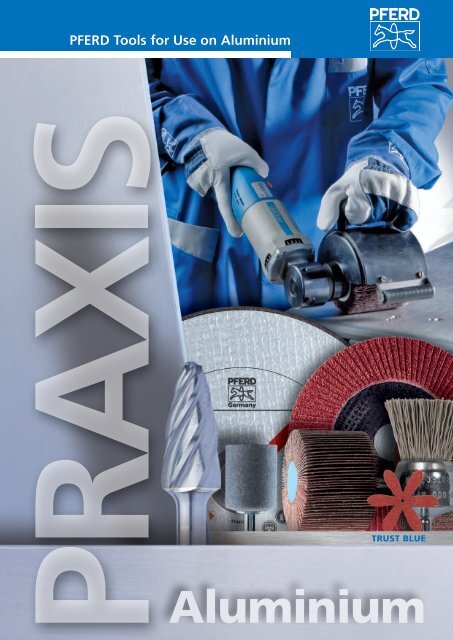

PFERD Tools for Use on Aluminium

PFERD Tools for Use on Aluminium

PFERD Tools for Use on Aluminium

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<str<strong>on</strong>g>PFERD</str<strong>on</strong>g> <str<strong>on</strong>g>Tools</str<strong>on</strong>g> <str<strong>on</strong>g>for</str<strong>on</strong>g> <str<strong>on</strong>g>Use</str<strong>on</strong>g> <strong>on</strong> <strong>Aluminium</strong>Introducti<strong>on</strong>, Table of C<strong>on</strong>tentsAugust Rüggeberg GmbH & Co. KG, Marienheide/Germany, develops,produces and markets tools <str<strong>on</strong>g>for</str<strong>on</strong>g> surface finishing and cutting materialsunder the brand name <str<strong>on</strong>g>PFERD</str<strong>on</strong>g>. For more than 100 years, <str<strong>on</strong>g>PFERD</str<strong>on</strong>g> has beena distinctive brand mark <str<strong>on</strong>g>for</str<strong>on</strong>g> excellent quality, top per<str<strong>on</strong>g>for</str<strong>on</strong>g>mance andec<strong>on</strong>omic value.<str<strong>on</strong>g>PFERD</str<strong>on</strong>g> produces a comprehensive tool range <str<strong>on</strong>g>for</str<strong>on</strong>g> the most diverse aluminiummachining and finishing tasks. All of these products have been purpose-developed<str<strong>on</strong>g>for</str<strong>on</strong>g> their respective applicati<strong>on</strong> and have proven themselves in practice.In the present issue of <str<strong>on</strong>g>PFERD</str<strong>on</strong>g> PRAXIS we have summarized our experience ofmany years, including the very latest know-how, <strong>on</strong> the specific machining andper<str<strong>on</strong>g>for</str<strong>on</strong>g>mance behaviour of tools <str<strong>on</strong>g>for</str<strong>on</strong>g> use <strong>on</strong> aluminium and its diverse alloys.<strong>Aluminium</strong>A Material with a Future ......................3More than 1,000 Alloys ......................4Properties of <strong>Aluminium</strong> ......................5Machinability Groups SOFT, TOUGH, HARD ...6<strong>Aluminium</strong> Machining Recommendati<strong>on</strong>s .........7Important Safety Instructi<strong>on</strong>s, oSa,<str<strong>on</strong>g>PFERD</str<strong>on</strong>g>ERGONOMICS ........................8Machining Processes ..........................9On pages 10-24 we show you which <str<strong>on</strong>g>PFERD</str<strong>on</strong>g> tools are bestsuited <str<strong>on</strong>g>for</str<strong>on</strong>g> solving the various applicati<strong>on</strong> needs in workingwith aluminium.Table of C<strong>on</strong>tents .......................... 9Abrasive Cut-Off and Cut-Out Work ......... 10-11Deburring ............................. 12-13Preparati<strong>on</strong> <str<strong>on</strong>g>for</str<strong>on</strong>g> Welding – Joint Preparati<strong>on</strong> ....14-15Preparati<strong>on</strong> <str<strong>on</strong>g>for</str<strong>on</strong>g> Welding – Surface Machining ..16-17Weld Dressing ..........................18-19Fine Grinding and Finishing ................20-21Texturing ..............................22-23Polishing .................................24<str<strong>on</strong>g>Tools</str<strong>on</strong>g> <str<strong>on</strong>g>for</str<strong>on</strong>g> <str<strong>on</strong>g>Use</str<strong>on</strong>g> <strong>on</strong> <strong>Aluminium</strong>from <str<strong>on</strong>g>PFERD</str<strong>on</strong>g> Catalogues 201-209 ...............25On pages 26-36 we describe the special properties ofindividual groups of tools which are particularly wellsuited <str<strong>on</strong>g>for</str<strong>on</strong>g> use <strong>on</strong> aluminium, adhering to the structure ofour <str<strong>on</strong>g>PFERD</str<strong>on</strong>g> Catalogues 201-209.Table of C<strong>on</strong>tents ..........................25Files .....................................26Rotary Cutters .............................27Hole Saws and Hole Cutters ..................28Mounted Points ............................29Grinding and Polishing <str<strong>on</strong>g>Tools</str<strong>on</strong>g> ...............30-31Cut-Off Wheels ............................32Rein<str<strong>on</strong>g>for</str<strong>on</strong>g>ced Grinding Wheels ..................33POLIFAN ® Flap Discs ........................34Industrial Power Brushes .....................35Power <str<strong>on</strong>g>Tools</str<strong>on</strong>g> ...............................362

<strong>Aluminium</strong>A Material with a FutureThe use of aluminium and its alloys is growing, and so are metalworkingapplicati<strong>on</strong>s involving this material – why?<strong>Aluminium</strong>, at about 8%, is the most abundant element in the earth’s crust afteroxygen and silic<strong>on</strong>. Given the material properties of aluminium and its alloys, i.e.■■extreme durability,■■low weight,■■corrosi<strong>on</strong> resistance,■■recyclability,aluminium materials have become progressively more widespread in recent years.The development of ever more lightweight parts which must nevertheless meetunchanged strength requirements has given rise to an ever-growing use ofaluminium alloys. The latter can be <str<strong>on</strong>g>for</str<strong>on</strong>g>med into virtually any shape using a varietyof industrially available processes (casting, rolling, extruding), which opens up awealth of opti<strong>on</strong>s to the industrial user or processor of aluminium alloys. At thelevel of joining technology, <strong>on</strong>e focus of development lies <strong>on</strong> adapting comm<strong>on</strong>metal-joining processes so as to make them suitable <str<strong>on</strong>g>for</str<strong>on</strong>g> use with aluminium alloys.In many segments and branches of industry, materials have to meet exactingdemands regarding surface quality, envir<strong>on</strong>mental per<str<strong>on</strong>g>for</str<strong>on</strong>g>mance and safety.Advanced transport systems are no l<strong>on</strong>ger c<strong>on</strong>ceivable without the use oflightweight aluminium comp<strong>on</strong>ents. In additi<strong>on</strong>, aluminium as a material groupperfectly satisfies today’s increasingly stringent envir<strong>on</strong>mental requirementsc<strong>on</strong>cerning product recyclability.Our goal is to provide you with optimum results and unsurpassed costefficiency in your aluminium machining and finishing work.By now, nearly all welding processes <str<strong>on</strong>g>for</str<strong>on</strong>g> joining aluminium and its alloys havebecome available <strong>on</strong> an industrial scale, reflecting the special properties of thismaterial.Special aluminium alloys have become the material of choice in a wide range ofapplicati<strong>on</strong>s from housings, vehicles, tank c<strong>on</strong>structi<strong>on</strong>, mechanical and facadeengineering to doors, windows, foundati<strong>on</strong>s, heat exchangers and aerospacecomp<strong>on</strong>ents.An increasingly numerous user community is aiming <str<strong>on</strong>g>for</str<strong>on</strong>g> optimum results andmaximum cost-efficiency in aluminium machining or processing. At <str<strong>on</strong>g>PFERD</str<strong>on</strong>g>, thedevelopment of new aluminium-working tools has there<str<strong>on</strong>g>for</str<strong>on</strong>g>e been a high priority<str<strong>on</strong>g>for</str<strong>on</strong>g> decades.3

<strong>Aluminium</strong>More than 1,000 AlloysIs all aluminium the same?Unsurprisingly, no. The catch-all term “aluminium” refers to a group of alloyswhich share aluminium as their main c<strong>on</strong>stituent – a broad range of metalliccompounds based <strong>on</strong> pure aluminium and <strong>on</strong>e or more additi<strong>on</strong>al elements.Over 1,000 aluminium alloys exist today. They all have been purpose-developedto improve the properties of the base metal.What do the various aluminium alloys have in comm<strong>on</strong>?■■They all c<strong>on</strong>tain at least 60% pure aluminium.■■Their specific gravity is much lower than that of steel.■■They are usually corrosi<strong>on</strong>-resistant.■■They have an excellent electrical and thermal c<strong>on</strong>ductivity.Which distincti<strong>on</strong>s are made between the various aluminium alloys?■■Wrought alloys and associated weld filler materials(sheet metal, strip, secti<strong>on</strong>s, rods, tubes, <str<strong>on</strong>g>for</str<strong>on</strong>g>gings)■■Casting alloys and associated weld filler materials(sand casting, gravity die casting, precisi<strong>on</strong> casting)In additi<strong>on</strong>, <strong>on</strong>e must differentiate between■■Heat-treatable and■■N<strong>on</strong>-heat-treatable alloys.In heat-treatable material, the state of the alloy is of key importance <str<strong>on</strong>g>for</str<strong>on</strong>g> itsmachining properties. By means of heat treatment processes such as agehardening or soft annealing, in combinati<strong>on</strong> with the use of different mixingratios, entirely different material properties can be achieved. The followingcharacteristics can all be modified:■■Strength■■Density■■Corrosi<strong>on</strong> resistance■■C<strong>on</strong>ductivity■■Machinability■■Visual appearance of the bare metal4

<strong>Aluminium</strong>Properties of <strong>Aluminium</strong>Which factors influence aluminium machining?The greatest challenge with most aluminium alloys lies in their machinabilityproperties. Depending <strong>on</strong> the alloy and its heat treatment c<strong>on</strong>diti<strong>on</strong>, the materialmay prove soft and ductile or hard and brittle in the machining process. Hardnessis an important alloy classificati<strong>on</strong> criteri<strong>on</strong>. A less-than-optimum geometry of thecutting faces will result in edge build-up, an effect comm<strong>on</strong>ly resp<strong>on</strong>sible <str<strong>on</strong>g>for</str<strong>on</strong>g> toolloading problems. It may also dramatically reduce tool life.Given the high oxygen affinity of aluminium, a dense layer of oxide will <str<strong>on</strong>g>for</str<strong>on</strong>g>m <strong>on</strong> itssurface up<strong>on</strong> exposure to air and water. This oxide protects the underlying metalfrom corrosi<strong>on</strong>, albeit not fully.What should be borne in mind with regard to mechanical machiningof surfaces?The material’s corrosi<strong>on</strong> behaviour is influenced str<strong>on</strong>gly by its surface propertiesand the way these are changed by grinding, polishing or brushing.While every surface smoothing operati<strong>on</strong> will enhance the corrosi<strong>on</strong> resistanceof aluminium, roughing jobs will generally diminish it. Particles of <str<strong>on</strong>g>for</str<strong>on</strong>g>eign matterimpressed into the surface will likewise impair the material’s corrosi<strong>on</strong> resistance.Mechanical surface machining of pure aluminium or alloys having a Brinellhardness of less than 40 HB requires cauti<strong>on</strong> and experience.The pressure exercised during grinding and polishing must be adapted to thematerial’s specific hardness since soft alloys tend to become gummy. In additi<strong>on</strong>,grinding dust or abrasive particles may be impressed into the surface, destroyingthe enhanced visual appearance <strong>on</strong>e intends to produce.Photo: Otto FuchsMany new aluminium-based alloys willstill be developed in the future, giventhat the properties of this materialmake it indispensable in our modernworld. <strong>Aluminium</strong> has there<str<strong>on</strong>g>for</str<strong>on</strong>g>e alsobeen called the ‘metal of the newcentury’.5

<strong>Aluminium</strong>Machinability Groups SOFT, TOUGH, HARDFor optimum machining results <strong>on</strong> aluminium and its diverse alloys according to EN standards, <str<strong>on</strong>g>PFERD</str<strong>on</strong>g> distinguishes threemachinability groups (Soft, tough, hard). Each of these represents a different Brinell hardness range. On thefollowing pages, suitable <str<strong>on</strong>g>PFERD</str<strong>on</strong>g> tools are allocated to each of these groups.Photo: Otto FuchsPhoto: Otto FuchsHBMACHINABILITY GROUPSOFTMACHINABILITY GROUPTOUGHMACHINABILITY GROUPHARD154060n N<strong>on</strong>-heat-treatable wrought alloysEN AW 1,000-1,999EN AW 2,000-2,999EN AW 3,000-3,999EN AW 5,000-5,999n Heat-treatable wrought alloysin a soft stageEN AW 6,000-6,999EN AW 7,000-7,999n Welding filler materialsn N<strong>on</strong>-heat-treatablealuminium casting alloysEN AC 5,000-5,999EN AB 5,000-5,999n Heat-treatable aluminiumcasting alloys in a soft stageEN AC 4,000-4,999EN AB 4,000-4,999n Welding filler materialsn Wrought alloys with lowsilic<strong>on</strong> c<strong>on</strong>tentsEN AW 4,000-4,999n Heat-treatable wrought alloysEN AW 6,000-6,999EN AW 7,000-7,999100n Heat-treated aluminiumcasting alloys with silic<strong>on</strong>c<strong>on</strong>tents < 12%EN AC 4,000-4,999EN AB 4,000-4,999n N<strong>on</strong>-heat-treated aluminiumcasting alloys with silic<strong>on</strong> c<strong>on</strong>tent< 12%EN AC 4,000-4,999EN AB 4,000-4,999120n Heat-treated wrought alloyswith chipbreaking properties130140150IndexHB = Brinell hardnessEN = European StandardAB = Alloyed aluminiumingotsAC = <strong>Aluminium</strong> castingsAW = Wrought aluminiummaterialsn <strong>Aluminium</strong> casting alloys withsilic<strong>on</strong> c<strong>on</strong>tent > 12%(resp<strong>on</strong>sible <str<strong>on</strong>g>for</str<strong>on</strong>g> high tool wear)n Self-hardening aluminium castingalloys without silic<strong>on</strong>EN AC 2,000-2,999EN AC 7,000-7,999EN AB 2,000-2,999EN AB 7,000-7,999n Heat-treated aluminiumcasting alloys without silic<strong>on</strong>EN AC 2,000-2,999EN AC 7,000-7,999EN AB 2,000-2,999EN AB 7,000-7,999n Weld filler materialsn Heat-treated wrought alloysEN AW 6,000-6,999EN AW 7,000-7,999n Weld filler materials6

<strong>Aluminium</strong><strong>Aluminium</strong> Machining Recommendati<strong>on</strong>sWhich recommendati<strong>on</strong>s must be observed in aluminium machining?Cutting speed [RPM]■■For an optimum surface finish, the cutting speed needs to be adapted to themachining process as well as to the alloy and its heat treatment state. Observethe RPM recommendati<strong>on</strong>s <strong>on</strong> the following pages.C<strong>on</strong>tact pressure■■Despite the good thermal c<strong>on</strong>ductivity of aluminium, local overheating due toexcessive grinding pressure may cause microstructural alterati<strong>on</strong>s in theaffected areas. As a result, the material’s visual appearance may be impairedafter subsequent electrolytic surface treatment.■■Avoid high c<strong>on</strong>tact pressures to prevent abraded particles and abrasive materialfrom getting impressed into the workpiece surface.■■Compared with c<strong>on</strong>venti<strong>on</strong>al steel materials, aluminium alloys must be groundwith a reduced c<strong>on</strong>tact pressure. This is the <strong>on</strong>ly way to avoid intense heatingof the workpiece and to achieve a good surface finish.Cooling■■The use of grinding oils and grinding grease prevents excessive temperaturebuild-up and helps to achieve good cooling, especially with finer-grained abrasives.Corrosi<strong>on</strong>■■To avoid c<strong>on</strong>tact corrosi<strong>on</strong> due to the presence of abraded material <strong>on</strong> themachined surface, the tools employed (e.g. brushes) must not c<strong>on</strong>sist of copperalloys or steel.■ ■ The use of abrasive or polishing wheels or brushes which have previously beenused <strong>on</strong> other metals is likewise to be avoided. A strict separati<strong>on</strong> of tools isabsolutely necessary.7

■ Lower vibrati<strong>on</strong>s■ Reduced noise■ Less dust development■ Optimized haptics at workThe Focus is <strong>on</strong> PeopleTRUST BLUE1Noise and Vibrati<strong>on</strong> Limits EU occupati<strong>on</strong>al safety directives transposed into German nati<strong>on</strong>al law Increased safety and improved health protecti<strong>on</strong> at work<strong>Aluminium</strong>Important Safety Instructi<strong>on</strong>s, oSa, <str<strong>on</strong>g>PFERD</str<strong>on</strong>g>ERGONOMICSSafety notes of the German Associati<strong>on</strong> of Workmen’sCompensati<strong>on</strong> InsurersIn its Rules <str<strong>on</strong>g>for</str<strong>on</strong>g> Safety and Health at Work (BGR 109), the GermanAssociati<strong>on</strong> of Workmen’s Compensati<strong>on</strong> Insurers defines practicesand precauti<strong>on</strong>s aimed at preventing hazards such as dust fires anddust explosi<strong>on</strong>s during grinding, brushing and polishing.PRECAUTIONS AGAINST LIKELY HAZARDSThe publicati<strong>on</strong> issued by the Associati<strong>on</strong> of Workmen’s Compensati<strong>on</strong> Insurersprovides in<str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong> <strong>on</strong> aspects such as:■■design of metalworking machines, associated equipment, workshops and storagerooms;■■extracti<strong>on</strong>, c<strong>on</strong>veyance, collecti<strong>on</strong>, storage and transport of dusts and associatedsludges;■■machining and separati<strong>on</strong> of different materials (aluminium and sparking materialssuch as steel);■■avoidance of igniti<strong>on</strong> sources;■■extinguishing systems and fire fighting;■■cleaning and maintenance;■■pers<strong>on</strong>al protective equipment and workwear;■■operating instructi<strong>on</strong>s, training and equipment inspecti<strong>on</strong>;■■hazard assessment, explosi<strong>on</strong> protecti<strong>on</strong> document, cleaning and maintenanceschedules;■■regulati<strong>on</strong>s of the German Associati<strong>on</strong> of Workmen’s Compensati<strong>on</strong> Insurers,rules, principles and in<str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong>, as wells as laws, ordinances and standards.Noise• Ear protecti<strong>on</strong> complying with EN352 is recommended <str<strong>on</strong>g>for</str<strong>on</strong>g> all applicati<strong>on</strong>s where the workpieceor machine is hand-held, irrespective of the noise level.• Ensure that the correct abrasive product is selected. An unsuitable product can produceexcessive noise.Vibrati<strong>on</strong>• Processes where the workpiece or machine is hand-held can cause vibrati<strong>on</strong> injury.• Acti<strong>on</strong> needs to be taken if tingling, pins and needles or numbness is experienced after 10minutes c<strong>on</strong>tinuous use of the abrasive product.• The effects of vibrati<strong>on</strong> are more pr<strong>on</strong>ounced in cold c<strong>on</strong>diti<strong>on</strong>s so keep the hands warm andexercise hands and fingers regularly. <str<strong>on</strong>g>Use</str<strong>on</strong>g> modern equipment with low vibrati<strong>on</strong> levels.• Maintain all equipment in good c<strong>on</strong>diti<strong>on</strong> and stop the machine and have it checked ifexcessive vibrati<strong>on</strong> occurs.• <str<strong>on</strong>g>Use</str<strong>on</strong>g> good quality abrasive products and keep them in good c<strong>on</strong>diti<strong>on</strong> during their life.• Maintain mounting flanges and back-up pads in good c<strong>on</strong>diti<strong>on</strong> and replace if worn ordistorted.• Do not grip the workpiece or machine too tightly and do not exert excessive pressure <strong>on</strong> theabrasive product.• Avoid c<strong>on</strong>tinuous use of the abrasive product.• <str<strong>on</strong>g>Use</str<strong>on</strong>g> the correct product. An unsuitable product can produce excessive vibrati<strong>on</strong>.• D<strong>on</strong>’t ignore the physical symptoms of vibrati<strong>on</strong> - seek medical advice.Disposal of abrasives• <str<strong>on</strong>g>Use</str<strong>on</strong>g>d or defective abrasives should be disposed in accordance with local or nati<strong>on</strong>alregulati<strong>on</strong>s.• Further in<str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong> can be obtained from material safety data sheets provided by the supplier.• Be aware that the abrasive product may be c<strong>on</strong>taminated with material from the workpiece orprocess after use.• Disposed abrasive products should be damaged to prevent them from being taken from wasteskips and reused.Safety recommendati<strong>on</strong>sPlease observe FEPA safety recommendati<strong>on</strong>s as well as the pictograms.Nati<strong>on</strong>al Associati<strong>on</strong>Tel.: 0228 / 635587Fax: 0228 / 635399Nati<strong>on</strong>al Associati<strong>on</strong>www.fepa-abrasives.orgIssue 1 – Nov 2004Important noticeEvery ef<str<strong>on</strong>g>for</str<strong>on</strong>g>t has been made toensure that all in<str<strong>on</strong>g>for</str<strong>on</strong>g>matin<strong>on</strong>supplied in this leaflet is accurateand up to date. We can notaccept, however, resp<strong>on</strong>sibility<str<strong>on</strong>g>for</str<strong>on</strong>g> any error or omissi<strong>on</strong>, nor <str<strong>on</strong>g>for</str<strong>on</strong>g>any c<strong>on</strong>sequential loss or damageso arising (E & OE).© FEPA 2004Not permitted <str<strong>on</strong>g>for</str<strong>on</strong>g>= Wear eye protecti<strong>on</strong>! =wet grinding!= Wear gloves! == Wear hearing protecti<strong>on</strong>! == Wear a respirator! ==Only permitted witha backing pad!<str<strong>on</strong>g>PFERD</str<strong>on</strong>g>ERGONOMICSTool selecti<strong>on</strong> affects the workingsituati<strong>on</strong> of the user and his completeworking envir<strong>on</strong>ment. It not <strong>on</strong>ly has agreat influence <strong>on</strong> the most ec<strong>on</strong>omicalproblem soluti<strong>on</strong>, it also has a majorinfluence <strong>on</strong> the health, safety andcom<str<strong>on</strong>g>for</str<strong>on</strong>g>t of the tool user.To be able to fulfill these increasedrequirements. <str<strong>on</strong>g>PFERD</str<strong>on</strong>g>ERGONOMICSsupplies soluti<strong>on</strong>s <str<strong>on</strong>g>for</str<strong>on</strong>g>■■Lower vibrati<strong>on</strong>s■■Reduced noise■■Less dust development■■Optimized hapticsNot permitted <str<strong>on</strong>g>for</str<strong>on</strong>g>face grinding!Do not use ifdamaged!Leaflet supplied and endorsed byAugust Rüggeberg GmbH& Co. KG<str<strong>on</strong>g>PFERD</str<strong>on</strong>g>-WerkzeugeHauptstraße 1351709 MarienheideTel. (0 22 64) 90Fax (0 22 64) 94 00www.pferd.com · info@pferd.comNot permitted <str<strong>on</strong>g>for</str<strong>on</strong>g> hand-held ormanually guided grinding!= Read the instructi<strong>on</strong>s!<str<strong>on</strong>g>PFERD</str<strong>on</strong>g>ERGONOMICSHealth and Safety at the WorkplaceFor further in<str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong> and suitable<str<strong>on</strong>g>PFERD</str<strong>on</strong>g> tools, see the brochures“<str<strong>on</strong>g>PFERD</str<strong>on</strong>g>ERGONOMICS – The Focus is<strong>on</strong> People” and “Health and Safety atthe Workplace – Noise and Vibrati<strong>on</strong>Limits“.FEDERATION·OF·EUROPEANPRODUCERS·OF·ABRASIVESSAFETY RECOMMENDATIONS FORTHE USE OF ABRASIVE PRODUCTSPASS ON THIS LEAFLET TO THOSE USING THE ABRASIVE PRODUCTThe recommendati<strong>on</strong>s c<strong>on</strong>tained in this leaflet shoult be followed byall users of abrasive products in the interests of their pers<strong>on</strong>al safety.GENERAL PRINCIPLES OF SAFETYAbrasive products improperly used can be very dangerous.• Always follow the instructi<strong>on</strong>s provided by the abrasive product and machinesupplier.• Ensure that the abrasive product is suitable <str<strong>on</strong>g>for</str<strong>on</strong>g> its intended use. Examine all abrasive products<str<strong>on</strong>g>for</str<strong>on</strong>g> damage or defects be<str<strong>on</strong>g>for</str<strong>on</strong>g>e mounting.• Follow the correct procedures <str<strong>on</strong>g>for</str<strong>on</strong>g> handling and storage of abrasive products.Be aware of the hazards likely during the use of abrasive products and observe therecommended precauti<strong>on</strong>s to be taken:• Bodily c<strong>on</strong>tact with the abrasive product at operating speed.• Injury resulting from product breakage during use.• Grinding debris, sparks, fumes and dust generated by the grinding process.• Noise.• Vibrati<strong>on</strong>.<str<strong>on</strong>g>Use</str<strong>on</strong>g> <strong>on</strong>ly abrasive products c<strong>on</strong><str<strong>on</strong>g>for</str<strong>on</strong>g>ming to the highest standards of safety. These products willbear the relevant EN standard number and/or the inscripti<strong>on</strong> “oSa”.• EN12413 <str<strong>on</strong>g>for</str<strong>on</strong>g> B<strong>on</strong>ded Abrasives.• EN13236 <str<strong>on</strong>g>for</str<strong>on</strong>g> Superabrasives.• EN13743 <str<strong>on</strong>g>for</str<strong>on</strong>g> Specific Coated Abrasives (vulcanised fibre discs, flap wheels, flapdiscs and spindle-mounted flap wheels).Never use a machine that is not in good working order or <strong>on</strong>e with defective parts.Employers should carry out a risk assessment <strong>on</strong> all individual abrasive processes to determine theappropriate protective measures necessary. They should ensure that their employees are suitablytrained to carry out their duties.This leaflet is <strong>on</strong>ly intended to provide basic safety recommendati<strong>on</strong>s. We str<strong>on</strong>gly recommendthat or more detailed in<str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong> <strong>on</strong> the safe use of abrasive products, comprehensive SafetyCodes are available from FEPA or your Nati<strong>on</strong>al Trade Associati<strong>on</strong>:• FEPA Safety Code <str<strong>on</strong>g>for</str<strong>on</strong>g> B<strong>on</strong>ded Abrasives and Precisi<strong>on</strong> Superabrasives.• FEPA Safety Code <str<strong>on</strong>g>for</str<strong>on</strong>g> Superabrasives <str<strong>on</strong>g>for</str<strong>on</strong>g> St<strong>on</strong>e and C<strong>on</strong>structi<strong>on</strong>.• FEPA Safety Code <str<strong>on</strong>g>for</str<strong>on</strong>g> Coated Abrasives.FEPA safety recommendati<strong>on</strong>s are available <str<strong>on</strong>g>for</str<strong>on</strong>g>download at www.pferd.com.<str<strong>on</strong>g>PFERD</str<strong>on</strong>g> is an oSafounding memberTogether with othermanufacturers, <str<strong>on</strong>g>PFERD</str<strong>on</strong>g>has undertaken voluntarily to producequality tools c<strong>on</strong><str<strong>on</strong>g>for</str<strong>on</strong>g>ming to themost exacting safety standards.oSa member companies manufactureto the most stringent specificati<strong>on</strong>sworldwide and are committedto c<strong>on</strong>tinuous product safety andquality m<strong>on</strong>itoring.<str<strong>on</strong>g>PFERD</str<strong>on</strong>g> tools carry the oSa mark.Have you got any questi<strong>on</strong>s aboutgrinding safety? Either during ourtraining seminars of our <str<strong>on</strong>g>PFERD</str<strong>on</strong>g>-AKADEMIE or through our field staffat your site – <str<strong>on</strong>g>PFERD</str<strong>on</strong>g> will be happy toprovide advice.8

Machining ProcessesTable of C<strong>on</strong>tentsPageAbrasive Cut-Off and Cut-Out Work10-11Deburring12-13Preparati<strong>on</strong> <str<strong>on</strong>g>for</str<strong>on</strong>g> Welding – Joint Preparati<strong>on</strong>14-15Preparati<strong>on</strong> <str<strong>on</strong>g>for</str<strong>on</strong>g> Welding – Surface Machining16-17Weld Dressing18-19Fine and Finishing Work20-21Texturing22-23Polishing24In the present <str<strong>on</strong>g>PFERD</str<strong>on</strong>g> PRAXIS issue, power tools and prime mover systems are symbolised by the following pictograms:Manualapplicati<strong>on</strong>sStraightgrindersAnglegrindersBelt grindersFlexible shaftdrivesRobotapplicati<strong>on</strong>sStati<strong>on</strong>aryapplicati<strong>on</strong>s9

Machining ProcessesAbrasive Cut-Off and Cut-Out WorkDescripti<strong>on</strong> of machining tasks:■■Cutting off secti<strong>on</strong>s, sheet metal,risers and pipes■■Producing cut-outs in tanks andswitchgear cabinets, e.g. <str<strong>on</strong>g>for</str<strong>on</strong>g> c<strong>on</strong>necti<strong>on</strong>sand pipe penetrati<strong>on</strong>s■■Producing cut-outs and notches insecti<strong>on</strong>al material and thin-walledpartsMACHINABILITY GROUPSOFTHSS hole sawsTC hole cutters15-60 HBCut-off wheels30-76 mm A 60 P SGMACHINABILITY GROUPTOUGHHSS hole sawsTC hole cutters40-150 HBCut-off wheels30-76 mm A 60 P SGMACHINABILITY GROUPHARDTC hole cuttersCut-off wheels30-76 mm A 60 P SGPhoto: Otto Fuchs100-150 HB10

Machining ProcessesAbrasive Cut-Off and Cut-Out WorkCut-off wheelsA 24/30/46/60 N SG-ALUCut-off wheelsA 24/30/46/60 N SG-ALUCut-off wheelsA 60 R SG-INOX40-150 HB15-60 HBCut-off wheelsA 24/30/46 N SG-ALUCut-off wheelsC 36 K SG-CHOPCut-off wheelsA 60 R SG-INOXCut-off wheelsC 30/46/60 R SGCut-off wheelsC 36 L SG-TABLE100-150 HB11

Machining ProcessesDeburringDescripti<strong>on</strong> of machining tasks:■■Deburring of edges,cut-outs and c<strong>on</strong>tours■■Chamfering■■Removing flash from castingsMACHINABILITY GROUPSOFTTC burrZ-ALUPoliflex ® finegrinding point TXAbrasive spiral bandsGSBZ-COOL, CO-COOLTC burrZ-ALU + coatingCOMBIDISC ®abrasive discsA-COOL, SiCGrinding oils 412 ALU15-60 HBPhoto: Otto FuchsHSS rotary cutterZ-ALUMounted pointsHardness F-ALUMounted pointsHardness LFan grindersZ-COOL, SiC,CO-COOLFlap wheelsPOLISTARPOLINOX ® unitizedwheels PNERMounted wheelbrushes, individualfilament type, RBU SiC/INOX, RBUIT INOXWheel brushes witharbor hole, individualfilament type,RBU SiC/INOXMACHINABILITY GROUPTOUGHTC burrZ-ALUPoliflex ® finegrinding point TXGrinding oils 412 ALU40-150 HBTC burrZ-ALU + coatingHSS rotary cutterZ-ALUMounted pointsHardness F-ALUMounted pointsHardness LCOMBIDISC ®abrasive discsA-COOL, SiC,CO-COOLFan grindersSiC, CO-COOL,Z-COOLPOLISTARAbrasive spiral bandsGSBZ-COOL, CO-COOLPOLINOX ® unitizedwheels PNERMounted wheelbrushes, individualfilament type,RBU SiC/INOXMounted wheelbrushes, individualfilament type,RBU INOX,RBUIT INOXWheel brushes witharbor hole, individualfilament type,RBU SiC/INOXMACHINABILITY GROUPHARDTC burrZ-ALUPoliflex ® finegrinding point TXGrinding oils 412 ALU100-150 HBPhoto: Otto FuchsTC burrZ-ALU + coatingTC burrZ-3Mounted pointsHardness F-ALUMounted pointsHardness MCOMBIDISC ®abrasive discsA-COOL, CO-COOL,SiCFan grindersZ-COOL, SiC,CO-COOLPOLISTARAbrasive spiral bandsGSBZ-COOL, CO-COOLPOLINOX ® unitizedwheels PNERMounted wheelbrushes, individualfilament type,RBU SiCMounted wheelbrushes, individualfilament type, RBUINOX, RBUIT INOXMounted wheelbrushes, individualfilament type,RBU SiC/INOX12

Machining ProcessesDeburringFibre discsA-COOL,CO-COOLPOLIFAN ®flap discsSG-A-COOLShort beltsA-COOL,CO-COOLTC burrsZ-ALU,Z-ALU + coatingRaspsCOMBICLICK ®A-COOL,CO-COOL, SiCGrinding oils412 ALURein<str<strong>on</strong>g>for</str<strong>on</strong>g>cedgrinding wheelsA 24 N SG-ALURein<str<strong>on</strong>g>for</str<strong>on</strong>g>cedgrinding wheelsC 24 Q SGFlaring cupbrush threaded,individual filamenttype, knotted,KBU INOX,KBG INOXWheel brusheswith arbor hole/threaded, knotted,RBG CT INOX,RBGIT CT INOXDisc brushes,individual filamenttype,DBUR SiCL<strong>on</strong>g beltsGrinding oils412 ALUHSS rotary cutterZ-ALUWheel brushesw. arbor hole, individ.filam. typeRBU SiC/INOXMounted wheelbrushes, individualfilament type,RBU SiC/INOX,RBUIT INOXDisc brushes,individ. filam.type, DBU SiCFiles <str<strong>on</strong>g>for</str<strong>on</strong>g> soft metalPLUS ® fileMachinist‘s file C1Milled tooth fileInterior brushesthreaded,IBU SiC/INOX15-60 HBFibre discsA-COOL,CO-COOLPOLIFAN ® flap discsSG-A-COOL,SGP-CO-COOLShort beltsA-COOL,CO-COOLTC burrsZ-ALU,Z-ALU + coatingFiles <str<strong>on</strong>g>for</str<strong>on</strong>g> soft metalCOMBICLICK ®A-COOL,CO-COOL, SiCGrinding oils412 ALURein<str<strong>on</strong>g>for</str<strong>on</strong>g>cedgrinding wheelsA 24 N/O SG-ALURein<str<strong>on</strong>g>for</str<strong>on</strong>g>cedgrinding wheelsC 24 Q SGFlaring cupbrush threaded,individual filamenttype, knotted,KBU INOX,KBG INOXWheel brusheswith arbor hole/threaded, knotted,RBG CT INOX,RBGIT CT INOXDisc brushes,individual filamenttype, DBUR SiCL<strong>on</strong>g beltsGrinding oils412 ALUHSS rotary cutterZ-ALUWheel brusheswith arbor hole,individual filamenttypeRBU SiC/INOXMounted wheelbrushes, individualfilament type,RBU SiC/INOX,RBUIT INOXDisc brushes,individualfilament type,DBU SiCPLUS ® fileMachinist‘s file C1Milled tooth fileInterior brushesthreaded,IBU SiC/INOX40-150 HBFibre discsA-COOL,CO-COOLCOMBICLICK ®A-COOL,CO-COOL, SiCGrinding oils412 ALURein<str<strong>on</strong>g>for</str<strong>on</strong>g>cedgrinding wheelsA 24 O SG-ALURein<str<strong>on</strong>g>for</str<strong>on</strong>g>cedgrinding wheelsC 24 Q SGPOLIFAN ®flap discsSG-A-COOL,SGP-CO-COOLFlaring cupbrush threaded,individual filamenttype, knotted,KBU INOX,KBG INOXWheel brusheswith arbor hole/threaded, knotted,RBG CT INOX,RBGIT CT INOXDisc brushes,individual filamenttype, DBUR SiCShort beltsA-COOL,CO-COOLL<strong>on</strong>g beltsGrinding oils412 ALUTC burrZ-ALUTC burrZ-ALU + coatingWheel brusheswith arborhole, individualfilament typeRBU SiC/INOXMounted wheelbrushes, individualfilament type,RBU SiC/INOX,RBUIT INOXDisc brushes,individualfilament type,DBU SiCFiles <str<strong>on</strong>g>for</str<strong>on</strong>g> soft metalPLUS ® fileMachinist‘s file C1Milled tooth fileDiam<strong>on</strong>d filesInterior brushesthreaded,IBU SiC/INOX100-150 HB13

Machining ProcessesPreparati<strong>on</strong> <str<strong>on</strong>g>for</str<strong>on</strong>g> Welding – Joint Preparati<strong>on</strong>Descripti<strong>on</strong> of machining tasks:■■Chamfering■■V-seam preparati<strong>on</strong>■■Grinding out shrink holes■■Preparati<strong>on</strong> of repair weldsMACHINABILITY GROUPSOFTTC burrZ-ALUAbrasive spiral bandsGSBZ-COOL, CO-COOLTC burrZ-ALU + coatingPOLIROLL ®15-60 HBHSS rotary cutterZ-ALUMounted pointsHardness F-ALUCOMBIDISC ®abrasive discsA-COOL,CO-COOL, SiCGrinding oils412 ALUMounted pointsHardness LMACHINABILITY GROUPTOUGHTC burrZ-ALUMounted pointsHardness LGrinding oils412 ALUTC burrZ-ALU + coatingAbrasive spiral bandsGSBZ-COOL, CO-COOL40-150 HBTC burrZ-ALU PLUSHSS rotary cutterZ-ALUMounted pointsHardness F-ALUPOLIROLL ®COMBIDISC ®abrasive discsA-COOL,CO-COOL, SiCMACHINABILITY GROUPHARDTC burrZ-ALUMounted pointsHardness MGrinding oils412 ALU100-150 HBTC burrZ-ALU + coatingTC burrZ-ALU PLUSTC burrZ-3PMounted pointsHardness F-ALUAbrasive spiral bandsGSBZ-COOL, CO-COOLPOLIROLL ®COMBIDISC ®abrasive discsA-COOL,CO-COOL, SiC14

Machining ProcessesPreparati<strong>on</strong> <str<strong>on</strong>g>for</str<strong>on</strong>g> Welding – Joint Preparati<strong>on</strong>Fibre discsA-COOL,CO-COOLCOMBICLICK ®A-COOL,CO-COOL, SiCGrinding oils412 ALURein<str<strong>on</strong>g>for</str<strong>on</strong>g>cedgrinding wheelsA 24 N SG-ALURein<str<strong>on</strong>g>for</str<strong>on</strong>g>cedgrinding wheelsA46 H SGP-WHISPER-ALUPOLIFAN ®flap discsSG-A-COOLShort beltsA-COOL, CO-COOLL<strong>on</strong>g beltsGrinding oils 412 ALURaspsFiles <str<strong>on</strong>g>for</str<strong>on</strong>g> soft metalPLUS ® fileMachinist‘s file C115-60 HBMilled tooth fileFibre discsA-COOL,CO-COOLCOMBICLICK ®A-COOL,CO-COOL, SiCRein<str<strong>on</strong>g>for</str<strong>on</strong>g>cedgrinding wheelsA46 H SGP-WHISPER-ALUPOLIFAN ®flap discsSG-A-COOLShort beltsA-COOL, CO-COOLL<strong>on</strong>g beltsFiles <str<strong>on</strong>g>for</str<strong>on</strong>g> soft metalPLUS ® fileGrinding oils412 ALURein<str<strong>on</strong>g>for</str<strong>on</strong>g>cedgrinding wheelsA 24 N/O SG-ALUGrinding oils 412 ALUMachinist‘s file C1Milled tooth file40-150 HBFibre discsA-COOL,CO-COOLPOLIFAN ®flap discsSG-A-COOLShort beltsA-COOL, CO-COOLFiles <str<strong>on</strong>g>for</str<strong>on</strong>g> soft metalCOMBICLICK ®A-COOL,CO-COOL, SiCL<strong>on</strong>g beltsPLUS ® fileGrinding oils412 ALURein<str<strong>on</strong>g>for</str<strong>on</strong>g>cedgrinding wheelsA 24 O SG-ALUGrinding oils 412 ALUMachinist‘s file C1Milled tooth file100-150 HBRein<str<strong>on</strong>g>for</str<strong>on</strong>g>cedgrinding wheelsA46 H SGP-WHISPER-ALUDiam<strong>on</strong>d files15

Machining ProcessesPreparati<strong>on</strong> <str<strong>on</strong>g>for</str<strong>on</strong>g> Welding – Surface MachiningDescripti<strong>on</strong> of machining tasks:■■Removing oxide skin■■Cleaning and removal ofimpurities without significantdimensi<strong>on</strong>al changes15-60 HBMACHINABILITY GROUPSOFTCOMBIDISC ®n<strong>on</strong>-woven discsVRW/VRH/PNERPoliflex ®fine grinding toolsPUR/GRPOLINOX ® -mounted pointsPNZ/PNL/PNR/PNGPOLINOX ®ring wheelsPNZ/PNL/PNR/PNG/PNERMounted wheelbrushes, individualfilament type,RBU SiCMounted wheelbrushes, individualfilament type,RBU INOX,RBUIT INOXWheel brushes witharbor hole, individualfilament type,RBU SiC/INOX40-150 HBMACHINABILITY GROUPTOUGHCOMBIDISC ®n<strong>on</strong>-woven discsVRW/VRH/PNERPoliflex ®fine grinding toolsGR/TXPOLINOX ®mounted pointsPNZ/PNL/PNR/PNGPOLINOX ®ring wheelsPNZ/PNL/PNR/PNG/PNERMounted wheelbrushes, individualfilament type,RBU SiCMounted wheelbrushes, individualfilament type,RBU INOX,RBUIT INOXWheel brushes witharbor hole, individualfilament type,RBU SiC/INOX100-150 HBMACHINABILITY GROUPHARDPhoto: Otto FuchsCOMBIDISC ®n<strong>on</strong>-woven discsVRW/VRH/PNERPoliflex ®fine grinding toolsGR/GHR/TXPOLINOX ®mounted pointsPNZ/PNL/PNR/PNGPOLINOX ®ring wheelsPNZ/PNL/PNR/PNG/PNERMounted wheelbrushes, individualfilament type,RBU SiCMounted wheelbrushes, individualfilament type,RBU INOX,RBUIT INOXWheel brushes witharbor hole, individualfilament type,RBU SiC/INOX16

<strong>Aluminium</strong> Working ProcessesPreparati<strong>on</strong> <str<strong>on</strong>g>for</str<strong>on</strong>g> Welding – Surface MachiningPOLIVLIES ®flap discsPOLICLEAN ®discPOLINOX ®unitized wheelsPNERPOLINOX ®unitized discPNERFlaring cupbrush threaded,individualfilament type,KBU INOXWheel brushes<str<strong>on</strong>g>for</str<strong>on</strong>g> anglegrindersRBU INOXDisc brushes,individualfilament type,DBUR SiCN<strong>on</strong>-woven abrasive beltsFiles <str<strong>on</strong>g>for</str<strong>on</strong>g> softmetalPLUS ® fileMachinist‘sfile C1Milled toothfileN<strong>on</strong>-wovenec<strong>on</strong>omy rollsPOLIVLIES ®hand padsManualbrushes <str<strong>on</strong>g>for</str<strong>on</strong>g>precisi<strong>on</strong>mechanics15-60 HBPOLIVLIES ® selfadhesivediscsAbrasivesheetsPOLIVLIES ®flap discsPOLICLEAN ®discPOLINOX ®unitized wheelsPNERPOLINOX ®unitized discPNERFlaringcup brushthreaded,individualfilament type,KBU INOXWheel brushes<str<strong>on</strong>g>for</str<strong>on</strong>g> anglegrindersRBU INOXDisc brushes,individualfilament type,DBUR SiCN<strong>on</strong>-woven abrasive beltsFiles <str<strong>on</strong>g>for</str<strong>on</strong>g> softmetalPLUS ® fileMachinist‘sfile C1Milled toothfileN<strong>on</strong>-wovenec<strong>on</strong>omy rollsPOLIVLIES ®hand padsManualbrushes <str<strong>on</strong>g>for</str<strong>on</strong>g>precisi<strong>on</strong>mechanics40-150 HBPOLIVLIES ®self-adhesivediscsAbrasivesheetsPOLIVLIES ®flap discsPOLICLEAN ®discPOLINOX ®unitized wheelsPNERPOLINOX ®unitized discPNERFlaringcup brushthreaded,individualfilament type,KBU INOXWheel brushes<str<strong>on</strong>g>for</str<strong>on</strong>g> anglegrindersRBU INOXDisc brushes,individualfilament type,DBUR SiCN<strong>on</strong>-woven abrasive beltsFiles <str<strong>on</strong>g>for</str<strong>on</strong>g> softmetalPLUS ® fileMachinist‘sfile C1Milled toothfileN<strong>on</strong>-wovenec<strong>on</strong>omy rollsPOLIVLIES ®hand padsManualbrushes <str<strong>on</strong>g>for</str<strong>on</strong>g>precisi<strong>on</strong>mechanics100-150 HBPOLIVLIES ®self-adhesivediscsAbrasivesheets17

Machining ProcessesWeld DressingDescripti<strong>on</strong> of machining tasks:■■Smoothing weld seams■■Removing defects■■Cleaning■■Levelling■■Reworking repair welds15-60 HBMACHINABILITY GROUPSOFTTC burrZ-ALUTC burrZ-ALU + coatingHSS rotary cutterZ-ALUMounted pointsHardness F-ALUMounted pointsHardness LAbrasive spiral bandsGSBZ-COOL, CO-COOLCOMBIDISC ®abrasive discsA-COOL, CO-COOL,SiCGrinding oils 412 ALUMounted wheelbrushes, individualfilament type,RBU INOX 0,30,RBUIT INOX 0,30Wheel brushes witharbor hole, individualfilament typeRBU INOXPencil brushes,knotted,SINGLETWIST ®PBGS INOX,PBGSIT INOXPencil brushes,individual filamenttype, PBU SiCPencil brushes,individual filamenttype, PBU INOX,PBUIT INOX40-150 HBMACHINABILITY GROUPTOUGHTC burrZ-ALUTC burrZ-ALU + coatingTC burrZ-ALU PLUSHSS rotary cutterZ-ALUMounted pointsHardness F-ALUMounted pointsHardness LAbrasive spiral bandsGSBCO-COOLCOMBIDISC ®abrasive discsA-COOL,CO-COOL, SiCGrinding oils 412 ALUMounted wheelbrushes, individualfilament type,RBU INOX 0,30,RBUIT INOX 0,30Wheel brushes witharbor hole, individualfilament typeRBU INOXPencil brushes,knotted,SINGLETWIST ®PBGS INOX,PBGSIT INOXPencil brushes,individual filamenttype, PBU SiC/INOX,PBUIT INOX100-150 HBMACHINABILITY GROUPHARDTC burrZ-ALUTC burrZ-ALU + coatingTC burrZ-ALU PLUSTC burrZ-3PMounted pointsHardness F-ALUMounted pointsHardness MAbrasive spiral bandsGSBCO-COOLCOMBIDISC ®abrasive discsA-COOL, CO-COOL,TX, SiCGrinding oils 412 ALURing wheelsA 24 M SGMounted wheelbrushes, individualfilament type,RBU INOX 0,30,RBUIT INOX 0,30Wheel brushes witharbor hole, individualfilament typeRBU INOXPencil brushes,knotted,SINGLETWIST ®PBGS INOX,PBGSIT INOXPencil brushes,individual filamenttype, PBU SiC/INOX,PBUIT INOX18

Machining ProcessesWeld DressingPOLIVLIES ®flap discs and selfadhesivediscsFibre discsA-COOL,CO-COOLCOMBICLICK ®A-COOL,CO-COOL, SiC,PNER, VRH, VRWGrinding oils412 ALUPOLICLEAN ®discRein<str<strong>on</strong>g>for</str<strong>on</strong>g>cedgrinding wheelsA 24 N SG-ALURein<str<strong>on</strong>g>for</str<strong>on</strong>g>cedgrinding wheelsA46 H SGP-WHISPER-ALUPOLIFAN ®flap discsSG-A-COOLPOLIFAN ®flap discsSGP-A-CURVE-ALUFlaring cupbrush threaded,individual filamenttype, KBU INOXFlaring cupbrush threaded,knotted,KBG INOXWheel brusheswith arborhole/threaded,knotted,RBG INOX,RBGIT INOXWheel brusheswith arborhole/threaded,individual filamenttype, RBG INOXShort beltsA-COOL,CO-COOLL<strong>on</strong>g beltsGrinding oils412 ALURaspsFiles <str<strong>on</strong>g>for</str<strong>on</strong>g> soft metalPLUS ® fileMachinist‘s file C1Milled tooth fileManual brushes<str<strong>on</strong>g>for</str<strong>on</strong>g> precisi<strong>on</strong>mechanics15-60 HBPOLIVLIES ®flap discs and selfadhesivediscsFibre discsA-COOL,CO-COOLCOMBICLICK ®A-COOL,CO-COOL, SiC,PNER, VRH, VRWGrinding oils412 ALUPOLICLEAN ®discRein<str<strong>on</strong>g>for</str<strong>on</strong>g>cedgrinding wheelsA 24 N/O SG-ALURein<str<strong>on</strong>g>for</str<strong>on</strong>g>cedgrinding wheelsA46 H SGP-WHISPER-ALUPOLIFAN ®flap discsSG-A-COOLPOLIFAN ®flap discs SGP-A-CURVE-ALUFlaring cupbrush threaded,individual filamenttype, KBU INOXFlaring cupbrush threaded,knotted,KBG INOXWheel brusheswith arborhole/threaded,knotted,RBG INOX,RBGIT INOXWheel brusheswith arborhole/threaded,individual filamenttype, RBG INOXShort beltsA-COOL,CO-COOLL<strong>on</strong>g beltsGrinding oils412 ALUFiles <str<strong>on</strong>g>for</str<strong>on</strong>g> soft metalPLUS ® fileMachinist‘s file C1Milled tooth fileManual brushes<str<strong>on</strong>g>for</str<strong>on</strong>g> precisi<strong>on</strong>mechanics40-150 HBPOLIVLIES ®flap discs and selfadhesivediscsFibre discsA-COOL,CO-COOLCOMBICLICK ®A-COOL,CO-COOL, SiC,PNER, VRH, VRWGrinding oils412 ALUPOLICLEAN ®discRein<str<strong>on</strong>g>for</str<strong>on</strong>g>cedgrinding wheelsA 24 O SG-ALURein<str<strong>on</strong>g>for</str<strong>on</strong>g>cedgrinding wheelsA46 H SGP-WHISPER-ALUPOLIFAN ®flap discsSG-A-COOLPOLIFAN ®flap discsSGP-A-CURVE-ALUFlaring cup brushthreaded,individual filamenttype, KBU INOXFlaring cupbrush threaded,knotted,KBG INOXWheel brusheswith arborhole/threaded,knotted,RBG INOX,RBGIT INOXWheel brusheswith arborhole/threaded,individual filamenttype, RBG INOXShort beltsA-COOL,CO-COOLL<strong>on</strong>g beltsGrinding oils412 ALUFiles <str<strong>on</strong>g>for</str<strong>on</strong>g> soft metalPLUS ® fileMachinist‘s file C1Milled tooth fileDiam<strong>on</strong>d filesManual brushes<str<strong>on</strong>g>for</str<strong>on</strong>g> precisi<strong>on</strong>mechanics100-150 HB19

Machining ProcessesFine Grinding and FinishingDescripti<strong>on</strong> of machining tasks:■■Surface roughing/depolishing■■Levelling and removal ofirregularities■■Removal of oxide skin■■Sec<strong>on</strong>dary burr removal■■Cleaning15-60 HBMACHINABILITY GROUPSOFT POLICAP ®POLIROLL ® /POLICO ®Fan grindersZ-COOL, SiC,CO-COOLFlap wheelsINOXCOMBIDISC ®abrasive discsA-COOL, CO-COOLCOMBIDISC ®n<strong>on</strong>-woven discsVRW/VRH/PNERGrinding oils412 ALUPoliflex ®fine grinding toolsPUR/GRPOLINOX ®mounted pointsPNZ/PNL SiCPOLINOX ®ring wheelsPNZ/PNL/PNR/PNG/PNERMounted wheelbrushes, individualfilament type,RBU SiCMounted wheelbrushes, individualfilament type,RBU INOX 0,15,RBUIT INOX 0,15Wheel brushes witharbor hole, individualfilament type,RBU SiC40-150 HBMACHINABILITY GROUPTOUGH POLICAP ®POLIROLL ® /POLICO ®Fan grindersZ-COOL, SiCFlap wheelsINOXCOMBIDISC ®abrasive discsA-COOL, CO-COOLCOMBIDISC ®n<strong>on</strong>-woven discsVRW/VRH/PNERGrinding oils412 ALUPoliflex ®fine grinding toolsGR/TXPOLINOX ®Mounted pointsPNZ/PNL SiCPOLINOX ®ring wheelsPNZ/PNL/PNR/PNG/PNERMounted wheelbrushes, individualfilament type,RBU SiCMounted wheelbrushes, individualfilament type,RBU INOX 0,15,RBUIT INOX 0,15Wheel brushes witharbor hole, individualfilament type,RBU SiC100-150 HBMACHINABILITY GROUPHARD POLICAP ®POLIROLL ® /POLICO ®Fan grindersZ-COOL, SiCFlap wheelsINOXCOMBIDISC ®abrasive discsA-COOL, CO-COOL,COMBIDISC ®n<strong>on</strong>-woven discsVRW/VRH/PNERGrinding oils412 ALUPoliflex ®fine grinding toolsGR/GHR/TXPOLINOX ®mounted pointsPNZ/PNL SiCPOLINOX ®ring wheelsPNZ/PNL/PNR/PNG/PNERMounted wheelbrushes, individualfilament type,RBU SiCMounted wheelbrushes, individualfilament type,RBU INOX 0,15,RBUIT INOX 0,15Wheel brushes witharbor hole,individual filamenttype, RBU SiC20

Machining ProcessesFine Grinding and FinishingPOLIVLIES ®flap discsPOLICLEAN ®discCOMBICLICK ®A-COOL,CO-COOL, SiC,PNER, VRH, VRWGrinding oils412 ALUShort beltsA-COOL, CO-COOLL<strong>on</strong>g beltsCar bodyfiles, specialblade typeAbrasivesheetsManualbrushes <str<strong>on</strong>g>for</str<strong>on</strong>g>precisi<strong>on</strong>mechanicsINOXPOLINOX ®unitized wheelsPNERPOLINOX ®unitized discPNERFibre discsA-COOL,CO-COOLPOLIVLIES ®self-adhesivediscsDisc brushes,individualfilament type,DBUR SiCGrinding oils 412 ALUN<strong>on</strong>-woven abrasive beltsEc<strong>on</strong>omy rollsN<strong>on</strong>-wovenec<strong>on</strong>omy rollsPOLIVLIES ®hand pads15-60 HBPOLIVLIES ®flap discsPOLICLEAN ®discPOLINOX ®unitized wheelsPNERPOLINOX ®unitized discPNERFibre discsA-COOL,CO-COOLCOMBICLICK ®A-COOL,CO-COOL, SiC,PNER, VRH,VRWGrinding oils412 ALUPOLIVLIES ®self-adhesivediscsDisc brushes,individualfilament type,DBUR SiCShort beltsA-COOL, CO-COOLL<strong>on</strong>g beltsGrinding oils 412 ALUN<strong>on</strong>-woven abrasive beltsCar bodyfiles, specialblade typeAbrasivesheetsEc<strong>on</strong>omy rollsN<strong>on</strong>-wovenec<strong>on</strong>omy rollsPOLIVLIES ®hand padsManualbrushes <str<strong>on</strong>g>for</str<strong>on</strong>g>precisi<strong>on</strong>mechanicsINOX40-150 HBPOLIVLIES ®flap discsPOLICLEAN ®discPOLINOX ®unitized wheelsPNERPOLINOX ®unitized discPNERFibre discsA-COOL,CO-COOLCOMBICLICK ®A-COOL,CO-COOL, SiC,PNER, VRH,VRWGrinding oils412 ALUPOLIVLIES ®self-adhesivediscsDisc brushes,individualfilament type,DBUR SiCShort beltsA-COOL, CO-COOLL<strong>on</strong>g belts ZGrinding oils 412 ALUN<strong>on</strong>-woven abrasive beltsCar bodyfiles, specialblade typeAbrasivesheetsEc<strong>on</strong>omy rollsN<strong>on</strong>-wovenec<strong>on</strong>omy rollsPOLIVLIES ®hand padsManualbrushes <str<strong>on</strong>g>for</str<strong>on</strong>g>precisi<strong>on</strong>mechanicsINOX100-150 HB21

Machining ProcessesTexturingDescripti<strong>on</strong> of machining tasks:■■Creati<strong>on</strong> of visual effects■■Achieving a homogeneoussurface finish■■Marbling■■Matt finishing, brush matting orsatin finishing■■Removal of surface defectsMACHINABILITY GROUPSOFTMarbling disc holder withn<strong>on</strong>-woven discsGrinding oils 412 ALU15-60 HBFan grindersZ-COOL, SiC, CO-COOLFlap wheelsPOLIFLAP ® grinding wheelsTexturing toolsPU-STRUCPoliflex ® marbling toolsPOLINOX ® mounted pointsPNZ, PNL, PNRCOMBIDISC ®n<strong>on</strong>-woven discsVRW/VRH/PNERPOLINOX ® ring wheelsPNZ, PNL, PNR, PNG, PNERMACHINABILITY GROUPTOUGHMarbling disc holder withn<strong>on</strong>-woven discsGrinding oils 412 ALU40-150 HBFan grindersZ-COOL, SiC, CO-COOLFlap wheelsPOLIFLAP ® grinding wheelsTexturing toolsPU-STRUCPoliflex ® marbling toolsPOLINOX ® mounted pointsPNZ,PNL, PNRCOMBIDISC ®n<strong>on</strong>-woven discsVRW/VRH/PNERPOLINOX ® ring wheelsPNZ, PNL, PNR, PNG, PNERMACHINABILITY GROUPHARDMarbling disc holder withn<strong>on</strong>-woven discsGrinding oils 412 ALU100-150 HBFan grindersZ-COOL, SiC, CO-COOLFlap wheelsPOLIFLAP ® grinding wheelsTexturing toolsPU-STRUCPoliflex ® marbling toolsPOLINOX ® mounted pointsPNZ, PNL, PNRCOMBIDISC ®n<strong>on</strong>-woven discsVRW/VRH/PNERPOLINOX ® ring wheelsPNZ, PNL, PNR, PNG, PNER22

<strong>Aluminium</strong> Working ProcessesTexturingPOLIVLIES ®flap discsCOMBICLICK ®PNERShort beltsA-COOL, CO-COOLAbrasive sheetsPOLICLEAN ®discCOMBICLICK ®n<strong>on</strong>-woven discsVRH, VRWL<strong>on</strong>g beltsPOLIVLIES ®hand padsPOLINOX ®unitized wheelsPNERPOLINOX ®unitized discPNERPOLIVLIES ®self-adhesivediscsGrinding oils 412 ALUN<strong>on</strong>-woven abrasive beltsN<strong>on</strong>-woven ec<strong>on</strong>omy rolls15-60 HBPOLIVLIES ®flap discsCOMBICLICK ®PNERShort beltsA-COOL, CO-COOLAbrasive sheetsPOLICLEAN ®discCOMBICLICK ®n<strong>on</strong>-woven discsVRH, VRWL<strong>on</strong>g beltsPOLIVLIES ®hand padsPOLINOX ®unitized wheelsPNERPOLINOX ®unitized discPNERPOLIVLIES ®self-adhesivediscsGrinding oils 412 ALUN<strong>on</strong>-woven abrasive beltsN<strong>on</strong>-woven ec<strong>on</strong>omy rolls40-150 HBPOLIVLIES ®flap discsCOMBICLICK ®PNERShort beltsA-COOL, CO-COOLAbrasive sheetsPOLICLEAN ®discCOMBICLICK ®n<strong>on</strong>-woven discsVRH, VRWL<strong>on</strong>g beltsPOLIVLIES ®hand padsPOLINOX ®unitized wheelsPNERPOLINOX ®unitized discPNERPOLIVLIES ®self-adhesivediscsGrinding oils 412 ALUN<strong>on</strong>-woven abrasive beltsN<strong>on</strong>-woven ec<strong>on</strong>omy rolls100-150 HB23

Machining ProcessesPolishingDescripti<strong>on</strong> of machining tasks:■■Polishing small surface areas■■High-gloss polishingMACHINABILITY GROUPSOFTCloth ringsPolishingpaste barsFelt flap discsShort beltsFelt typeFelt pointsGrindingcompoundsCOMBICLICK ®felt discsPolishing pastebars15-60 HBFelt fangrindersPolishing pastebarsGrindingcompoundsFelt wheelsGrindingcompoundsCOMBIDISC ®felt discsMACHINABILITY GROUPTOUGHCloth ringsPolishingpaste barsFelt flap discsShort beltsFelt typeFelt pointsGrindingcompoundsCOMBICLICK ®felt discsPolishing pastebars40-150 HBFelt fangrindersFelt wheelsPolishing pastebarsGrindingcompoundsGrindingcompoundsCOMBIDISC ®felt discsMACHINABILITY GROUPHARDCloth ringsPolishingpaste barsFelt flap discsShort beltsFelt typeFelt pointsGrindingcompoundsCOMBICLICK ®felt discsPolishing pastebars100-150 HBFelt fangrindersFelt wheelsPolishing pastebarsGrindingcompoundsGrindingcompoundsCOMBIDISC ®felt discs24

<str<strong>on</strong>g>PFERD</str<strong>on</strong>g> <str<strong>on</strong>g>Tools</str<strong>on</strong>g> <str<strong>on</strong>g>for</str<strong>on</strong>g> <str<strong>on</strong>g>Use</str<strong>on</strong>g> <strong>on</strong> <strong>Aluminium</strong>Table of C<strong>on</strong>tentsPageCatalogue 201Files and Rasps 26Catalogue 202Burrs27-28Catalogue 203Mounted Points29Catalogue 204Fine Grinding and Polishing <str<strong>on</strong>g>Tools</str<strong>on</strong>g>30-31Catalogue 205Diam<strong>on</strong>d and CBN <str<strong>on</strong>g>Tools</str<strong>on</strong>g>26Catalogue 206Grinding and Cut-Off Wheels32-34Catalogue 208Industrial Power Brushes35Catalogue 209Tool Drives3625

<str<strong>on</strong>g>PFERD</str<strong>on</strong>g> <str<strong>on</strong>g>Tools</str<strong>on</strong>g> – Catalogues 201-209Catalogues 201 and 205 – Files<str<strong>on</strong>g>PFERD</str<strong>on</strong>g> files are suitable <str<strong>on</strong>g>for</str<strong>on</strong>g> deburring, chamfering, rough filing and smoothingwork <strong>on</strong> aluminium and aluminium alloys. Tool loading problems are preventedby a tooth geometry adapted specifically to the requirements associated withworking soft, sticky materials. As a result, minimum ef<str<strong>on</strong>g>for</str<strong>on</strong>g>t is needed to achieve ahigh-grade surface finish.Machinability group SOFTRaspsDeveloped originally <str<strong>on</strong>g>for</str<strong>on</strong>g> woodworking applicati<strong>on</strong>s,these tools also give excellent results <strong>on</strong> aluminium.Machinability group SOFT, TOUGH and HARD (Hardness: 15-150 HB)Files <str<strong>on</strong>g>for</str<strong>on</strong>g> soft metalParticularly suitable <str<strong>on</strong>g>for</str<strong>on</strong>g> deburring, chamfering,roughing and smoothing work <strong>on</strong> soft, sticky materials.<str<strong>on</strong>g>PFERD</str<strong>on</strong>g> PLUS ® filesFor general use such as rough filing, smoothing and deburring.Machinist’s files – Cut 1Perfect <str<strong>on</strong>g>for</str<strong>on</strong>g> deburring.Car body files (special blade type)For producing very good, scratch-free surfaces.Milled tooth filesThese files ensure very high stock removal.Machinability group HARDDiam<strong>on</strong>d files (Catalogue 205)Particularly well suited <str<strong>on</strong>g>for</str<strong>on</strong>g> deburring.Products made to orderFiles can be manufactured to specific applicati<strong>on</strong> needs by special arrangement.NoteFor further in<str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong>, please referto our <str<strong>on</strong>g>PFERD</str<strong>on</strong>g> Tool Manual, Catalogues201 and 205.Files201Diam<strong>on</strong>d and CBN <str<strong>on</strong>g>Tools</str<strong>on</strong>g>205Recommendati<strong>on</strong>s <str<strong>on</strong>g>for</str<strong>on</strong>g> useLoaded files can be cleaned using our HBF 10 file brush.26

<str<strong>on</strong>g>PFERD</str<strong>on</strong>g> <str<strong>on</strong>g>Tools</str<strong>on</strong>g> – Catalogues 201-209Catalogue 202 – BurrsTungsten carbide burrsThese tungsten carbide burrs give excellent results in aluminium work such as welddressing, fettling of castings, deburring, chamfering and geometry adjustments.A large number of geometrical shapes and dimensi<strong>on</strong>s (3-16 mm dia.), two cutsand a coating developed specifically <str<strong>on</strong>g>for</str<strong>on</strong>g> this material are available to meet variousneeds in machinability groups SOFT, TOUGH and harD.Our ALU and ALU PLUS cuts reflect the most recent standards of technology.Developed specifically <str<strong>on</strong>g>for</str<strong>on</strong>g> use <strong>on</strong> aluminium, their geometries ensure optimummachining results at high cutting speeds of up to 1,100 m/min.TC burrs with ALU cutTC burrs with ALU PLUS cutTC burrs with HC-NFE coatingALU cutVc 600-1,100 m/minAn optimum tooth geometry ensuresgood chip removal. Tooth base loading isprevented, even <strong>on</strong> sticky materials. For usein machinability groups SOFT, TOUGH andharD.Vc 450-700 m/minPreferable <str<strong>on</strong>g>for</str<strong>on</strong>g> coarse milling of aluminiumalloys in machinability groups TOUGH andharD, as well as <str<strong>on</strong>g>for</str<strong>on</strong>g> n<strong>on</strong>-ferrous metals ingeneral. The special tooth geometry ensureshigh stock removal.Vc 600-1,100 m/minThe tool of choice <str<strong>on</strong>g>for</str<strong>on</strong>g> l<strong>on</strong>g-chip, stickyn<strong>on</strong>-ferrous metals in machinability groupsSOFT, TOUGH and harD. Improvedfricti<strong>on</strong> and sliding properties reduce the<str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong> of built-up edges. High stockremoval and durability are the hallmarks ofthis range.HSS rotary cuttersThanks to their special tooth geometry and close tolerances, high-speed steel(HSS) rotary cutters are particularly suitable <str<strong>on</strong>g>for</str<strong>on</strong>g> deburring, chamfering, fettling andgeometry adjustment work <strong>on</strong> aluminium parts, where they produce an enhancedsurface quality. HSS rotary cutters with ALU cut can be used in numerous shapesand dimensi<strong>on</strong>s.HSS rotary cutters with ALU cut and with our special cut <str<strong>on</strong>g>for</str<strong>on</strong>g> light alloysguarantee cost-efficient results and are also ideal <str<strong>on</strong>g>for</str<strong>on</strong>g> use <strong>on</strong> materials inmachinability groups SOFT and TOUGH when working with a low-poweredmachine in the low RPM range.HSS rotary cutter with ALU cutVc = 300 m/minAn optimum tooth geometry ensures goodchip removal.Recommendati<strong>on</strong>s <str<strong>on</strong>g>for</str<strong>on</strong>g> useHSS rotary cutter with special cut <str<strong>on</strong>g>for</str<strong>on</strong>g>light alloysVc = 300 m/minParticularly suitable <str<strong>on</strong>g>for</str<strong>on</strong>g> coarse deburring andfettling work <strong>on</strong> light alloy comp<strong>on</strong>ents andcastings.■■The cost-efficiency of burrs and rotary cutters is c<strong>on</strong>tingent <strong>on</strong> an adequatepower output and appropriate RPM of the machine.To select the right cut <str<strong>on</strong>g>for</str<strong>on</strong>g> a given applicati<strong>on</strong>, note the following rule:The harder and more brittle the material, the finer the cut should be.■■The coating of tungsten carbide burrs prevents tool loading problems undermost applicati<strong>on</strong> c<strong>on</strong>diti<strong>on</strong>s, even with very sticky alloys. With uncoated burrs,grinding oil can be used to prevent tooth bases from clogging up too quickly.Products made to orderIf our extensive Catalogue rangeshould not include what you need, wecan produce custom products tailoredto your requirements in terms of■■tooth specificati<strong>on</strong>s■■shank length■■diameter.Especially in high-volume manufacturing,milling operati<strong>on</strong>s areincreasingly robotized. For suchapplicati<strong>on</strong>s <str<strong>on</strong>g>PFERD</str<strong>on</strong>g> offers burrs androtary cutters providing still closertolerances and c<strong>on</strong>stant stock removal.Please do not hesitate to c<strong>on</strong>tact us.The applicati<strong>on</strong> technicians in ourtechnical customer support departmentwill be glad to help.27

<str<strong>on</strong>g>PFERD</str<strong>on</strong>g> <str<strong>on</strong>g>Tools</str<strong>on</strong>g> – Catalogues 201-209Catalogue 202 – Hole Saws and Hole CuttersHSS hole sawsHSS hole saws are excellent <str<strong>on</strong>g>for</str<strong>on</strong>g> producing accurate cut-outs fast. Their high-gradeHSS tooth set guarantees cost-efficient per<str<strong>on</strong>g>for</str<strong>on</strong>g>mance, particularly <strong>on</strong> thin-walledaluminium comp<strong>on</strong>ents in the SOFT and TOUGH machinability groups. A l<strong>on</strong>gservice life and burr-free edges are achieved with these tools.HSS hole saws sets<str<strong>on</strong>g>PFERD</str<strong>on</strong>g> offers five different sets of holesaws in the most comm<strong>on</strong> diametersused by craftsmen, plumbers, fittersand electricians (Germany andinternati<strong>on</strong>al).TC hole cuttersThanks to their high-grade tungsten carbide tips, these TC hole cutters provideoutstanding results and superior cost-efficiency <strong>on</strong> aluminium alloys in the SOFT,TOUGH and harD machinability groups. Two versi<strong>on</strong>s (flat, deep) facilitatemachining <strong>on</strong> diverse workpieces, including curved surfaces.8 mmTC hole cutters are supplied in two heights:■■8 mm (flat versi<strong>on</strong>) <str<strong>on</strong>g>for</str<strong>on</strong>g> use <strong>on</strong> sheet metal and flat material,available in various diameters from 16 to 105 mm.■■35 mm (deep versi<strong>on</strong>) <str<strong>on</strong>g>for</str<strong>on</strong>g> use <strong>on</strong> pipes and curved surfaces,available in various diameters from 16 to 60 mm.35 mmRecommendati<strong>on</strong> <str<strong>on</strong>g>for</str<strong>on</strong>g> use■■To reduce cutting <str<strong>on</strong>g>for</str<strong>on</strong>g>ces, paraffin should be used when sawing aluminium.This will ensure a smoother operati<strong>on</strong> of the tool while also extending its servicelife.NoteFor furtherin<str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong>, pleaserefer to our <str<strong>on</strong>g>PFERD</str<strong>on</strong>g>Tool Manual,Catalogue 202.Burrs20228

203 I 1<str<strong>on</strong>g>PFERD</str<strong>on</strong>g> <str<strong>on</strong>g>Tools</str<strong>on</strong>g> – Catalogues 201-209Catalogue 203 – Mounted PointsMounted points are suitable <str<strong>on</strong>g>for</str<strong>on</strong>g> pre-grinding, deburring, chamfering, fettling andfine-grinding aluminium and associated alloys in the SOFT, TOUGH and harDmachinability groups. Since the spaces between grit particles (chip clearance) arevery small <strong>on</strong> these tools, they are particularly susceptible to loading. <str<strong>on</strong>g>PFERD</str<strong>on</strong>g> hasthere<str<strong>on</strong>g>for</str<strong>on</strong>g>e developed a special b<strong>on</strong>d which ensures unsurpassed stock removal overthe entire tool life even <strong>on</strong> soft, sticky materials.Mounted points – hardness F-ALUThese tools are made with a vitrified b<strong>on</strong>d and green silic<strong>on</strong> carbide. A specialtreatment prevents loading <strong>on</strong> sticky materials. The hardness F-ALU denotes <strong>on</strong>eof the softer and most aggressive b<strong>on</strong>ds available <str<strong>on</strong>g>for</str<strong>on</strong>g> mounted points.Hardness F-ALUProducts made to orderBy special arrangement we can produce mounted points adapted specifically toyour applicati<strong>on</strong> needs, e.g.■■other dimensi<strong>on</strong>s and shapes■■different grit sizes and abrasive types■■bespoke grain mixtures■■special shank diameters and lengths.In additi<strong>on</strong>, <str<strong>on</strong>g>PFERD</str<strong>on</strong>g> supplies impregnated special product versi<strong>on</strong>s in hardnessgrades M and L <str<strong>on</strong>g>for</str<strong>on</strong>g> use <strong>on</strong> aluminium. These tools are specially designed toprevent loading <strong>on</strong> particularly sticky aluminium materials (machinability groupSOFT).Hardness MHardness LRecommendati<strong>on</strong>s <str<strong>on</strong>g>for</str<strong>on</strong>g> use■■Mounted points of hardness grade F-ALU per<str<strong>on</strong>g>for</str<strong>on</strong>g>m best at a recommendedperipheral speed of 20-40 m/s.■■The use of grease or grinding oil is recommended.■■Mounted points are used with flexible shafts or (electric or air-powered)straight grinders.Safety notes■■All mounted points in the <str<strong>on</strong>g>PFERD</str<strong>on</strong>g> range are approved <str<strong>on</strong>g>for</str<strong>on</strong>g> a maximum peripheralspeed of 50 m/s. Applicable RPM limits <str<strong>on</strong>g>for</str<strong>on</strong>g> various shank lengths and shankdiameters are defined in EN 12413. It is absolutely necessary to comply withthese maximum values to prevent the tool shank from buckling in use.NoteFor furtherin<str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong>, pleaserefer to our <str<strong>on</strong>g>PFERD</str<strong>on</strong>g>Tool Manual,Catalogue 203.Mounted PointsMounted Points20320329

<str<strong>on</strong>g>PFERD</str<strong>on</strong>g> <str<strong>on</strong>g>Tools</str<strong>on</strong>g> – Catalogues 201-209Catalogue 204 – Grinding and Polishing <str<strong>on</strong>g>Tools</str<strong>on</strong>g>Fine grinding and polishing tools are suitable <str<strong>on</strong>g>for</str<strong>on</strong>g> pre-grinding, deburring,chamfering, fettling, fine grinding, texturing and polishing operati<strong>on</strong>s <strong>on</strong>aluminium and its alloys in machinability groups SOFT, TOUGH and harD.The tools which are suitable <str<strong>on</strong>g>for</str<strong>on</strong>g> machining aluminium can be summarized ingroups:■■Coated abrasive tools■■N<strong>on</strong>-woven abrasive tools■■B<strong>on</strong>ded abrasive tools■■Polishing toolsCoated abrasive toolsin Catalogue 204:■■Abrasive spiral bands■■POLIROLL ® , POLICO ®■■Fan grinders, flap wheelsand flap rolls■■COMBIDISC ® grinding discs■■Special tools■■Short and l<strong>on</strong>g belts■■Ec<strong>on</strong>omy rolls andsheet material■■Fibre discs andvelcro-backed abrasive discs■■COMBICLICK ® fibre discs■■Grinding oil 412 ALUCoated abrasive toolsCoated abrasive tools, with a cover b<strong>on</strong>d actively supporting the grinding process,are suitable <str<strong>on</strong>g>for</str<strong>on</strong>g> use <strong>on</strong> aluminium surfaces. The additi<strong>on</strong>al cover layer cools theworkpiece and prevents aluminium from adhering to the spaces between abrasiveparticles. Silic<strong>on</strong> carbide (SiC) is highly suitable <str<strong>on</strong>g>for</str<strong>on</strong>g> use <strong>on</strong> aluminium due to theshape of its grains. Depending <strong>on</strong> grit size, coated abrasive tools can provide highremoval rates (e.g. during chamfering with 36 grit fibre discs) or a very fine surfacefinish if a fine-grained abrasive is used (e.g. pre-polishing with a 320 grit fangrinder).The service life of coated abrasive tools can be greatly extended through the useof our grinding oil 412 ALU. This oil prevents chip particles from adhering to theabrasive surface and thereby prevents loading problems.Activegrinding layerStructure of coated abrasiveproductsBackingmaterialBasic b<strong>on</strong>d Top b<strong>on</strong>d AbrasiveparticlesN<strong>on</strong>-woven abrasive toolsin Catalogue 204:■■COMBIDISC ® n<strong>on</strong>-woven discs■■COMBICLICK ® n<strong>on</strong>-woven discs■■POLINOX ® mounted points,wheels and drums■■Special tools■■POLIVLIES ® discs■■POLIVLIES ® self-adhesive discs■■POLICLEAN ® tools■■Short belts, n<strong>on</strong>-woven typesN<strong>on</strong>-woven abrasive toolsThe very open structure of the n<strong>on</strong>-woven abrasive material prevents loadingand heat build-up during grinding. N<strong>on</strong>-woven abrasive tools are excellent <str<strong>on</strong>g>for</str<strong>on</strong>g>producing fine and ultra-fine finishes, light cleaning, removing oxide layers, andcreating surface textures.Structure ofn<strong>on</strong>-wovenabrasiveAbrasive gritSynthetic fibresResin30

<str<strong>on</strong>g>PFERD</str<strong>on</strong>g> <str<strong>on</strong>g>Tools</str<strong>on</strong>g> – Catalogues 201-209Catalogue 204 – Grinding and Polishing <str<strong>on</strong>g>Tools</str<strong>on</strong>g>Recommendati<strong>on</strong>s <str<strong>on</strong>g>for</str<strong>on</strong>g> use:■■In aluminium machining applicati<strong>on</strong>s, coated abrasive tools per<str<strong>on</strong>g>for</str<strong>on</strong>g>m best atthe recommended peripheral speed of 20-40 m/s.■■N<strong>on</strong>-woven abrasive tools give best results <strong>on</strong> aluminium when used at therecommended peripheral speed of 10-20 m/s.■■Polishing operati<strong>on</strong>s should be carried out at peripheral speedsof 5-10 m/s.■■The use of a grinding oil is recommended as it protects the tool from prematurewear.■■Suitable power sources are flexible shaft drives or (electric or air-powered)straight grinders.B<strong>on</strong>ded abrasive toolsB<strong>on</strong>ded abrasive tools give outstandingper<str<strong>on</strong>g>for</str<strong>on</strong>g>mance in fine grinding andpre-polishing jobs, e.g. <strong>on</strong> aluminiummoulds <str<strong>on</strong>g>for</str<strong>on</strong>g> plastic injecti<strong>on</strong> moulding(blow moulding of PET bottles).Fine grinding tools adapted to eachapplicati<strong>on</strong> are available in the mostdiverse shapes and a broad rangeof grit types, grit sizes and hardnessgrades.B<strong>on</strong>ded abrasive toolsin Catalogue 204:■■Poliflex ® mounted points■■Poliflex ® abrasive discs■■Poliflex ® blocksPolishing tools<str<strong>on</strong>g>PFERD</str<strong>on</strong>g> offers an extensive range ofaluminium polishing tools in diversediameters, hardness grades, gritsizes, types and shapes, as well asthe associated polishing pastes/compounds.Products made to orderIf our extensive Catalogue range should not include what you need, we canproduce bespoke soluti<strong>on</strong>s <str<strong>on</strong>g>for</str<strong>on</strong>g> your applicati<strong>on</strong> needs, e.g.■■other dimensi<strong>on</strong>s and shapes■■different grit sizes and abrasive types■■bespoke grain mixtures■■special shank diameters and lengths.Please talk to our sales representatives. The applicati<strong>on</strong> technicians in ourtechnical customer support department will be glad to help.B<strong>on</strong>ded abrasive toolsin Catalogue 204:■■Felt points and discs■■COMBIDISC ® felt discs■■COMBICLICK ® felt discs■■Felt flap discs■■Short abrasive belts – felt type■■Cloth rings■■Grinding compounds■■Polishing pastesNotesAll <str<strong>on</strong>g>PFERD</str<strong>on</strong>g> tools aremanufactured andtested to applicablesafety standards.For furtherin<str<strong>on</strong>g>for</str<strong>on</strong>g>mati<strong>on</strong>, pleaserefer to our <str<strong>on</strong>g>PFERD</str<strong>on</strong>g>Tool Manual,Catalogue 204.Fine Grinding and Polishing <str<strong>on</strong>g>Tools</str<strong>on</strong>g>20431

<str<strong>on</strong>g>PFERD</str<strong>on</strong>g> <str<strong>on</strong>g>Tools</str<strong>on</strong>g> – Catalogues 201-209Catalogue 206 – Cut-Off WheelsFor cutting aluminium and its alloys, <str<strong>on</strong>g>PFERD</str<strong>on</strong>g> has developed a range of specialcut-off wheels. These products c<strong>on</strong>tain no fillers which might leave undesirableresidue <strong>on</strong> the workpiece. The surfaces can there<str<strong>on</strong>g>for</str<strong>on</strong>g>e be welded immediatelyafterwards.They can be used <strong>on</strong> angle grinders of all output categories.Cut-off wheels – hardness N-ALUCut-off wheels of hardness grade N-ALU provide aggressive stock removal andare not susceptible to loading problems <strong>on</strong> aluminium workpieces in machinabilitygroups SOFT, TOUGH and harD. They are laminated <strong>on</strong> both sides with asilver-coated labelling film which prevents metal adhesi<strong>on</strong> and clogging of theabrasive material.Products made to orderBy special arrangement, cut-off wheels <str<strong>on</strong>g>for</str<strong>on</strong>g> use <strong>on</strong> aluminium can be manufacturedto specific applicati<strong>on</strong> needs.Special specificati<strong>on</strong>s may include, e.g.■■n<strong>on</strong>-standard sizes and widths■■different grit types, e.g. SiC.Recommendati<strong>on</strong>s <str<strong>on</strong>g>for</str<strong>on</strong>g> use:■■1.0 mm disc width: especially <str<strong>on</strong>g>for</str<strong>on</strong>g> sheet metal■■1.6 mm disc width: <str<strong>on</strong>g>for</str<strong>on</strong>g> thin-walled workpieces■■2.4 mm disc width: <str<strong>on</strong>g>for</str<strong>on</strong>g> general cut-off work■■2.9 mm disc width: <str<strong>on</strong>g>for</str<strong>on</strong>g> maximum tool life and high lateral stabilitySafety notesAbrasive manufacturers, machine producers and users c<strong>on</strong>tribute equally toensuring grinding safety. All <str<strong>on</strong>g>PFERD</str<strong>on</strong>g> tools are built to meet applicable safetyrequirements. However, the ultimate resp<strong>on</strong>sibility <str<strong>on</strong>g>for</str<strong>on</strong>g> the correct handling andsafe operati<strong>on</strong> of power tools and abrasive products rests with the user.In particular, the following rules apply:■■The maximum operating speed [m/s] stated <strong>on</strong> the product labelmust not be exceeded.■■The use of flanges having two different diameters is to be avoided.32

<str<strong>on</strong>g>PFERD</str<strong>on</strong>g> <str<strong>on</strong>g>Tools</str<strong>on</strong>g> – Catalogues 201-209Catalogue 206 – Rein<str<strong>on</strong>g>for</str<strong>on</strong>g>ced Grinding WheelsFor grinding work <strong>on</strong> aluminium and aluminium alloys, <str<strong>on</strong>g>PFERD</str<strong>on</strong>g> has developedspecial rein<str<strong>on</strong>g>for</str<strong>on</strong>g>ced grinding wheels which provide high stock removal and will notload even when used <strong>on</strong> soft alloys.Rein<str<strong>on</strong>g>for</str<strong>on</strong>g>ced grinding wheels – hardness N-ALUThese tools deliver outstanding stock removal even at low c<strong>on</strong>tact pressure, thuseffectively preventing loading problems <strong>on</strong> alloys in machinability groups SOFTand TOUGH. Rein<str<strong>on</strong>g>for</str<strong>on</strong>g>ced grinding wheels made by <str<strong>on</strong>g>PFERD</str<strong>on</strong>g> are suitable <str<strong>on</strong>g>for</str<strong>on</strong>g> usewith angle grinders of all output categories. They c<strong>on</strong>tain no fillers which mightleave undesirable residue <strong>on</strong> the workpiece. Machined surfaces can there<str<strong>on</strong>g>for</str<strong>on</strong>g>e bewelded right away.Rein<str<strong>on</strong>g>for</str<strong>on</strong>g>ced grinding wheels – hardness O-ALUSuitable <str<strong>on</strong>g>for</str<strong>on</strong>g> alloys in machinability groups TOUGH and harD.Rein<str<strong>on</strong>g>for</str<strong>on</strong>g>ced grinding wheels – hardness H-ALUThe rein<str<strong>on</strong>g>for</str<strong>on</strong>g>ced grinding wheel WHISPER ALU is an innovative high-per<str<strong>on</strong>g>for</str<strong>on</strong>g>mancetool <str<strong>on</strong>g>for</str<strong>on</strong>g> unusually high demands <strong>on</strong> stock removal, surface quality and workingcom<str<strong>on</strong>g>for</str<strong>on</strong>g>t. Very soft, smooth grinding characteristic and high degree of workingcom<str<strong>on</strong>g>for</str<strong>on</strong>g>t with low vibrati<strong>on</strong>, dust and noise levels. Very high machining capacityfrom the very start.Suitable <str<strong>on</strong>g>for</str<strong>on</strong>g> alloys in machinability groups SOFT, TOUGH, harD.Products made to orderRein<str<strong>on</strong>g>for</str<strong>on</strong>g>ced grinding wheels <str<strong>on</strong>g>for</str<strong>on</strong>g> use <strong>on</strong> aluminium can be manufactured to yourspecific applicati<strong>on</strong> needs by special arrangement.Special specificati<strong>on</strong>s may include, e.g.■■n<strong>on</strong>-standard sizes and widths■■different grit types, e.g. SiC.Recommendati<strong>on</strong>s <str<strong>on</strong>g>for</str<strong>on</strong>g> use■■7.2 mm disc width: suitable <str<strong>on</strong>g>for</str<strong>on</strong>g> general-purpose grinding.Safety notes■■The maximum operating speed [m/s] stated <strong>on</strong> the product label must not beexceeded.■■In some countries, 178/230 mm dia. rein<str<strong>on</strong>g>for</str<strong>on</strong>g>ced grinding wheels are subject tospecial regulati<strong>on</strong>s regarding the use of special flanges and/or adapter systems.33