentric bushingØ 25Ø 8Standard assemblytop: Pivot bearing,ITS 96, size 3-6,one locking devicebottom: Face-mounted floorbolt as pivot(released for slidingfunction)Optional equipmenttop: Second locking device(for reshuffle bypassstacking)bottom: Optional secondface-mounted floorbolt or deadlock3.5Locking deviceø7M6ø10415 812913.560 110735007/08 63

<strong>HSW</strong>Panel Types<strong>HSW</strong>-RDouble ActionSliding Panels ITSDouble action sliding panelWith integrated ITS 96,size 3-6 concealed doorcloser, for operation asdouble action passdoor whenthe frontage is closed.75Track rollerTop pivotDouble actionsliding panel5075633±5Double action sliding panelwith integrated<strong>DORMA</strong> ITS 96concealed door closer,size 3-6Double action sliding panelswith <strong>DORMA</strong> ITS 96, size 3-6door closers are characterisedby their exceptional ease ofinstallation and operation.These passdoor panels aregenerally equipped with abottom deadlock and top lockingdevice plus a bottom floorbolt operating as the pivotbearing (released for the slidingfunction).The ITS 96 does not featurea hold-open function asstandard.For these panel types pleaseconsider our notes on portalsystems on page 89.3.5Glazing height =Total height - 329 mmLocking deviceø7M6ø108-104151515 860 50min.30129±2.513.5Face-mountedfloor boltEccentric bushingØ 25Ø 87360 1105064 07/08

<strong>HSW</strong>Notes07/08 65

<strong>HSW</strong>Panel Types<strong>HSW</strong>-ISO<strong>HSW</strong>-ISO panel types and functionsDouble glazing withthermal-break frame profiles.Panel typesThese double-glazed panelswith their frames ofthermal-break profiles(frame material group 2.1)offer outstanding protectionagainst the influences of theweather, effective thermalinsulation and comfortabletemperatures - even close tothe frontage surface - duringseasonal changes and in thewinter months. And all theseeffects are ideally enhancedby laterally arranged, interlockingmultiple-lip seals plusautomatically extending topand bottom rubber seals thatare pressed against the trackrail and floor when thefrontage is closed.Glass thickness 8-49 mm.Max. panel sizesand weightsSingle actiondoorSingle actionpanel,non-sliding,equipped withTS 92/93 doorcloser(optional)Sliding panelFixed whenfrontage closed.Single actionsliding panelSingle actionsliding panelfor door accesswhen frontageclosed; withITS 96 EN 3-6concealed camactiondoorcloser, or withTS 92/TS 93cam-action doorclosers ifrequired.Fixed screenNon-slidingside screen withtop retainingbrackets andbottom rail.Max. system height3000 mm3000 mm3000 mm3000 mmMax. panel width1100 mm1100 mm 1100 mm1100 mmMax. panel weight120 kg120 kg 120 kg 120 kgThe individual panels can also be of differing widths.The largest width should not exceed max. 115% of the smallest width.66 07/08

<strong>HSW</strong>-ISO system designIrrespective of the functionof the individual panels, an<strong>HSW</strong>-ISO system comprisesthe following basiccomponents:721 Installation-efficient<strong>DORMA</strong> substructure toaccommodate track railmounting requirements(optional)2 Track rail for bolting tothe substructure.3 Carrier4 Suspension assembly andbearing profile for safeand easy sliding of thepanels5 Glazing rail6 Sealed double glazingunit (by others)Glass thickness 8-49 mm7 Automatically extendingrubber seal8 Insulating strips in thethermal-break profile9 Bottom frame profile78757559 671645372233±51041234568-4964651622106128977FFL807/08 67

<strong>HSW</strong>Panel Types<strong>HSW</strong>-ISOSingle action doorSingle action door with wallconnection profileSingle action panel,non-sliding, operatesindependently of the restof the system.Single action door with wall connection428 150160 140The single action door withwall connection arm assemblycan be swung round 170°, soleaving the entire operatingzone free. The closed panel issecured by a mortise centrelock.Single action door with wall connectionInward openingOutside5916559Outward openingOutside37581591622GlazingheightFrame height6464Panel height insideTotal height2222Inside8153759 59522InsideIn order to provisionally determine the glazing area per panel, please applythe following formula:Approx. glazing area per panel = Panel width x total height x 0.786The precise dimensions of the sealed double glazing units to be orderedshould be exclusively taken from the approval drawing releasedby <strong>DORMA</strong>-Glas.68 07/08

Fixed screenNon-sliding side screen thatdecouples from the rest ofthe system.Fixed screen with wall connectionOutside165964Inside762259Fixed screen with wall connection profileOutside16577 37The fixed screen has thesame appearance as thesliding panels.Instead of the automaticallyextending bottom rubberseal, it features a bottomrail.GlazingheightFrame heightPanel height insideTotal heightInside642259 54In order to provisionally determine the glazing areaper panel, please apply the following formula:Approx. glazing area per panel= Panel width x total height x 0.78The precise dimensions of the sealed double glazingunits to be ordered should be exclusively taken fromthe approval drawing released by <strong>DORMA</strong>-Glas.Thermal and sound insulationTable (extract) for determining the k-value ofvarious types of glazing installed inconjunction with frame material group 2.1.Measurements performed by the Institut fürFenstertechnik e.V. (Inst. of WindowTechnology) of Rosenheim, Germany usingan installed 4-panel system revealed a soundreduction level of min. 27 dB.Double glazingwith …mmair gap> 6 to < 8> 6 to < 10> 10 to < 162 x > 6 to < 82 x > 8 to < 10Glazingk v3.4 W/m 2 K3.2 W/m 2 K3.0 W/m 2 K2.4 W/m 2 K2.2 W/m 2 KWindows and frenchdoors including framek F3.2 W/m 2 K3.0 W/m 2 K2.9 W/m 2 K2.5 W/m 2 K2.3 W/m 2 KDate and featuresTS 92TS 93Closing strength/sizeClosing force, variableClosing speed adjustmentNon-handedLatching speed adjustmentCushioned stay limit adjustmentHold-open adjustmentWeightLengthOverall depthHeightEN 2-4via adjusting screwvia valveyesvia valve80°-120°75°-150°1.9 kg281 mm47 mm65 mmEN 2-5via adjusting screwvia valveyesvia valve80°-120°75°-150°3.5 kg275 mm53 mm60 mmEN 5-7via adjusting screwvia valveyesvia valve80°-120°75°-150°5.2 kg285 mm62 mm71 mm07/08 69

<strong>HSW</strong>Panel Types<strong>HSW</strong>-ISOSliding PanelSliding panelFixed when the frontage orpartition is closed.Glazing heightSliding panelsThe sliding panels are themoving elements. Once intheir closed position, theyare locked down. Facemountedfloor bolts areavailable as an option forthe bottom glazing rail.Frame heightPanel height insideTotal height6In order to provisionally determine the glazing area per panel, please applythe following formula:Approx. glazing area per panel = Panel width x total height x 0.78The precise dimensions of the sealed double glazing units to be orderedshould be exclusively taken from the approval drawing releasedby <strong>DORMA</strong>-Glas.Horizontal sections of the sliding panels with connection detailsSliding panel to wall connection profileOutside5773716Sliding panel to sliding panelOutside577 5916 166464Inside2259 54622 2259 766Inside70 07/08

<strong>HSW</strong>Panel Types<strong>HSW</strong>-ISO Single ActionSliding PanelSingle action sliding panelwith <strong>DORMA</strong> ITS 96, size 3-6cam-action door closerSingle action sliding panel with integrated ITS 96300 184ITS 96 door closerintegrated in the profile(concealed installation)This panel type is installedwhere doors need to beopened in one direction. Thecam-action door closer can befitted so that the single actionpanel is either inward oroutward opening.Glazing heightFrame heightPanel height outsideTotal heightStandard assemblytop: Pivot bearing,ITS 96, size 3-6one locking devicebottom: Face-mounted slidebolt as pivot (releasedfor sliding function)Optional equipmenttop: Second locking device(for reshuffle bypassstacking)bottom: Optional secondface-mountedslide boltHorizontal section of single action panels,inward or outward opening16Outward opening8155922 16Function ofthe toplocking deviceStatus of lockingdevice for dooroperation129Status of lockingdevice for sliding12964622 2259581Inward opening2207/08 71

<strong>HSW</strong>Panel Types<strong>HSW</strong>-ISOReshuffle Bypass StackingStacking in the reshufflebypass configurationThis special stackingarrangement is applied whenthe panels should be parked ina niche and no single actionend panel should be visible inthe frontage.Please also see the followingillustrations.Sliding panel in bypass travel mode (sliding end panel)Single action sliding panel in bypass travel mode (outward opening only)72 07/08

<strong>DORMA</strong> <strong>HSW</strong>Notes07/08 73

<strong>HSW</strong>AccessoriesVertical Seals OverviewSeals retrofittableSeals individually customisedThe following retrofittable profiles areavailable to provide the necessary lateralsealing so that the horizontal sliding can bemade draught-proof for winter operation.These frame profiles for rendering doors draught-proof areindividually manufactured and therefore need to be takeninto account when designing the horizontal wall system.All the relevant specifications must be provided with thesystem order.Aluminium alloy profilewith brushFinelinewith brush seal (pages 75-80)for 10 mm glass4for 10 mmand 12 mm glass13304for 12 mm glassClear plastics profile(not for single/double action end panelsor double action sliding panels)for 10 mm glassfor 12 mm glass44412 10121033.533.532LineSingle action door with brush seal (page 81)for 10, 12 and13.5 mm glass321013.51210/12LineSliding door with rubber seal (pages 82-84)for 10, 12 and13.5 mm glass3213.5Silicone joint10/12117544544Bond with silicone15Silicone joint11574 07/08

<strong>HSW</strong>AccessoriesVertical SealsFinelineFineline SealEnd panelNon-moving and alwaysequipped with a bottomdeadbolt with the optionof an additional top bolt orside-action deadlock.Can be designed as a singleaction or double action door.Single action or double action end panel with floor pivotø 9.8AdaptedCalculation of the glass width= Panel width – 16 mmAs-delivered length (total height – 70)57.5M4Profile length adapted on site2520463As-delivered condition:Cut lengths supplied fromfactory= Partition height – 100 mmHoles and recesses arepre-machined in the profilefor the bottom glazing railonly.Any further machining workrequired for connection tothe top glazing rail has to beperformed on site.Bottom drill hole or recess forend-mounted floor bolt machinedby <strong>DORMA</strong>-Glas327 113Installation instructionsWhen fitting the glazing rails, please ensure that the glass protrusion is even overthe full length.Prior to profile machining, first hang the panels from the overhead track and thenalign.07/08 75

<strong>HSW</strong>AccessoriesVertical SealsFinelineSliding panelFixed when the frontage orpartition is closed.The sliding panels are themoving elements. Once intheir closed position, they arelocked down. The componentsavailable for this are providedin the bottom glazing rail inthe form of face-mountedfloor bolts, end-mounted floorbolts, end pin bolts ordeadlocks.Sliding panelø 9.818.5AdaptedCalculation of the glass width= Panel width – 16 mmAs-delivered length (total height – 130)M4Profile length adapted on site252014137Sliding panelAs-delivered condition:Cut lengths supplied fromfactory= Partition height – 100 mmHoles and recesses arepre-machined in the profilefor the bottom glazing railonly.Any further machining workrequired for connection tothe top glazing rail has to beperformed on site.32Bottom drill hole or recess for end-mountedfloor bolt machined by <strong>DORMA</strong>-GlasInstallation instructionsWhen fitting the glazing rails, please ensure that the glass protrusion is even over thefull length.Prior to profile machining, first hang the panels from the overhead track and thenalign.Use the factory-stamped recesses in the bearing profile for accurate adjustment of thetop Fineline profile.76 07/08

Sliding panels in segmentedconfigurationsFixed when frontage orpartition closed.The sliding panels are themoving elements. Once intheir closed position, they arelocked down. The componentsavailable for this are providedin the bottom glazing rail inthe form of face-mounted floorbolts, end-mounted floor bolts,end pin bolts or deadlocks.Sliding panels in segmented configurationsø 9.8AdaptedProfile toupper face ofbrush carrierBrush13Calculation of the glass width= Panel width – 16 mmAs-delivered length (total height – 70)57.5M4Profile length adapted on site2520Sliding panel4137 1As-delivered condition:Cut lengths supplied fromfactory= Partition height – 100 mmHoles and recesses arepre-machined in the profilefor the bottom glazing railonly.Any further machining workrequired for connection tothe top glazing rail has to beperformed on site.32Installation instructionsWhen fitting the glazing rails, please ensure that the glass protrusion is even overthe full length.Prior to profile machining, first hang the panels from the overhead track and thenalign.07/08 77

<strong>HSW</strong>AccessoriesVertical SealsFinelineDouble action sliding panelDouble action panel with RTStransom-concealed door closerfor door access when frontageor partition closed.Double action sliding panelM4RTS 85Calculation of the glass width= Panel width – 16 mmAs-delivered condition:Cut lengths supplied fromfactory= Partition height – 100 mmHoles and recesses arepre-machined in the profilefor the bottom glazing railonly.Any further machining workrequired for connection tothe top glazing rail has to beperformed on site.As-delivered length (total height – 165)AdaptedProfile length adapted on site2020Slidingpanel321476513 52M4x25Double action slidingpanel with RTSInstallation instructionsWhen fitting the glazing rails, please ensure that the glass protrusion is even overthe full length.Prior to profile machining, first hang the panels from the overhead track and thenalign.78 07/08

Folding sliding panelHinged, with lock and slidebolt at the bottom, latchingbolts top and bottom forfixing the final folding panelto the sliding panel.Folding sliding panel11Lock with lever handle and strike box optional.932105011117417880MilledMilledø5050Calculation of the glass width= Panel width – 16 mmAs-delivered condition:Cut lengths supplied fromfactory= Partition height – 100 mmHoles and recesses arepre-machined in the profilefor the bottom glazing railonly.Any further machining workrequired for connection tothe top glazing rail has to beperformed on site.7Installation instructionsWhen fitting the glazing rails, please ensure that the glass protrusion is even overthe full length.Prior to profile machining, first hang the panels from the overhead track and thenalign.07/08 79

<strong>HSW</strong>AccessoriesVertical SealsFinelineFineline SealProfile machiningThis is performed by <strong>DORMA</strong>-Glas for the end-mounted andface-mounted slide bolts.Fineline seal with end-mounted slide bolt714ø1612 1360304220M4x3037M4x1845337028Fineline seal with face-mounted slide bolt714139730205233706580 07/08

<strong>HSW</strong>AccessoriesVertical SealsLineLine SealSingle action or double actionend panelsNon-moving and alwaysequipped with a bottomdeadbolt with the option ofan additional top bolt orside-action deadlock.Can be designed as a singleaction or double action door.Single action or double action end panel with floor pivotø 9.8AdaptedCalculation of the glass width= Panel width – 30 mmAs-delivered length (total height – 70)57.5M4Profile length adapted on site2520463As-delivered condition:Cut lengths supplied fromfactory= Partition height – 100 mmHoles and recesses arepre-machined in the profilefor the bottom glazing railonly.Any further machining workrequired for connection tothe top glazing rail has to beperformed on site.Bottom drill hole orrecess for end-mountedfloor bolt machinedby <strong>DORMA</strong>-GlasInstallation instructionsWhen fitting the glazing rails, please ensure that the glass protrusion is even overthe full length.Prior to profile machining, first hang the panels from the overhead track and thenalign07/08 81

<strong>HSW</strong>AccessoriesVertical SealsLineSliding panelFixed when the frontage orpartition is closed.The sliding panels are themoving elements. Once intheir closed position, they arelocked down. The componentsavailable for this are providedin the bottom glazing rail inthe form of face-mountedfloor bolts, end-mounted floorbolts, end pin bolts ordeadlocks.Sliding panelAdaptedø 9.8Calculation of the glass width= Panel width – 30 mmAs-delivered condition:Cut lengths supplied fromfactory= Partition height – 100 mmHoles and recesses arepre-machined in the profilefor the bottom glazing railonly.Any further machining workrequired for connection tothe top glazing rail has to beperformed on site.M4Profile length adapted on siteAs-delivered length (total height – 130)252033.5425 15Bottom drill hole or recess for end-mounted floor boltmachined by <strong>DORMA</strong>-GlasSliding panel13.5Installation instructionsWhen fitting the glazing rails, please ensure that the glass protrusion is even overthe full length.Prior to profile machining, first hang the panels from the overhead track and thenalign.82 07/08

Double action sliding panelDouble action panelwith RTS transom-concealeddoor closer for door accesswhen frontage or partitionclosed.Double action sliding panelM4RTS 85Calculation of the glass width= Panel width – 30 mmAs-delivered condition:Cut lengths supplied fromfactory= Partition height – 100 mmHoles and recesses arepre-machined in the profilefor the bottom glazing railonly.Any further machining workrequired for connection tothe top glazing rail has to beperformed on site.As-delivered length (total height – 165)AdaptedProfile length adapted on site202033.5Slidingpanel13.5425 401565M4x30Double action slidingpanel with RTSInstallation instructionsWhen fitting the glazing rails, please ensure that the glass protrusion is even overthe full length.Prior to profile machining, first hang the panels from the overhead track and thenalign.07/08 83

<strong>HSW</strong>AccessoriesVertical SealsLineProfile machiningThis is performedby <strong>DORMA</strong>-Glas for theend-mounted andface-mounted slide bolts.Line seal with end-mounted slide bolt1512ø2542565 30M4x402030M4x35453345Line seal with end-mounted slide bolt1533.513.542585 3030337038,36584 07/08

<strong>HSW</strong>Notes07/08 85

<strong>HSW</strong>AccessoriesFloor TrackFloor Track for sliding panelsA floor track in the form ofa stainless steel channelsection (U-profile) is alsoavailable as an option.This can be used for <strong>HSW</strong>-Gand <strong>HSW</strong>-R sliding panelsirrespective of the partitionlayout. In special cases andafter technical clarification,it may also be used with<strong>HSW</strong>-GP sliding panels. Forthis, the end-mounted floorbolt usually applied forstraight-line partitionconfigurations is replaced bya combination of guide pinand end pin.The guide pin must bevertically below the trackroller and is adjustable in therange +/- 10mm.For abutment to singleaction/double action endpanels and also in the caseof angled configurations, aface-mounted floor bolt isreplaced by a bottomdeadlock.Sliding panelGlass height = Total height – 308202535 33±5100752.565Sliding panel465972110014.5Hex head boltM6 x 35, 10 mm A/FThe floor track is available inthree designs:Straight90° curve135° curveThe individual track sectionsare abutted and fixed in placeby means of a stainless steelconnector.In its as-delivered condition,the floor track comes with awelded flange for fixing to theunfinished floor. This can beremoved if not required.Straight90° curve 135° curve86 07/08

R1Floor track Stacking track detailFloor track1(10.5}Floor track connector12.5+0.31R190°12.5±1 (14.5)Max. length 3 m5011102091°Floor fixing flangeCan be removed if not required<strong>HSW</strong> floor track configuration with a 90° stacking track arrangement<strong>HSW</strong> floor track configuration with a 135° stacking track arrangement40<strong>HSW</strong> floor track configuration with a parallel stacking track arrangement40R100R100135°90°4040(19)276214 12021407/08 87

<strong>HSW</strong> / <strong>FSW</strong>MiscellaneousMeasuring upImportant site measurementsHeight ofstructural ceilingSubstructureheightHeight ofsuspendedceilingTrack1-metre datum line(site reference dimension)<strong>HSW</strong> system heighttrack heightTop surfaceof structural floorFFLTop surface offinished floorClear width (finished wall)Stackingtrack depthReshuffle bypassStacking trackwidthWall frontage/closed wall system88 07/08

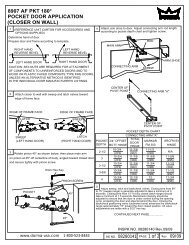

Notes on portal systemsMaintenance recommendation forhigh-frequency <strong>HSW</strong> systemsHorizontal glass walls have been developed in order to provideretail outlets with generous and enticing frontages –entrances that offer easy accessibility and an invitingappearance for customers. When the frontages are closed,they can double up as expansive shop windows.In cases where double-action sliding panels are used formain entrances as a portal system (i. e. shopping malls orsimilar operated <strong>HSW</strong> systems) they are submitted to veryhigh daily traffic volumes and usage frequency rates. Thedoor closers and pivot bearings used by <strong>DORMA</strong>-Glas havebeen successfully tested in accordance with the requirementsof EN 1154. EN 1154 specifies 500,000 test cyclesfor manually operated closing devices. High-frequency portalsystems such as the above can reach this number of cyclesafter just a few months. Consequently, <strong>DORMA</strong>-Glas recommendsthat such units be regularly maintained.The higher the usage levels, the more frequently the equipmentshould be serviced by either the installation firm or asimilarly specialised fitter.Planning toolsFor planning of intelligent glass solutions weoffer you several planning tools which allow youto create secure and professional solutions forany kinds of glass doors and toughend glassassemblies.The planning tools DGES and MANET COMPACT enable youto prepare designs and cost calculations quickly, reliablyand professionally. The software provides you with allnecessary documentation such as dimensioned technicaldrawings, glass sizes and preparation measures.Your benefits:Easy to operateProfessional and error-free preparation of offersRapid response to incoming requests for quotationsHighly reduced planning costs for time and moneysavingsDGES Fittings(for internal doors and toughend glass assemblies),Art. No. 800.51.248.6.32DGES <strong>HSW</strong> (for horizontal sliding walls),Art. No. 800.51.247.6.32DGES Showers (for glass shower cubicles),Art. No. 600.51.600.9.03MANET COMPACT planning tool(for MANET pivoting and sliding doors),Art. No. 800.51.329.6.32FinishesDeviations in colour due to production procedures cannot betotally excluded.<strong>HSW</strong> systems with surface finishes 502, 503, 700 and 701contain different component materials.In the case of <strong>FSW</strong> (folding/sliding) systems, for example,the folding hinges are always of aluminium, while thestandard surface finish for brush profiles and end covers isblack anodised (E6/C35). These various components andalso the top locks can also optionally be anodised orpowder-coated so that they resemble the ordered surfacefinish.Owing to the use of different materials and processes,variations can occur in the appearance of the surfacefinishes and colours.FinishesAluminium <strong>DORMA</strong>-Glas similar similarDescription No. Eloxal l Eloxal llAlumin. mill finish 100Alumin. silver 101 EV1 C 0Alumin. similar satinstainl. steel 107Alumin. similar satinstainl. steel 113 C 31(for profile material)Special anodised 199Coated colours <strong>DORMA</strong>-Glas similar similarDescription No. HEWI-Nr. RALAlumin. white 300 99 9016Special coated colour 399BrassDescriptionBrasspolished varnished 502Brass polished 503Stainless steelDescriptionSatin stainless steel 700Polishedstainless steel 701General care instructions<strong>DORMA</strong>-GlasNo.<strong>DORMA</strong>-GlasNo.The surface finishes of the fittings are not maintenance-freeand should be cleaned according to their material and design.For metallic surfaces (anodised finishes, stainless steel) pleaseuse appropriate cleaning agents without abrasive additives only.For varnished surfaces please use appropriate solvent-freecleaning agents only.Brass surfaces (without surface protection) have to be treatedwith an appropriate maintenance agent on occasion, to avoidtarnishing.07/08 89

WN 800.51.181.6.32 · 07/08 · GB · 2 · BD · 08/08Division GlasbeschlagtechnikGlass fittings and accessories<strong>DORMA</strong>-Glas GmbHPostfach 32 68D-32076 Bad SalzuflenMax-Planck-Straße 33 - 45D-32107 Bad SalzuflenTel. +49 5222 924-0Fax +49 5222 21009www.dorma.com