CIP - Cold Isostatic Press Pin Closure - Hasmak.com.tr

CIP - Cold Isostatic Press Pin Closure - Hasmak.com.tr

CIP - Cold Isostatic Press Pin Closure - Hasmak.com.tr

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

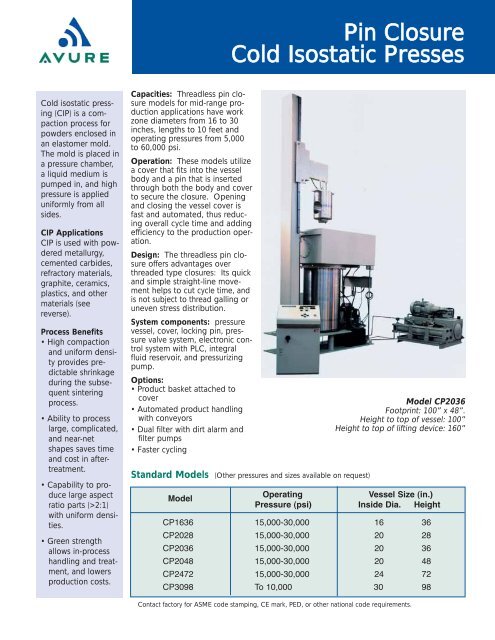

<s<strong>tr</strong>ong>Pin</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Closure</s<strong>tr</strong>ong><s<strong>tr</strong>ong>Cold</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Isostatic</s<strong>tr</strong>ong> <s<strong>tr</strong>ong>Press</s<strong>tr</strong>ong>es<s<strong>tr</strong>ong>Cold</s<strong>tr</strong>ong> isostatic pressing(<s<strong>tr</strong>ong>CIP</s<strong>tr</strong>ong>) is a <s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>pactionprocess forpowders enclosed inan elastomer mold.The mold is placed ina pressure chamber,a liquid medium ispumped in, and highpressure is applieduniformly from allsides.<s<strong>tr</strong>ong>CIP</s<strong>tr</strong>ong> Applications<s<strong>tr</strong>ong>CIP</s<strong>tr</strong>ong> is used with powderedmetallurgy,cemented carbides,refractory materials,graphite, ceramics,plastics, and othermaterials (seereverse).Process Benefits• High <s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>pactionand uniform densityprovides predictableshrinkageduring the subsequentsinteringprocess.• Ability to processlarge, <s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>plicated,and near-netshapes saves timeand cost in after<strong>tr</strong>eatment.• Capability to producelarge aspec<strong>tr</strong>atio parts (>2:1)with uniform densities.• Green s<strong>tr</strong>engthallows in-processhandling and <strong>tr</strong>eatment,and lowersproduction costs.Capacities: Threadless pin closuremodels for mid-range productionapplications have workzone diameters from 16 to 30inches, lengths to 10 feet andoperating pressures from 5,000to 60,000 psi.Operation: These models utilizea cover that fits into the vesselbody and a pin that is insertedthrough both the body and coverto secure the closure. Openingand closing the vessel cover isfast and automated, thus reducingoverall cycle time and addingefficiency to the production operation.Design: The threadless pin closureoffers advantages overthreaded type closures: Its quickand simple s<strong>tr</strong>aight-line movementhelps to cut cycle time, andis not subject to thread galling oruneven s<strong>tr</strong>ess dis<strong>tr</strong>ibution.System <s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>ponents: pressurevessel, cover, locking pin, pressurevalve system, elec<strong>tr</strong>onic con<strong>tr</strong>olsystem with PLC, integralfluid reservoir, and pressurizingpump.Options:• Product basket attached tocover• Automated product handlingwith conveyors• Dual filter with dirt alarm andfilter pumps• Faster cyclingStandard Models (Other pressures and sizes available on request)ModelModel CP2036Footprint: 100” x 48”.Height to top of vessel: 100”Height to top of lifting device: 160”OperatingVessel Size (in.)<s<strong>tr</strong>ong>Press</s<strong>tr</strong>ong>ure (psi) Inside Dia. HeightCP1636 15,000-30,000 16 36CP2028 15,000-30,000 20 28CP2036 15,000-30,000 20 36CP2048 15,000-30,000 20 48CP2472 15,000-30,000 24 72CP3098 To 10,000 30 98Contact factory for ASME code stamping, CE mark, PED, or other national code requirements.

<s<strong>tr</strong>ong>CIP</s<strong>tr</strong>ong> Applications<s<strong>tr</strong>ong>Cold</s<strong>tr</strong>ong> isostatic applications include cementedcarbide rolls and wear parts, nozzles, blocks,and crucibles for the refractory indus<strong>tr</strong>y,iso<strong>tr</strong>opic graphite, ceramic insulators, tubesfor chemical applications, ferrites, metal filters,preforms, and plastic tubes and rods.Cemented carbide productsParts produced from isostatically pressedgraphiteLong refractory nozzles and stoppersMetal filters produced to net shapeHigh voltage ceramic insulatorsMolybdenum billets weighingapprox. 1000 kgAvure Autoclave Systems, Inc.3721 Corporate Drive • Columbus, OH 43231(614) 891-2732 • Fax: (614) 891-4568www.avureae.<s<strong>tr</strong>ong>com</s<strong>tr</strong>ong>ISO-9001:2000Quality System Certified© 2006 Avure Autoclave Systems, Inc. Printed in U.S.A.